Home / Electrodes

Back

Reading time: 2 min

0

1052

The simplest method of welding metals is electric arc welding.

A special advantage is the existence of different types of electrodes for welding work. However, this is also a big disadvantage, since it makes it difficult for beginners to choose.

Which model should be used for those who have just begun to be interested in the basics of welding?

Our recommendation is MP-3 electrodes. The MP-3 model is designed for simple work.

After reading this article, you will no longer have questions about this brand of welding rods.

- Specifications

- Application

- Conclusion

Where are they used?

Welding electrodes MP-3S are designed for joining parts made of low-alloy steels with low carbon content using manual arc welding. They are used for welding such critical structures as pipelines, tanks, pipe fittings, and handling equipment.

When installing pipelines, it is possible to form non-rotating joints. Tanks that operate under high pressure can be serviced and repaired. Application areas include the oil and gas industry, shipbuilding and engineering industries. They also find application in everyday life.

MP-3S electrodes can be used regardless of the climatic conditions in which the welding process takes place.

Purpose

When performing welding work, direct and alternating current sources can be used. In some cases, it is possible to use a household electrical network for them. MP-3 electrodes are highly technologically advanced. Welding with such electrodes can be carried out in all spatial positions, except vertical from top to bottom. MP-3 welding electrodes are characterized by easy initial and re-ignition of the welding arc, which is accompanied by stable combustion and moderate metal loss from spattering. The slag crust is easily separated from the finished weld. When carrying out highly qualified welding work at elevated conditions, the use of MP-3 welding electrodes ensures the production of defect-free seams. In addition, MP-3 electrodes can be used for welding wet and poorly rust-free metals.

Characteristics

In construction stores you can easily find LEZ MR-3S electrodes, manufactured by the well-established Losinoostrovsky Electrode Plant. They comply with the requirements of GOST 9466.

LEZ MR-ZS electrodes have a rutile coating, which consists mainly of titanium dioxide, which is the mineral rutile. In addition, the coating may contain other elements that increase the toughness of the deposited metal. This reduces the likelihood of defects such as pores and cracks appearing in the weld. Rutile coating ensures rapid ignition of the arc, both primary and secondary.

In this case, the weld pool is reliably protected from the harmful effects of oxygen and nitrogen. LEZ electrodes MR-ZS have technical characteristics:

- An electrode with a rutile coating is classified as a consumable element.

- The internal rods are made of Sv-08 wire.

- The main alloying elements included in the rod are carbon and silicon. It contains small amounts of manganese, sulfur and phosphorus.

- Welding can be carried out in all positions, with the exception of moving the electrode from top to bottom.

- Possibility of working with different types of current.

- Long arc welding is acceptable.

- The spray coefficient is in the range of 9-13 percent.

- Good meltability of the edges of the metal being welded.

- Electrodes can weld parts with a thickness of 3 to 20 millimeters.

The diameters of the electrodes are in the range of 3-6 millimeters. As the cross-sectional size increases, the length of the electrodes increases.

The welding current is set depending on the diameters of the electrodes used and the spatial position during the welding process. So, for example, if MR-ZS 3mm electrodes are used, then in a vertical position a current of 90-110 Amperes is set. In lower and ceiling positions, these values can be increased.

Welding electrodes MR-ZS 3mm have different packaging. For example, if you need to use a large number of consumables, it makes sense to purchase welding electrodes MR-ZS 3mm 5kg. The number of electrodes that fits in one package depends on the weight. The weight of one electrode with a diameter of 3 millimeters is 30 grams. If you purchase a pack whose weight is two and a half kilograms, then it will contain 86 electrodes with a cross section of three millimeters. A five-kilogram package will hold 54 electrodes with a diameter of 5 millimeters.

What brand are Blue Coated Welding Electrodes?

Today there are many brands of electrodes. All of them are aimed at a certain type of product that secures the material. In this article we will talk about the brand of welding electrodes with blue coating. MR-3S electrodes with blue coating are intended for special structures made of carbon steel with a resistance of 490 MPa. Welding is carried out in all positions using direct and alternating current.

The main characteristics of the brand: - has a rutile coating; -coefficient -8.5 g/Ah; -electrodes allow welding of rusty, not exactly cleared of oxides and other metals. It also provides ease of welding, which is very important in a ceiling position. The brand allows welding at low currents. The electrodes have increased sensitivity when welding resulting in concave welds. Technological properties of the brand: - welding of an elongated arc shape is allowed; -150-180 C is a mandatory condition for calcining the electrodes; - a choice of electrodes is provided.

Welding parameters can be divided into additional and basic types. Additional parameters include the thickness and composition of the material, the position of the electrode, and the main parameters are the polarity and current value, diameter, voltage and speed of the mark.

