In terms of its functionality, an engraver is very similar to a conventional drill or grinder, but its main purpose is to process parts of miniature size. Using such equipment and special working attachments for the engraver, you can effectively perform various technological operations, which include drilling, milling, grinding, engraving, etc.

Cutting a steel pipe with a cutting disc for a drill

The list of materials that can be processed using an engraver is also quite extensive. These are soft and malleable wood, hard steel, fragile glass or ceramics, various types of plastic and even bone. Naturally, to process different materials with an engraver, different working attachments are used, differing in both design and material of manufacture.

What are engraver attachments?

Working attachments or tools used to work with an engraver are presented in a wide variety on the modern market. Their design includes two main elements:

- a shank with which the tool is fixed in the chuck of the equipment used;

- the working part, which performs the main functions, interacting with the material being processed.

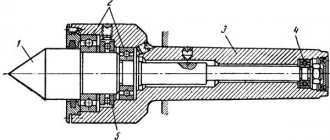

The working part of these nozzles is designed for processing metal surfaces

The choice of working attachments for an engraver is influenced by the following factors: characteristics of the material being processed and the list of technological tasks that need to be performed. Those home craftsmen and specialists who work with an engraving machine on a regular basis try to immediately purchase a set of attachments for the engraver, which includes tools of various sizes and purposes. Depending on the needs and financial capabilities of a particular engraving artist, this may be a more modest set, including several dozen necessary tools, or a professional set, which includes attachments for performing various works on metal, wood and other materials.

When choosing working tools for an engraver, you should take into account that some of its models can be equipped with collet chucks that are suitable for attachments only of a certain brand. To use such equipment in conjunction with any type of attachments, you will have to purchase universal collets for the engraver, which are also sold in whole sets.

Classification of nozzles

There are a large number of varieties of equipment for working with a mini drill. The wide range on the market allows you to select attachments for wood and many other materials that engraving equipment can work with. Also, individual craftsmen make them themselves.

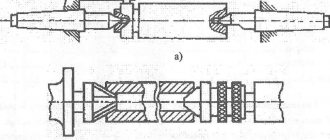

Structurally, the attachments (burs) consist of two parts;

- tail, clamped in the tool chuck (diameter from 0.8 to 8 mm);

- worker who processes materials.

Equipment is classified according to two main criteria:

- by the type of material from which they are made;

- by area of use (purpose).

By type of material processed

Based on the material, engraver cutters are of the following types.

- Made of hard alloys (carbide) with small and large working parts. There are different types of notches on them. Designed for initial or intermediate processing of workpieces of different hardness.

- Diamond-coated steel, used for basic work operations with various materials.

- Disc holders that can be equipped with felt, cutting, or rubber wheels, depending on the properties of the workpiece and the nature of the work performed.

- Rubber with the addition of corundum, used in processing metal workpieces.

- Abrasive, which are used to perform work on stone, metal, glass, and ceramics.

- Felt, intended for polishing wooden surfaces.

There are also combination burs that have a steel shank and a carbide working part. Their area of application corresponds to the material of the head.

Carbide equipment is of high quality, durable and is one of the most expensive consumables for Dremels . The shape of the tips determines the features of its application. With the help of such peak burs, it is good to process bone, plastic, and make tracing (indicate the contours of the picture). Diamond attachments are also of high quality, even if the kit they are included in is classified as cheap consumables.

On the market you can find a set of burrs, all the elements of which are marked with some color - it indicates the level of sharpening. Those marked black are the most productive burs, while the sharpness of green or blue ones is worse. The yellow-marked attachments are the best choice when finishing workpieces.

By purpose

You can use an engraver with attachments not only for engraving, but also for performing other work operations. The breakdown of consumables used in the operation of straight grinders is presented in the table below.

| Work performed | Nozzles used |

| engraving | the varieties discussed above are suitable |

| drilling | performed using steel or carbide drills |

| polishing | circles made of felt, cotton, felt, sandpaper, leather, as well as special devices (holders) that you can wrap yourself (for example, with felt) |

| grinding | grinding stones (of various shapes and from different materials) and wheels (of sandpaper), diamond rings, rubber cylinders |

| tongue and groove | burs with a spherical working part |

| cutting | cutting discs |

| milling | cutters |

| cleaning surfaces (for example, from rust, scale) | wire (steel), thread, fabric brushes |

| finishing of holes or cavities | diamond cutters |

| creating grooves | cone burs |

Consumables from each group can be used when processing various materials. At the same time, milling equipment is used mainly by professionals.

Dremels, which have a flexible shaft installed, are equipped with any types of consumables that fit the diameter of the tool chuck.

