A multitool is a wide-ranging household device that can cope with a variety of tasks. A video about what a renovator can do demonstrates that he can process soft linoleum, wood or even metal with equal ease, allowing him to perform work that is simply impossible to do with other tools.

Renovator is a universal device for cutting and grinding hard and soft materials

The multifunctional renovator is a fairly “young” unit, invented only about 50 years ago. Initially, it was used only in medicine to remove plaster after fractures. But subsequently the tool was improved, equipped with a gearbox and introduced to the automotive and construction markets.

Currently, a multitool is a vibration-type unit for cutting and grinding a wide variety of materials. It is equipped with numerous removable attachments, and is used primarily as an auxiliary device. The renovator’s capabilities are used for small jobs or in places that simply cannot be reached with specialized tools.

You may like

Massage roller is good. A massage roller with vibration is even better. Why? If only because, in combination with the weight of your body, vibrations provide a deeper massage. Also, thanks to the presence of 3 levels of vibration, you can adjust the power of the massager, focusing on which areas and how deeply you need to massage. Important to know: the roller can be used without vibration

Our massage roller is a multifunctional device; it was created to work with those areas of the body that are sometimes difficult to massage with your hands. Ideal for the lower extremities, especially for large muscle groups, such as the hips or ankles. But the vibration function is not recommended for back massage. This roller works with body weight and vibration!

An effective post-workout massage will restore your feeling of comfort! Sit on the floor, select the desired intensity of the roller and massage each muscle group. The good news is that vibration works for you. For optimal results, we recommend massaging each area for at least 3 minutes. Be sure to check out our videos for some details and exercises!

Turning on the roller: Place the switch in the ON position and press the START button. Intensity adjustment: Press the START button. 1 press - low intensity, 2 presses - medium intensity, 3 presses - high intensity. Turning off the roller: Place the switch in the OFF position. Charging the battery: (Charges via USB port. Cable included) Connect the supplied cable to the USB port. 5V/1A adapter: charges in 6h 30m:

Do not immerse in water. Do not disassemble. For adults. Not suitable for pregnant women. Consult your physician before use if you wear a pacemaker, have any health problems, or are unsure whether the device is appropriate for you. Using a massage roller may cause discomfort and marks on the skin. If significant discomfort or pain occurs, consult your physician.

Length: 33 cm Diameter: 13 cm

For optimal post-workout recovery, complement your foam rolling treatment with recovery drinks, protein bars, massage balls (ideal for releasing trigger areas), compression or electrical stimulation.

Wood bits

Wood is one of the most common materials in construction and finishing work, and therefore wood attachments for renovators vary depending on the specific operation with wood:

- for cutting wood, a cutting disk of a spade-shaped, rectangular or other complex shape, called a saw blade, is useful - its functions include plunge-cutting or other sawing not only of wood, but also of other materials (plastic, soft metal, etc.);

- a segmented saw blade has the shape of an incomplete circle, often with a cut edge or with part of a segment of complex shape; sometimes manufacturers complete their multifunctional tools with a full-circle blade;

- for cutting work with wood, you may also need a depth limiter - with its help you can make cuts of certain sizes even without visual control, which will be especially important for hard-to-reach places;

- The rasp disk and sanding pad are used for rough processing of wood and removing large burrs.

Eating methods

Like any tool, the multitool is powered by mains or battery. Each method has its own capabilities. Mobility is a distinctive quality of any battery-powered tool. For work outdoors or where there are no electrical networks, such a device will come in handy. In addition, there are other advantages of the battery device:

- Light weight.

- Relatively low noise during operation.

- The low power of the electric motor allows you to work for a long time.

Selection principles

When choosing metal scissors, it is recommended to consider the following parameters:

- food type;

- tool power;

- electric motor speed;

- maximum workpiece thickness;

- rotation angle value;

- protective equipment and additional devices;

- adjusting the gap between the blades.

Advantages and disadvantages

Advantages of electric scissors:

- reduction of metal processing costs;

- the load is placed on the electric motor and gearbox;

- interchangeability of cutting blades;

- cutting line accuracy;

- absence of edge defects;

- reduction of cutting waste;

- injury prevention.

