The Resanta trademark, popular in Russia, belongs to the Latvian one, the country of origin is China. High quality and low cost of products, as well as a good understanding of the functionality required by the consumer, have allowed the manufacturer to increase production volumes more than tenfold since 1993. The range has also expanded significantly: the company produces several dozen different types of electrical products.

Resanta welding equipment differs in cost, but even the most affordable devices surprise with their excellent quality and excellent performance characteristics.

Features of Resanta welding equipment

Any welding machine heats up during operation. There is a special parameter that characterizes this phenomenon: PN - load duration. For Resanta brand equipment it is 70%. That is, after continuous operation for 7 minutes, the device must be allowed to cool for 3 minutes. This is one of the best indicators among various brands of welding equipment.

Additional functions that Resanta welding machines are equipped with are arc forcing, hot start, sticking prevention. There is protection against current overloads.

Table 1. Special functions of Resanta welding machines:

| Function name | Arc Force (ARC FORCE) | Hot Start | Anti-stick (ANTI STICK) |

| Function description | Allows you to stabilize combustion by automatically increasing the current strength, which leads to an intensification of the arc. | Provides guaranteed arc ignition due to a short-term increase in welding current. | Automatic reduction of welding current when electrode sticking is detected. |

| Applying a function | Relevant when working with thin metals at low welding currents. | Improves weld quality by reducing the likelihood of lack of penetration and good fusion | To prevent calcination and subsequent damage to the electrode when stuck. |

The best inverters for manual MMA welding

This section presents inverter machines for the simplest type of welding - coated electrodes.

Eurolux IWM190 - budget option

4.9

★★★★★ editorial assessment

89% of buyers recommend this product

See review

One of the most inexpensive inverters provides comfortable welding work due to its light weight (3.7 kg), wide current range from 10 to 190 A and Hot Start function.

The device can operate without loss of efficiency with an input voltage from 140 to 260 V. The permissible diameter of the electrodes is 1.6-5 mm. The front panel of the device contains a current regulator and indicators of the current state of the inverter.

Advantages:

- Overload protection;

- Wide range of welding currents;

- High duty cycle coefficient 70% at maximum;

- Arc Force;

- The cost is slightly higher than 4 thousand rubles.

Flaws:

- Short complete cables (2 and 1.5 m);

- Demanding on the quality of electrodes.

Eurolux is an entry-level inverter for small volumes of welding work. It will be an excellent assistant for a summer resident and will be useful in a private home and garage.

Fubag IQ200 – compact and powerful model

4.8

★★★★★ editorial assessment

88% of buyers recommend this product

See review

A new product in the range of welding inverters from a German manufacturer is suitable for most household welding work. The device has a wide current adjustment range from 20 to 200 A, has a built-in cooling system and overload protection.

It’s nice to see a full range of useful functions in a “home” inverter: afterburner, anti-sticking, hot start. Thanks to them, you can comfortably work with any 1.6-5 mm electrodes.

Advantages:

- Good set of functions;

- Compact and lightweight (3 kg);

- Stable operation at low input voltage from 150 V;

- High efficiency due to the use of IGBT transistors.

Flaws:

- Relatively low PV coefficient of 40%;

- You cannot approach the current regulator with work gloves.

Thanks to its good functionality and honest characteristics, the IQ200 can be recommended to both professionals and beginners. But the device itself is designed only for short-term work with long breaks.

Resanta SAI-220 – the most functional of the “handbrake”

4.7

★★★★★ editorial assessment

87% of buyers recommend this product

See review

Resanta MMA inverters can be called the best in terms of price, functionality and quality.

Hot start, anti-sticking of the electrode and an increased threshold value of the welding current of 220 A allow you to make high-quality seams and metal cutting. At the same time, long-term continuous operation remains possible, and arc stability is maintained even at low input voltage.

Resanta SAI-220 is the simplest model in the line and is only suitable for learning welding. But it has a compact analogue 220K, differing only in smaller dimensions and weight, as well as a more advanced variation labeled “PN”.

This device already has a display with large and bright numbers, and its settings will be easier to understand.

Advantages:

- Sturdy case with IP21 protection;

- Wide range of current settings (from 10 A);

- Stable operation at a voltage of 140 V;

- High PV – 70%.

- Case included.

Flaws:

- Lack of afterburner function;

- Does not tolerate hypothermia well.

Resanta SAI-220 is suitable for both novice welders and experienced welders - just choose the appropriate modification.

