A chainsaw is a complex unit whose operation is based on a two-stroke internal combustion engine. To operate an internal combustion engine, a carburetor is required. In this mechanism, fuel is mixed with air, and this mixture is supplied to the engine cylinder for combustion. The operation of the internal combustion engine largely depends on the carburetor, which needs periodic adjustment. You can adjust the carburetor of a chainsaw yourself, but to do this you will need to know the instructions described below.

Adjusting the carburetor of a Chinese chainsaw

Carburetors installed on Chinese-made saws are made similarly to European ones and have the same adjustment screws.

Adjusting the carburetor of a Chinese chainsaw follows the algorithm presented above, and differs in that when initially adjusting the screws (L) and (H), they must be turned out two turns. Next, the carburetors of the Chinese saw are adjusted in the same way as European ones.

Read about how to adjust the carburetor of a Chinese chainsaw in just 3 steps here (a very useful article). As an example, we recommend looking at the article about adjusting the carburetor on a Carver chainsaw.

Chainsaw CARVER starting problems and repairs

Chainsaw CARVER PROMO PSG 45-15 1st serious test and 1st breakdown Find out how to test yourself.

Carburetor design on a Carver chainsaw

Most modern chainsaws (Carver is no exception) have either completely identical carburetors from the first manufacturer (for example, Walbro), or are very similar in design. But even with the difference in the external appearance of the body, the operating mechanism of all carburetors is completely uniform.

But the carburetors on Carver saws differ from other chainsaws in the availability of regulation. The adjustment screws on most other pollen models are hidden under the body and often have uniquely shaped recesses. Therefore, they can only be adjusted with special branded screwdrivers, which are sold in service centers. The Carver carburetor is adjusted with an ordinary flat-head screwdriver. The case has three holes for screw adjustment. Therefore, the carburetor on a Carver chainsaw can be adjusted without even removing the cover.

Operating principle of a Carver carburetor

After starting the chainsaw motor, the air damper opens, through which purified air enters a diffuser with a small filter. Gasoline gets there through calibrated holes in the jets. The amount of air-fuel mixture that enters the combustion chamber from the carburetor is regulated by the position of the throttle valve, connected by a rod to the throttle handle.

The needle valve cuts off the flow of gasoline to the carburetor when it is full. Gasoline passes through a filter before entering the injectors, reducing the risk of clogging the calibrated holes in them.

Situations in which adjustment is necessary

New chainsaws are supplied by the manufacturer with already adjusted carburetors. This is called standard adjustment. But for the normal running-in process, it is necessary to reduce the maximum engine speed and adjust the carburetor. After break-in, the chainsaw needs fine tuning to achieve maximum engine efficiency.

If there is too much fuel in the mixture, engine parts are poorly lubricated and premature wear occurs. Also, a poor quality mixture can cause the engine to jam due to overheating (this is one of the reasons why a chainsaw

does not start).

This is what a jammed, overheated piston looks like from a disassembled chainsaw with an incorrectly configured carburetor.

Adjustment is necessary when the engine does not idle, stalls, or does not develop full power. Carburetor adjustment should be carried out with clean air and fuel filters. We also recommend reading an interesting article that details the main reasons why a chainsaw

starts and immediately stalls.

When is adjustment generally necessary?

In particular, in rare cases it is necessary to adjust the carburetor of a chainsaw; more often problems arise related to fuel consumption or wear of parts. But sometimes “symptoms” indicate the need to regulate the mechanism. Here are some signs:

- When the engine starts, it stops immediately. Alternatively, it won't start at all. The reason is too much air and not enough fuel.

- Fuel consumption increases as a result. Large amount of exhaust gases. This is due to the reverse process. Oversaturation of the mixture with fuel.

Reasons for failure may be mechanical:

- Due to severe vibration, the protective cap is damaged, causing all three bolts to become loose.

- Due to wear on the engine piston. In this case, adjusting the chainsaw carburetor will only help temporarily; it is better to replace the worn part.

- Due to clogging caused by poor quality fuel, scale or filter damage. The carburetor requires complete disassembly, cleaning and adjustment.

If the chainsaw suddenly stops working, it must be disassembled to find out the reasons.

How to properly adjust a chainsaw carburetor

During operation of the tool, situations arise when it is necessary to adjust the carburetor of the chainsaw. In the article, we will figure out when to adjust, how to do it correctly and whether it is worth adjusting yourself, or is it better to send it to a specialized service. The carburetor is an important component; the service life of the saw depends on how correctly it works.

- Situations in which adjustment is necessary

- Tools

- How is the carburetor adjusted?

- Process description

- Adjusting the carburetor of a Chinese chainsaw

- Video

- Summing up

How to properly adjust the carburetor on a chainsaw with your own hands?