The disadvantages include individual shortcomings, which depend on the requirements for certain operations of cutting metal with a power tool.

Manufacturers and cost

Scissors are produced in Europe and China, as well as Russia. The price of scissors starts from 2,000 rubles and can reach 130,000 rubles. It is recommended to purchase equipment with a warranty.

For cutting metal

One of the slowest jobs with a multifunctional tool is cutting metal parts. In terms of the speed of “biting” into the material, the renovator is several times behind the grinder, so for such purposes it is used only in the most extreme situations. Typically, a multitool is used to cut protruding nails flush, drywall profiles, small pipes (up to 30 mm) or damaged car body parts. To work with metal more or less confidently, the tool must have at least 300 W of power, otherwise it will jam and heat up.

Metal scissors - evolution!

When it comes to small amounts of work, it is much more economical to purchase manual metal shears

When purchasing, pay attention to their type - there are regular and lever models. The usual type is characterized by simplicity of design - the handle and cutting part are made of one whole element

When working with such tools, the cutting efficiency depends directly on the force applied and the length of the handle.

Lever scissors have a more complex design: the elements of the cutting part are connected to the handles by hinges, which allow you to increase the pressure with additional lever transmission force. As a result, you need to apply much less force in your work compared to conventional scissors.

We advise you to study - Rococo style in the interior - sophistication of decoration and delicacy of colors

Both types are created for both straight and through cuts. Straight cutting tools have long blades that can be used to cut metal along the entire length of a sheet in one motion. There are universal scissors that are used for through cutting, straight cutting, and for cutting out contours. And for particularly delicate work, there are shaped metal scissors, which have a special blade shape for cutting complex curves and small radii.

Manufacturers also take into account the fact that all people are divided into right-handers and left-handers, so the same scissors will not suit everyone. Conventional scissors are divided into left-handed and right-handed based on the location of the cutting edge; accordingly, it is more convenient for left-handed people to work with left-handed ones. However, in the case of metal scissors, the opposite is true! Right-handed people get left-handed options, and left-handed people get right-handed ones. This nuance is due to the fact that when cutting, the master needs to see the marking line, and with the standard ratio “right-handed - right-handed scissors, left-handed - left-handed” the line is not visible!

However, a person who professionally cuts metal will have both the first and the second. The need for this arises because with right-handed scissors it is more convenient to cut right-handed radii, when the cutting arc passes from left to right - this is how their cutting part is sharpened. The situation is the same with the left ones - they are ideal for left radii. However, with electric scissors everything is simpler - this form of evolution of construction scissors has a completely different operating principle!

Photo of electric metal shears, dumskaya.net

Photo of using electric scissors, dumskaya.net

Photo of cutting metal with scissors, dumskaya.net

Photo of electric scissors, dumskaya.net

Photo of electric scissors, dumskaya.net

Additional tips and tricks for working with a renovator

- It is recommended to work as a renovator for no more than 15–20 minutes, after which the tool should be allowed to “rest” for 10 minutes. If you ignore this recommendation, there is a chance of burning the device.

- Securely fix the workpiece. This will make work more convenient, improve quality and accuracy, especially during cutting.

- Preparation of the workplace. There should be no small parts or devices on the workbench, especially cutting ones. Vibrations may cause them to fall off the table.

- Before you begin, you should remove debris and dust from the workbench - all this can become airborne during work.

Corner

This is another simple but very necessary tool, which will also cost you cheap - only $8. Every professional has a corner in his suitcase, and for good reason. It is ideal for marking cutting lines on lumber, marking circular saw cuts, and measuring angles for rafters and stairs.

Typically, a corner is purchased for the first home renovation and is used for many years. It is always worth buying a metal corner, because it costs the same as a plastic one, but the latter will certainly break sooner or later.

Purpose and types of metal cutting

Before individual parts of certain sizes are manufactured, sheet and profile materials are cut.

In boiler production, three cutting methods are used: mechanical, autogenous and electrical. These cutting methods have a fundamental difference in the impact they have on the properties of the metal, in their implementation and in their efficiency.

