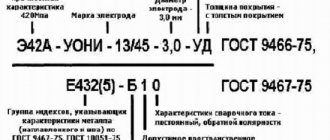

Why is labeling necessary? What does the number or letter mean in the electrode markings? These and many other questions are often asked by beginning welders. In this article we will tell you how to decipher the labels on the packaging and teach you to understand the details of the markings and their features.

But first, a definition. The marking of welding electrodes is a set of numbers and letters that encrypt information about the various characteristics of the rod. Each letter or number corresponds to its own information. The marking and the characteristics encoded in it influence the selection of components, be it electrodes for alternating current or electrodes for direct current. The electrodes themselves are divided according to many characteristics, which we will talk about later, and we will explain the markings along the way.

Type and marking

The first set of letters and numbers you see on the electrode packaging indicates the type of rod. The example above shows the marking E50A. Such rods are suitable for welding low-alloy and high-alloy steel. The marking of welding electrodes itself consists of the following symbols:

- The letter E. It is used to mark electrodes intended for manual arc welding.

- A number (in this case “50”). This is the tensile strength, sometimes written “50 kgf per square millimeter or /mm2”.

- The letter A. It means that the seam is plastic and has increased impact strength.

As you can see, at this stage the symbol for welding electrodes is very simple; just remember (or write down on a piece of paper) what each letter and number means.

Now let's talk about the existing types of electrodes. Try to remember them or write them down, as this will make your future work easier. So, for welding low-alloy or carbon steel, the following types of rods are suitable for us: E38, E42, E46, E50, E42A, E46A, E50A, E55, E60, E70, E85, E100, E125, E150. Do not forget that the number after the letter “E” indicates the tensile strength; the stronger the steel, the higher the number should be.

If you need to weld heat-resistant steel, then the following electrodes are suitable: E-09M, E-09MH, E-09H1M, E-05H2M, E-09H2M1, E-09H1MF, E-10H1MNBF, E-10H3M1BF, E10H5MF. To work with high-alloy steel, which has special properties, manufacturers offer more than forty types of electrodes, but here are the most popular ones: E-12X13, E-06X13N, E-10X17T, E-12X11NMF, E-12X11NVMF. If you need to fuse a surface layer with special properties, then use electrodes E-10G2, E-10G3, E-12G4, E-15G5, E-16G2ХМ, E-30G2ХМ (there are also 38 more types).

Well, there are many types, but this is just the beginning. Among other things, electrodes are divided according to other criteria. Which one?

Tungsten electrodes: classification, description

Tungsten is a metal that is practically impossible to find in its pure form; it is often used in argon arc welding , since it is refractory and is capable of maintaining its strength during a long welding process. In addition, tungsten elements are needed in very small quantities for welding.

When purchasing tungsten electrodes, pay attention not only to their color, but also to the country of manufacture. It is highly desirable that it be China, because this country is the largest supplier of metal in the world.

Tungsten electrodes fall into three key categories:

- AC products. When exposed to current, mainly magnesium, aluminum and alloys of these metals are welded. Often this type of welding is used to protect the process from contamination;

- DC electrodes. In this case, yttrium or thorium is added to the electrode, which can pose a danger to humans. Such electrodes are best used for welding in open areas or where there is good ventilation. Using them, you can weld metals such as bronze, steel, nickel, copper, tantalum, and carbon alloys. Also, when welding, do not forget about personal protective equipment;

- universal tungsten electrodes are used for welding copper, tantalum, nickel, bronze, titanium and steel products. They work well with alternating and direct current, and are often used in pipeline welding, as they are excellent at joining thin metal sheets and masking seams.

Before purchasing tungsten electrodes of one type or another, be sure to familiarize yourself with the properties of the material that will be used for welding in order to select an element of one type or another.

By index group

This is one of the most complex markings; beginners often do not understand it, because several numbers contain many characteristics at once. Typically, a group of indexes is written on the packaging with electrodes for welding high-alloy steel, so this already simplifies understanding. Let's take a closer look at what each number means in our example.

So, number 5 is the corrosion resistance of the seam. Number 1 is the maximum operating temperature at which the heat resistance of the seam is indicated. Number 4 is the working temperature of the seam. The number (4), taken in brackets, indicates how much ferrite phase is in the weld. The larger each digit is, the correspondingly larger the value. Below is a table with the characteristics of the weld metal for welding high-alloy steels; after studying it, you will understand what each number means.

The symbol of electrodes for surfacing can consist of two parts, and not of 3-4 numbers, as we said earlier. To an index of 3-4 digits, an index of three digits is added, written with a hyphen and separated by a fraction with the first index. For example, E300/32-1. The number 32 indicates the hardness of the metal that can be welded. The number 1 means that the hardness of such electrodes is ensured without thermal effects. Sometimes you can see the number 2, it means that hardness is provided after thermal exposure.