What affects the main parameters?

First of all, this is the welding current. Increasing the speed can cause penetration to increase, which causes a change in energy and pressure. The blue color of the coating guarantees 100% protection against counterfeiting and other mistakes. The moisture composition before use should not exceed 0.7%. Before use, heat up to 200 degrees. Electrodes are used for structures no more than 3-20 mm. Other products will not be suitable and will go unnoticed.

Let's look at the main features of the MP-3S brand from other companies:

1. The first is the ease of introducing electrodes into welding. This point cannot be ignored, since this is the most important difference with the blue coating. 2. One hundred percent quality of welding materials in different types. 3. Welding is carried out at low currents. 4.Welding can take place from power sources. 5. Savings in manufacturing and work. 6.Minimum claims regarding the welder’s work and equipment.

A high-quality electrode should provide a stable arc, uniform coverage, rapid removal of slag, and no welding problems. Recently, sales of this model have increased. Because it guarantees quality and reliability. The following certificates for obtaining the MP-3C brand: - certificate of compliance with GOST; - sanitary maintenance for electrodes; - certificate of recognition of a valid mark by the register.

Welding electrodes with blue coating are used for welding metal structures: construction tanks, wires and others. In stores, electrodes are sold by weight. Buyers will be able to purchase the stamp per kilogram. The cost of the service in each store may vary in accordance with Russian legislation. Determining the brand was worth some problems, but still, each buyer chooses products according to his needs.

For critical parts made of cast iron, where the requirements for metal purity are high, MNC-2 electrodes can be used. They are perfectly amenable to machining after welding, have a strong metal composition and increased density. Suitable for…

Designation

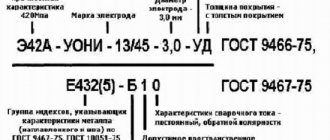

The letter “E” indicates that we are talking about electrodes intended for manual arc welding. The numbers “46” provide information about the value of tensile strength, which is measured in kgf/mm2. MP-3 is the brand of designated electrodes. “LUX” is a trade name assigned to its products by the manufacturer.

Next comes the cross-sectional diameter of the electrode. The letter “U” indicates that low-alloy steels with a low carbon content can be welded with these electrodes. The next letter “D” means that the electrode has a thick coating. The letter "E" refers to the designation of coated consumable electrodes, according to the international classification.

The number “43” is the value of tensile strength after the welding process is completed. “0” means that the elongation does not exceed 18 percent. (3) refers to the impact strength value of the deposited metal.

The letters “RC” stand for rutile-cellulose coating. One letter “P” will mean that the coating is purely rutile. The last two digits “11” indicate that welding with these electrodes can be carried out in all positions, excluding the movement of the electrode from top to bottom. The designation is applied to a tag glued to the packaging. This allows you to find out what characteristics the MP-3C electrode has and make the right choice.

Application

As we wrote above, E46 electrodes are used primarily for welding low-alloy and carbon steel. To be more precise, they are suitable for working with steel with a carbon content of no more than 0.3% and for steels with a low content of alloying components (structural steels, for example).

Type e46 includes a dozen brands of electrodes. And among them there are not just grades intended for carbon or low-alloy steel. Among them there are brands intended for a specific type of work. For example, the OZS-17N grade is designed specifically for welding in the lower spatial position using alternating current. And the OZS-32 grade is indispensable when working with galvanized steel. If you perform specific work and a specific brand of electrode has already been developed for it, then we recommend choosing that one.

Advantages

LEZ MR-3S electrodes have characteristics due to which they have undoubted advantages:

- The resulting connection is highly durable.

- Ignition of the arc is easy, as is its re-ignition.

- The arc can be short or medium length.

- The seam formed is smooth and has a good appearance.

- There are no clearly defined transition zones between the surfacing and the base metal.

- The rutile coating protects the seam from slag getting into it and the formation of oxidation on the surface.

- Spattering of metal during welding is insignificant.

- Easy separation of slag crust.

- It is possible to connect parts of considerable thickness.

- Connecting wet surfaces and those with traces of corrosion.

- No release of harmful substances during combustion of the coating.

- The seam is resistant to corrosion.

- The welding process is highly productive.

- Electrodes can be used to make not only long seams, but also short tacks.

These advantages are the reason for the widespread use of electrodes of this brand.

general information

E46 is not a brand, but a type of electrodes, which includes several brands. It’s easy to decipher this marking: “E” means “for manual welding,” and 46 is the force per 1 square meter. mm cross-section of the weld, measured in kilograms. Thanks to this marking, you can find out in advance how strong the finished seam will be, with a diameter of 4 mm, for example.