Chainsaw. a necessary, and from time to time simply necessary, tool for the owner of a personal home. It has the highest degree of independence and can be used in field conditions where there is no ability to connect to the power supply network. For some craftsmen, a chainsaw is one of the main devices that perform a huge amount of work almost every day. Such loads knock down the factory options installed for all fundamental components of the motor.

The operating mode is often changed by the carburetor, which has to be readjusted. Without understanding the design and operating mechanism of this element, it is impossible to make it correctly. The question concerns many users who work closely with chainsaws, so it is useful to look at it more carefully.

- Design and operation principle

- When is adjustment

? - Regulatory instruments

- How to properly adjust the carburetor

with your own hands? - How to install Chinese-made dust dusters?

READ Hammer Stl1200 210c Miter Saw Review

Process description

- If the chainsaw carburetor is not adjusted and it is not possible to start the chainsaw, then the adjustment begins by installing screws (L) and (H) to the standard setting position. This is 1/5 turn of the screws until they are fully tightened.

- After which, you need to start the engine, let it run a little and warm up.

- The next step is setting the low speed mode. Optimal engine operation at low end can be achieved by adjusting the screw (L) and idle speed (T). To do this, first screw (L) is tightened until maximum engine speed is reached, then released by 1/4, and screw (T) is used to return the idle speed to normal.

- After adjusting the operation at the “lower” range, the traction and maximum engine speed are adjusted. To do this, slowly tighten the screw (H) and check the speed using the readings of the electronic tachometer. It is unacceptable to exceed the maximum engine speed declared by the manufacturer!

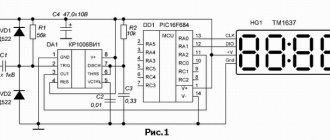

Location of carburetor adjustment screws on a Husqvarna chainsaw.

An important step is to check the saw in all operating modes after adjustment; to do this, you need to let the chainsaw cool, and then start it according to the cold tool starting algorithm. If the saw starts up normally and idles smoothly, you need to check how it cuts. If during the inspection process shortcomings in the power of the chainsaw are discovered, then it is necessary to repeat the adjustment of the screw (H) by unscrewing it and checking the traction in operation.

We recommend watching a video on how to clean and adjust the carburetor

chainsaw, the author of which also talks about the harmful effects of fuel on the components of the carburetor. The example shows how to restore your carburetor using an inexpensive repair kit.

How is the carburetor adjusted?

The chainsaw setup algorithm is quite simple and consists of the following steps:

- Warming up the engine to operating temperature (the adjustment must be carried out only on a warm engine, this will allow for more accurate adjustment).

- Adjusting the engine for smooth operation at low speeds.

- Setting

the carburetor to properly supply the fuel mixture at maximum speed. - Precise adjustment of the carburetor for idle operation.

- Checking the chainsaw in all modes.

Almost all carburetor models have three adjustment screws.

- Screw (T) is responsible for fine adjustment in idle mode.

- Screw (H) adjusts

operation at maximum speed. - Screw (L) regulates mixture formation at low speeds.

By tightening screws (L) and (H), the fuel supply and mixture become leaner, and the speed increases accordingly.

Adjusting the carburetor of a Chinese chainsaw

Carburetor adjustment screws L - minimum speed and H - maximum engine speed.

Adjusting the carburetor on a Chinese chainsaw (practice)

Now let’s look at how to properly adjust a chainsaw carburetor in more detail.

When customization is required

Modern “three-screw” carburetors of Carver chainsaws are practically not designed for manual adjustment at home. The screws are designed for factory settings, are securely secured against rotation during vibration by stable springs and do not change their position arbitrarily.

READ Carburetor Adjustment for Chainsaw MS 660

But the carburetor screws of the Carver chainsaw are accessible for adjustment through special holes, without removing the casing, using a regular screwdriver. This suggests that such models structurally require periodic adjustment of the carburetor.

The reason for this cannot be stated from a technical point of view. Only versions available:

- The Carver Carver chainsaw is in an area of strong vibration, so the screws unscrew spontaneously.

- There is a rough spring installed which cannot secure the screw like other models.

- Periodic adjustment is necessary due to the technical characteristics of the carburetor and the internal combustion engine of the Carver chainsaw as a whole.