Spark MIG-305SP – 2-in-1 hybrid

4.6

★★★★★ editorial assessment

86% of buyers recommend this product

The features of this unit are its relatively low power (6.4 kW), as well as separate adjustment of arc voltage and welding current within the range of 20-305 A, which is very atypical for models in the budget price category. And most importantly, we have a full-fledged semi-automatic hybrid with the possibility of manual welding.

The manufacturer decided to save money on additional functionality. Iskra received only the essentials for solving standard tasks: a quick wire threading button, an overload indication and the ability to change polarity in semi-automatic mode.

Advantages:

- Ability to work without a gas environment in MMA mode;

- Rich equipment including a shield and knee pads;

- Continuous operation – 60%;

- Low cost for a semi-automatic machine.

Flaws:

Lack of quick release torch connection.

“Iskra” is a simple but reliable inverter that is suitable for occasional use in the country or in the garage. Moreover, it can be used both as a semi-automatic MIG and as a regular MMA device.

Resanta models are suitable for all types of welding

The most popular models of Resanta welding equipment are inverter machines SAI 140 - 250. They are universal and also easy to operate. Some models are sold complete with a case, making it easier to store and carry the device.

The SAIPA model is a semi-automatic machine, equipped with mechanisms for adjusting gas supply and wire drawing, which significantly increases welding productivity. One of the best models in the line is SAIPA 190 MF.

The PROF series is equipped with automatic adjustment systems, which allows them to be used for manual arc welding at low mains voltage.

The lineup is completed by:

- SAIPN series – for household use, for operation at reduced voltage;

- SAIAD – devices designed for argon welding. Allows you to obtain perfectly even seams when welding non-ferrous metals and alloy steels;

- The COMPACT series – SAI K – has reduced dimensions;

- Devices designed for welding polypropylene pipes - ASPT series. Used for repair and installation of water pipes. The most popular model is ASPT 1000;

- Inverter welding machine, for three-phase voltage 380 V - SAI 315;

Features of the welding inverter Resanta SAI 220

In this article we will tell you in great detail everything you need to know about SAI-220. You will also see the diagram of the Resanta SAI 220 welding inverter. And it will definitely be useful to you if you decide to carry out minor repairs or assemble a similar device with your own hands.

general information

Resanta SAI-220 is a portable welding inverter designed for manual arc welding with coated electrodes. To operate it, it is enough to have a socket and a 220V household power supply.

When welding, you can use electrodes with a diameter of up to 5 millimeters. The maximum welding current is 220 Amperes, which is enough for students and summer residents. The open circuit voltage is 85V. The arc ignites without any problems, so you can weld all types of metals.

The equipment in SAI-220 is standard. There are two cables with a holder and a terminal, the cables themselves are 2 meters long each. Also in the box you will find a power cable, its length is 170 cm. We believe that this is clearly not enough to perform some work. So use an extension cord.

There is nothing else in the box. If necessary, you can buy a model with a convenient case, and also purchase a welding mask and other personal protective equipment separately.

The device is equipped with additional functions “anti-stick” and “hot start”. Now even the cheapest inverters have these functions, so they won’t surprise you. But one cannot fail to note the presence of such functionality in SAI-220. After all, the “anti-stick” and “hot start” functions will especially appeal to those who are just starting to learn the basics of welding. They simplify and speed up your work.

Advantages and disadvantages

The pros and cons of the Resanta SAI 220 device are the same as all other inverters in this price category. But let's start with the good.

The first thing you will like is that it works from a regular 220V household outlet. You don't need any special type of connection, just plug the plug into the socket and you're good to go. The main thing is that your household electrical networks operate without strong power fluctuations.

Another plus is the use of modern IGBT-type transistors in the design of this device. Thanks to them, it was possible to introduce additional functions and reduce the dimensions of the SAI-200. You can hang the inverter on your shoulder using the included strap and conveniently transport it or cook it in hard-to-reach places.

Additional features are another big plus. The device is protected from overheating and is equipped with anti-stick and hot start functions. They simplify your work and make welding more productive.

In general, the device is well built. The case is durable, made of metal. And to use this inverter, it is enough to have basic theoretical knowledge. It’s not for nothing that this model is often used specifically for studying. It is easy to use, all adjustments are intuitive.

Now about the disadvantages. First of all, devices like SAI-220 are not recommended for professional welding work. Of course, a master of his craft can make decent seams with a Chinese inverter for 2,000 rubles, but a home craftsman or a practicing student is unlikely to have the same skills.

