When sending large-sized cargo, there is a need for reliable, high-quality packaging and securing, ensuring maximum safety during transportation. Unlike traditional packaging materials - cardboard, polyethylene, wire, boxes made of boards, etc. - durable steel tape reliably fastens loads.

Products of any weight, dimensions, types are tied and firmly fixed. Fastening metal strips are used even when transporting fragile products packed in low-reliability containers. For example, double-glazed windows, trays of eggs, boxes of dishes, cans of preserves, etc.

What materials is the bandage tape made from?

The main raw material is high-quality low-carbon steel or stainless steel AISI 201, A-2, which has high strength and resistance to adverse weather conditions (temperature changes, high humidity).

The most common grades of low-carbon steels are manufactured according to GOSTs 380-88, 1050-88, 16523-89:

- Steel 70.

- Steel 10.

- 08 KP.

- 08 PS.

- 1 PS.

- Steel 45.

- 60С2А.

- 51HFA.

Steel strips that have undergone additional heat treatment maintain geometric parameters, retain the shape of the packaged product, and do not deform it during loading/unloading, transportation, or storage. Metal packaging does not change its properties and retains its original shape in frost and heat.

Metal tapes treated with zinc, anti-corrosion varnish or special polymer coatings are used to fasten products that are stored for a long time in the open air or in large refrigerated compartments.

Galvanized products do not rust, remain unchanged when in contact with aggressive chemicals, and have increased strength and tear resistance.

Types of steel packaging tapes

Depending on the accuracy of execution, the packaging material is marked with the letters T and Ш:

- W – accuracy of tape width 15 – 50 mm;

- T – thickness accuracy 0.2–1.8 mm;

- There are no markings on standard precision products.

Classification of low-carbon steels depending on the physical state of the material:

| Tensile strength (N/mm2) | Elongation level (%) | |

| N – hard-worked | 60 | not indicated |

| PN – semi-hardened | Z5 | from 7 |

| M – soft | 25 | from 17 |

Steel strips are produced in three stages:

- Cutting.

- Heat treatment, galvanizing.

- Applying varnish or other coatings.

- Packing in rolls.

Winding of rolls is carried out in several ways: single-, double-, multi-row, “jumbo”. The ends of the winding are fixed with interlocking perforated joints.

Advice: When choosing packaging material, you need to know the technical characteristics of the goods (dimensions, weight, product category). It also doesn’t hurt to know the quality of the road surface, distance, travel time.

What is cold-worked steel

Metal hardening (hardening of the surface layer) is performed in two ways:

- Mechanical processing (plastic deformation of metal workpieces by external mechanical influence, for example, cold hardening, “firing” of parts with shot from hard grades of steel).

- Heat treatment (plastic deformation, stamping of soft plastic tape, annealed in a special furnace).

A little theory: As a result of hardening, the internal parameters of the metal change: the structure of low-carbon steels, the crystal lattice, the phase composition. The outer layer of cold-worked metal acquires additional strength and hardness.

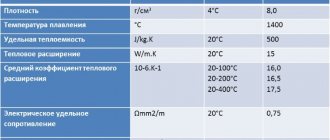

Main characteristics

For types of metal packaging tape (GOST 3560-73), minimum tensile strength values are provided:

- soft – 250 N/mm;

- semi-hardened – 340 N/mm;

- cold-worked – 590 N/mm.

Another important characteristic is the relative elongation indicators. The minimum value is regulated by type:

- for semi-cold-hardened – 7%;

- for soft ones – 17%.

Packing tape dimensions:

- width – 15; 20; thirty; 40; 50 mm;

- thickness – 0.20; 0.25; 0.30; 0.40; 0.50; 0.70; 0.80; 0.90; 1.0; 1.2; 1.5; 1.8 mm.

Consumers have the opportunity to choose products of varying production precision, which can be normal or increased in terms of thickness and width. Steel tape for packaging is sold in rolls. Weight ranges from 20 to 200 kg (according to the width of the products).

