Technical copper

In the annealed state, it is quite plastic, but has relatively low strength. The chemical composition of technical grades of copper is determined by GOST 859–41. Technical grades are used in the smelting of copper alloys as a charge material. Technical grade M0 is used in the manufacture of high-purity alloys and current conductors. M1 in the manufacture of semi-finished products obtained by rolling, in the production of high-quality bronzes that do not contain tin. M2 is a technical grade used for the production of bronzes for the production of high-quality semi-finished products that are processed under pressure. The MZ technical grade is in demand for semi-finished products that are produced by rolling, the production of standard quality bronzes and other casting alloys, as well as non-critical electrical contacts (like the M2 alloy). Technical grade M4 is used in the smelting of cast bronzes.

Technical characteristics of various grades of copper

Due to their properties, various grades of copper are very popular in the industrial environment. This metal is good because it is flexible and, regardless of the operating environment, with the exception of exposure to sulfur dioxide and ammonia, it is resistant to corrosion.

The external distinctive feature of copper is its pink-red color. Depending on the purity, copper is divided into types with the technical designations M1, M2, M3. This metal comes into production in the form of wire, sheets, pipes, and rods.

This is due to different application situations.

Schedule

Based on its composition, copper is divided into oxygen-free and deoxidized; the symbol is M0 and M1, respectively. Oxygen-free is used in the manufacture of parts for electrical, electronic, and electrovacuum industrial products. O2 in oxygen-free brands is no more than 0.001%, and in deoxidized ones - 0.01%.

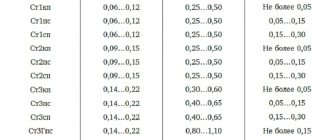

The breakdown of copper grades is presented in the table:

Impurities in copper alloys

Impurities contained in copper (and, naturally, interacting with it) are divided into three groups.

Forming solid solutions with copper

Such impurities include aluminum, antimony, nickel, iron, tin, zinc, etc. These additives significantly reduce electrical and thermal conductivity. The grades that are primarily used for the production of conductive elements include M0 and M1. If the copper alloy contains antimony, its hot pressure treatment becomes significantly more difficult.

Impurities that do not dissolve in copper

These include lead, bismuth, etc. Although they do not affect the electrical conductivity of the base metal, such impurities make it difficult to process by pressure.

Impurities that form brittle chemical compounds with copper

This group includes sulfur and oxygen, which reduces the electrical conductivity and strength of the base metal. The sulfur content of the copper alloy greatly facilitates its machinability by cutting.

Copper grades and their applications

Features of production and application

The number of countries that, besides the Russian Federation, have standardized the M2 type alloy is significantly less than for M1. The geography of its production (except for the USA and Japan) is clearly shifted towards Central and Eastern Europe:

- Japan (JIS standard), USA – C1821, C12500.

- Poland (PN standard) – Cu99.7G.

- Czech Republic (CSN standard) – 423004.

- Austria (ONORM standard) – Cu-C.

M2 is easily welded by pre-tinning using electrodes made from the refractory metals tungsten and molybdenum. Butt welds are made using electrical transformers. Thin joints are welded with acetylene torches. Cutting soft material is difficult.

The M2 alloy is easily stamped, but to reduce the number of fists after annealing, special technological preparation is required. The following are produced from M2 copper:

- pressed pipes (GOST 617-2006);

- cold-rolled semi-finished products for pressure treatment (soft and hard, GOST 1173-2006);

- elements of cryogenic technology;

- anodes and shaped casting parts.

In order to increase corrosion resistance, the surfaces of ferrous metals are coated with molten copper. Using the M2 alloy, brass, bronze and copper-nickel alloys are produced. The most common type of semi-finished product is copper wire.