So, if you want to develop your welding skills, look towards more powerful and technologically advanced welding machines. They will give you more opportunities and unlock your potential.

Scheme

Beginners may think that we only need one diagram of the Resanta 220 inverter welding machine from the SAI line. But it is not so. Below we have placed four diagrams at once that will help you perform simple repairs or construct a similar inverter with your own hands.

№1

№2

№3

№4

We do not recommend performing soldering work unless you have sufficient experience and at least basic knowledge of electrical engineering. Each electrical diagram is available in high resolution, just open the images in new tabs.

Instead of a conclusion

Resanta SAI-220 is not an amazing inverter. It doesn't have any special features, big equipment or distinctive features. It is one of dozens of inverters from other manufacturers at a similar price.

But this does not mean that this device does not deserve your attention. Moreover, it can be found without problems in many localities of the CIS. And in large cities there are official service centers where you can repair and service the device.

Our verdict is this: buy Resanta SAI-220 if you can easily find it in your city. If you are a summer resident or a beginner, you will not notice the difference between this inverter and any other in this price category. So buy what is easier to find and where there is service. We wish you good luck in your work!

Main technical characteristics

A large assortment implies significant differences between equipment models in terms of technical characteristics. But there are parameters that the manufacturer considers key and tries to maintain at the same level in all models of its products.

For Resanta welding machines, this characteristic is the input voltage. Models of the SAI series are designed to operate in a wide range from -35% of the nominal (220V) to +10%, which is 140 and 240 volts, respectively. Equipment of the PROF series can cope with work even at a lower input voltage – 100 V.

To work with metals of different thicknesses, electrodes with diameters from 1 mm to 6 mm are used. The maximum diameter of the electrode ranges from 4 mm, for the simplest and low-power models, to 6 mm for the device with a three-phase connection SAI-315 and the most powerful two-phase SAI-250 and SAI-250K. Another characteristic that affects the quality, speed and ability to work with refractory and thick products is the value of the welding current.

Models, their brief characteristics

Each model has a wide range of welding voltage adjustments, which allows you to work under almost any conditions. They are equipped with a dial for convenient voltage adjustment, thanks to which the current strength is set very accurately. They are marked with a digital designation that shows the maximum current that welding can produce during operation. For example, the SAI-190 welding machine, capable of delivering up to 190 Amperes.

The linear series has the following models of welding machines:

- SAI

- SAIPA

- PROF

- Mon

Now let's take a closer look at each of them. SAI is the first welding that the company began to produce; it has proven itself over many years with quality and stability of operation. Compatible with piece electrodes protected by a gas environment.

SAIPA is still the same SAI, only supplemented with a wire drawing mechanism and a gas supply control valve. The supply of welding material is controlled using the control panel; gas is supplied through the rear valve. The most common model is SAIPA165.

PROF - designed for the needs of professionals, they can operate at very low voltage and in overloaded power transmission networks. The minimum voltage consumption threshold is 100 Volts. They are used in large industries and construction sites.

PN is the simplest, easy to use and relatively inexpensive. Designed for domestic use, they can operate at a voltage quite low for a home - 140 Volts. Very well suited for areas with poor electricity supply. They show high stability and proper quality of work. Can be used to repair metal structures or create new ones.

All models have an official guarantee and the possibility of technical support on all issues. Repairs are carried out in any warranty case. The body is made of metal; the design may contain plastic elements, such as handles, toggle switches, power switching relays

Resanta SAI 160

Technical characteristics of SAI 160:

- The operating load at which the device functions normally is 150-260 Volts.

- Weight is four and a half kilograms, provides very high mobility.

- The supplied operating current varies in a very wide range from 10 to 160 Amperes.

- It has the following functions: anti-sticking, arc forced, hot start.

- Able to work without interruption at unstable voltage. At the same time, the quality does not suffer at all.

Resanta SAI 190K

Technical characteristics of SAI 190:

- It operates at a normal voltage of 220 Volts and is capable of continuous operation during sudden voltage surges over a fairly wide range.

- Operating current from 10 to 190 Amperes.

- Has the same additional functions as SAI 160.

- A thermostat is installed that protects against overheating. During continuous operation, every 7-10 minutes, you must turn off the device for 3-5 minutes to cool.

- Dynamics of operating temperature from minus 10 to plus 40 degrees Celsius.