During the production process, quality control of the packaging tape is carried out. Products must have no torn, uneven edges and no delamination. Allowed:

- small films (detachments);

- minor marks on the metal surface;

- subtle risks;

- minimal layer of scale.

Conditions for delivery and storage of steel packaging tapes

- Before shipping, the rolls are stacked in stacks of several pieces.

- To prevent the stack from falling apart and maintaining stability, it is tied in several places with wire or rigid metal strips.

- To prevent steel strips from losing their presentation during transportation, they are pre-coated with a protective layer of preservative industrial lubricant.

- The finished stacks are wrapped in polyethylene, container fabric, waxed paper, or polymer film.

Important: In some cases, for a fee, they are wrapped in thin sheet steel. To facilitate loading/unloading, they are placed on special wooden or metal pallets and firmly fixed with steel strips.

Basic requirements for packaging steel strips

- the surfaces of metal strips must be smooth without breaks or delaminations;

- the tape goes on sale in the form of rolls weighing 40–200 kg and a width of more than 20 mm; and with a width of up to 20 mm, the permissible weight of the roll is 20 - 80 kg;

- Large dents are not allowed on the edges of the strips;

- deviation from straightness (crescent) should not be more than 5 mm per linear meter.

Small defects are allowed on metal surfaces: specks, prints, the thinnest layer of scale, barely visible marks, depressions, minimal peeling.

Packing steel tape, from 55 rubles per kg.

Packaging cold-rolled steel tape , made from low-carbon high-quality steel, is ideal for enterprises and firms that regularly deal with tying various types of reinforcement, construction products, rolled metal (for example, stainless pipes), transporting double-glazed windows and other fragile items that require careful handling during transportation.

Cold-rolled steel packaging tape is not afraid of the influence of aggressive chemical compounds and dampness, since most of it is produced with a special polymer coating made of galvanized material, which perfectly protects the product from external influences throughout the entire period of its use. GOST 3560 divides packaging tape into several types according to the following indicators:

- in terms of production accuracy: W - increased accuracy in width and T - in thickness, standard accuracy according to the specified parameters (the product is sold without applying additional markings);

- according to the condition of the material: N - hard-worked, PN - semi-hardened, M - soft.

The thickness of the tape varies from 0.2 to 1.8 mm, width - from 15 to 50 mm. Permissible deviations in product dimensions depend on their specific parameters and accuracy class; they can range from 0.02 to 0.15 mm in length and from 0.5 to 2 mm in width. By agreement with the buyer, the product can be produced with a non-standard width (for example, 321, 137, 239, 120 mm), but provided that its thickness is within 0.25–0.4 mm (width deviation in this case should not exceed 1 mm).

The relative elongation of strips made of semi-work-hardened material should be more than 7% (of soft material - more than 17%), elongation for strips of cold-worked metal is not provided. The packaging product, in addition, must have the following indicators of (temporary) resistance to tearing:

- cold-worked material – from 60 N/mm2;

- semi-hardened – from 35 N/mm2;

- soft – from 25 N/mm2.

Steel with low carbon content (51HFA, 70, 10, 08kp 1ps, 60S2A, 45, 08ps and others) for the production of packaging tape must comply with the provisions set out in State Standards 1050-88, 380-88, 16523-89. In some cases, it is possible to manufacture products from carbon steels, if the consent of the consumer is obtained.

Special requirements for the characteristics of the finished product:

- absence of delaminations and flaws on the surface of the product;

- weight of one roll: 40–200 kg with a tape width of more than 20 mm and 20–80 kg with a width of up to 20 mm;

- small individual dents on the edges of the product are possible, but they should not have dimensions exceeding more than half the permissible deviations in width;

- per 1 m of tape length, a crescent shape of up to 5 mm is allowed.

