GAS FURNACE is an industrial furnace for melting metals using gas. The gas burner operates from a central gas line and cylinders. Russian factories successfully operate gas stoves; they are economical with low consumption. For ferrous and non-ferrous metals, we recommend Russian-made gas furnaces. ZAVODRR RUSSIA – these are gas furnaces for aluminum, copper, cast iron from professionals!

Operating principle of gas furnaces

Gas melting furnaces are quite economical due to the relatively low price of this type of fuel.

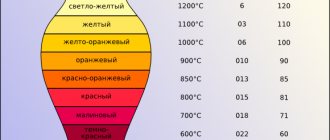

In such furnaces, very precise temperature control in the crucible is possible. High quality insulating materials can significantly reduce heat losses. Gas furnaces are used primarily for melting non-ferrous metals. The operating principle of such furnaces is based on the interaction of gas and air, forming a combustible mixture. A gas furnace for melting metals is characterized by fast heating and long-term maintenance of the optimal temperature inside the refractory chamber. Allows its use for the melting process of a wide range of materials.

Gas furnaces for melting non-ferrous metals

Non-ferrous metals include copper, magnesium, bronze, lead, aluminum, and titanium. Each metal has its own melting characteristics. Any gas furnace for melting non-ferrous metals must have the ability not only to melt, but also to quickly heat up. Depending on the required characteristics of the melt, the configuration of the furnace and gas burners is selected. Gas furnaces quickly melt non-ferrous metals, because they do not have a high melting point: aluminum 660 °C, copper 1083 °C, lead 327 °C, zinc 419 °C.

Non-ferrous metals are melted using a removable refractory graphite crucible. Conventional lining takes a lot of time (stuffing, drying). Crucibles are changed within 15-30 minutes without stopping the work process.

Reverb melting crucible

The reverberant melting crucible has served as a standard in aluminum production almost from day one. The variations in execution are impossible to list, as are all the types of scrap that were processed. Some models of this unit are stationary, tilt, front load, top load and multi-chamber models. Each of the listed models has its own strengths and weaknesses.

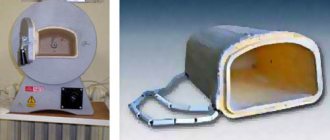

Front loading melting furnace

Front-load dryer (Figure 3) - a front-loading or front-loading oven is a device equipped with a door across the entire width of the oven to provide full access to the inside of the oven. Loading is done using a forklift or, more commonly, using a special loading machine. The advantage of this type of device is considered to be the ability to completely unload the furnace during continuous operation, as well as the ability to work with the highest possible productivity. The weak point of the oven is that it requires several loading operations to completely fill it due to the internal geometry of the oven. This furnace is suitable for large and medium-sized manufacturers for various smelting specifications.

Figure 3 – Front-loading melting furnace

Vertical loading melting furnace

Vertical loading (Figure 4) - a top (vertical) loading oven is a device with a removable lid to provide full access to the inside of the oven. Loading is done using a gantry crane and a loading bucket. The advantage of this type of model is the ability to fully load it in a very short time. The furnace is designed to be completely unloaded after each melting cycle, with the ability to easily change melts. The weakness of this furnace is the loss of heat when the lid is removed, which requires special control of the sequence of loading and melting operations.

This model is good for large aluminum processors, for large volumes, for processing a wide variety of scrap/scrap.

Figure 4 – Vertical loading melting furnace

Multi-chamber melting furnace

A multi-chamber melting furnace (Figure 5) is a complex of various chambers designed for special tasks of physically changing the processed scrap. Cameras are uploaded in a variety of ways, including uploading through the receiver, as well as uploading through the main portal.

Figure 5 – Multi-chamber melting furnace

The receptacle feed furnace includes an external receptacle for supplying feedstock. The standard set of processed materials includes extruded scrap, shavings and trimmings, bagged scrap, as well as material with low weight parameters and low relative density. This type of raw material requires rapid immersion below the crucible level to avoid oxidation and metal loss.

This type of furnace is recommended for use in the production of a limited number of smelts with a standard alloy recipe. The difficulty of multi-purpose application lies in the limited possibility of changing the recipe in this furnace model. The model can be a different combination of chambers, depending on the intended raw material and the available area for placing the furnace [9].

Gas furnaces for aluminum smelting

Aluminum smelting is carried out in electric, gas, crucible, electric resistance and induction furnaces. To obtain a well-mixed aluminum melt, it is best to use induction melting furnaces. If you want to save money, then you need to use gas ovens. In general, the choice of furnace depends on the purpose of the alloy and the nature of production.

Crucible or rotary furnaces are also used for melting aluminum and its alloys. A gas crucible furnace for aluminum melting has the necessary power and various modifications. In turn, crucible furnaces can be gas or induction. The model is selected depending on the current metal processing needs.