Tools

To adjust, you will need the following tools: tachometer, screwdrivers, and in rare cases, special keys. Let's look at their purpose, necessity of availability and cost.

| Tool | Purpose | Recommended | |

| Screwdriver set (slotted screwdriver) | On most chainsaws, you will need a simple flathead screwdriver to turn the adjustment bolts. | 300 – 700 rubles | Necessarily |

| Special adjustment key | For example, to adjust the carburetor on Husqvarna chainsaws you will need a special key; it is available only in certified service centers authorized for repairs by the manufacturer. This measure is aimed at reducing breakdowns due to incorrect settings by inexperienced users and those who carry out repairs without official permission to do so. | Out of stock | Depends on the chainsaw |

Required tools and materials

To adjust the carburetor of chainsaws, use slotted or Phillips screwdrivers 3.5 mm wide. The type of tool depends on the device model and country of origin.

Tools for carburetor adjustment

Before carrying out work, clean the fuel and air filters from traces of oil and other contaminants. For cleaning, use pure gasoline or synthetic detergents (acetone).

Attention! Flushing the unit must be carried out in strict compliance with fire safety requirements.

Pure gasoline and its analogues are used to remove contaminants from the surface of the part. Internal channels are treated with kerosene, white spirit or diesel fuel. Before using synthetic substances, remove all rubber and plastic elements.

Thorough cleaning of parts is carried out by disassembling them using open-end wrenches and spanners. To remove contaminants in hard-to-reach places, use plastic syringes or special containers.

Setting the speed on the chainsaw

For those who have a chainsaw, adjusting the carburetor with their own hands is not particularly difficult. To do this, you need to study the structure of the carburetor and remember the sequence of actions performed to regulate the elements on which the correct operation of the parts of the carburetor itself and the elements located near it depends.

Before adjusting the chainsaw carburetor, you need to prepare the device. For these purposes, the following actions are performed:

- The engine is warmed up, for which it starts approximately ten minutes before the start of repair work, and turns off after it begins.

- The air filter is checked and washed.

- The chain is stopped by turning screw T as far as it will go.

To ensure the safety of repair work, it is necessary to prepare a flat surface so that the tool can be placed on it carefully, and the chain can be turned in the opposite direction. You will need a tachometer to determine if the carburetor is malfunctioning.

Anyone who wants to know how to adjust the carburetor on a chainsaw should take into account that this procedure consists of two main stages. The first is carried out with the engine turned on, the second - after the engine has warmed up.

To successfully adjust the carburetor, you should first study the instructions for using a specific chainsaw model to clarify additional nuances of adjusting this equipment.

At the first stage, the low and high speed screws are turned clockwise until they stop, and then turned in the opposite direction one and a half turns and maintained in this position.

At the second stage, the engine is switched to medium speed to warm up for ten minutes. The screw responsible for regulating the idle speed must be moved clockwise. You can release it only when the motor enters stable operation mode. Care should be taken to ensure that the chain remains stationary during this process.

When the engine is idling, it may stall. In such a situation, you should immediately turn the screw clockwise until it stops. In some cases, the chain becomes dislodged. In such situations, you need to turn the screw counterclockwise.

When deciding how to properly adjust a chainsaw, you need to check the functioning of the motor at maximum speed. When the engine is functioning correctly, after pressing the accelerator, the speed quickly increases to fifteen thousand revolutions per minute.

If there is no such reaction or the speed increases too slowly, turn the screw marked L counterclockwise. It is important to ensure moderation of the movement, since the rotation should not be more than one-eighth of a 360-degree turn.

The maximum number of revolutions is limited using the adjusting screw marked H. To reduce the number of revolutions, turn it counterclockwise, and to increase it, turn it in the opposite direction. The maximum frequency should not be more than fifteen thousand revolutions per minute. When turning this screw, ignition processes should be taken into account. If even barely noticeable failures occur, the maximum speed must be reduced.

How to adjust the carburetor on a chainsaw so that it functions correctly at idle? To do this, the following conditions must be met:

- The chain remains stationary at idle.

- The sound produced by the engine resembles the sound of a four-stroke unit.

- The engine increases speed at an accelerated pace even when the accelerator is lightly pressed. With a gradual increase in pressure, the motor speed increases proportionally, reaching the maximum permissible level.

If inconsistencies with these conditions are detected, the main configuration stage must be repeated.

To correctly configure the carburetor of a Chinese chainsaw, you should remember its factory settings, and then turn on the engine. To accurately set your parameters, you will have to keep it running for several hours in the future. In some cases, this problem can be solved immediately after running the engine for ten minutes, but many models from Chinese manufacturers require special handling.

Settings

performed in the following order:

- Regulation begins at idle speed. It is necessary to achieve a smooth increase in engine speed using adjusting screws, so first you need to leave it running for some time at low speeds. The movement of the chain along the bar represents a deviation from the norm. In this case, the optimal position should be achieved by adjusting using the outermost screws so that the chain does not move.

