Metallography is an applied branch of metal science that studies the structure and composition of metals and alloys. The subject of its study is the composition, shape, spatial arrangement, relationships, as well as quantitative and qualitative characteristics of the micro- and macrocomponents that form the physical structure of the metal. The main instrumental method used in metallography is the visual examination of polished samples of the material under study at high magnification.

At its core, metallographic analysis is universal and can be used not only to study the structural features of metals. Therefore, over time, it began to be used in the study of other materials, including non-metallic ones. As a result, new types of structural analysis have appeared: ceramography, plastography, etc., which use scientific developments, equipment and instrumental methods of metallography. Now all these areas are united into a single research discipline, which bears the general name of materialography.

What is metallographic analysis

Metallographic studies should not only determine the physical and chemical properties of a metal sample, but also describe such operational characteristics of its material as hardness, ductility, strength parameters, corrosion resistance, etc. Metallographic methods make it possible to obtain all these characteristics by studying the composition and structure of polished metal samples under a microscope at high magnification.

In the case of non-destructive testing, metallographic examinations are carried out directly on the product, for which portable optical equipment is used. During destructive testing, samples are cut out from the analyzed area of a part or workpiece, from which metallographic sections are then made - thin plates with a perfectly polished surface.

Most often, metallography is used in the study of samples made of steel and cast iron, which is due to the characteristics of the physical and metallurgical structure of these materials. Another area where metallography is widely used is the analysis of special alloys made of non-ferrous metals: titanium, tantalum, zirconium, etc. In addition, not a single examination of pipelines and metal structures that have been damaged as a result of accidents and disasters can be done without metallographic studies.

Inspection of welded joints

Methods for monitoring welded joints

The use of modern welding methods does not exclude the formation of various types of defects in the seams, which reduce the mechanical strength of welded structures. Defects in welds are divided into external and internal. External defects: uneven gap between the edges of the product, external cracks, cuts, lack of penetration, the presence of slag on the surface, etc. - are easily identified by external inspection.

Internal defects are: inclusion of slag and oxides, lack of penetration of weld edges, internal cracks, gas pores, etc.

The quality of weld metal and welded joints is checked both with and without destruction.

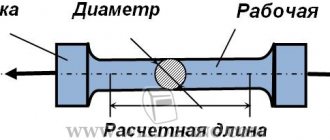

A static tensile test to failure of a sample cut entirely from deposited metal (Fig. 243, a) makes it possible to determine the yield strength, tensile strength, relative elongation and transverse contraction of the weld metal.

The tensile strength of the welded joint (Fig. 243, b) is determined by a tensile test.

The impact bending test of special notched specimens (Fig. 243, c) establishes the impact strength of the deposited metal or heat-affected zone. The static bending test of the welded joint (Fig. 243, d) gives an idea of the toughness of the metal. Determining the hardness of a seam and a welded joint gives an approximate assessment of the mechanical properties of the metal.

Rice. 243. Types of samples for testing: a - tensile testing of weld metal; b - welded joint; c - for impact strength and d - for static bending.

Hydraulic and pneumatic tests

Hydraulic and pneumatic tests of welded products are used for all products operating under pressure (containers, tanks, vessels, pipelines, tanks, etc.). The essence of the test is as follows: in vessels filled with water, using a hydraulic press, a pressure is created that exceeds the working pressure by 1.25 ÷ 1.5 times. After 5 minutes of exposure under this pressure, the latter is reduced to working pressure and then the product is tapped with a hammer to identify through hairline and other cracks. After the hydraulic test, a pneumatic test is performed, where the pressure is usually equal to the working pressure for a given vessel.

Testing seams with kerosene for density

Vessels operating without excess pressure are subjected to this test. The test consists of smearing the seam with chalk on one side, and brushing it with kerosene on the other. If there are through defects in the seam, spots will form on the chalk-coated surface, indicating a loose connection.

Metallographic studies

Metallographic studies of welded joints consist of analyzing the macro- and microstructure of the metal. Macrostructural analysis establishes the nature of primary crystallization, penetration depth, the presence of pores, slag inclusions, cracks, segregation and structural inhomogeneities. Microstructural analysis based on the structural composition determines the approximate carbon content in the deposited metal (when welding steels), the presence of inclusions of nitrides and oxides, the release of carbides in special steels, as well as microcracks, lack of penetration, etc.

Stages and methods of research

A comprehensive study of the physical composition and structure of the metal is carried out in specialized metallographic laboratories. Despite the wide variety of techniques intended for various metals and alloys, in general all research in metallography includes the following stages:

- Preparation of metallographic sections - thin polished metal plates.

- Various types of etching and other types of polished sections.

- Studying the structure of a sample under a microscope.