Diamond burs for engraving work

The most popular types of working attachments used to complete engraving installations include diamond burs for engravers. The base of such a tool is made of tool steel, and diamond powder is applied only to their working part. The mechanical characteristics of diamond powder make it possible to successfully use the attachment for processing hard materials such as steel, ceramics, glass, artificial and natural stones.

Expensive dental diamond burs have a long service life

Diamond burs (or cutters) are used primarily for finishing shaped holes. As a rule, diamond consumables for engravers are sold in whole sets of 10–20 tools of various shapes and sizes. When working with them, you should strictly follow the rules of their operation so as not to damage the diamond coating. The standard shank diameter of diamond-type engraving bits is 3 mm.

Main features of nozzles

The tool is designed for finishing a fairly large number of various materials. They can process ceramics, wood, glass and plastic products, and hard steel.

To work with each of them, different nozzles with different design specifics are used.

Today, specialized enterprises offer a wide range of different attachments necessary for carrying out operations with this tool. Their design contains two main components:

- the working part that performs the main function when interacting with the product being processed;

- a shank that secures this element in the equipment socket.

When choosing this device, pay attention to certain points: the technological goal that needs to be achieved, and the material being processed, or more precisely, its characteristics.

In addition, take note that some engraver models are equipped with collet chucks. Only certain brands of attachments are suitable for them. To use such equipment, you must additionally acquire universal collets .

The use of diamond burs in engraving

Among the most popular types of attachments included in professional kits are diamond burs. The basis of such equipment is made of tool steel.

In this case, the working part is coated with diamond powder . Thanks to the latter, the device is capable of quite successfully processing steel, glass, ceramics, natural and artificial stones.

The use of diamond burs is most advisable if there is a need to refine a shaped hole. They are most often sold in sets of ten to twenty pieces , differing in shape and size.

The operation of burs must be carried out in compliance with certain rules that help prevent damage to the diamond coating. Standard models are equipped with a shank with a diameter of three millimeters.

Abrasive tools

The most budget-friendly option for use in conjunction with a drill or engraver are attachments, the working part of which is made of rubber and abrasive material. The diameter of their shank is 2.3 mm, and they are used mainly for work on metal, including stainless steel. Abrasive tools are usually sold in sets of 6 pieces and have different working part configurations.

Abrasive cutters (aluminum oxide) for processing steel and non-ferrous metals

Some manufacturers (in particular,) produce abrasive engraving attachments in various colors, which allows the user to easily determine the category of the tool. Thus, red abrasive wheels, intended for working on metal, are made of aluminum oxide, and green ones, made of silicon carbide, are used for processing stone, glass and ceramic products. For the convenience of performing various technological operations, diamond cutters are made with different shapes of the working part, but their shanks always have the same diameter.

Using abrasive attachments for an engraver, operations such as boring holes, grinding surfaces, etc. are performed. These attachments are optimal for use at home; for a professional, their capabilities will not be enough.

Nozzles can be in the form of removable working heads mounted on the corresponding shank

Most popular brands

Modern markets offer a wide range of attachments for engravers. Thanks to this, you can choose exactly those tools that will correspond to your financial capabilities and the needs necessary in a particular case.

If we talk about professional-level equipment, the most popular and sought-after brands include Dexter and Dremel . The products of these companies can be effectively used for processing metal, wood, glass and other materials.

Although these devices are expensive, they are quite reliable and durable to use. One nozzle of these brands can last ten times longer than its Chinese counterpart. In addition, these tools have high processing accuracy.

As a budget brand, you should pay attention to, which offers for a relatively small amount to buy a set that includes up to 180 units of all kinds of attachments with different shapes, sizes and design features. Such kits are equipped with tools for drilling holes, milling, diamond and abrasive attachments, and cutting discs.

As for equipment from Chinese manufacturers, there is a very mixed opinion about them. Although they cost several times less than high-quality instruments, such instruments cannot boast of their reliability .

Moreover, Chinese kits contain significantly fewer components than branded versions. However, professionals in their field will, in principle, be able to cope with such equipment. True, you will have to change tools often.

Making your own nozzles

To carry out simple engraving work at home, the necessary tools can be made from scrap materials.

For example, the simplest cutter is made from a corrugated wheel from a lighter or a dowel on which working teeth are first cut.

To make a sanding attachment, it will be enough to use a wooden drum equipped with a shank with sandpaper glued to its side surface.

Most hand-made attachments cope well with the tasks assigned to them. At the same time, their costs are minimal.

Which equipment option to choose depends entirely on the requirements and capabilities of the master , be it a Chinese-made tool, a homemade one, or a professional device.