The influence of current polarity on the tig welding process

The polarity of the welding current significantly affects the nature of the process of arc welding in an inert gas with a tungsten electrode. Unlike welding with a consumable electrode (which includes MMA and MIG/MAG welding), when welding with a non-consumable electrode in a protective atmosphere of an inert gas, the differences in the nature of the welding process in reverse and direct polarity are of the opposite nature.

So, when using reverse polarity, the TIG welding process is characterized by the following features:

– reduced heat input into the product and increased heat input into the electrode (therefore, when welding with reverse polarity, the non-consumable electrode must be of a larger diameter at the same current; otherwise it will overheat and quickly collapse); – the melting zone of the base metal is wide but shallow; – the effect of cathodic cleaning of the surface of the base metal is observed, when, under the influence of a flow of positive ions, the oxide and nitride films are destroyed (the so-called cathode sputtering), which improves the fusion of the edges and the formation of the seam.

While when welding with straight polarity the following is observed:

– increased heat input into the product and reduced heat input into the electrode; – the melting zone of the base metal is narrow but deep.

As in the case of MMA and MIG/MAG welding, differences in arc properties for direct and reverse polarity in TIG welding are associated with the asymmetry of energy release at the cathode and anode. This asymmetry, in turn, is determined by the difference in the voltage drop in the anode and cathode regions of the arc. Under non-consumable electrode welding conditions, the cathode voltage drop is much lower than the anode voltage drop, so less heat is generated at the cathode than at the anode.

Below is the approximate amount of heat generated in different sections of the arc in relation to TIG welding at a welding current of 100 A and when using straight polarity (as the product of the voltage drop in the corresponding area of the arc and the welding current):

– in the cathode region: 4 V x 100 A = 0.4 kW at a length of ≈ 0.0001 mm – in the arc column: 5 V x 100 A = 0.5 kW at a length of ≈ 5 mm – in the anode region: 10 V x 100 A = 1.0 kW over a length of ≈ 0.001 mm.

Due to the fact that when welding with direct polarity there is an increased heat input into the product and a reduced heat input into the electrode, when welding with direct current, direct polarity is used. At the same time, due to the fact that heat is released mainly in the anode region, only those areas of the base metal to which the arc is directed melt, i.e. where the anode is located.

By type of coverage

This is one of the last values in the marking. Like many other characteristics of the electrode, it is indicated by a letter. In our example, the letter is “B” (base coating), but there are also “C” (cellulose), “A” (sour), “P” (rutile) and “P” (other). The letters can be connected to indicate electrodes with a special coating (for example, “RC” stands for rutile-cellulose). If the coating contains iron powder, then the letter “Zh” is added (for example, “BZh” means the main coating with iron powder).

Welding Electrode Specifications

Welding electrode

- a metal or non-metallic rod made of electrically conductive material, designed to supply current to the product being welded. Currently, more than two hundred different brands of electrodes are produced, and more than half of the entire produced range are consumable electrodes for manual arc welding.

Welding electrodes are divided into consumable and non-consumable. Non-consumable electrodes are made from refractory materials, such as tungsten in accordance with GOST 23949-80 “Non-consumable tungsten welding electrodes”, synthetic graphite or electrical coal. Consumable electrodes are made from welding wire, which, according to GOST 2246-70, is divided into carbon, alloyed and high-alloyed. A layer of protective coating is applied over the metal rod using pressure crimping. The role of the coating is to metallurgically treat the weld pool, protect it from atmospheric influences and ensure more stable arc combustion.

| Classification of welding electrodes | |||

| Non-metallic welding electrodes | Metal welding electrodes | ||

| Non-melting | Non-melting | Covered | Uncoated |

| Graphite Carbon | Tungsten Thorinated Lanthanum Itrated | Steel Cast Iron Copper Aluminum Bronze and others | Used in the early stages of development of welding technology. Now they are used in the form of a continuous wire for welding in shielding gases. |

Classification of coated metal welding electrodes according to GOST 9466-75. In accordance with GOST 9466-75, coated metal electrodes for manual arc welding of steels and surfacing are classified according to their purpose, mechanical properties and chemical composition of the deposited metal (types), types and thickness of coatings, as well as some welding and technological characteristics.