With the mechanical method, metal separation occurs due to the action of an external force. With the autogenous method - due to the combustion of the metal in a stream of oxygen. In electric cutting, metal is melted in the flame of an electric arc. Both methods can be manual or mechanized. In addition to the above, the mechanical method can be divided into two types:

— cutting carried out by clean cutting (removal of chips with a cutter).

Depending on the profile of the material being cut, special tools, devices and machines are used during cutting.

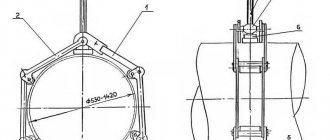

Rice. 1. Scissors:

a – manual; b – chair.

Cutting thin sheet metal with scissors. Chip cutting.

Cleaving cutting is carried out using hand and chair shears (Fig. 1, a and b), lever (Fig. 2), vibration, guillotine, disk (Fig. 3) shears, press shears, and special cutting dies.

Rice. 2. Lever scissors.

Looking at the cut part of the sheet, we see three stripes: two of them, which are at the edges, will be narrow and shiny, these are traces of the cutting of knives (a and c), and the surface in the middle will be matte (b) from chipping (Fig. 4). Small cracks and burrs can be observed along the cut line. In addition, a strip of metal with a thickness of 2 - 3 mm, when squeezed with knives along the entire cut line, will be hardened.

Depending on the structure being manufactured, work hardening and cracks must be planed.

Rice. 3. Disc shears.

Cleaving cutting occurs as follows: the material to be cut 2 is placed between two knives 1 and 3 (Fig. 5), of which the lower 3 is usually stationary, and the upper 1 is movable. The upper knife 1, lowering, presses on the metal, pressing it against the lower knife. Both knives are somewhat pressed into the metal. As the knives are pressed into the metal, its cross-section decreases, first small and then large cracks appear, and it breaks off.

Manual models of metal scissors and their manufacture

The manufacturing process of hand scissors involves the use of two options:

- Forging

- Casting

Cast scissors are suitable for farming, they are inexpensive and do an excellent job. With frequent use of scissors, the blade quickly becomes dull, so they need periodic sharpening. This tool can only cut thin sheet steel up to 2 mm.

This is interesting!

The hinge mechanism on hand scissors consists of two parts, which is done specifically to double the applied physical force.

Manufacturers also produce lever products that are made from two different materials. The cutting part is made of high-quality material, which increases their service life. The handles of such devices are made of ordinary steel, which has a positive effect on the cost of the tool. Using lever shears allows you to cut metal without much effort.

https://youtube.com/watch?v=tMWfrA_y7hg%3F

When purchasing hand scissors, you need to consider the placement of the knives. They are straight, as well as left and right. Straight ones are designed for smooth cutting, as well as cutting out large round shapes. As for the left and right shapes of the blades, here you need to know the following:

- Left - used to make cuts in the left direction. The left scissors should be used primarily while holding them in the right hand. When working with a tool with left-handed blades, the left side of the blades enters from below

- Right - used when it is necessary to bend to the right side. When working, you should hold such a tool in your left hand. When cutting with scissors, the right side goes under the sheet from below, which allows you to make an even cut

To make it easier to distinguish them, manufacturers paint the handles in different colors. The right scissors are painted green, and the left scissors are painted red. When using hand-held cutting devices, everyone has encountered the fact that when cutting a long sheet, the plane becomes bent and bent. This usually happens when using scissors with a symmetrical arrangement of knives. To prevent creases from forming, when cutting a long sheet of steel, you need to use a tool with asymmetrical knives.

https://youtube.com/watch?v=ZecPUOymWqE%3F

This is interesting!

Instruments with asymmetrical knives are extremely rare on sale.

The reason for such low popularity is their high cost. However, in order to make an even and neat cut, it is recommended to buy just such metal scissors with asymmetrical blades. What can be cut with hand metal scissors:

- Galvanized steel

- Corrugated sheet

- Metal tiles

- Sheet metal

- Steel mesh

- Linoleum

- Rubber

- Ruberoid

The advantage of hand-held metal shears is that they cost 10 times less than power tools.