Working attachments for grinding and polishing

An engraving machine, as mentioned above, can be successfully used for fine grinding and polishing of products made from various materials. A roller cutter made of felt is used as a working attachment to perform such technological operations. Since felt does not have outstanding abrasive qualities, such a tool is used only in conjunction with special polishing pastes.

Polishing discs can be used for roughing or finishing, as well as for finishing irregularly shaped surfaces

The choice of polishing pastes of a certain type, which differ significantly from each other in their characteristics and chemical composition, depends primarily on the properties of the material that will be processed with their help. Thus, grinding of hard metal surfaces is performed using pastes based on paraffin and polishing powder. Special polishing pastes based on diamond powder of various fractions are intended for work on wood and glass. With their help, you can not only effectively remove scratches from the surface of wood and glass, but also bring the product into a perfectly smooth state. Experts recommend giving preference to those in which diamond powder has a fraction size of 3/2 and 5/3.

Accessories such as felt grinding attachments for working on wood, metal, glass and other materials are successfully used not only in conjunction with a specialized engraving unit: they can be equipped with a dental drill and simple hand-held devices.

Replaceable sanding attachments

Types of nozzles

There are a huge number of accessories for drills. Some of them are designed for ease of drilling, others allow you to create large diameter holes, and others help with grinding and polishing. There are also highly specialized devices, for example, a cutter for a mini-drill for wood, which turns a hand tool into a mini-milling machine.

It is not always necessary to have a strictly vertical hole passing through the entire workpiece. There are times when it is necessary to drill at a precisely specified angle, and also several parallel holes. Here the drilling angle limiter will come to the aid of the master. Basically, these are lightweight structures that fit onto the drill and ensure its precise positioning.

Another useful accessory for an electric drill is a depth stop. The limiter is included in the basic package of delivery of almost any drill. The device is extremely simple - it is a metal rod that does not allow drilling deeper than the specified value.

Working attachments for professional engravers

A separate category of working attachments that engravers are equipped with are professional series tools. Specialists for whom working with an engraving machine is their main activity, as a rule, have at their disposal entire sets of various attachments that differ in the material of manufacture, design and shape of the working part. If we talk about the most typical composition of such a set, then it necessarily includes:

- cutters for engravers of various shapes, sizes and designs;

- drills that turn the engraving machine into an effective drill;

- diamond, abrasive and felt rollers;

- wire nozzles, with the help of which they clean the treated surfaces from traces of corrosion and other contaminants;

- cutting discs for engravers, which are quite difficult to purchase individually.

For professionals, each attachment is designed for a specific operation.

The presence of such a capacious set of tools for a specialist who uses an engraver in his professional activities is explained very simply. Often, high-quality and accurate work on the smallest details on the surface of the workpiece is not possible only with a milling cutter, a cutting disc for an engraver, and other tools of the same size. That is why, even within the processing of one product, tools often have to be changed, choosing attachments suitable for performing a certain technological operation.

In addition, the presence of a specialist set of tools, which includes drills, cutters, cutting wheels for engravers and cutters of many other types, is an indicator of professionalism and indicates that this is an experienced person who is good at his job. Craftsmen who constantly work with engraving devices choose expensive sets of tools from the professional series for another reason that it is quite difficult to purchase individual tools from such sets (in particular, a cutting wheel for an engraver).

Special holders allow you to quickly change the necessary attachments

Polishing and grinding attachments

As already noted, engravers are used to polish objects made from different materials.

Typically, for this kind of work, a felt nozzle , which is pre-coated with a special polishing paste, which acts as an abrasive component.

Polishing discs can be used for both rough and final finishing. They are also often used when there is a need to refine a surface that has an irregular shape.

To choose the most suitable paste, you must first determine the properties of the material of the product that needs to be sanded. To process a hard metal surface, for example, it is advisable to use pastes based on polishing powder and paraffin .

from diamond dust with various fractions of grains are perfect . They can very effectively get rid of scratches on glass and wooden surfaces and bring them to a perfectly smooth state. In this case, the most recommended powders are those containing diamond fractions 5/3 and 3/2.

Felt attachments for grinding can be used both when processing wood, metal, glass, and to equip drills in dental clinics or simple hand-held devices.

Work kits for professionals

The professional series equipment is represented by a separate category of attachments.

Good craftsmen usually have at their disposal sets of tools that differ in design, materials of manufacture, and shape of the working part.

In most cases, such kits consist of the following components:

- Various cutters for engraver.

- Abrasive, diamond and felt nozzles.

- Drill, thanks to which the installation can be used as a drill.

- Cutting discs.

