To ensure that the device lasts as long as possible and does not damage other electrical devices in the house, you should study the electromagnetic compatibility card, which can be found on page 3 of the inverter passport.

General information about the manufacturer

The headquarters of the Resanta company is located in Latvia; the devices are assembled partly from Chinese components. The company specializes in the production of welders for various fields of activity:

They can be used both in the country house and in the garage to perform a small amount of work. Connect to a 220 V power supply. Recommended for beginners and those just learning to cook. The welding current range ranges from 120-200 A. Some models are equipped with smooth arc adjustment.

Household.- Professional. Allows you to obtain a higher quality seam. Popular among small car repair shops and ordinary housing and communal services employees. Ideal for repair work in harsh conditions. They have an increased time of continuous operation when compared with household models, which are designed for intermittent short-term operation. Welding current varies between 200-300 A.

- Industrial. They are used in welding critical structures made of various materials, when high demands are placed on the quality of the weld. The power of the devices varies between 250-500 A. It is allowed to use welding wire on a reel with a diameter of 0.5 to 0.8 mm.

The line of welding machines is represented by plasma cutting devices, as well as inverters of the following lines:

- Compact;

- PN (ability to operate on reduced voltage);

- PROF (professional with extended continuous operation time).

In addition, the company is engaged in the development and production of stabilizers (which may be required to ensure stable operation of a welder in a country or garden area), thermal equipment, and measuring equipment.

According to research by MegaResearch for the period 2014-2015, the Resanta trademark was recognized as the best in the domestic market of welding and stabilization equipment.

Calculation of power consumption of a welding inverter

- 10-03-2015

- 41

- 97

The power consumption of a welding inverter is quite easy to calculate using a simple formula. To understand all the nuances associated with the operation of a welder and the aspects of calculating its power, you need to clarify several points that everyone who welds needs to know. And it doesn’t matter where you carry out welding work, at home, in the garage, at the dacha or in a professional team of a large workshop or factory.

Types of welding inverters

Inverter-type devices are divided into three categories. Household inverters are designed for a short duration of switching on and operation from a single-phase alternating current network of 220 V. This means that such a device can only be operated at maximum power for a short time - 20-30 minutes, giving it a rest equal to this time or exceeding it by an order of magnitude. Semi-professional devices allow you to increase operating time from 5 to 8 hours without interruption. For semi-professional inverters, rest time is reduced due to design features. Professional inverters are designed to consume 220/380 V current, often from a three-phase electrical network.

Modern types of welding machines.

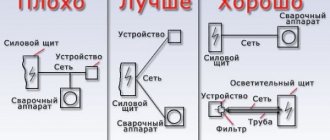

Household, semi-professional and some professional welding units are designed to operate from a 220 V network. However, it should be remembered that for household electrical networks the maximum load current cannot exceed 160 A. The power consumption of all accessories, such as sockets, plugs and power circuit breakers, is not calculated to exceed this threshold.

Therefore, connecting an inverter welding machine with higher performance will either trigger the circuit breaker, or cause the contact at the plug-socket interface to burn out, or, most dangerously, lead to the electrical wiring to burn out. This is against all safety regulations. So, when powering a professional unit from a household electrical outlet to operate with a welding current of more than 160 A, be prepared for problems. But it's better not to allow this.

Return to contents

The design of the welding inverter is such that first an alternating voltage of 220 V with a frequency of 50 Hz is converted into direct voltage, and then into an alternating high-frequency voltage with an operating oscillation frequency of up to 200 Hz. After this, the voltage is again converted to constant and supplied to the welding arc. Arc quality control occurs automatically, using the microprocessor filling of the inverter control unit. Electrode sticking, so common when welding using a transformer, practically disappears.

Diagram of the internal structure of the inverter.

For short circuits lasting less than 0.5 seconds, the control unit generates a sequence of short but very powerful current pulses. This leads to the destruction of the resulting liquid metal bridges. When a short circuit lasts 0.5 seconds, the inverter simply turns off without freezing the electrode or overheating the unit circuits. This device is basic for all types of inverters and distinguishes them from transformers and rectifiers based on a diode bridge.

The most important property of a welding inverter is energy consumption. It doesn’t matter what the power consumption of an inverter-type device is, it is almost completely spent on welding. From this we can conclude that the efficiency of the inverter unit is very high. From 85 to 95%.