Percentage composition

| Percentage composition of material | |||||||||||||

| Copper alloy grades | Fe | Ni | S | Cu | As | Pb | O | Sb | Bi | Sn | P | Zn | Ag |

| M1 | ≤ 0.005 | ≤ 0.0020 | ≤ 0.004 | 99.9 | ≤ 0.0020 | ≤ 0.005 | ≤ 0.05 | ≤ 0.002 | ≤ 0.001 | ≤ 0.002 | ≤ 0.004 | ≤ 0.003 | |

| M 1р | ≤ 0.005 | ≤ 0.0020 | ≤ 0.005 | 99.9 | ≤ 0.0020 | ≤ 0.005 | ≤ 0.01 | ≤ 0.002 | ≤ 0.001 | ≤ 0.002 | from 0.002 to 0.012 | ≤ 0.005 | |

| M 2 | ≤ 0.05 | ≤ 0.2 | ≤ 0.01 | 99.7 | ≤ 0.01 | ≤ 0.01 | ≤ 0.07 | ≤ 0.005 | ≤ 0.0020 | ≤ 0.05 | |||

| M 2p | ≤ 0.05 | ≤ 0.2 | ≤ 0.01 | 99.7 | ≤ 0.01 | ≤ 0.01 | ≤ 0.01 | ≤ 0.005 | ≤ 0.0020 | ≤ 0.05 | |||

| M 3 | ≤ 0.05 | ≤ 0.2 | ≤ 0.01 | 99.5 | ≤ 0.01 | ≤ 0.050 | ≤ 0.08 | ≤ 0.050 | ≤ 0.003 | ≤ 0.05 | |||

| M 3р | ≤ 0.05 | ≤ 0.2 | ≤ 0.01 | 99.5 | ≤ 0.05 | ≤ 0.03 | ≤ 0.01 | ≤ 0.05 | ≤ 0.003 | ≤ 0.05 | from 0.005 to 0.06 |

Use of copper in medicine

The use of copper in the medical industry can be found quite often. According to the norms of traditional medicine, copper is an extremely important element of human life. In our body, copper is present in a volume of 2 * 10-4% of a person’s total weight. Every day we consume approximately 60 mg of copper with food, but only 2 mg is absorbed, but this is the amount that is the daily norm for an adult. Copper is extremely important in the process of hemoglobin biosynthesis, as well as in maintaining sugar, cholesterol and uric acid levels. In order for the cardiovascular system, brain, and digestive tract to function as expected, copper is needed. With a chronic lack of copper in the human body, the following diseases develop:

- anemia;

- osteoporosis;

- glaucoma;

- psoriasis;

- the heart muscle atrophies;

- a person gets tired quickly and loses weight;

- Cholesterol accumulates in the body.

The richest foods containing copper are:

- Champignon;

- potato;

- Cod liver;

- whole grain;

- oysters and cuttlefish.

Pure copper

Grade M0 contains 99.95% Cu and no more than 0.05% impurities. According to special technical conditions, several grades of vacuum copper and especially oxygen-free pure copper are produced, which is used in the electric vacuum industry. Strips, tapes, rods, and pipes are produced from oxygen-free copper of series A and B. Tapes and rods are made from vacuum pure copper. Rods are produced from pure copper, which is deoxidized with manganese. All these semi-finished products are used in the electrovacuum industry. Oxygen-free pure copper is characterized by a low (-100°C) recrystallization temperature.

Basic properties of copper

Physical properties

In air, copper acquires a bright yellowish-red hue due to the formation of an oxide film. Thin plates have a greenish-blue color when examined through them. In its pure form, copper is quite soft, malleable and easily rolled and drawn. Impurities can increase its hardness.

This is interesting: VGP pipe - decoding, description, advantages and scope of application

The high electrical conductivity of copper can be called the main property that determines its predominant use. Copper also has very high thermal conductivity. Impurities such as iron, phosphorus, tin, antimony and arsenic affect the basic properties and reduce electrical and thermal conductivity. According to these indicators, copper is second only to silver.