| Name | Thickness, mm | Width, mm | Price |

| Steel packaging tape | 0.3 | 20 | Check price |

| Steel packaging tape | 0.3 | 45 | Check price |

| Steel packaging tape | 0.4 | 20 | Check price |

| Steel packaging tape | 0.5 | 19 | Check price |

| Steel packaging tape | 0.5 | 20 | Check price |

| Steel packaging tape | 0.7 | 19 | Check price |

| Steel packaging tape | 0.7 | 20 | Check price |

| Steel packaging tape | 0.8 | 19 | Check price |

| Steel packaging tape | 0.8 | 20 | Check price |

| Steel packaging tape | 0.9 | 20 | Check price |

| Steel packaging tape | 0.9 | 30 | Check price |

| Steel packaging tape | 0.2 | 15 | Check price |

| Steel packaging tape | 0.2 | 20 | Check price |

| Steel packaging tape | 0.2 | 30 | Check price |

| Steel packaging tape | 0.2 | 40 | Check price |

| Steel packaging tape | 0.2 | 50 | Check price |

| Steel packaging tape | 0.25 | 15 | Check price |

| Steel packaging tape | 0.25 | 20 | Check price |

| Steel packaging tape | 0.25 | 30 | Check price |

| Steel packaging tape | 0.25 | 40 | Check price |

| Steel packaging tape | 0.25 | 50 | Check price |

| Steel packaging tape | 0.3 | 15 | Check price |

| Steel packaging tape | 0.3 | 30 | Check price |

| Steel packaging tape | 0.3 | 40 | Check price |

| Steel packaging tape | 0.3 | 50 | Check price |

| Steel packaging tape | 0.4 | 15 | Check price |

| Steel packaging tape | 0.4 | 30 | Check price |

| Steel packaging tape | 0.4 | 40 | Check price |

| Steel packaging tape | 0.4 | 50 | Check price |

| Steel packaging tape | 0.5 | 15 | Check price |

| Steel packaging tape | 0.5 | 30 | Check price |

| Steel packaging tape | 0.5 | 40 | Check price |

| Steel packaging tape | 0.5 | 50 | Check price |

| Steel packaging tape | 0.7 | 15 | Check price |

| Steel packaging tape | 0.7 | 30 | Check price |

| Steel packaging tape | 0.7 | 40 | Check price |

| Steel packaging tape | 0.7 | 50 | Check price |

| Steel packaging tape | 0.8 | 30 | Check price |

| Steel packaging tape | 0.9 | 15 | Check price |

| Steel packaging tape | 0.9 | 40 | Check price |

| Steel packaging tape | 0.9 | 50 | Check price |

| Steel packaging tape | 1 | 20 | Check price |

| Steel packaging tape | 1 | 30 | Check price |

| Steel packaging tape | 1 | 40 | Check price |

| Steel packaging tape | 1 | 50 | Check price |

| Steel packaging tape | 1.5 | 30 | Check price |

| Steel packaging tape | 1.5 | 40 | Check price |

| Steel packaging tape | 1.5 | 50 | Check price |

| Steel packaging tape | 1.8 | 30 | Check price |

| Steel packaging tape | 0.5 | 13 | Check price |

Standard sizes and prices of cold-rolled tin-plated low-carbon steel strip

| Name | Dimensions, mm | Price |

| Cold-rolled tin-plated steel strip | 0.11x43-45 | Check price |

| Cold-rolled tin-plated steel strip | 0.30x52.7 | Check price |

| Cold-rolled tin-plated steel strip | 0.30x130 | Check price |

| Cold-rolled tin-plated steel strip | 0.35x59-70 | Check price |

| Cold-rolled tin-plated steel strip | 0.35x100 | Check price |

| Cold-rolled tinned strip | 0.3x52.7 | Check price |

| Cold-rolled tinned strip | 0.3x130 | Check price |

| Cold-rolled tinned strip | 0.35x70 | Check price |

| Cold-rolled tinned strip | 0.35x59 | Check price |

| Cold-rolled tinned strip | 0.35x100 | Check price |

Standard sizes and prices of cold-rolled low-carbon steel strip

| Name | Thickness, mm | Width, mm | Price |

| Cold-rolled strip made of low-carbon steel 0.10-0.49x38 | 0,10-0,49 | 38 | Check price |

| Cold-rolled strip made of low-carbon steel 0.50-0.99x36 | 0,50-0,99 | 36 | Check price |