- Wire nozzles used to clean the surface from dirt and corrosion.

All these components of the kit allow a specialist to carry out accurate and high-quality work on even very small parts. To do this, of course, quite often it is necessary to change the tools used to select a more suitable equipment option for a particular situation.

But the end result is worth it. The presence of a large set of masters is often evidence of his professionalism and experience.

Brief overview of brands

Today, finding engravers and working attachments to equip them on the domestic market does not present any problems. At the same time, the variety of equipment and tools available for free sale allows you to choose them to suit your needs and financial capabilities.

Professional grade attachments

Those craftsmen who engrave wood, metal and other materials at a professional level and already have the appropriate equipment at their disposal should pay attention to working attachments produced under the Dremel and Dexter trademarks. The high cost of such equipment for an engraver is fully justified by its exceptional reliability and durability. Another important advantage that a milling cutter, cutting wheel, drill, as well as any other tool of these brands has, is high processing accuracy.

High-quality consumables are purchased by both professionals and home craftsmen who respect their craft.

When choosing Dremel or Dexter working attachments, keep in mind that one such tool can last as long as 10 Chinese-made attachments. The fact that in the assortment of these companies you can find nozzles of various purposes and standard sizes speaks in favor of purchasing fairly expensive but high-quality products from well-known manufacturers. So, these can be various cutters for a drill or engraver, drills of different diameters, disk tools, as well as any other types of cutters designed for working on wood, metal, ceramics, and glass.

Budget models

Cheap, but decent quality attachments are offered by the domestic manufacturer. At affordable prices you can purchase sets of attachments, including up to 180 tools of the most popular types, designs, sizes and shapes. These sets contain tools for drilling, cutting discs for a drill or engraver, milling attachments, diamond and abrasive cutters, and much more.

All attachments included in the Zubr brand set are placed in a plastic case, making it easy to both store and carry to the job site.

Nozzles from Chinese manufacturers

There are two opinions about Chinese-made nozzles. On the one hand, their quality and reliability are in question, on the other hand, they cost significantly less than branded equipment. A Chinese milling attachment for an engraver, a cutting disc or a drill bit for drilling will not last long, but it won’t be such a shame to throw them away, given their cost. If a professional works behind the engraver, then even a cheap Chinese cutter will not prevent him from doing the job efficiently (although he will have to change such a tool more often).

Chinese attachments for a drill or engraver can be recommended to beginning engravers, who can use them to acquire their first skills in this matter.

Affordable prices of Chinese attachments allow beginning engravers to purchase large sets “to try”

For curved cutting

There is an interesting device that allows you to turn a drill into a jigsaw. The device is fixed in a chuck and makes it possible to cut wood-based sheet material, plastic and even thin sheet metal. The cutting tool is a movable file.

This device is a useful thing in the household, but the nozzle has a fairly high price. If you need to make curved cuts frequently, you should consider purchasing an inexpensive jigsaw.

There are other similar devices. Drill attachments for drilling round holes in wood are very popular. They help overcome the drill size limitation typical for most models and drill a hole of any diameter.

Homemade attachments for engraving machines and drills

For simple engraving work in a home workshop, you can make a cutter, cutting disc, grinding and polishing wheels yourself. As a simple cutter to equip an engraver or drill, you can use a grooved wheel from a regular lighter or a dowel, on the head of which working teeth are cut. Making a working attachment for grinding or polishing is also quite simple: for this you can use a wooden drum with a shank, sandpaper glued to the side surface of it.

Many homemade attachments for an engraving machine (if they are used to perform not too complex work) perform well, and the cost of their production is minimal.

Homemade attachments for the engraver

You can buy attachments for the engraver not only factory-made, but also make them yourself. Workshop specialists and home craftsmen have come up with many options that are suitable for performing various operations with different materials.

To make your own polishing, grinding, milling, drilling consumables for a Dremel, as well as cutting devices, use the following materials and parts:

- plywood;

- sandpaper;

- remnants of abrasive wheels of different thicknesses from an angle grinder (grinder);

- felt;

- felt;

- various fabrics and rubber;

- steel wire;

- a wheel from a cheap lighter;

- old burs and drills (they are sharpened);

- electric razor knives;

- hacksaw blades;

- metal caps, for example, from beer bottles;

- champagne corks;

- an ordinary dowel (its head has teeth) and others.

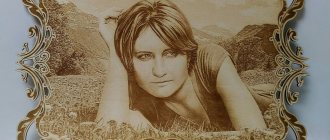

The photographs below show some home-made devices ready for practical use for a milling-type engraving device.