Copper has high densities, melting points and boiling points. An important property is also good resistance to corrosion. For example, at high humidity, iron oxidizes much faster.

Copper lends itself well to processing: it is rolled into copper sheets and copper rods, and drawn into copper wire with a thickness brought to thousandths of a millimeter. This metal is diamagnetic, that is, it is magnetized against the direction of the external magnetic field.

Chemical properties

Copper is a relatively low-active metal. Under normal conditions in dry air, its oxidation does not occur. It reacts easily with halogens, selenium and sulfur. Acids without oxidizing properties have no effect on copper. There are no chemical reactions with hydrogen, carbon and nitrogen. In humid air, oxidation occurs to form copper (II) carbonate, the top layer of platinum. Copper is amphoteric, meaning it forms cations and anions in the earth's crust. Depending on the conditions, copper compounds exhibit acidic or basic properties.

Key Facts

Copper is a very important material for humans. The first tools that people used were copper products. Previously, metal processing was carried out using the cold method, which is confirmed by various archaeological finds in North America. Even before the arrival of Columbus, the Indians preserved such traditions. It has been established that 7,000 years ago people mined and used copper ore. It is thanks to its pliability that it has become very popular.

Copper has a reddish tint due to the small amount of oxygen in the composition. If this element is completely excluded, the tint will be yellowish. If you polish copper, it will have a bright shine. The higher the valence, the weaker the shade. For example, copper carbonates are usually green or blue in color.

After silver, copper is the second metal that has good electrical conductivity. Because of this, it is actively used in electronics. Copper reacts poorly to oxygen. It becomes covered with a film due to oxidation in the fresh air.

Copper oxide can be obtained by calcining copper, bicarbonate or nitrate in air. This compound is capable of having an oxidizing effect on organic compounds.

If you dissolve copper in sulfuric acid, copper sulfate comes out. It is used in the chemical industry and is also used as a preventative against crop pests.

Depending on the influence of impurities on the character of the overall copper alloy, 3 main groups can be distinguished.

- The first includes those compounds that, together with copper, create solids. This applies to arsenic and antimony. This also includes iron, zinc, nickel, tin, aluminum, phosphorus and others.

- The second group consists of compounds that are practically insoluble in copper. An example is bismuth, lead and others. Because of them, treatment by pressure is difficult. This has virtually no effect on electrical conductivity.

- The third group is sulfur and oxygen. Together with copper, they create chemical compounds that are distinguished by their fragility.

This is interesting: Bronze - composition, properties and characteristics of the alloy

Features of popular copper alloys

Alloy M1 is manufactured in accordance with GOST 859-2014, is a highly plastic and well-processed metal, and has the highest copper content (99.9%). Additional elements include zinc, nickel, phosphorus, iron, arsenic, oxygen, tin, bismuth (total no more than 0.1%). The electrical resistivity is 0.018 μOhm. The alloy can be of two types - hard (M1t) and soft (M1m), they differ in strength and fluidity. Rolled metal is in demand in the automotive and aircraft industries, in the creation of current conductors, cryogenic equipment, wire and rods.

Alloy M2 has a lower copper ratio in the composition (99.7%). The remaining 0.3% comes from nickel, iron, antimony, oxygen, tin, lead, sulfur, and arsenic. This grade is ductile and does not rust, is excellent in pressure processing and is used for the manufacture of copper-based alloys and refrigeration parts.

Alloy M3 is technical copper; it contains the smallest percentage of metal among those presented (99.5%). The same elements as in M2 are used as alloying components, only in a larger proportion (up to 0.5%), which makes this alloy the most affordable. Optimally suitable for metal products that are sold by rolling methods, as well as cast alloys.

Copper m1 m2 m3 difference

Due to their properties, various grades of copper are very popular in the industrial environment. This metal is good because it is flexible and, regardless of the operating environment, with the exception of exposure to sulfur dioxide and ammonia, it is resistant to corrosion.