| Cold-rolled strip made of low-carbon steel 1.00-2.00x34 | 1,00-2,00 | 34 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.4x15 | 0,4 | 15 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.5x15 | 0,5 | 15 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.8x15 | 0,8 | 15 | Check price |

| Cold-rolled steel strip made of low-carbon steel 0.9x22 | 0,9 | 22 | Check price |

| Cold-rolled steel strip made of low-carbon steel 1.0x24 | 1,0 | 24 | Check price |

| Cold-rolled steel strip made of low-carbon steel 1.2x30 | 1,2 | 30 | Check price |

| Cold-rolled steel strip made of low-carbon steel 1.5x34 | 1,5 | 34 | Check price |

Standard sizes and prices of steel tape for cable armoring

| Name | Thickness, mm | Price |

| Steel tape for cable armoring (galvanized) | 1,00 | Check price |

| Steel tape for cable armoring (galvanized) | 0,80 | Check price |

| Steel tape for cable armoring (galvanized) | 0,50 | Check price |

| Steel tape for cable armoring (galvanized) | 0,40 | Check price |

| Steel tape for cable armoring (galvanized) | 0,30 | Check price |

Packing cargo with steel tape

Metal bandage tapes are manufactured in accordance with GOST 3560-73. They are in demand in warehouses and in the workshops of manufacturing enterprises:

- woodworking and furniture factories;

- reinforcement, pipe, rolling lines;

- enterprises producing building materials (bricks, pipes for ventilation, heating, lumber, foam blocks, fittings, double-glazed windows);

- mechanical engineering;

- food, light industry.

Products are stacked in stacks, stacks, groups and firmly fixed using steel straps. Volumes are created that differ in shape, weight and other parameters. The formed batches are loaded onto vehicles for shipment to the consumer or distributed compactly on pallets or warehouse shelves.

Helpful advice: To simplify work with elastic metal, workers use mechanical devices to tighten the tape. Special devices tension the metal and create the necessary tightening force. The goods do not wrinkle, but also do not fall apart during storage, transportation and loading/unloading.

Universal steel strips are used both for bonding coarse building materials and for transporting delicate loads.

Thanks to the formation of additional stiffening ribs, crumpled packages placed in stacks are reliably protected from possible deformations when they come into contact with each other or adjacent surfaces.

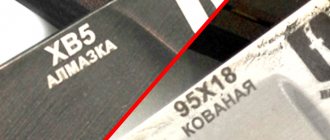

Steel packing tape

steel tape is available in three versions:

- with anti-corrosion coating (black + wax);

- galvanized;

- without cover.

By type, tapes are divided into:

- soft (350N/mm2)

- cold-worked (750N/mm2)

- high strength (850N/mm2)

By winding, tapes are divided into:

- single-row

- multi-row

- jumbo

Uncoated tape

Coated Tape (Black + Wax)

Steel tape, metal tape is cut from high-quality steel 08PS, St3, 08KP, 08Yu according to GOST 3560-73, GOST 503-81. Steel belts are used for packaging various materials (brick, wood, tiles, etc.). Metal packaging tape is widely used for lining boxes, containers, and pallets for various purposes.

Steel metal tape is used with manual packaging tools: MUL-17 (Ukraine), M4K-10 (Ukraine). This tool does not require staples to attach the tape; the tape is cut through, forming a reliable, strong dovetail connection.

steel packaging tapes are fastened using metal staples with a special tool: a manual mechanical tool (tensioner and clipper) or an ITATOOLS pneumatic tool.

