Home / Electrodes

Back

Reading time: 3 min

0

1314

Professional welders know firsthand about the electrodes of the Swedish company ECAB - OK-46.

The rods have many positive qualities that greatly facilitate work in any spatial position.

- General information

- Technical features

- Application

- Analogs

Description

Electrodes of this brand are used for welding products and structures made from carbon and low-alloy steels . You can perform welding work using them in absolutely any position. The work can be performed on both alternating and direct current. Quite often, electrode products of this brand are used for manual arc welding. One of the characteristic features of these products is the presence of a rutile coating. By using them to connect products by welding, you can obtain a high quality seam. The electrodes themselves are characterized by low sensitivity to metal contamination - dirt and rust.

How to choose electrodes

For pipeline work, it is more efficient to select electrodes with a low rated voltage. Most models are made with cellulose coating. They are optimally suited for surfacing external layers. It should also be noted that their temporary resistance mark should be no more than 300 milliamps (MPa).

To correctly select electrodes for working with carbon steel , you should buy models with rutile coating. It is necessary to ensure that the nominal voltage deviation is approximately 6 V. The average value of the tensile strength parameter must be at least 350 MPa. The value of good electrodes in modern markets is approximately 600 rubles.

Electrodes OK-46

To be able to work with carbon steel, it is necessary to select ESAB OK-46 electrodes. Their performance is pretty good. For example, the tensile strength indicator is 400 MPa. In this case, cracks in the seams can be easily sanded out. However, such electrodes are not suitable for working with alternating current. Their coating is made of cellulose. This model is also not suitable for work on a pipeline. The maximum voltage with straight polarity will not exceed 75 V. Large overheating does not harm the electrodes. You can buy them in packs of twenty and thirty pieces. Their cost on average is 500 rubles.

OK-46 electrodes received a certificate from the National Academy of Control and Welding.

Model OK-46 2.5 mm

This model is designed for metal surfacing. Its parameters are similar to the model described above. In this case, the coating should be made of cellulose. The maximum voltage with straight polarity is no higher than 55 V. The tensile strength mark reaches a level of 40 MPa. If you trust customer reviews, these electrodes are optimal for working with stainless and carbon steel. Its filler metal costs are low. The model is not suitable for continuous current welding.

It is also important to emphasize that OK-46 electrodes are characterized by a slight deviation of the nominal voltage. Listening to the reviews of the owners, we can make the observation that the electrodes are moderately sensitive to rust. The smallest possible angle of inclination of the electrode is 36 degrees. The modification shows quite high sensitivity to various contaminants. Users can purchase anti-cathode electrodes OK-46 only in packs of 50 pieces. Their average cost on the market is about 750 rubles.

Electrodes OK-46 3mm

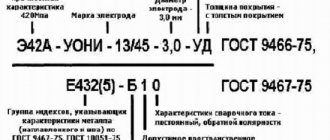

The mentioned OK-46 electrodes (their state standard number is 9466−75) are a budget option for modifying the electrodes. They are characterized by high viscosity. This was made possible to a large extent due to the use of rutile coating. The comparative elongation of the mark is at the level of 20%. Temporary resistance is no more than 45 MPa. According to customer reviews, the model is suitable for pipeline work. Problems rarely arise with metal structures of various shapes. This brand is sold in packs of 15 or 40 pcs. Prices for such products vary from 450 to 600 rubles.

Use of OK-46 4 mm electrodes

OK-46 elements are distinguished primarily by their high-quality coating. The brand is quite often used for work on pipelines. The tensile strength indicator is no higher than 55 MPa. The impressive diameter of the electrodes makes it possible to carry out complex manipulations with metal surfacing. The brand has low sensitivity to edges. If you trust users, then the waste of deposited metal is within the normal range. However, negative features are still present:

- Mainly welders complain about susceptibility to rust.

- Before using network elements, their working surface must be cleaned for a long time.

- The model cannot be used with alternating voltage.

- The smallest possible angle of inclination of the element is 35 degrees.

- The impact strength of the specified brand is at the level of 77 J.

purchase elements of the OK-46 in specialized mono stores at a price of 650 rubles.

Model OK-46 5 mm

The presented 5 mm model is sold with cellulose. According to the owners, it is excellent for surfacing metal. Its maximum voltage with reverse polarity does not exceed 12 V. This grade cannot be used for short arc welding. The maximum permitted tilt angle is 75 degrees. The tensile strength indicator is around 300 MPa. The surface coating is initially designed to be of small thickness. At the same time, the consumption of the presented model is not particularly high. Users have the opportunity to purchase OK-46 5 mm network elements at prices starting from 650 rubles.

Reasons for popularity

When using these electrodes, experts note the ease of ignition of the primary arc. A repeated arc also occurs without unnecessary difficulties. Working with them, you can easily weld tacks, as well as create root and short welds .

Many specialists also choose products from this brand because they provide comfort when performing work, especially when it becomes necessary to weld wide gaps. This task often arises when performing work on the installation of metal structures. During welding work with these electrodes, slag appears. However, it can be removed from the seam surface without any difficulty.

Applications of Lincoln electrodes

These electrodes are suitable for working on edges as well as pipelines. They are also often used for welding metal structures. The threshold voltage of the mark with reverse polarity is at the level of 22 V. The temporary resistance of the electrodes does not exceed 360 MPa. In this case, the minimum permissible tilt angle is 23 degrees. The grade is often used for metal surfacing. The seam in this case turns out to be quite neat.