The external distinctive feature of copper is its pink-red color. Depending on the purity, copper is divided into types with the technical designations M1, M2, M3. This metal comes into production in the form of wire, sheets, pipes, and rods.

This is due to different application situations.

Schedule

Based on its composition, copper is divided into oxygen-free and deoxidized; the symbol is M0 and M1, respectively. Oxygen-free is used in the manufacture of parts for electrical, electronic, and electrovacuum industrial products. O2 in oxygen-free brands is no more than 0.001%, and in deoxidized ones - 0.01%.

The breakdown of copper grades is presented in the table:

Variety of copper products

Rods made from this metal vary in shape and can be round, square, or hexagonal. In addition, they are divided into cold-deformed, so-called “drawn”, hot-deformed, or “pressed”. Their production takes place in strict compliance with GOST 1535-91, using copper grades such as M1, M1r, M2, M3, M3r according to GOST 859.

The degree of hardness of the finished rods is: medium, hard and soft. Copper grade M2 is used, as well as M1, M1r, M2r, M3, M3r according to GOST 859, in accordance with the GOST 1173-93 standard.

There is also a division according to normal accuracy in thickness and increased in width, normal accuracy in thickness and width, increased accuracy in thickness and optimal accuracy in width.

Copper wire can be soft or hard. In production, copper grade M1, GOST 859, GOST 434-78 is used.

Pipe manufacturing

In order to produce high-quality copper pipes suitable for further use, you need to know which brand to use, as well as comply with certain technical requirements that are prescribed in GOST 617-90. Thus, in industrial production the M3 brand is used, as well as M1, M1r, M2, M2r, M3r, GOST 859 and chemical. composition GOST 15527 L96.

Pipes come in the following varieties: pressed and cold-deformed, hard, medium-hard and soft.

Production of strips and sheets

Strips and sheets are made in accordance with GOST 495-92, for this they use copper with the following markings: M1, M1r, M2, M2r, M3, M3r GOST 859.

Normal and high precision production methods are used for cold-rolled sheets and strips.

The size of hot-rolled sheets varies from six hundred to three thousand mm in width, and in length - from one thousand to six thousand.

According to the degree of hardness, cold-rolled sheets and strips on an industrial scale are soft, hard, and medium.

Variety of copper alloys

The most common alloy in industry is brass. It is a compound of zinc and copper. When a third, fourth, fifth, etc. appears in this composition. element, brass becomes complex, or special. In this case, it receives an aluminum, iron-manganese, manganese-tin-lead prefix.

This alloy is well suited for work involving casting, pressing, and cutting, since, unlike the usual composition of copper, it is characterized by increased resistance to fracture, elasticity and endurance. These qualities facilitate the processing of parts.

Brass rods are made in compliance with GOST 2060-90. Manufacturing accuracy is increased, normal and high. Plasticity – hard, medium, and soft.

Brass wire is produced taking into account GOST 1066-90, brass grades L68, L80, L63, LS59-1 are used. The chemical composition is regulated by GOST 15527.

The tape is produced in accordance with GOST 2208-91. Brass L85, L90, L80, L68, L63, LS59-1, LMts58-2 is used, the chemical composition is determined by GOST 15527. Condition: semi-solid, soft, hard, spring-hard and extra-hard. Normal production accuracy is acceptable - in width and thickness, in thickness and increased accuracy in width, increased accuracy in thickness and normal accuracy in width.

Special grades are also produced - for stamping, anti-magnetic, with increased crescent accuracy, with a normalized extrusion depth that can withstand bending testing.

You can see all this in the photo.

Brass pipes are produced in accordance with the GOST 494-90 standard. Cold-rolled and drawn pipes are grades L63 and L68, and pressed pipes are grades L63, L60, LS59-1, LZhMts59-1-1, chemical. composition GOST 15527. Length – 1-6 m.

Special products – pipes of increased precision, special curvature, anti-magnetic.