Return to contents

Before you start calculating the power consumption of an inverter welding machine, you need to know the following:

- Input voltage range.

- Welding current range.

- Welding arc voltage.

- The efficiency of a specific welding machine model.

- Duration of switching on.

- Model specific power factor.

Inverter characteristics

The range of welding current is needed in order to find out under what characteristics of the electric current network we will have to work. It is probably no secret to anyone that often in our electrical networks there is no rated voltage of 220 V. Often it barely reaches 200 V. It should be remembered: the voltage drop when connecting a household-type welding inverter is 5-10% of the total network rating. Therefore, the best power indicators will be found in inverters that are designed for supply voltages from 150-170 V to 220-250 V.

The range of welding current gives us the values of the maximum and minimum levels; the power of the device directly depends on these parameters. For household inverters, these indicators at the lower limit vary from 10 to 50 A, and at the upper limit 100-160 A. The output current voltage, which can also be called the welding arc voltage, ranges for inexpensive household models from 20 to 30 V. The efficiency of Inverters with a maximum output current of 160 A, as a rule, rarely exceed 0.85%. The high efficiency of the welding unit directly depends on the duration of operation.

Return to contents

The power-on duration is a characteristic that shows how high-quality the device you are going to use. This is usually a percentage of the inverter's continuous operating time relative to its total usage time. An indicator of 50% will indicate that when working for 2.5 minutes, the device should rest for 2.5 minutes. The lower the indicator, the longer the circuits must rest and the faster the automatic shutdown relay will operate in case of overheating.

On the contrary, a high percentage will show that the device can be used for a long time, interrupting only to replace the electrodes and check the weld.

Scheme of operation of a welding inverter.

The power percentage is calculated by dividing the continuous operation time by the sum of the continuous operation time and the pause time until the device is turned on again. The result is multiplied by 100. For example, the device worked properly for 3 minutes until the overheating protection tripped, then it was at rest for 2 minutes, after which it was ready for work again:

3 min / (2 min + 3 min) x 100 = 60

The power factor for household or semi-professional inverter-type welding machines rarely exceeds the threshold of 0.6-0.7. You just need to remember this.

All the values needed for calculation can be easily found in the technical documentation for this device, on the manufacturer’s website, or on the casing of the welding machine itself.

Let's imagine that, as an example, we have a welding machine powered by an alternating current network of 160-220 V, having a maximum current value of 160 A with a maximum welding arc voltage of 23 V. The efficiency of this inverter model is 0.89, and the duty cycle indicator, the duration of operation, is 60%.

Now we calculate the maximum power consumption of the inverter with the above parameters. To do this, we first multiply the maximum output current value by the maximum output voltage. We divide the resulting result by the efficiency value of the device.

https://moiinstrumenty.ru/www.youtube.com/watch?v=UX81XigBgBY

160 A x 23 V / 0.89 = 4135 Watts

4.1 kW is the power that the device consumes directly during welding. Average power is calculated by multiplying the maximum power value by the on-time indicator:

4135 Watt x 0.6 = 2481

Average inverter power is the most relevant metric because welding typically does not occur continuously over many hours or days. There are pauses when the welder needs to change the electrode or prepare parts for subsequent processing. Often, welding work can be carried out at a lower current, in which case the total power consumed by the inverter will also decrease. We substitute into the first formula the values that can be set on the console of the welding unit and find the required power parameters.

Return to contents

Table of types of electrodes.

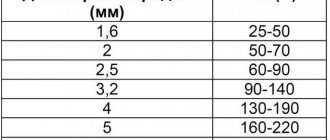

Novice welders often have the question of what diameter electrodes to use for certain output current parameters and metal thickness?

- When the metal thickness is 1-4 mm, electrodes with a diameter of up to 2 mm are used. The current strength set at the output should be selected optimally in the range from 20 to 90 A.

- When the metal thickness is 5-7 mm, electrodes 3 mm in diameter are used. The current strength is set in the range of 90-130 A.

- If the metal has a thickness of 8-12 mm, use 4 mm electrodes. Current strength is in the range of 140-180 A.

- Metal 12-16 mm thick is welded with electrodes 5 mm in diameter at a current of 180-220 A.