Budget gas furnace for aluminum smelting

Hello DIY enthusiasts, in this instruction we will look at how to make a budget furnace for melting aluminum. Having such a furnace, you can cast various aluminum products, including parts for homemade products. As for the source material, it can be free; for such purposes, you can melt drink cans, at the same time cleaning the environment. The stove is assembled on the basis of a fire extinguisher body; a gas cylinder is also suitable, but you need to work with it carefully. The oven is heated with a gas burner, and a household hair dryer is used to obtain the desired temperature. If you are interested in a homemade product, I suggest you study the project in more detail!

Materials and tools used by the author:

List of materials:

- fire extinguisher housing or gas cylinder; - small fire extinguisher (for the crucible); — bolts and nuts; — profile pipes; — wheels for trolleys; - round pipes; — heat-resistant paint; — refractory cement (or other insulator); — sheet stainless steel; - household hair dryer; — gas cylinder and gas burner; - round timber.

List of tools:

- Bulgarian; — drill with crowns; - welding machine; - Miter saw; - tape measure, marker.

Furnace manufacturing process:

Step one. Assembling the base

We assemble the base for the stove; for the body we will need a fire extinguisher or a similar tank. If you use a gas canister, be sure to clean the inside of it or take other measures to make cutting safe. We cut off the neck of the fire extinguisher; this part will later be the lid for our stove.

Next, we will make a base for the body on which the stove will stand. We weld a crosspiece from profile pipes, and for convenient movement of a heavy stove, the author installed wheels from a cart on the crosspiece. We weld the crosspiece to the stove body and additionally strengthen the structure with round timber posts.

Step two. Lid

We make a lid for the stove, the neck of the fire extinguisher acts as it. The lid will be filled with cement, so it will be quite heavy and will need a strong hinge. The author vertically welded a round piece of wood to the stove, which acts as an axis, and a piece of pipe is welded to the lid. As a result, the lid opens to the side with a slight movement of the hand.

Step three.

Inner insert We need to make an inner insert, this will be the part of the oven in which the very high temperature will be reached. We make the insert from stainless steel and it is better to choose a thicker metal. We cut off the required piece and bend it into a pipe, welding the joint. We also weld the bottom from a piece of stainless steel.

Step four.

Final touches with the body In the body of the furnace, as well as in the insert, we drill a hole with a crown, and then insert a pipe through which hot gases will flow into the furnace. We weld the pipe well to the body and to the insert. As for the lid, you will need to weld a piece of iron pipe from the inside, which is needed to pour the insulator into the lid. We also weld a long handle in the form of a piece of iron pipe to the lid. In order for the solution to be securely fixed in the lid, it is recommended to weld iron plates, bolts, etc. to it from the inside.

Step five.

Pouring the insulator The body is ready, pour the insulator inside the furnace. For such purposes, it is recommended to use heat-resistant oven solutions. Regular cement will crack quickly. If there is nothing suitable, you can use clay and sand. To increase strength, the author decided to reinforce the solution with iron mesh. Distribute the solution evenly inside and let it dry for two days or more.

Step six.

Final touches Finally, we need to weld the pipe to the pipe to install the gas burner, after which the stove can be started. We light the burner, and to obtain a large amount of heat, we pump air with a household hairdryer. The flames are seething in the furnace, it should burn during the first start, and moisture will also come out of the insulator.

Step seven.

Crucible We make a crucible for melting aluminum, here the author used a small fire extinguisher, release the contents and cut off the neck. Next, we need to weld the bolts and nuts to the body; we will use them to grab the crucible with a handle. As for the handle, we bend it from round timber. Everything must be reliable, otherwise liquid metal poured on you can be fatal.

That's all, now you can get to work, load the aluminum, install the crucible in the furnace and start it up. As aluminum is melted, it must be added to the crucible and stirred. Slag will form on top, it is advisable to remove it. As a result, the author cast a massive aluminum plate, pouring the contents of the crucible into sand. At this point the project can be considered completed, I hope the homemade product was useful for you, and you found interesting ideas. Good luck and creative inspiration if you decide to do this again. Don't forget to share your ideas and crafts with us!

Source

This post may contain affiliate links. This means I earn a small commission from links used at no additional cost to you. See my privacy policy for more information.

oven, melting, do it yourself

Gas furnaces for melting ferrous metals

Ferrous metals can be smelted in different furnaces. Induction steelmaking furnaces are considered ideal, but they consume a large amount of electricity. Therefore, some foundries use gas furnaces. Ferrous metals take longer to melt in such furnaces and do not have the best chemical composition, but the savings are 2-3 times.