Copper Applications

Copper processing goes deep into history. Initially, people used copper sheets to make jewelry and household utensils. And only then a method for producing bronze was discovered by combining an alloy of tin and copper. Thus began the Bronze Age.

The time you live in and the Bronze Age are separated by millennia, but copper is still widely used today. If we look inside old televisions, receivers, transformers, and other wonders of technological progress of the last century, we will find whole spools of copper wire there.

In modern industry, copper and alloys have an importance that is difficult to overestimate, so the price of copper is quite high. But, nevertheless, almost all equipment is made using this metal.

In addition, copper is an excellent thermal conductor. Therefore, it is the number one metal used in the production of air conditioners. And the strength and impermeability of copper pipes allows them to be used for transporting certain types of caustic liquids and gases.

Copper is widely used in various industries, and the list is so large that it is impossible to list everything now.

Without touching on the topic of industry, wire from this valuable metal is used to create works of art. For example, trees made of beads. Small beads are strung on it, and thanks to the flexibility of this material, the finished product takes the shape required for the composition.

Copper grades - characteristics, marking and its interpretation

Copper grades are widely represented in various industries: this non-ferrous metal, due to its unique characteristics, is one of the most common. All grades of this metal are distinguished by high ductility and corrosion resistance when used in various environments, with the exception of ammonia and sulfur dioxide gases.

Copper circle Ø 30

Modern industry produces copper blanks in the form of sheets, pipes, wires, rods and bars. There are oxygen-free (M0) and deoxidized (M1) copper, products from which are widely used in the electrical, electronic and electrovacuum industries. Oxygen-free brands contain O2 within 0.001%, in deoxidized ones - 0.01%.

Today there are quite a lot of grades that are classified according to the purity of the base metal content: M00, M0, M1, M2 and M3. Also common are the M1p, M2p and M3p brands, which are characterized by an oxygen content of 0.01% and phosphorus of 0.04%. For example, grades M1, M2 and M3 contain oxygen in the range of 0.05–0.08%.

Copper gradeM00M0M0bM1M1rM2M2rM3M3rM4

| copper,% | 99,99 | 99,95 | 99,97 | 99,90 | 99,90 | 99,70 | 99,70 | 99,50 | 99,50 | 99,00 |

Biological value for humans

Copper belongs to the category of vital elements, and the body of an adult contains about 100 grams of this metal. A reassessment of the toxicity of this substance was carried out in 2003 by the World Health Organization. Studies have found that copper is not a cause of diseases of the digestive tract, and does not provoke the development of Wilson-Konovalov disease (hepatocerebral dystrophy affecting the liver and brain), as previously thought. Scientists have concluded that a lack of copper is more harmful to human health than its excess.

The bactericidal properties of copper have been known for a long time, and recent studies in this area have confirmed the effectiveness of the metal in the prevention of swine flu and infection by Staphylococcus aureus. In experiments, it was found that 99% of pathogenic bacteria die on a copper surface within 2 hours. Therefore, copper and its alloys are widely used for water disinfection. In Europe, door handles, locks, hinges and railings are made from this metal, which are installed in medical institutions and public places.

Methods for obtaining copper

In nature, copper exists in compounds and in the form of nuggets. The compounds are represented by oxides, bicarbonates, sulfur and carbon dioxide complexes, as well as sulfide ores. The most common ores are copper pyrite and copper luster. The copper content in them is 1-2%. 90% of primary copper is mined using the pyrometallurgical method and 10% using the hydrometallurgical method.

1. The pyrometallurgical method includes the following processes: enrichment and roasting, smelting for matte, purging in a converter, electrolytic refining. Copper ores are enriched by flotation and oxidative roasting. The essence of the flotation method is as follows: copper particles suspended in an aqueous medium adhere to the surface of air bubbles and rise to the surface. The method allows you to obtain copper powder concentrate, which contains 10-35% copper.