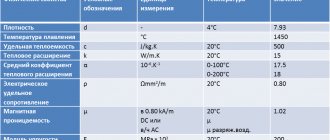

Technical data, steel strip

| Tape dimensions mm | There are grams in one meter | Breaking force, kg | Approximate number of kg in one ring |

| 0.3x20 | 48 | 200 | 60-80 kg |

| 0.35x20 | 56 | 240 | 60-80 kg |

| 0.4x20 | 64 | 270 | 60-80 kg |

| 0.45x20 | 72 | 300 | 60-80 kg |

| 0.5x13 | 52 | 220 | 20 kg |

| 0.5x13_nagart. | 52 | 490 | 20 kg |

| 0.5x15 | 60 | 250 | 20 kg |

| 0.5x16 | 64 | 270 | 20 kg |

| 0.5x16_nagart. | 64 | 610 | 20 kg |

| 0.5x16_galv. | 64 | 270 | 20 kg |

| 0.5x19 | 76 | 320 | 20 kg |

| 0.5x19_nagart. | 76 | 730 | 20 kg |

| 0.5x19_galv. | 76 | 320 | 20 kg |

| 0.5x20 | 80 | 340 | 60-80 kg |

| 0.5x20_nagart. | 80 | 765 | 60-80 kg |

| 0.5x20_galv. | 80 | 340 | 60-80 kg |

| 0.5x28 | 112 | 470 | 30 kg |

| 0.5x28_galv. | 112 | 470 | 30 kg |

| 0.5x36 | 144 | 600 | 40 kg |

| 0.5x36_galv. | 144 | 600 | 40 kg |

| 0.7x20 | 112 | 470 | 60-80 kg |

| 0.7x20_nagart. | 112 | 1070 | 60-80 kg |

| 0.7x30 | 168 | 707 | 80-100 kg |

| 0.8x30 | 192 | 805 | 90-110 kg |

| 1.0x30 | 240 | 1010 | 110-120 kg |

| 1.2x30 | 288 | 1210 | 120-140 kg |

| 1.5x30 | 360 | 1515 | 120-140kg |

Steel strap clamp

There are 1000 pieces in a box

Lockless fastening option, Dovetail type. Requires special tools

To fasten the steel strip, you can use hand-held mechanical and pneumatic tools

The main range of mechanical tools is represented by models MUL-17 and M4K (Ukraine), pneumatic tools - by equipment from ITATOOLS (Italy)

Tape tying device M4K-10

Performs the function of tensioning and fastening steel tape. The principle of operation is to tension a metal strip, form a lock directly from the strip (without using staples) and cut off the excess. Moreover, the strength of the lock is more than 80% of the strength of the tape itself.

Pneumatic tool ITA40

Pneumatic tool for working with steel strip using a clamp. Makes single or double perforation.

Convenience

To optimize labor costs during the packaging process, we recommend using a steel strip unwinder

Unwinder H95

Unwinder CA120HSY

With this packaging material you can purchase:

Pneumatic Tool for Steel Belt

14 Products

Unwinders for steel strips

2 Products

Hand tool for steel belt

9 Products

Why are metal bandage tapes so popular?

Metal tape is the most popular packaging material. In addition to cargo packaging, steel strips are used in electrical installation work. With their help, self-insulating SIP wires are securely attached to various supports: reinforced concrete, wooden poles, and house walls.

The main advantages are excellent technical and operational characteristics:

- Versatility of use.

- Minimizing cases of deformation and damage to goods.

- High strength, reliable fastening, resistance to ultra-high mechanical loads.

- Neatness, the appearance of the cargo remains open to external review.

- Compact, convenient packaging for use (coils, rolls).

- Large selection of standard sizes.

- Availability, relatively low cost.

- Transportation of goods by various modes of transport.

Important: Stainless steel bandage tapes are not magnetic and the edges and edges are rounded. Due to the absence of burrs and sharp edges, cases of cuts and injuries to workers are minimized. The wound bobbins are supplied in lengths of 50 or 25 meters in plastic or cardboard packages.

Tape Tightening Tools

When using bandage metal strips, manual, pneumatic, and mechanical devices are used. The market offers various models produced by well-known manufacturers. These machines greatly facilitate work with packaging material and provide reliable fastening of goods with sharp edges and corners.

Enterprises that produce products in small volumes use hand-held tools. Manual packaging machines like M4K-10 are relatively inexpensive. The mechanisms are easy to operate, do not require special skills, are reliable and durable.