- There is a transition to medium speed speed. In some cases, this is accompanied by engine smoke. This defect is eliminated by tightening the screw to supply a less saturated fuel mixture. However, the engine speed will increase. It is necessary to change the settings until the engine begins to increase speed smoothly when you press the throttle, without interruptions or sudden jerks.

- The chainsaw motor is being checked. The tool is switched to minimum speed, after which the lever is quickly pressed and held at maximum pressure for three seconds. If problems occur in the functioning of the motor, the screw should be gradually loosened until the optimal position is reached.

- The chainsaw should work in real conditions for some time. To do this, you need to saw the wood, and then inspect all the parts involved in this process. If there are deviations, they must be corrected using adjusting devices. After eliminating all defects and setting the optimal settings for supplying the fuel mixture, the setup procedure is completed.

Signs of proper instrument tuning

The correct setting is indicated by the following:

Carburetor operation diagram

- At idle, the tool does not stall and the chain does not move along the bar.

- The device operates without smoke.

- The engine has good throttle response.

Throttle response is the engine's ability to quickly pick up speed when the throttle lever is pressed.

Adjusting the chainsaw carburetor affects the proper operation of the device. Incorrect adjustment or lack thereof can lead to malfunctions of the unit and damage to it.

Violation of the requirements of the operating rules leads to premature failure of the chainsaw with subsequent repairs.

Any steps to set up the chainsaw are described in detail in the operating instructions for the device. The technical documentation describes in detail the sequence of actions for setting up the saw for operation. Compliance with these requirements guarantees the restoration of the original parameters of the equipment with high accuracy.

Related video: Chinese chainsaw - carburetor repair and adjustment

Publications on the topic

Troubleshooting the Husqvarna 142 chainsaw

Chainsaw Partner 350 – do-it-yourself repair

What to do if the Shtil 180 saw does not start - finding the cause

Adjusting the chainsaw carburetor

Using a chainsaw greatly simplifies life even for amateurs, and in some professions it is almost irreplaceable. But, like any relatively complex equipment, a chain saw requires regular maintenance. If it is performed untimely or of poor quality, this leads to various malfunctions. One of the most common causes of problems is the incorrect setting of the chain saw carburetor, which becomes confused due to the displacement of the adjusting screws under the influence of vibrations or as a result of unsuccessful attempts to adjust it.

Adjustment of the chainsaw is required in the following cases:

- The factory settings of the chainsaw carburetor are off;

- the engine starts with effort and stalls almost instantly;

- debris particles entering the fuel distribution mechanism due to a malfunction of the air purification system;

- the exhaust is too thick, the fuel consumption is too high, the fuel does not burn completely in the cylinder;

- significant wear of the piston group (in this case, adjusting the chainsaw carburetor is a temporary measure).

READ How to Choose a Chain for a Electric Saw

The carburetor is designed to prepare the fuel mixture for supply to the engine. Violations of the proportions in the fuel mixture lead to malfunctions in the functioning of the engine.

adjusting the carburetor of a Chinese-made chainsaw

The design of carburetors in different models of chain saws varies, but they all operate on the same principle. The air flow moves quickly through the channel. The speed of its movement is regulated using a damper that blocks the channel. The fuel supplied into the channel through the atomizer is mixed with air, after which the resulting air-fuel mixture enters the engine.

The carburetor always consists of the same set of parts, although it may vary slightly depending on the manufacturer. It consists of the following parts:

- The basis. It is a special tube that has an external resemblance to an aerodynamic design. Air flow passes through it. In the middle of the tube in the transverse direction there is a valve, the position of which can be changed. The more it is pushed into the passage, the less air enters the motor.

- Diffuser. This is the narrowed part of the pipe. With its help, an increase in the speed of air flow is ensured precisely in the part from which the fuel is supplied.

- Float chamber. This element is shaped like a tank. It is used to continuously maintain an optimal fuel level before entering the channel from which air is supplied.

- Channels for fuel supply. The fuel mixture is located in the float chamber, from where it enters the nozzle and then is fed into the atomizer.

In order for the operation of the tool to be efficient and smooth, maximum output, and economical fuel consumption, timely adjustment of the chainsaw carburetor is required. Before performing this, check the cleanliness of the air and fuel filters. On most chainsaws, adjustment is made using three screws: high speed, low speed, idle.

Adjusting the carburetor must be done with the utmost care, since errors are fraught with very significant consequences, including engine failure.

Signs of a correct setting are the following:

- engine acceleration is fast and smooth;

- the chain remains motionless at idle;

- The engine produces a smooth sound when running, reminiscent of the sound of a four-stroke unit.

Adjusting the carburetor of a Chinese chainsaw is done in the same way as for models produced by European manufacturers; in fact, Chinese analogues are copies of famous brand tools, but with some changes.