Copper ores and concentrates with a significant sulfur content are subject to oxidative roasting. When heated in the presence of oxygen, sulfides are oxidized, and the amount of sulfur is reduced by almost half. Poor concentrates containing 8-25% copper are roasted. Rich concentrates containing 25-35% copper are melted without resorting to roasting.

The next stage of the pyrometallurgical method for producing copper is smelting for matte. If lump copper ore with a large amount of sulfur is used as a raw material, then smelting is carried out in shaft furnaces. And for powdered flotation concentrate, reverberatory furnaces are used. Melting occurs at a temperature of 1450 °C.

In horizontal converters with side blowing, the copper matte is blown with compressed air in order for the oxidation of sulfides and ferrum to occur. Next, the resulting oxides are converted into slag, and sulfur into oxide. The converter produces blister copper, which contains 98.4-99.4% copper, iron, sulfur, as well as small amounts of nickel, tin, silver and gold.

This is interesting: Ejector - what is it? The principle of operation of ejector pumps and their design

Blister copper is subject to fire and then electrolytic refining. Impurities are removed with gases and converted into slag. As a result of fire refining, copper is formed with a purity of up to 99.5%. And after electrolytic refining, the purity is 99.95%.

2. The hydrometallurgical method involves leaching copper with a weak solution of sulfuric acid, and then separating copper metal directly from the solution. This method is used for processing low-grade ores and does not allow for the associated extraction of precious metals along with copper.

Copper

Soft, ductile metal of pinkish-golden color. Its beauty has attracted people since ancient times, so the first products made from copper were jewelry.

In the presence of oxygen, copper ingots and copper products acquire a reddish-yellow hue due to the formation of a film of oxides. In a humid environment in the presence of carbon dioxide, copper turns greenish.

Copper has high thermal and electrical conductivity, which ensures its use in electrical engineering. Does not change properties over a wide range of temperatures from very low to very high. Not magnetic.

In nature, deposits of copper ore are more often found on the surface than other metals. This allows open-pit mining. Large copper nuggets with high copper purity and copper veins are found. In addition, copper is obtained from the following compounds:

- copper pyrite,

- chalcocite,

- bornite,

- covellin,

- cuprite,

- azurite,

- malachite.

Copper alloys, their properties, characteristics, grades

The production of copper alloys makes it possible to improve the properties of copper without losing the main advantages of this metal, as well as to obtain additional useful properties.

Copper alloys include: bronze, brass and copper-nickel alloys.

Brass

This is an alloy of copper and zinc. In addition to zinc, it also contains other alloying additives, including tin.

Brasses are corrosion-resistant alloys. They have anti-friction properties to resist vibrations. They have high fluidity rates, which gives products made from them a high degree of resistance to heavy loads. In brass castings, segregation areas are practically not formed, so the products have a uniform structure and density.

Brasses are marked with a set of alphanumeric codes, where the first letter is always L, meaning brass itself. Next comes a digital indicator of the percentage of copper in brass. The remaining letters and numbers indicate the content of alloying elements as a percentage. Brasses use the same letter designations for alloying elements as bronzes.

An example of double brass marking: L85. It stands for “brass with a copper content of up to 85%, the rest is zinc.”

An example of multi-component brass marking: LMtsA57-3-1. It stands for “brass with a copper content of up to 57%, manganese - up to 3%, aluminum - up to 1%, the rest is zinc.”

Bronze

An alloy of copper and tin. However, with the development of technology, bronzes also appeared, in which, instead of tin, aluminum, silicon, beryllium and lead were introduced into the alloy.

Bronze is harder than copper. They have higher strength ratings. They are better suited to metal forming, especially forging.

Marking of bronzes is carried out using alphanumeric codes, where the first letters are Br, meaning bronze itself. Additional letters indicate alloying elements, and numbers after the letters indicate the percentage of such elements in the alloy.