Tip: Experienced craftsmen recommend using designs with a ratcheting mechanism. These manual machines are easy to use. The working material does not need to be pushed, it is fed using a ratchet mechanism, the design includes a long handle and a built-in cutter.

To perform packaging operations in large volumes in a short time, more complex tools are used: mechanical or pneumatic.

These devices are much more productive than their manual counterparts and work with large-sized products. When packing large, heavy loads, it is advisable to use mechanized tools that evenly secure the bandage tape in each zone.

Power tools

Depending on the shape and weight of objects, locking and lockless devices are used, powered by mechanical or pneumatic drives.

Objects with flat surfaces are tied with steel tape using the punched fastening method using combined tools that are in demand when tying various building materials:

- pipes;

- lumber;

- furniture blanks;

- reinforced concrete slabs;

- fittings;

- double-glazed windows, etc.

When tying large-sized round-shaped loads or other complex configurations, locking machines with tensioner-seals are used. Here the ends of the tape are secured using special metal locks.

Important: Universal combined mechanisms perform several functions in one cycle: tensioning, fastening, cutting the ends of steel strips, forming locking joints called “dovetails”. “3 in 1” devices are easily adjusted to the parameters of steel belts: thickness, width. Such tools are easy to use; the master does not have to put in too much effort.

Cold-rolled steel packaging cold-hardened tape — Moscow

How to get great deals from steel mesh suppliers: Moscow

Cold-pressed steel packaging cold-hardened tape.

As a rule, in the construction field you can often encounter the fact that this or that material is needed right now. and it doesn’t matter what city it is, Moscow or a completely different region.

Today, to solve this problem, we offer a Supplier search system that helps clients and customers find mutually beneficial cooperation. Want to know exactly how this happens?

Quite simple if you use the latest technology and the World Wide Web. So, you go to the website METAL100.ru and leave your request, let it be cold-cold steel packaging cold-worked tape, specify the region Moscow. Although, it is worth noting that your search may not be limited only to the capital. These may be other regions of the Russian Federation, and with one click you can cover all cities of the CIS. At this point, your work is almost finished, since the automatic system itself sends out mailings to suppliers. And they usually respond within 3 minutes.

It is after this period of time that you will begin to receive offers for cold-rolled steel packaging cold-hardened packaging tape to your email. The information will contain not only wholesale and retail costs, but also delivery times and possible delivery conditions if the region is not Moscow. As you can see, everything is quite simple and such a system is somewhat reminiscent of a virtual tender, which you can announce without filling out a whole stack of papers.

Now, of course, you want to know which link you can use to submit your application. You will find her address below:

Send a request to suppliers

You understand that from now on you have a unique opportunity through which you can save your time. Forget about unnecessary searches. After all, now all suppliers themselves will offer you their goods. And you decide who to give preference to. By the way, the site is also good because information about the cost of rolled metal is updated daily and you can verify the obligations of the supplier if he is an authorized user. This will help you avoid possible mistakes and save you from scammers.

Profitable deals are a reality, which tomorrow can become a great chance for you to buy everything you need of excellent quality at the lowest price.

New construction portal STROIM100.RU - Main suppliers and prices for building materials.

| Concrete products | Plastic pipes | Drywall | Corrugated sheet |

| Brick | Metal-plastic | Fasteners and hardware | Galvanization |

| Cement and concrete | Pipe fittings | Sawmatirial | Metal tiles |

| Soil and sand | Valves | Plywood | Roofing steel |

| Crushed stone and gravel | Flanges | Fiberboard chipboard OSB | Additional elements |

The project brought to your attention is an information portal where prices of the main suppliers of building materials, such as Brick, Concrete, Floor Slabs, Drywall, Metal-plastic pipes and much more are presented.

The main goal of the project is to provide potential buyers, on the basis of free access, with information about the availability, price and quality of various building materials, indicating the coordinates of potential suppliers.

Convenient navigation of the Stroim100 portal makes it as easy as possible to navigate, select the desired type of building materials, see supplier prices, send applications, announce tenders. The features offered to users reduce the time spent searching, help select the best items and compare prices from suppliers.

Happy shopping and transactions on the portal!