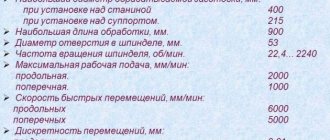

Parameters of the Quantum 250 model

Screw-cutting lathes “Quantum 250” have an electric motor with a total power of 750 W. In this case, the frequency indicator is at around 50 Hz. The height of the centers is 125 mm. The machine can process a part with a length of no more than 550 mm. The width of the device frame is 135 mm. The average spindle speed is 600 rpm. The maximum is allowed to reach 2800 rpm. The internal cone is installed in the MK 3 series.

The spindle diameter is 21 mm. The stroke of the upper carriage of the caliper is 70 mm. The quill cone in the device is of class MK 2. The tailstock can be moved to a distance of no more than 70 mm. In this case, the longitudinal feed is 0.1 mm per revolution. The metric thread pitch limit is 3.5 mm. The length of the mechanism cutter is 13 mm. The total height of this screw-cutting lathe is 1250 mm, width 600 mm, depth 475 mm. The weight of the unit is 125 kg.

Operating instructions, passport

Before starting work, it is necessary to check the oil level in the oil indicators. Apply the required amount of oil to all indicated lubrication points. Check the strainers for chips and dirt. If necessary, rinse in kerosene.

Pour coolant into a special container in the cabinet.

Conduct an external inspection of electrical equipment.

- Why get started:

- Set the spindle rotation speed.

- Set the feed amount.

- Start work.

After finishing, clean the machine from chips and dirt, clean the filters.

The lathe's passport can be downloaded for free from the link - Passport for the OT-5 screw-cutting lathe.

Varieties

The choice of equipment is based on its purpose and the purpose for which it is purchased. Before making a purchase, you need to determine exactly for what purposes it will be used. According to their purpose, all turning units are divided into three main types:

Tabletop

Desktop devices that are used at home have the main difference in size, and therefore weight. Their smallest weight is 13 kilograms, and the maximum should not be higher than 100 kilograms. This type of machine is used to process small metal parts.

Using this device, you can perform the following operations:

- Grind parts in the shape of a cylinder or cone.

- Trim the ends of the parts.

- Sand the finished product.

- Make a hole in the part by drilling.

- Widen the hole.

- Apply both external and internal threads.

Important!

It will not be possible to process parts at the same speed on a home lathe as on professional equipment. But the finished product will be of the same quality. This will be especially noticeable if the operation of the unit is controlled using a numerical control system.

Similar metal lathes have many areas where they are used. In particular, they are used in small workshops, and not just at home. Also in car repair shops.

Universal

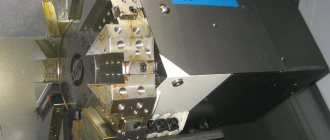

In the second half of the 20th century, technology made it possible to abandon narrow-profile special machines and move to the use of a device that has the ability to cope with many tasks simultaneously. Universal machines are capable of performing more than one operation at a time.

The two main parameters are the largest diameter of the workpiece that can be machined above the bed and also the largest distance between the rotating centers. These are the two main parameters that set the maximum dimensions of the parts. Universal machines are easy to use and easy to maintain.

Important!

Unlike similar CNC models, universal machines can be purchased at a fairly low price.

School

A lathe of this type is a real godsend for many, since it is easy to use this equipment and almost everyone can learn how to operate it. Using it, you can easily process elements of any shape, including conical and cylindrical, you can cut threads without any problems and even, if necessary, roll, grind and sharpen tools.

In this case, you can process not only metal, but also plastic and wood. By purchasing additional devices, you can expand the capabilities of the device. For example, cutting teeth, doing milling. This machine can process wheelsets, couplings and other complex elements.

However, the capabilities of the teaching machine have limitations, but this does not affect its demand. With its help you can perform a set of standard operations. The training machine is compact and oversized, so you don’t need a large room to place it; a garage or a small school classroom will suffice.

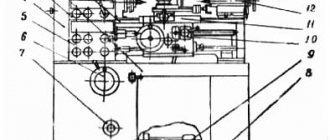

Lathe-screw-cutting

The most popular in demand is the screw-cutting lathe. Machines of this type are used for turning and many other operations. This machine can process products weighing up to 10 tons, and the distance between centers can vary within 8 meters.

Recommended Specifications and Features

Based on established standards of technical characteristics, you can choose a high-quality machine at an affordable price. Different types of machines: lathes, drilling, boring, gear cutting, etc., have different technical features that need to be paid attention to in order to avoid problems and early equipment failure.

Dimensions

The main parameter based on which the machine is selected is size. Each machine, presented in a range of sizes, has standardized components. This indicates that the design process has been greatly simplified and the cost of repairs will be less.

The construction of size ranges is carried out in accordance with a geometric progression, where the main parameter is located in the same row. The standard width of the product should be 2000-3150 mm.

Weight

The weight of the machine must correspond to approximately 2140 kg, and the maximum weight of the workpieces processed: the maximum weight of the part installed in the chuck is 300 kg, and on the centers - 1.3 tons.

Workpiece diameter

The largest diameter of the workpiece, which is recommended, passing through the inside of the spindle hole is 45 mm, despite the fact that the hole itself is 47 mm. Above the bed, the diameter of the workpieces is 400 mm, and above the support – 220 mm.

Center-to-center size

Overall dimensions of the machine with a center distance of 1000 mm: length - 2812 mm, width - 1166 mm and height - 1324 mm.

Drive power

The drive power should be approximately 10 kW.

Machines of the Triod brand

The machines are distinguished by their versatility. At the same time, it is possible to bore various parts. The voltage of the devices is quite high. Separate mention should be made of management. There are usually 6 speeds for spindle rotation. Quill cones, as a rule, are installed in the MK 2 class. At the same time, the internal cone of the spindle is in the MK 4 series. The maximum diameter for processing parts on machines is no less than 130 mm. In this case, the length of the product is allowed up to 700 mm. The rotation speed limits are quite wide. The mechanism can be accelerated to a maximum of 1600 rpm. The only drawback is the problematic gearbox. In some cases, it may jam, and then the machine has to be sent in for repairs.