Letter designations of bronze alloying elements:

- A – aluminum,

- B – beryllium,

- F – iron,

- K – silicon,

- Mts – manganese,

- N – nickel,

- O - tin,

- C – lead,

- C – zinc,

- F – phosphorus.

An example of marking tin bronze: BrO10S12N3. It stands for “tin bronze with a tin content of up to 10%, lead – up to 12%, nickel – up to 3%.”

An example of decoding aluminum bronze: BrAZh9-4. It stands for “aluminum bronze with an aluminum content of up to 9% and iron up to 4%.”

Copper-nickel alloys

- Cupronickel is an alloy of copper and nickel. Iron and manganese may be present in the alloy as additives. Special cases of technical alloys based on copper and nickel:

- Nickel silver – additionally contains zinc,

- Constantan – additionally contains manganese.

Cupronickel has high corrosion resistance. It lends itself well to any type of mechanical processing. Non-magnetic. It has a pleasant silver color.

Due to its properties, cupronickel is, first of all, a decorative and applied material. Jewelry and souvenirs are made from it. For decorative purposes it is an excellent substitute for silver.

There are 2 brands of cupronickel available:

- MNZHMts – an alloy of copper with nickel, iron and manganese;

- MH19 is an alloy of copper and nickel.

Copper m1 – Copper grades according to GOST 859 M1, M2, M3

alexxlab | 12/05/2018 | 0 | Questions and answers

- Copper grades according to GOST 859 M1, M2, M3

- Copper M1 / Auremo

- Copper M1r / Auremo

- properties, characteristics, composition.

Mass fraction of impurities in copper M1 GOST 859-2001 - Copper grades - classification, physical properties, application +

- MV copper (vacuum copper) + Anodes, graphite, solder... › Russian metal We offer MV copper to order.

- We supply electrical copper M1E to order.

Copper grades according to GOST 859 M1, M2, M3

Due to their properties, various grades of copper are very popular in the industrial environment. This metal is good because it is flexible and, regardless of the operating environment, with the exception of exposure to sulfur dioxide and ammonia, it is resistant to corrosion.

The external distinctive feature of copper is its pink-red color. Depending on the purity, copper is divided into types with the technical designations M1, M2, M3. This metal comes into production in the form of wire, sheets, pipes, and rods.

This is due to different application situations.

Schedule

Based on its composition, copper is divided into oxygen-free and deoxidized; the symbol is M0 and M1, respectively. Oxygen-free is used in the manufacture of parts for electrical, electronic, and electrovacuum industrial products. O2 in oxygen-free brands is no more than 0.001%, and in deoxidized ones - 0.01%.

The breakdown of copper grades is presented in the table:

Designations

NameMeaning

| Designation GOST Cyrillic | M1 |

| Designation GOST Latin | M1 |

| Translit | M1 |

| By chemical elements | Cu1 |

Description

M1 copper is used : for the production of current conductors; rental; high-quality tin-free bronzes; cryogenic equipment products; round drawn thin-walled pipes; cold-rolled foil and strip, cold-rolled and hot-rolled sheets and plates for general purposes; wires for the manufacture of metal shielding braids of the PML type, intended for shielding wires and cables; hot-rolled and cold-rolled anodes used for galvanic coating of products; cold-deformed rectangular tape with a thickness of 0.16−0.30 mm, intended for coaxial trunk cables; radiator tapes intended for the manufacture of cooling tubes and radiator plates; drawn pipes of rectangular and square cross-section, intended for the manufacture of conductors for stator windings of liquid-cooled electrical machines; profiles for the manufacture of rotors of submersible electric motors; round welding wire and round welding rods drawn and pressed with a diameter from 1.2 to 8.0 mm, intended for automatic welding in an inert gas environment, submerged arc and gas welding of non-critical structures made of copper, as well as the manufacture of electrodes for welding copper and cast iron.

Note

M1 copper is obtained by melting cathodes. Copper grade M1 in chemical composition corresponds to copper grade Cu-ETP according to Euronorm EN 1652:1998.