For this, the same screws H, L and T are used. The standard for carburetors of Chinese chain saws is the position of the screw L, in which it is loosened by one and a half turns compared to the fully clamped state. For screw H, the standard is one turn from the same position. Idle speed adjustment is performed on a warm engine.

On some models, only the idle speed is adjusted. However, owners of Chinese chain saws and service employees talk about the increased difficulty of adjusting the carburetor for tools produced by Chinese manufacturers. Even for experienced craftsmen, adjusting a Chinese chainsaw takes a little more time, unlike original tools.

Add a commentCancel reply

You must be logged in to post a comment.

Adjustment Tools

For the carburetor option, a Philips or slotted screwdriver of various lengths or thickness is useful; The size depends on the design of this unit and the features of the motor assembly. It must be emphasized that some manufacturers make carburetors designed for the use of special tools.

Namely, for the option of Husqvarna carburetors and other tools imported from other countries, special screwdrivers may be useful. It is advisable to clarify this question even when purchasing a chainsaw, so that you can purchase the necessary additional equipment in advance.

In addition, purified gasoline or acetone will be useful for washing and cleaning the device. They are used to clean the external surfaces of the carburetor. All internal channels are washed with kerosene, diesel fuel or snow-white alcohol. Before washing, the carburetor is dismantled, all rubber or plastic parts that may be damaged by contact with harsh chemical compounds are removed.

To disassemble the carburetor, open-type wrenches or spanners are used. The internal channels are washed in specially designated trays; from time to time, plastic syringes are used for this.

In what cases is it necessary to adjust the carburetor of a chainsaw?

Here is a list of the most common cases in which tuning

chainsaw carburetor:

- The engine starts, but the chainsaw

stalls, or it cannot be started at all. The cause may be too much air in the fuel chamber. - Increased fuel consumption. It can occur due to excessive saturation of the mixture that enters the engine with fuel. For the engine to work well, the mixture must be of high quality.

- The bolts in the carburetor have become loose due to a damaged carburetor body.

- Debris getting into the carburetor. This can happen if the filter is damaged or low-quality fuel is used. You will need to completely disassemble the carburetor

, clean it and re-tune it. - The engine idles poorly or does not develop full power.

Important! If the engine runs poorly because the piston is worn out, adjusting the carburetor will not work. In addition, along with the adjustment, it is advisable to clean the carburetor of debris - this will increase the effectiveness of the procedure.

When is carburetor adjustment necessary?

Initially, from the time the tool was sold, all carburetors were tuned and tuned at the factory. However, during operation, the settings are gradually lost, and the operating mode changes in accordance with operating conditions. Signs of a bad carburetor may include:

- gasoline consumption is too high, thick smoke comes out of the exhaust pipe;

- the engine power is clearly not enough to perform normal tasks;

- motor speed floats;

- after starting, the motor stops either immediately or after a few seconds

- the engine cannot be started at all;

- The chainsaw shoots in the engine of the tool are sharp clamps.

It should be noted that when starting a new engine, the carburetor is set to a reduced fuel supply to limit engine power. After the end of the run, the fuel supply increases to the nominal value. These adjustments are made using adjusting screws on the carburetor body (usually two or three).

Adjusting the chainsaw carburetor

Chainsaws are a very popular gardening tool. They have gained great popularity among gardeners and those who care for the territory in their home areas. Construction or repairs cannot be done without chainsaws. Chainsaws are even more important in the lumberjack profession.

Any chainsaw

requires proper care, maintenance and adjustment before operation. If you put too much stress on the tool, it may shorten its life and cause the tool to break.

Today we will talk about that part of the chainsaw mechanism, the task of which is to prepare the fuel before it is supplied to the engine cylinder. This function is performed by the carburetor

chainsaws. How well the chainsaw works and how much fuel it consumes during operation will depend on it. If you see that your gasoline chain saw is starting to run erratically, the carburetor may need to be adjusted.

Adjusting the carburetor fuel-air mixture supply mechanism - when it is needed

The first adjustment of the chainsaw carburetor is performed immediately after purchasing a new tool. This is done for the purpose of running in the tool’s motor. To run in the internal combustion engine of a chainsaw, you need to limit the maximum speed, which is done using adjusting screws. As soon as the run-in is completed, which lasts 2-3 tanks of burned fuel, it is necessary to make adjustments again, but only this time with the aim of establishing the maximum number of revolutions.