- Analysis of the obtained images and description of the results.

The choice of one or another method of metallographic analysis depends on the physical and chemical characteristics of the material being studied, among which one of the most significant are the sizes and contrast of its grains.

Sample preparation

In metallography, when preparing test samples, laboratory equipment is used that is designed specifically for grinding, polishing and etching.

Grinding and polishing units are machines with a round rotating table on which abrasive paper or non-woven material impregnated with a grinding suspension is attached. Metallographic sections are attached to the equipment using thermosetting polymers or epoxy resin, and the accuracy of their pressing to the grinding wheel is controlled by an electronic control system. After such processing, individual structural elements of the metallographic sample are clearly visible even with the naked eye, while others become clearly visible under an optical microscope. The crystal structure of some metals does not require additional chemical treatment, since it is clearly visible in polarized light. For other materials, metallography usually uses chemical or electrolytic etching, which makes the structural layout of the metallographic section more distinct.

Equipment

The grain size of metallic materials ranges from 1 to 1000 microns. Therefore, during metallographic studies, various types of equipment with appropriate resolution are used:

- light optical microscopes with various types of illumination;

- transmission electron microscopes;

- scanning electron microscopes;

- X-ray diffraction installations.

Optical microscopes used in metallography have a resolution of no more than 0.2 microns, and samples are usually studied at a magnification in the range of 50÷1000x. Metallographic analysis also uses equipment with much lower magnification, which allows large crystalline formations, such as dendrites, to be included in the field of view. To increase image contrast, microscopes in metallography are equipped with optical devices that make it possible to study an object in reflected light (using the light or dark field method) and with illumination by polarized beams.

If it is impossible to obtain proper results using optical equipment, electron microscopes are used in metallography. Such studies are resorted to much less frequently, since this type of metallographic analysis is much more expensive and takes more time. In addition, these devices have a number of technical limitations.

For scanning electron microscopes used in metallography, at magnifications less than 500x, the image clarity becomes lower than that of light microscopes. And translucent ones, as a rule, are not intended for use at magnifications less than 2000x. X-ray diffraction installations are used less frequently in metallography, because they are highly specialized and are more designed to determine the proportion of different fractions having different crystal structures.

Determination of quantitative indicators

Quantitative metallography is used to evaluate the geometric parameters and spatial arrangement of crystalline elements and impurities using various types of mathematical modeling. These can be either simple interpolation methods based on measuring the layer thickness or visible linear dimensions of particles, or the construction of stereometric models. In the latter case, metallography uses stereological methods, which make it possible to obtain quantitative information about a three-dimensional object by processing data obtained from the geometric characteristics of its two-dimensional sections.

Scope of application

Metallographic control is mandatory for those types of equipment where metal is exposed to high temperatures, critical pressure and aggressive environments. This includes installations, apparatus, pipelines and containers in the energy, oil and gas, chemical and nuclear industries. There are at least a dozen GOSTs that establish regulatory characteristics and procedures for the use of metallography, and an even larger number of industry instructions, methods and regulations. For example, metallographic methods for assessing the grain size of steel in high-pressure steam pipelines at power plants (t up to 600 ºC, P up to 200 atmospheres) are regulated by GOST-5639. And in the event of their emergency failure, the industry regulatory document prescribes mandatory metallographic control.

Have any of you ever encountered metallographic testing of welds? In what cases is this used and how do metallographic examinations relate to flaw detection? Please write about your experience in the comments to this article.

Where is metallography used?

In the oil and gas industry

Study of the operational reliability of field pipes (GOST R 53580-2009 “Steel pipes for field pipelines”) - metallographic inspection of the longitudinal weld seam of welded pipes

In the chemical industry

Metallographic examination (control) of the base metal and welded joints made by fusion welding from low-carbon, low-alloy, medium-alloy, high-alloy and two-layer steels, as well as non-ferrous metals (copper, aluminum, silver, titanium) in the manufacture of vessels and apparatus intended for work in oil refineries , petrochemical, chemical and gas industries. (RD 24.200.04-90)

In the heat-affected zone and in the base metal of the welded joint, if necessary, check:

- contamination with non-metallic inclusions according to GOST 1778;

- microstructure according to GOST 5640; GOST 8233;

- grain size according to GOST 5639;

- alpha phase content (in high-alloy steels) according to GOST 11878;

- susceptibility to intergranular corrosion according to GOST 6032.

Also, metallography is included in the list of studies to determine the residual life of technological equipment of oil refining, petrochemical and chemical industries (Module MOOR-98)

In energy

Quality assessment and investigation of the causes of damage to welded joints of steam pipelines of thermal power plants (MU 34-70-161-87). Grain score assessment of steam pipeline bends according to GOST 5639.