- Metal with a thickness of over 15 mm must be exposed to electrodes starting from 6 mm with a current strength of 220 A at the inverter output.

It is better to weld metal with a thickness of more than 15 mm using a gas welding machine.

https://moiinstrumenty.ru/www.youtube.com/watch?v=2Q6BEjCp_t8

The use of electric welding may be unprofitable and high-cost in this case.

moiinstrumenty.ru

The lineup

The Resanta range of inverters includes a large number of different devices that differ in power and purpose. Let's look at several of the company's most popular welding inverters.

Resanta SAI 220

The welding inverter Resanta SAI 220 is a powerful unit for a professional workshop. It is popular among companies engaged in casting and processing of metal of various grades and thicknesses. The maximum welding current is 220 A, which allows you to work with an electrode with a diameter of 5 mm.

Need to know: the operating power of the device is 6.6 kW. Therefore, a fixed home network may not be able to withstand such a load.

There is the possibility of smoothly adjusting the current from 10 to 220 A. Continuous welding is allowed, with a one-time load of 70% for 7 minutes. The cost in retail stores can reach 9,000 rubles.

Main technical characteristics

A large assortment implies significant differences between equipment models in terms of technical characteristics. But there are parameters that the manufacturer considers key and tries to maintain at the same level in all models of its products.

For Resanta welding machines, this characteristic is the input voltage. Models of the SAI series are designed to operate in a wide range from -35% of the nominal (220V) to +10%, which is 140 and 240 volts, respectively. Equipment of the PROF series can cope with work even at a lower input voltage – 100 V.

To work with metals of different thicknesses, electrodes with diameters from 1 mm to 6 mm are used. The maximum diameter of the electrode ranges from 4 mm, for the simplest and low-power models, to 6 mm for the device with a three-phase connection SAI-315 and the most powerful two-phase SAI-250 and SAI-250K. Another characteristic that affects the quality, speed and ability to work with refractory and thick products is the value of the welding current.

User reviews

Based on reviews that are posted both on specialized forums and on the pages of online stores, we can conclude that in most cases the characteristics declared by the manufacturer do not correspond to reality, namely, some models of the PN series do not work with a voltage deviation of 15%, although according to the established regulations, they must function normally from 140 V, which can cause certain difficulties when welding in a summer cottage or garden, when it is almost impossible to obtain a stable voltage in the network.

Conventional household-grade welders are more stable, they are excellent for welding various alloys with a stick electrode, but before this it is advisable to clean the material; at a distance of 10-20 mm from the seam, the metal must be cleaned of dust, paint, water or rust, otherwise the seam may collapse.

If you believe the comments of the craftsmen who repair inverters, it is almost impossible to find spare parts in the event of a breakdown, since they are supplied by the factory to a certain volume, there is no surplus for repairs.

The official representative office refuses to supply spare parts to private clients, and specialized service centers refuse to sell. They explain the reason for the refusal - an order from above. The only option to restore the unit is to give it for repair to a professional technician, who will be able to remake the fastenings for fixing individual elements of the system and will install analogues, followed by checking the functionality of the device.

Conclusion

If we discard all the imperfections of post-warranty service, the Resanta welding inverter is a fairly reliable, functional and highly commendable device, since the defect rate (my own observation) is no more than 8 units per 100 units sold.

It must be remembered that it is prohibited to operate the unit during rain (outdoors) or in a damp room, or if the cable insulation is damaged. If the inverter has been at sub-zero temperatures for a long time, then before turning it on, it is necessary to keep the unit for at least two hours in a warm room to prevent condensation.

Features of operation of welding machines "Resanta"

In order to successfully and without difficulty use the resanta welding machine, it is necessary to operate it correctly. Before connecting the device, you should make sure that the ground cable and power cable are connected to the connectors, and that the start switch is in the “Off” position. Then, using the adjustment knob, you should set the minimum current value and only after that it is permissible to turn on the welding machine.

During operation, it is necessary to ensure air flow. To do this, there must be enough free space around the device. The internal space should be cleaned of accumulated dust. By observing these conditions, you can avoid overheating of the device.

It should be remembered that when moving the device from low temperature conditions (less than zero) to a heated room, you cannot immediately turn it on. You need to wait until the condensation that appears due to the temperature difference dries completely. This takes from 2 to 3 hours.