Among domestic electrodes, the E46 type is usually classified as ANO-4, ANO-6, ANO-21, ANO-29M, ANO-32, ANO-36, OZS-3, OZS-4, OZS-4I, OZS-6, OZS -12, OZS-21, MR-3, MR-3S and SEOK-46. These brands are produced by many factories. In our opinion, the Arsenal, LEZ, and SpetsElectrode electrodes deserve good reviews. These brands are available from the listed manufacturers.

The scope of application of type E46 electrodes is very large. They can be used to weld low-alloy and carbon steels. They are suitable for welding general purpose metal structures. And most welding work in production falls under these characteristics. Next we will tell you in more detail how and where these electrodes are used.

You may have heard that in addition to e46 there are also electrodes of the e46a type. Their differences are insignificant, but they still exist. E46a electrodes are intended for seams that are less demanding in terms of quality. They do not have to be very plastic and viscous.

Varieties

There are several types of electrodes of this brand. This sometimes leads to a dead end when faced with a choice. Therefore, it is necessary, for example, to understand how the MP-3 electrodes differ from the MP-ZS. These species have a lot in common with each other. Their composition and main characteristics are identical. However, there is one feature that answers the difference between the MP-3 and MP-ZS electrodes.

Consumables of the MP 3C brand contain additives, due to the presence of which the arc is ignited more easily and the stability of its combustion increases. They can be used when using a low-power welding inverter. During the welding process, less manganese is released, the seams are more uniform, and their formation is easier.

The MP 3C brand has proven itself well in household use. But MP 3 electrodes can be called more universal. They are used both in everyday life and in industrial work.

Technical process

Welding can be carried out with both types of currents. If direct current is used, then reverse polarity must be installed on the equipment. The current strength is selected depending on the cross-sectional value of the consumable and its position in space.

It is advisable to pre-clean the surface to be welded, but welding surfaces with traces of contamination and oxides is allowed. During the welding process, the electrode should be held at an angle of approximately 45 degrees. This will reduce the formation of slag and its entry into the weld pool.

Movements with the electrode should be made quickly, moving from the edge of one edge to the edge of the second. When welding large-sized products, it is advisable to fix them with tacks using the same electrodes.

Features of application

Rutile electrodes grade 3C are used primarily for welding critical metal structures, pipelines and other parts made of sheet metal, profile pipes, and shaped steel. Welding is performed in the tear-off weld mode:

- An arc is lit at the left edge of the joint.

- The electrode is passed from left to right.

- It comes off and goes to the left.

Cook very quickly so that the seam does not have time to cool.

A lot of slag is formed; it completely covers the bathtub and the entire width of the seam. The melting point of the coating is significantly higher than that of the steel being welded. Therefore, it floats and is easily separated after cooling, even in multi-pass seams. The welding pace must be high so that the metal and slag do not have time to harden.

When operating on direct current with MR electrodes, reverse polarity is preferred.

The peculiarity of using MP-3 electrodes is, first of all, that it is possible to weld untreated edges of parts. Scale, dust and moisture do not affect the quality of the seam. They evaporate during the melting of steel and combine with the slag. The seam is obtained with high technical characteristics:

- impact strength – about 8 kgf m/cm²;

- elongation – 17–19%;

- tensile strength – up to 46 kgf/mm².

The current strength is selected according to the diameter of the electrode. For a 3 mm MP, 100–140 A is sufficient; the largest ones (6 mm) require a current of 300 A to be set.

Metal spattering when welding with MR electrodes is small. The slag lays down evenly and is easily removed.

During the welding process, the MR electrode must be held at an angle of approximately 45°. When titanium dioxide melts, a lot of slag is formed. When the electrode is positioned straight, it enters the melting bath and remains in the seam, forming slag cavities. The movements of the arc should be fast, from left to right, from one edge to the other.

Storage

The quality of the weld, as well as the shelf life of the electrodes themselves, depends on compliance with the rules of their storage. The main condition is storage in a room where there is no dampness and the required temperature is maintained. A thermometer and a device for determining humidity will help fulfill these requirements.

If the electrodes are stored in cardboard packaging, then they must be installed on a rack at some distance from the floor. It is also permissible to store them in special plastic tubes.

Rules of use and storage

Buying electrodes is not enough; you need to know how to use them. Before you start work, you need to prepare the material. All edges and welded surfaces must be clean and dry. In this case, the connection will be of high quality, and cooking will be convenient.

Electrodes are supplied in packages and moisture-proof film. But this is not always enough. If storage conditions are incorrect, the electrodes may absorb a lot of moisture or be subject to mechanical stress. The first can be “cured”. If it turns out that the rods have become too wet, they need to be calcined in a special oven. This is done for an hour at a temperature of about 160 - 170°C. After this they will be ready to go.

Store electrodes in dry places and in rooms with minimal humidity.