In addition to break-in, chainsaw carburetors are adjusted when:

- Knocking down the settings set after running in

- If the internal combustion engine is difficult to start

- If the engine does not develop speed or when you press the gas, the chainsaw stalls

- Wear of the piston group, but only in this case, adjusting the chainsaw carburetor is a temporary measure, since the internal combustion engine needs a major overhaul

- If the engine does not idle

- Unit vibrations

- Presence of carbon deposits on the spark plug

- Increased fuel consumption. This phenomenon can be detected by an excessive amount of smoke. If you unscrew the spark plug, it will be black with soot.

Where are the carburetor adjustment screws located?

Many malfunctions during the operation of a gasoline unit arise precisely because of incorrect settings of the chainsaw carburetor or when they are knocked down. To restore the previous performance of the tool, you will need to adjust the mechanism. Many beginners entrust this process to specialists, for which the masters charge a lot of money. It's time to figure out the adjustment and do it yourself, since this process does not require disassembling the mechanism.

Read also: Batteries that can be charged price

Carburetor design

A carburetor is a mechanism that is responsible for preparing a mixture of fuel and air, which is then supplied to the engine cylinder. Most chainsaws have very similar carburetors, so they are set up in the same way.

The main structural parts of a carburetor on a chainsaw:

- Aluminium case. Aluminum is chosen as a material due to its low weight. Chainsaws are tools that constantly need to be held and carried, so reducing the weight of the tool is a very important task facing the manufacturer.

- Diffuser and air damper, which are located at the inlet of the carburetor.

- Jets are valves that provide dosage of fuel that is supplied to the carburetor.

- The atomizer, which is responsible for injecting fuel into the chamber.

- Fuel chamber.

Idle speed adjustment

First of all, you need to find the position at which the highest idle speed will be by turning screw L. Once you, using the tachometer, find this position, you need to turn the low speed screw (L) a quarter (1/4) counterclockwise . The chainsaw chain can rotate. If this happens, you need to unscrew the idle speed screw (T) counterclockwise until the chain stops moving completely.

How to set the maximum speed of a chainsaw?

To change the maximum speed, you need to interact with screw H. If you tighten the screw, the speed will become higher, and if you unscrew it, it will become lower. As a rule, the highest permissible engine speed ranges from 11500-15000 per minute. If you try to work with an even larger number, ignition problems will begin. In this case, the screw is slightly unscrewed.

READ STIHL chainsaw spark plug gap

Acceleration check

If you press the gas button of the chainsaw, the engine should increase the number of revolutions. This should happen fairly quickly. If the tool picks up speed slowly, you need to unscrew screw L a little, no more than 1/8 of a turn.

When setting

finished, you need to re-check the operation of the chainsaw at idle speed - the engine should work properly and the chain should remain motionless. If the engine is unstable or the chain moves, the adjustment must be repeated, skipping the basic adjustment step.

About the carburetor device

The carburetor is used to mix the combustible mixture with air, observing predetermined proportions. If precise doses are not followed, engine performance is compromised. When a large amount of air is supplied when mixing components, but not enough fuel, the mixture is considered “lean”.

Oversaturation cannot be tolerated, since with a large amount of fuel compared to air, engine failure or wear is also possible. Carburetor adjustment is necessary not only before initial use, but also when identifying any deviations in its operation. Before you start using your chainsaw, be sure to check it.

Carburetor components

The carburetor design contains a standard set of elements, but may vary slightly depending on the manufacturer. Components:

- The basis . This is a special tube that visually resembles an aerodynamic design. Air passes through it. In the transverse direction there is a damper in the middle of the pipe. Its position can be changed. The more it is pushed into the passage, the less air is supplied to the engine.

- diffuser _ This is an extended part of the tube. With its help, the air supply speed is increased exactly in the segment from which the fuel exits.

- channels _ The fuel mixture is contained in a float chamber, then passes into a stream from which it flows into the atomizer.

- Float chamber . This is a separate structural element that resembles the shape of a tank. It is designed to constantly maintain an optimal level of fuel fluid before entering the channel from which air enters.

Don't know which chainsaw to choose? Read our article.

Are you looking for a cheaper model, but reliable and time-tested? Russian chainsaws.

Or research foreign chainsaw manufacturers such as Calm.

How to properly adjust a chainsaw carburetor

The vast majority of gasoline saw carburetor models have three adjustment screws:

- idle speed (T);

- low speed (L);

- high speed (H).

Setting the required parameters is done by rotating these screws.

To fine-tune the carburetor, use an electronic tachometer. It will allow you to easily determine the engine speed of the chainsaw.

Acceleration check

If you press the gas button of the chainsaw, the engine should increase the number of revolutions. This should happen fairly quickly. If the tool picks up speed slowly, you need to unscrew screw L a little, no more than 1/8 of a turn.