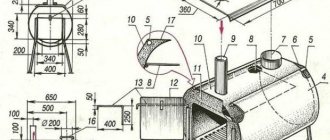

Rotary oven Scrap Manager™

The Scrap Manager™ rotary oven has an external shape that almost resembles an inclined cylindrical oven, but rotates around its central axis. This oven first appeared on the market at the end of 1970 and has undergone numerous improvements since then (Figure 2).

Figure 2 – Scrap Manager™ tilting rotary ovens

The Scrap Manager™ rotary furnace is used to remelt rejected castings, extruded scrap, used can scrap (UBC), and aluminum dross. This type of scrap has a relatively low density relative to surface area. Therefore, the material must melt quickly to avoid burning out a thin layer of material.

Suitable for melting various alloys, which involves frequent changes of metals in the furnace and for processing all kinds of scrap/scrap. The furnace can operate on clean and contaminated scrap using proper equipment to limit environmental pollution. The furnace is used as a secondary cycle melting furnace, and also as a primary unit for recycling its own waste. Also used for recycling automotive lead-alkaline batteries.

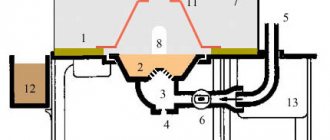

Gas muffle furnaces

A muffle furnace for melting metal can be electric or gas. Metal processing takes place in a muffle - a special space that prevents metal from coming into contact with fuel. Gas muffle furnaces vary in temperature level in the working space. Muffles can be ceramic, fiber or ceramic fiber. Muffle furnaces are used for heat treatment and smelting of non-ferrous metals, they have limited melting temperatures, and are suitable for both domestic and industrial use.

The gas muffle furnace is characterized by internal design features and contains a heavy-duty muffle chamber inside, which additionally protects the metal from foreign impurities during remelting.

Making a nozzle with your own hands

Before you start using a product made at home with your own hands, you need to go through the following procedures:

- The burner must undergo a quality check at the local Rostechnadzor office in accordance with the regulations established in the Federal Law on the Safety of Buildings and Structures dated December 30, 2009.

- After this check, it is necessary to obtain a certificate from Rostekhnadzor regarding the suitability of the burner for operation.

Read also: DIY wind vane

In order to start making the nozzle, you need the following materials:

- A valve that will serve to regulate the fuel supply of the device. To supply gas to the burner, you must use the valve installed on the gas source.

- Steel pipe. It is desirable that it have a thickness of up to 2 mm and a length of up to 100 mm.

- Steel cap for making a fuel dispenser. You can also use a jet from a blowtorch.

- Steel handle. It can be made from a regular fitting.

- Rubber for handle lining.

- Wire. It will be used for welding.

You will also need the following tools:

- Welding machine.

- Grinder for cutting parts.

For homemade production, an atmospheric nozzle is preferable due to the simplicity of its design. The procedure is as follows:

- First, screw the cap onto the valve. For example, if a standard VK-74 valve is used, then the cap has a conical thread.

- Then, by cutting the existing steel pipe with a grinder to the required size, the nozzle of the future nozzle is made - its basis.

- Next, the nozzle is welded to the cap using wire. In this case, the cap and nozzle should not touch.

- A piezoelectric element is installed , which is needed to activate the device.

After this, the product is ready for installation.

Attention! To install a system for supplying fuel to the stove from a central heating system, you need special equipment and experience working with gas systems.

Furnace installation

When installing a finished unit in a furnace, take into account what materials it is made of:

The gas nozzle - the heart of the stove - must be of high quality and correctly installed. If this unit malfunctions, fuel-related problems may occur, which can lead to irreversible consequences.

Gas consumption of gas melting furnaces

Gas consumption during operation of melting furnaces depends on the gas burner. Low and medium pressure burners are installed on gas thermal furnaces. A correctly selected gas burner should provide:

- supplying the required amount of gas and air to the combustion zone;

- good mixing of the charge;

- complete combustion of gas with a minimum excess air ratio;

- good heat exchange inside the melting unit, eliminating local overheating;

- stable operation within the required range of changes in thermal output.

Gas consumption when melting 1 ton of copper or aluminum charge ranges from 60 to 100 m3/hour.

Manufacturing and installation of a burner in a closed gas furnace

Let's consider two options - make a burner from scratch, using the recommendations of experienced home craftsmen, or use a ready-made design, adapting/modifying some of its characteristics. It should be noted that in the first case you should have very high qualifications, as well as have experience in setting up and, at a minimum, repairing such devices. Otherwise, the matter may end in an explosion, burns, and other troubles. The easiest way for a forge is to make a ball burner, which belongs to the group of fuel-burning units with a tangential supply of a torch to the working space of the forge. This burner consists of the following parts:

- Confusion bell made of heat-resistant steel type X18N9T.