Additionally, special (for example, diamond) pastes are used with homemade products. At the same time, specialists achieve the result of finishing processing of workpieces of different densities, comparable in quality to the use of factory analogue burs.

Homemade engraver attachments are suitable for performing a variety of work at home. They will also save money through the use of available, cheap materials and parts from improvised or broken (unnecessary, old) mechanisms.

A wide variety of different attachments allows you to use a Dremel to perform a wide range of different jobs with different materials. It is better to select consumables that comply with the recommendations of equipment manufacturers. Professional kits are a guarantee of product quality, but they are expensive. To save money, you can make the necessary devices yourself. Just keep in mind that in this case the warranty service for the mini-drill is lost, and during operation the load on the tool may increase.

Ideas for using an engraver at home

The capabilities of the engraving machine are not limited to precision operations in the professional field. Using the device, you can easily solve minor household problems, for example:

- clean dishes and cutlery, as well as metal surfaces;

- sharpen scissors, knives, sharp objects, and other tools;

- polish the surface of plastic or metal products, jewelry;

- trim or grind small parts;

- apply a design to leather items, furniture;

- engrave an inscription on glassware and metal products;

- make a stone souvenir, keychain or pendant;

- clean the textured surface.

This list is quite diverse. Just use a little imagination and your home will be transformed.

As you can see, the scope of application of the engraver is quite wide. By choosing the right attachments, you can perform various types of work both in a specialized field and at home.

We examined the main issues in choosing attachments for an engraver, their characteristics, purpose and application. We got acquainted with the manufacturers and ratings of the most popular models. Taking into account all the nuances of the choice, you will acquire a truly useful set of tools that will delight you with reliability and long service life!

Video - What you can do with an Engraver

Recommendations for choosing nozzles

Typically, a milling attachment for an engraver is included with the purchased tool. But with constant use, it wears out over time. Also, cutters may be needed for specific operations - then you need to buy new burs in order to continue working with the Dremel.

The ideal option is to purchase products recommended by the engraver manufacturer. In such cases, the warranty from the companies for the device in use is retained. But it happens that original consumables cannot be obtained for some reason, or they will be very expensive given the small volume of upcoming work operations. Then you will need to purchase analogues or even use homemade ones. In this case, the main rules of choice are as follows.

- You should focus on the diameter of the shanks that is suitable for the Dremel chuck: most often it is 2.4 or 3.2 mm.

- You need to purchase attachments for metal and other materials depending on the type of work you plan to perform.

- To engrave, you can also use inexpensive kits, for example, made in China or Russia.

- For constant, long-term work with a mini-drill (especially with hard materials), it is recommended to purchase high-quality, professional sets, and for occasional engraving, household ones are sufficient.

When learning various Dremel operations, inexpensive products are suitable. Over time, they should be abandoned in favor of better quality equipment.

Voting for the best set of attachments for an engraver

Which engraver attachment set would you choose or recommend?

Bison 35902-N238

0.00 % ( 0 )

Dremel 723-100

0.00 % ( 0 )

Bison 35900-N180

0.00 % ( 0 )

Deko DH 100

0.00 % ( 0 )

Dremel 724 150

100.00 % ( 1 )

Stayer 2991-H5

0.00 % ( 0 )

Kolner KMGS 100

0.00 % ( 0 )

Stayer 29905-H134

0.00 % ( 0 )

Stayer 29900-H186

0.00 % ( 0 )

Mekkan MK 92704

0.00 % ( 0 )

KWB 5109-00 106

0.00 % ( 0 )

Stayer Master 29906-H191

0.00 % ( 0 )

Types and purpose of cutters and attachments

Drill attachments come in the following types:

- Abrasive attachments: cutting discs, cones, reverse cones and other rotating bodies. Designed for grinding thread parts.

- Wire brushes for roughing material.

- Steel cutters of different shapes. To perform basic operations - cutting out contours and sampling the background.

- Serrated blades. For processing thin relief details.

- Drill. For drilling through or blind holes.

- Balls for polishing and grinding thread parts.

- Felt circles. Serve for final polishing.

The cutters are made of high-strength and wear-resistant tool steel. Abrasive attachments are made mainly based on corundum. Abrasive attachments coated with diamond chips are particularly wear-resistant and precise.

Wood carving cutters

The collet clamp allows you to accurately secure and center the replacement tool. However, with strong lateral loads, its tightening must be checked periodically. The quick-release clamp does not have this drawback, but only tool shanks specially designed for it are suitable for it.

Diamond burs for engraving

Diamond burs rightfully hold the title of the most popular attachments for engravers. They are included in the professional packages of these instruments. The tool is strong and durable if used correctly.