Advantages and disadvantages of Resanta welding machines

Small dimensions and light weight are characteristic of all inverter-type welding machines without exception. In Resanta products of the COMPACT type, these qualities are maximally developed.

Table 2. The COMPACT series devices have the minimum dimensions and weight:

| Function name | Arc Force (ARC FORCE) | Hot Start | Anti-stick (ANTI STICK) |

| Function description | Allows you to stabilize combustion by automatically increasing the current strength, which leads to an intensification of the arc. | Provides guaranteed arc ignition due to a short-term increase in welding current. | Automatic reduction of welding current when electrode sticking is detected. |

| Applying a function | Relevant when working with thin metals at low welding currents. | Improves weld quality by reducing the likelihood of lack of penetration and good fusion | To prevent calcination and subsequent damage to the electrode when stuck. |

The welding machine of the lower part of the model range is not expensive and is available to welders with a low level of income. The versatility allows the equipment to be widely used to successfully solve any problem.

Resanta machines are equipped with automation, which simplifies operation and increases the speed of welding work. Models such as SAIPA 135, SAIPA 165 are equipped with automatic supply of consumables, which improves the quality of work.

The disadvantages of the equipment include the lack of additional accessories for cheap models and the high cost of top-end representatives of the series.

How to choose a good welding machine?

The owner of a tractor, a car, a summer house, or a house with a subsidiary farm will always have work to do on steel welding, but calling a specialist at the slightest need will cost a penny. For just installing a fence, a welder can charge more than a good welding machine with a mask and a pack of electrodes costs (they will come apart during the self-learning process). Perhaps even with leggings.

To choose the best welding machine for your home, it is important to consider the scope and conditions of its use. One of the first criteria for choosing a peak inverter is welding current

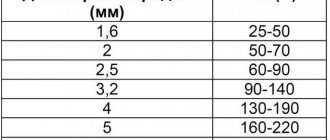

The higher it is, the larger the diameter of the electrode you can use and thicker metals can be scalded. For guidance, see the table.

| Electrode, mm | Metal thickness, mm | Current, A |

| 1,6 | 1-2 | 25-50 |

| 2 | 2-3 | 40-80 |

| 3 | 3-4 | 80-160 |

| 4 | 4-6 | 120-200 |

| 5 | 6-8 | 180-250 |

For home use, a device that works with electrodes up to 4 mm in diameter is sufficient.

Based on the type of welding, the machines are divided into:

- MMA – manual welding (classic) with a coated consumable electrode. Pros: Suitable for working with metals of any thickness, except the thinnest. Disadvantages: the resulting slag must be removed, which is especially inconvenient when welding in several passes. Feature: when choosing electrodes, you should take into account the current - alternating or direct. Works with electrodes up to 4-5 mm.

- MIG/MAG – consumable material – consumable electrode in an inert (MIG) or active (MAG) shielding gas. Used for joining ferrous and non-ferrous metals. The electrode in the form of a wire is automatically fed from the coil. The method is applicable only for working with thin metals; it allows you to weld sheet materials less than 1 mm thick and structures made of profiles with a wall thickness of up to 20 mm.

- TIG – argon arc welding – a refractory electrode with a diameter of up to 5 mm is used in an inert gas atmosphere. The consumable is an filler rod (up to 1 mm thick), the electrode itself usually does not melt. Used for welding steel, non-ferrous metals, including dissimilar pairs. To work you need an argon cylinder.

There are universal semi-automatic welding machines of the MMA+MIG/MAG and MIG/MAG+TIG types - they combine the capabilities of the tools described above - they will allow you to perform a wide range of work on joining ferrous and non-ferrous metals, of different thicknesses, and their alloys.

Also pay attention to:

- Duty cycle or load duration - since electronic components operating with colossal current heat up quickly, household devices need regular cooling. Specified in % for 10-minute intervals. For example: 40% indicates that the device can operate at a current close to the peak for 4 minutes, then it needs 6 minutes to cool down (the time also depends on the operating current and the ambient temperature). Multiple values can be specified for different current strengths.

- Protection against surges in mains voltage - shows peak deviations from the norm, for budget models it is within 15%.

- Current adjustment range - the ability to change the current allows you to adapt to welding with any electrodes in different conditions. Depends on the device, starts from 5-20 A and ends with maximum values of 180-250 A.