- Steel tubular body shaped like a double truncated cone.

- Gas supply head.

- Air supply head.

- Mouths.

- Regulators for the amount of gas-air mixture.

To make such a burner you need: 1.5-inch pipes, a sheet blank with a thickness of at least 1.2 mm for the confuser, two fittings and three flanges for connecting the elements. It is better to make a welded structure from heat-resistant steel, and welding must be done under submerged arc or using inert gas. High-pressure hoses can be used as air and gas supply pipes, the diameters of which will correspond to the connecting dimensions of the housing. Fixing clamps and high-quality seals made of gasoline-oil-resistant high-temperature rubber are also required. All other elements are connected using threads.

Read also: Melting lead at home

Horn with a homemade gas burner

On some websites there are recommendations for making a burner body by rolling a tubular blank. But at high jet pressures, plastic hardening of the material can lead to the emergence of zones of internal stress, which, when starting the burner, often cause cracking in the body metal.

The option of installing a burner from a used gas stove is much simpler. You will first need to determine the fuel costs required to quickly heat the metal for forging. When selecting a finished design, the power of the main unit (boiler, stove, etc.) for which the device was used is established. The product of this value by the efficiency (for gas it is 0.89...0.93) gives the desired power value W. It is a little more difficult to establish the gas consumption T. The calculation algorithm is as follows:

- The calorific value of the fuel Q is determined (for propane, 3600 kJ/m3 can be taken);

- Using the formula T = 3.6W/Q, the flow rate is determined.

- Based on the calculation results, all the necessary shut-off and control valves are selected: valves, tees, o-rings, etc.

Installing a burner in a forge for forging with your own hands is done as follows. First, a confuser is inserted into the prepared lining hole, and the burner mouth is attached to it through a sheet gasket made of heat-resistant steel. The product itself is attached to it, and tubes for supplying air and gas are screwed in. They check the effectiveness of the regulators, after which they carry out a test run of gas from a cylinder or a stationary network. All work must be carried out in a well-ventilated area. At the slightest smell of gas, installation work is stopped and the source of possible leaks is determined.

If you find an error, please select a piece of text and press Ctrl+Enter.

Gas burners, also called burners, are key design elements of any gas furnace.

The task of such a device is to create a mixture of fuel , in this case natural gas, and air in order to maintain the combustion process in the heating device.

Hydraulic gas furnaces

Hydraulic gas furnaces save resources due to the absence of intermediate heating elements. During the melting of metal in crucible gas furnaces, no smoke or unpleasant odor is generated, which creates comfortable working conditions.

Hydraulics has a distinctive feature: it is a smooth and uniform drainage of metal. Hydraulic cylinders and a hydraulic station help with this.

| Options | RG-150A | RG-250A | RG-450CA | RG-500 |

| Operating temperature, ˚С | 850 | 850 | 1250 | 1250 |

| Maximum load for aluminum, kg | 250 | 250 | 450 | 500/1500 |

| Melting speed for aluminum, copper kg/h | 100 | 100 | 150 | 200-250/600 |

| Gas consumption, m3/t | 90-110 | 90-110 | 90-110 | 90-110 |

| Temperature control accuracy, ˚С | ±5 | ±5 | ±5 | ±5 |

| Surface temperature, ˚С | ≤50 | ≤50 | ≤50 | ≤50 |

| Control cabinet voltage | 220V 50HZ | 220V 50HZ | 220V 50HZ | 220V 50HZ |

| Tilt speed, mm/sec | 30-70 | 30-70 | 30-70 | 30-70 |

Gas furnaces with gearbox

Gas furnaces on a gearbox for melting metal create a high temperature in the melting unit. Such furnaces can easily melt non-ferrous and ferrous metals with a melting temperature of up to 1600 °C within 30-60 minutes.

The gearbox allows you to perform an emergency manual drain of metal in the event of a power outage.

Stationary shaft gas furnaces

Stationary shaft gas furnaces differ from other models in the absence of a tilting mechanism to drain molten metal. The molten metal is in a graphite crucible, and after the smelting process it is removed from the furnace manually using lifting mechanisms.

The range of stable operation of the burner of a stationary gas furnace is characterized by its regulation of thermal power, i.e., the ratio of the maximum thermal power to the minimum, showing its accelerated capabilities. The burner design must provide the thermal power required for the installation, a wide range of gas flow control, flame stability without the use of artificial combustion stabilizers, and the absence or acceptable concentration of harmful substances in combustion products.

In the case of short-term operation on gas of a different composition, there is no point in remaking the burner, but it is better to recalculate the nominal pressure of the gas and air in front of it. The amount of combustion air remains practically constant if the thermal power of the burner is maintained.