When setting

finished, you need to re-check the operation of the chainsaw at idle speed - the engine should work properly and the chain should remain motionless. If the engine is unstable or the chain moves, the adjustment must be repeated, skipping the basic adjustment step.

How does a carburetor work?

- When starting the engine, the air damper in the carburetor opens.

- The movement of the piston reduces the pressure in the air valve. This causes air to enter the diffuser. Its exact amount depends on the position of the air damper.

- Fuel enters the float chamber. The jets regulate the speed at which this happens.

- Gasoline and air mix with each other in a diffuser to form a fuel-air mixture. It is directed into the cylinder. The mixture can be lean (lots of air, little petrol) or rich (little air, lots of petrol). Its power and speed depend directly on the amount of mixture entering the engine.

All processes occurring in the engine do not have a cyclical, but a constant basis.

How does a chainsaw carburetor work, on what principle does it work?

Modern car engines are no longer equipped with a carburetor. Meanwhile, previously, almost every driver knew how to adjust it. Today, chainsaws with injection engines have already begun to appear on sale, but carburetor models will hold the palm for a long time, because their cost is 5-15 times lower than that of the modern version.

PHOTO: msc.snail.ru So far the only chainsaw model with injection is the STIHL MS 500i

The carburetor consists of several main parts:

- aluminum body;

- diffuser and air damper at the inlet;

- jets (valves for regulating fuel supply);

- sprayer (it is the one that provides injection);

- fuel (float) chamber.

The operating principle of a chainsaw carburetor is quite simple. Fuel is supplied continuously, and its quantity is regulated by jets. Air enters through the air damper due to the vacuum of air created by the piston. In the diffuser, fuel and air are mixed. It is this fuel-air mixture that enters the cylinder, causing the engine to work.

PHOTO: aredi.ruThis carburetor is from a Partner 350 chainsaw

How to properly adjust a chainsaw carburetor

The vast majority of gasoline saw carburetor models have three adjustment screws:

- idle speed (T);

- low speed (L);

- high speed (H).

Setting the required parameters is done by rotating these screws.

To fine-tune the carburetor, use an electronic tachometer. It will allow you to easily determine the engine speed of the chainsaw.

How to set the maximum speed of a chainsaw?

To change the maximum speed, you need to interact with screw H. If you tighten the screw, the speed will become higher, and if you unscrew it, it will become lower. As a rule, the highest permissible engine speed ranges from 11500-15000 per minute. If you try to work with an even larger number, ignition problems will begin. In this case, the screw is slightly unscrewed.

Carburetor design

A carburetor is a mechanism that is responsible for preparing a mixture of fuel and air, which is then supplied to the engine cylinder. Most chainsaws have very similar carburetors, so they are set up in the same way.

The main structural parts of a carburetor on a chainsaw:

- Aluminium case. Aluminum is chosen as a material due to its low weight. Chainsaws are tools that constantly need to be held and carried, so reducing the weight of the tool is a very important task facing the manufacturer.

- Diffuser and air damper, which are located at the inlet of the carburetor.

- Jets are valves that provide dosage of fuel that is supplied to the carburetor.

- The atomizer, which is responsible for injecting fuel into the chamber.

- Fuel chamber.

Adjusting the chainsaw carburetor

Chainsaws are a very popular gardening tool. They have gained great popularity among gardeners and those who care for the territory in their home areas. Construction or repairs cannot be done without chainsaws. Chainsaws are even more important in the lumberjack profession.

Any chainsaw requires proper care, maintenance and adjustment before use. If you put too much stress on the tool, it may shorten its life and cause the tool to break.

Today we will talk about that part of the chainsaw mechanism, the task of which is to prepare the fuel before it is supplied to the engine cylinder. This function is performed by the chainsaw carburetor. How well the chainsaw

and how much fuel it spends during operation. If you see that your gasoline chain saw is starting to run erratically, the carburetor may need to be adjusted.

Carburetor repair of a Carver saw: possible malfunctions and their elimination

After the chainsaw has produced 50-70 liters or more of gasoline, the filters and injectors may become clogged.

The assembly was disassembled, washed, blown with compressed air and returned to work.

Most mechanical damage to a Carver carburetor is caused by the elastic diaphragm becoming rough over time and unable to function properly.

You can disassemble the carburetor and replace the diaphragm if you can find such a spare part. However, such components are of little use for repair, and it is easier to replace the entire carburetor of the Carver chainsaw, and sometimes all the chainsaws used.

To adjust the carburetor of a Carver chainsaw, it is enough to know the structure and principle of operation. Knowing them, using simple tools and following the setup algorithm described in the article, you can easily set it up at home. It is important to understand that tuning is still a serious process, and if you are not confident in your abilities, it is better to return the chainsaw to the workshop.