Types of electrodes by purpose:

— for welding carbon and low-alloy structural steels with a tensile strength of up to 60 kgf/mm? (600 MPa). They are designated by the letter U (GOST 9467-75); — for welding alloyed structural steels with a temporary tensile strength of over 60 kgf/mm? (600 MPa). They are designated by the letter L (GOST 9467-75); — for welding alloyed heat-resistant steels. They are designated by the letter T (GOST 9467-75); — for welding high-alloy steels with special properties. They are designated by the letter B (GOST 10052-75); — for surfacing surface layers with special properties. They are designated by the letter H (GOST 10051-62).

The above standards provide for the division of electrodes into types, in accordance with the mechanical properties and chemical composition of the deposited metal. The numbers denoting each type of electrode - E42, E42A, E50, etc., characterize the guaranteed minimum tensile strength in kgf/mm?, and the letter A - increased plastic properties, viscosity and limitations on the chemical composition.

Types of electrodes based on coating thickness.

According to the thickness of the coating, electrodes are divided depending on the ratio D/d (D is the diameter of the coated electrode; d is the diameter of the rod): - with a thin coating (D/d < 1.2). Denoted by the letter M; — with medium coverage (D/d < 1.45). Denoted by the letter C; — with a thick coating (D/d < 1.8). Denoted by the letter D; — with a particularly thick coating (D/d > 1.8). They are designated by the letter G.

GOST 9466-75 also provides for three groups of electrodes - 1, 2, 3, characterized by requirements for the quality (accuracy) of electrode manufacture, the condition of the coating surface, as well as the sulfur and phosphorus content in the deposited metal.

Types of electrodes by type of coating: - with acid coating (A); — with main coating (B); — with cellulose coating (C); — with rutile coating (P); — with a mixed type coating (with a double letter designation); — with other types of coatings (P).

| Correspondence table of electrode markings by type of coating: | ||

| Coverage type | Designation according to GOST 9466-75 | International ISO designation |

| Sour | A | A |

| Basics | B | B |

| Rutile | R | R |

| Pulp | C | C |

| Mixed coatings | ||

| Acid-rutile | AR | AR |

| Rutile-basic | RB | R.B. |

| Rutile-cellulose | RC | R.C. |

| Other (mixed) | P | S |

| Rutile with iron powder | RJ | R.R. |

Types of electrodes according to the permissible spatial positions of welding or surfacing: - for welding in all positions with symbol 1; - for welding in all positions except vertical from top to bottom - 2; - for the positions of the bottom, horizontal on a vertical plane and vertical from bottom to top - 3; - for the lower and lower in the boat - 4. Structure of coated metal welding electrodesCoated electrodes for manual arc welding are rods, usually from 250 to 450 mm in length. Made from welding wire with a coating layer applied to it. One of the ends of the electrode, 20–30 mm long, is cleared of coating for its fastening in the electrode holder.

Structure of the coated welding electrode:

The main classification of electrode coatings: - Stabilizing coatings are materials containing elements that easily ionize the welding arc. They are applied in a thin layer to electrode rods (thin-coated electrodes) intended for manual arc welding. — Protective coatings are a mechanical mixture of various materials designed to protect the molten metal from exposure to air, stabilize the arc, alloy and refine the weld metal. — Magnetic coatings are also used, which are applied to the wire during the welding process due to electromagnetic forces arising between the energized electrode wire and the ferromagnetic powder located in the hopper through which the electrode wire passes during semi-automatic or automatic welding. The main types of electrode coatings: — Ore-acid electrode coatings contain oxides of iron and manganese, silica, and a large amount of ferromanganese; To create gas protection for the welding zone, organic substances (cellulose, wood flour, starch, etc.) are introduced into the coating. — Rutile electrode coatings are receiving significant use in connection with the development of mining of the mineral rutile, consisting mainly of titanium dioxide TiO2. In addition to rutile, the coatings contain silica, ferromanganese, calcium or magnesium carbonates. — Calcium fluoride electrode coatings consist of calcium and magnesium carbonates, fluorspar and ferroalloys. — Organic electrode coatings consist of organic materials, usually oxycellulose, to which are added slag-forming materials, titanium dioxide, silicates, etc. and ferromanganese as a deoxidizing agent and alloying additive.

Coated welding electrodes are produced in two ways: - crimping - dipping

By spatial position

Each type of electrode is designed to work in a specific position. In our example, this rod for working in any position except vertical is designated by the number “2”. There is also a number “1” (fully universal), “3” (for working horizontally on a vertical plane) and “4” (for lower corner joints). These numbers correspond to international standards and most of both domestic and foreign materials are marked with them.

Other criteria for selecting tungsten electrodes

Tungsten-based elements marked WP are used in AC welding of aluminum alloys with good arc stability. Welding taking place in an inert gas environment guarantees high-quality work and a neat, durable seam. When choosing non-consumable heat-resistant tungsten elements, pay attention to the following:

- electrode type;

- its composition;

- alloying additives;

- product parameters;

- quality of sharpening;

- density;

- tip geometry.