If you believe the reviews of welders, the consumption of electrodes is quite significant. The brand's sensitivity to rust is low. The presented model is not afraid of slag leakage. The user can buy electrodes at a price of 760 rubles.

Advantages

It is precisely because of their advantages that these electrodes have become very popular.

- Easy ignition when used for welding with these electrodes.

- Possibility of their use for welding products with galvanized coating.

- Low heat input. This makes it possible to use them for welding joints of large gaps.

Consumables of this brand are distinguished by high quality indicators. Therefore, they are used in a wide variety of industrial sectors, where the task is to create high-quality welded materials.

When using these electrodes, metal spatter is minimized. In addition, the slag that appears on the surface of the weld is easily removed. As a result, the welded material acquires an aesthetic appearance. Although these electrodes are versatile, they are best used for making short and root welds . Their advantage, such as the ability to perform welding work in any position, makes them indispensable when performing welding in confined spaces.

Purpose and subtleties of application

OK-46 electrodes can serve as the main filler material for filling joints and voids in metal products, as well as an additional material for tack welding and pre-assembly of structures.

Self-cleaning weld

OK-46 electrodes are not recommended for use when welding long seams. They are designed for applying short rollers. The brand of consumables ensures a high-quality and even seam with a smooth transition to the main surface. During welding, the metal almost does not spatter; a small amount of slag separates itself. The advantages of these electrodes are best demonstrated when welding seams with a deep root location.

When using OK-46 welding electrodes, you are guaranteed to obtain strong and reliable tack welds necessary for the installation of metal structures and utilities.

Consumables are packaged in a sealed bag and cardboard box. Thus, they are reliably protected from moisture and mechanical damage. Will withstand multiple shipments and long-term storage.

Electrodes OK 46: technical characteristics

- In electrodes of this brand, welding wire made of steel grades Sv08 and Sv08a is used as rod materials.

- The diameter of the welding wire used in these electrode products can vary from 2 to 5 mm.

- The surfacing productivity when using them in welding operations is 1.4 kilograms per hour.

- The operating current for electrodes of this brand is as follows: 3 mm - 80-130A, 4 mm - 110-170A, 5 mm - 150-200A.

The manufacturer of these electrode products packages the products in boxes that are made of high quality cardboard with good strength characteristics. a heat-shrink film as an additional layer , which provides reliable protection of welding products from external factors, and in addition, the ability to store them for a long time. At the same time, this loss of quality characteristics of the products is excluded. On the outside, the packaging with electrodes has a durable coating that can withstand various impacts that occur during the transportation of products and during their storage in a warehouse.

Technical features

Electrode OK-46 has the following technical characteristics:

- melting rod with rutile-cellulose coating;

- made of welding wire Sv08G2S, intended for performing work of increased responsibility, surfacing;

- welding with any polarity;

- no-load electrical voltage - no more than 50V;

- easy initial, re-ignition;

- rod diameter - 1.60, 2.5, 3.2, 4.0 and 5.0 mm;

- Recommended calcination at max 90° C – 60 min.

The only disadvantage of the OK-46 rutile-cellulose rod is the high price, which is compensated by the high quality of work. The following application will help you select the current strength for the diameter of the bar.

Features of application

Using consumables of this brand, you can perform welding work in vertical areas, as well as below. These products are used for working with products made from low-alloy steels and alloys, which are characterized by a yield strength of 380 MPa .

When using these electrodes, it is not necessary to pre-clean the surfaces of products and structures or dry them, since factors such as humidity and rust do not have a big impact on the quality characteristics of the weld being created. The initial ignition when welding with these electrodes is easy. This eliminates the reduction in the speed of welding work when:

- creating short seams;

- point contact.

It is advisable to use consumables of this brand for welding work when the risk of burning through the metal is high. For example, when the task is to ensure a reliable connection of products that have a small thickness, or when welding parts that have a galvanic coating. Using this consumable at idle, the voltage value is at a low level, which makes it possible to weld from simple power sources that are intended for domestic use.

Application

The purpose of these electrodes is welding of various types of steels and non-ferrous metals. ESAB OK 46 electrodes are practically insensitive to corrosion and dirt, so there is no need to thoroughly clean the metal if you are welding in a hard-to-reach place.

The OK 46 brand is often called universal, and this is true. These electrodes provide excellent weld quality, stable arcing and ease of welding even on the most capricious metals, such as aluminum. These rods can be set on fire without any problems after they have been forced to die out. But the best results are achieved when welding short joints and tacks. In this case, the seam should be as wide as possible.

Any polarity can be used for welding. The type of current can be either alternating or direct. Can be cooked in almost all spatial positions. The weight of the pack is 5.3 and 6.6 kg depending on the diameter. Welding electrodes OK brand 46 can be replaced with brands OZS 12, OZS 6, ANO 4, ANO 6, ANO 29 M, ANO 23 and MR-3. They do not provide the same level of quality, but are cheaper and have similar characteristics.

Before welding, it is recommended to calcinate the electrodes in an electric furnace at a temperature of no more than 90 degrees. Duration of calcination - 1 hour.