In addition to the main characteristics, beginners will be interested in such functions as:

- hot start – simplifies arc ignition;

- arc force - automatic increase in current when the electrode approaches the welded metal during ignition to prevent sticking;

- anti-sticking - after the electrode sticks, no power is supplied to it until it is torn off from the surface to be welded;

- open circuit voltage - the parameter shows how easy it is to ignite and maintain the arc: at 80-90 V - even a beginner can handle it, at voltage values below 40-50 V - the work will turn into a quest, especially for beginners.

What to choose for home use:

- inverter - a compact, budget and universal solution for the home handyman, for occasional use at home;

- semi-automatic – a specialized tool for welding non-ferrous and thin metals, alloy steels;

- rectifier – used for working with non-ferrous metal, low-carbon and high-alloy steels;

- transformer is the most common device in industry; it is advisable to buy it for the production of metal structures in large volumes.

Purchase of welding equipment

The choice of a Resanta welding machine is made easier by the fact that each series has its own characteristics that make the model suitable for certain operating conditions. For amateur welders who need equipment for everyday use, the model ranges of both SAI - a standard modification, and SAIPN - specially designed for networks with low and unstable voltage levels are suitable.

Once the model range has been determined, it is necessary to select the power of the device. To weld steel sheets from 5 mm, electrodes with a thickness of 4 mm or more are required, which means the power of the device must be higher than 140A. Most household tasks do not involve joining such thick steel, so machines with a maximum welding current of 140 - 160 A are suitable for home and garden use.

If you intend to use it only in domestic conditions, then there is no need to overpay for functions and parameters that will only be useful when carrying out large volumes of welding work at an industrial enterprise or at a construction site. The inexpensive SAI 140 model is often chosen for home use.

General information about the manufacturer

The headquarters of the Resanta company is located in Latvia; the devices are assembled partly from Chinese components. The company specializes in the production of welders for various fields of activity:

- Household.

They can be used both in the country house and in the garage to perform a small amount of work. Connect to a 220 V power supply. Recommended for beginners and those just learning to cook. The welding current range ranges from 120-200 A. Some models are equipped with smooth arc adjustment.

- Professional. Allows you to obtain a higher quality seam. Popular among small car repair shops and ordinary housing and communal services employees. Ideal for repair work in harsh conditions. They have an increased time of continuous operation when compared with household models, which are designed for intermittent short-term operation. Welding current varies between 200-300 A.

- Industrial. They are used in welding critical structures made of various materials, when high demands are placed on the quality of the weld. The power of the devices varies between 250-500 A. It is allowed to use welding wire on a reel with a diameter of 0.5 to 0.8 mm.

The line of welding machines is represented by plasma cutting devices, as well as inverters of the following lines:

- Compact;

- PN (ability to operate on reduced voltage);

- PROF (professional with extended continuous operation time).

In addition, the company is engaged in the development and production of stabilizers (which may be required to ensure stable operation of a welder in a country or garden area), thermal equipment, and measuring equipment.

Features of operation of welding machines "Resanta"

In order to successfully and without difficulty use the resanta welding machine, it is necessary to operate it correctly. Before connecting the device, you should make sure that the ground cable and power cable are connected to the connectors, and that the start switch is in the “Off” position. Then, using the adjustment knob, you should set the minimum current value and only after that it is permissible to turn on the welding machine.

During operation, it is necessary to ensure air flow. To do this, there must be enough free space around the device. The internal space should be cleaned of accumulated dust. By observing these conditions, you can avoid overheating of the device.

It should be remembered that when moving the device from low temperature conditions (less than zero) to a heated room, you cannot immediately turn it on. You need to wait until the condensation that appears due to the temperature difference dries completely. This takes from 2 to 3 hours.

Recommendations for use and repair

Inverter failure is most often associated with unsatisfactory operating or storage conditions:

- Penetration of moisture into the housing;

- Dust accumulation inside the case disrupts the normal cooling mode and leads to overheating of electronic components;

- Violation of equipment operating modes recommended by the manufacturer.

To identify faulty components, you need to remove the housing from the device and inspect the electronic components. If there is carbon deposits, cracks, dark spots on the printed circuit boards, or swollen capacitors are found, then the faulty elements should be replaced. If no obvious signs of failed components are found, then it is necessary to troubleshoot using measuring instruments, checking the electrical diagram.

If independent repair of electronic equipment raises questions and difficulties, then it is better to contact the service department, experienced specialists. Searching and ordering spare parts should also be entrusted to professionals from service centers.