Well, and, of course, as mentioned above, pay attention to the markings, consisting of Latin letters, numbers and colors.

Transcript example

To consolidate, let's look at the decoding of the brand of electrodes using the example of ANO-21.

1: Electrode type (E46, suitable for low alloy steels with low tensile strength). 2: Brand (ANO-21, respectively). 3: Diameter (in our case 2.5 millimeters). 4: Purpose (letter “U” means for carbon or low-alloy steel), etc.

We deliberately did not finish deciphering the markings so that you could do it yourself. Write down the remaining numbers from the photo on a piece of paper and decipher them. Deciphering the electrode markings seems so complicated only at first glance; in fact, it’s enough to do it yourself once to understand the whole point. You can take several different electrode packages and write out the entire transcript yourself to practice.

Uncoated consumable electrodes

Uncoated electrodes (or welding wire) are now widely used. Technical conditions and GOST (2246-70) define about 80 of its types. However, for domestic needs, units are used for welding metal structures from ordinary rolled steel or stainless steel. The wire is divided into alloyed (represented in GOST by 30 grades, containing up to 10% alloying elements), low-alloyed (6 types, containing alloying additives up to 2.5%) and high-alloyed (41 grades in GOST, the content of alloying impurities exceeds 10%) , depending on the percentage of alloying substance.

Welding wire is designated by the letters “SV” at the beginning of the marking. Then comes the designation of hundredths of a percent of carbon, followed by the name and percentage of the alloying element(s). If the percentage is not explicitly stated, it ranges from 0.5 to 1%.

Alloying impurities in the wire composition are designated as follows:

| Litera | Designation in the periodic table (number) | Element |

| "A" | N (7) | Nitrogen |

| "B" | Nb (41) | Niobium |

| "IN" | W (74) | Tungsten |

| "G" | Mn (25) | Manganese |

| "D" | Cu (29) | Copper |

| "M" | Mo (42) | Molybdenum |

| "WITH" | Si (14) | Silicon |

| "T" | Ti (22) | Titanium |

| "X" | Cr (24) | Chromium* |

| "N" | Ni (28) | Nickel* |

| "YU" | Al (13) | Aluminum |

| "F" | V (23) | Vanadium |

| "C" | Zr (40) | Zirconium |

Also, at the very end of the marking there may be one or two letters “A”, which means a high or very high degree of purification of the steel used.

Thus, the marking “Wire 3 SV04Х19Н9” means a 3-mm consumable electrode with a carbon content of 0.04%, chromium - 19% and nickel - 9%. Wire with chromium and nickel in the composition (indicated in the table with an asterisk) is used for welding alloy steels that are resistant to corrosion (stainless steel).

Differences in electrodes by brand and diameter

There is an opinion among experienced welders that when using an inverter, you can weld with any electrodes. As a rule, such an opinion is based only on the personal experience of such specialists engaged in performing work of a certain type (welding structures from profile pipes or angles). When performing work using an inverter, no serious requirements are placed on the connection regarding its tightness, so electrodes with a diameter of 0.5–2 mm can be used without problems.

The choice of diameter and brand of electrode should be based on the thickness of the metal that needs to be connected with them. Parts of large thickness require long-term welding; accordingly, the electrode for welding them must be selected with a larger diameter. You still need to learn how to work with small-diameter welding electrodes; they burn out very quickly. Typically, such products are used for tack work.

Which electrodes are best to choose is also influenced by the type of work for which they are planned to be used. Thus, to perform complex route work, it is necessary to select electrodes of large diameter, and the installation of structures from profile elements can be carried out with products with a diameter of up to 2 mm. These electrodes are used, in particular, in the installation of sectional doors and the manufacture of various enclosing structures from profile pipes and corrugated sheets.

Methods of welding metals

The most common option for joining metal parts is arc welding, when bonding occurs due to melting under the influence of the high temperature of an electric arc. Based on the type of equipment used, process conditions, and other technical characteristics, the following types of methods are distinguished:

degree of mechanization of arc welding production - manual and automatic;- the nature of the enclosure of the joining place: submerged, in protective gas, in the open air;

- type of electric current - alternating or direct;

- equipment: transformers and welding inverters;

- type of gas used for protection;

- polarity - reverse or direct;

- type of electrodes for welding: melting, non-burning and others.

The connection using the manual arc method is carried out using rods of different types and is carried out under a submerged arc and protective gas. The peculiarity of the method is that the welder monitors the quality of the weld as he works and has the ability to change the parameters: current value, arc length and other component factors.