Source

Country construction and renovation are not complete without the use of chainsaws, as well as garden care. A malfunctioning tool can stop your entire job, so it's important to be able to take it apart yourself, find the problems, and fix them. With enough experience and dexterity, you can even adjust the carburetor of a chainsaw. The procedure is complex, to be more precise. Jewelry. How to carry out corrective procedures, we suggest getting a divorce today.

In what cases is it necessary to adjust the carburetor of a chainsaw?

Here is a list of the most common cases in which it is necessary to adjust the carburetor of a chainsaw:

- The engine starts, but the chainsaw stalls, or it cannot be started at all. The cause may be too much air in the fuel chamber.

- Increased fuel consumption. It can occur due to excessive saturation of the mixture that enters the engine with fuel. For the engine to work well, the mixture must be of high quality.

- The bolts in the carburetor have become loose due to a damaged carburetor body.

- Debris getting into the carburetor. This can happen if the filter is damaged or low-quality fuel is used. You will need to completely disassemble the carburetor, clean it and re-tune it.

- The engine idles poorly or does not develop full power.

Important! If the engine runs poorly because the piston is worn out, adjusting the carburetor will not work. In addition, along with the adjustment, it is advisable to clean the carburetor of debris - this will increase the effectiveness of the procedure.

Idle speed adjustment

First of all, you need to find the position at which the highest idle speed will be by turning screw L. Once you, using the tachometer, find this position, you need to turn the low speed screw (L) a quarter (1/4) counterclockwise . The chainsaw chain can rotate. If this happens, you need to unscrew the idle speed screw (T) counterclockwise until the chain stops moving completely.

Sources:

https://prokatinstrymenta.ru/karbyurator-benzopily-regulirovka-oborotov/https://dnipro-m.ua/news/regulirovka-karbyuratora-benzopily/https://dnipro-m.ua/news/regulirovka-karbyuratora- benzopily/#pravilnaya-nastrojka

How to properly adjust the carburetor with your own hands?

After flushing and completely cleaning the carburetor, reassemble it and begin tuning. First, you should understand the purpose of the adjustment screws. The abstract will help with this, but some general points should be taken into account immediately. More common screw designations:

- H regulates the state of the main jet, in other words, regulates the highest speed of rotation of the motor shaft;

- L regulates no-load currents (responsible for the lowest shaft rotation speed)

- T regulates the idle speed of the engine. It can also be indicated by the signs LA or S; on some carburetor models this is completely not the case.

Rotating screws H and L clockwise depletes the air-fuel mixture, and counterclockwise enriches it (the amount of gasoline increases). When screw T rotates, the shaft rotation speed in idle speed changes clockwise, it increases, and in the reverse direction it decreases.

Sketch two Carburetor adjustment mechanisms

Before taking direct action, you should find and carefully study information about the position of the adjusting screws (the magnitude of the rotation angles during adjustment). This information is available in the instructions for the chainsaw. Then you need to prepare the work area, lay the pollen on a flat horizontal plane, directing the chain in the opposite direction from you. Remove all covers, foam and air filter. With all this, the preliminary operations are considered completed, and you can begin the main part of the work.

Carburetor adjustment procedure:

- Gently turn screws H and L clockwise until they stop. Be careful not to break the screws, this will result in complete loss of the carburetor.

- Unscrew both screws one and a half turns.

- Run the engine for 10 minutes and warm it up. This is the right moment, since it is unrealistic to correctly adjust the carburetor on a cool engine.

- By turning screws H and L, alternately adjust the shaft rotation at high and low speeds.

- By adjusting the position of screw T (or it may have a different designation), the idle speed of the chainsaw is adjusted. It is necessary to achieve smooth and measured operation of the motor. It is important to look at whether the circuit is idle at idle or not. If it moves, turn the screw a little more counterclockwise.

You can check the operation of the motor visually and auditorily. A very rich mixture will cause thick smoke from the exhaust. When the lean mixture is fed, a whistling sound is heard while the saw is running. The excessive economy mode is harmful; if the L screw is installed to dump fuel, difficulties will arise in starting the engine. If the H screw is installed at an angle, the saw will noticeably lose power. You can find the correct setting by the following aspects:

- at idle the engine does not linger and the chain does not move;

- there is no excess smoke from the exhaust pipe when the engine is running;

- the engine shows good throttle response (quickly picks up speed when the accelerator is pressed).

A detailed description of the option is available in the instructions supplied with the equipment in the delivery kit. This should be carefully studied, since there may be some features or certain requirements set by the manufacturer and are associated only with this model of saw. If all requirements are accurately met, the chainsaw's performance will be restored to its original state.