Stainless steel A2 and A4

A2 and A4 are abbreviated names for grades of stainless austenitic steels.

Austenitic steel has a number of remarkable properties, which have ensured its very wide use in the national economy. Steels A2 and A4 are non-toxic and corrosion resistant. They are well subjected to mechanical and heat treatment, as well as welding. Fasteners made from A2 and A4 steels are practically non-magnetic, strong and durable. They retain their properties perfectly at high and low temperatures. A2 steel has a domestic analogue - stainless steel grade 08Х18Н10 and a foreign analogue - grade AISI 304 (in the USA). Assembly units, parts and fasteners made of A2 steel are used in the oil, food, chemical and gas industries; in instrument making and shipbuilding; in construction during the installation of ventilated facades and stained glass structures, as well as in the manufacture of pumping equipment. Products made from A2 steel retain their strength properties over a wide temperature range: from low (-200 degrees Celsius) to high (+425 degrees Celsius).

A4 steel is similar in its characteristics to A2, but its scope of application has expanded significantly due to the addition of 2-3% molybdenum, which contributes to its higher resistance to corrosion in environments containing acids, salts and chlorine. Products made from A4 stainless steel retain their strength properties at low (up to -60 degrees Celsius) and high (up to +450 degrees Celsius) temperatures. These products are used: in the chemical industry, where they are exposed to aggressive environments; in shipbuilding (fastening elements and rigging products) for protection from the destructive effects of sea water; in swimming pools containing chlorinated water. Stainless steel A4, like A2, also has a domestic analogue - steel type 10Х17Н13М2 and a foreign analogue - AISI 316 (in the USA).

A2 steel and A4 steel are excellent for the manufacture of stainless fasteners of high accuracy class A, which are used to create strong and durable critical connections. Bolts and nuts of this class are made, for example, on computer numerical control (CNC) lathes. The difference in thread diameters, external for a bolt and internal for a nut, after finishing on a machine does not exceed 0.25...0.3 millimeters. However, the price of parts made from stainless steel will be significantly higher than those made from ordinary carbon steel. The strength class for bolts made of stainless austenitic steel grade A2 and steel grade A4 is 50, 70 or 80.

Types and advantages of stainless steel

Grades A2 and A4 are stainless austenitic steels that are highly resistant to corrosion and have virtually no magnetic properties. Both grades lend themselves well to welding, heat and mechanical treatment. They are used to make durable and reliable parts with increased resistance to temperature fluctuations.

A2 grade steel has a Russian analogue 08Х18Н10, and an analogue according to American standards AISI 304. Parts made of this alloy can be used at temperatures from −200 °C to +425 °C. The material has increased resistance to corrosion and aggressive environmental influences.

A4 steel, unlike A2, is made with the addition of 2-3% molybdenum. As a result, the chemical resistance of the material increases. In particular, this alloy better withstands the effects of chlorine, acids, salts and other aggressive substances. Stainless steel parts of this brand are used for the manufacture of fasteners that can be exposed to relevant environments. They can also come into contact with sea and chlorinated water and be used in the chemical and oil and gas industries. The Russian analogue of A4 stainless steel is grade 10Х17Н13М2. The analogue according to American standards is AISI 316 steel.

Due to their properties, austenitic stainless steels of grades A2 and A4 make it possible to produce hardware with the following functional advantages:

- High resistance to corrosion and aggressive substances.

- There is no need to apply anti-corrosion coatings.

- Increased strength characteristics, wear resistance.

- Resistance to temperature fluctuations and critical temperatures.

- Almost complete absence of magnetic properties.

- Fire resistance. The connection between structures is maintained during a fire, which can be key to the rescue and evacuation of people.

- Compliance with sanitary requirements. Stainless steel does not interact with working environments, which allows the use of hardware in the food, pharmaceutical and medicine industries.

Stainless steel fasteners retain their appearance and shine throughout their entire service life. It does not rust, does not become covered with plaque. Thanks to this, hardware can be used to assemble structures for which aesthetic parameters are important.

The difference between brand A1 and A3

A240 fittings have a number of significant differences from other similar products:

| Options | A1 | A3 |

| Marking | A240 | A400, A500 |

| Product type | Welded, without processing | Standard, with corrosion protection |

| Material | Low alloy steel | High alloy steel |

| Surface type | Smooth | Periodic |

| Dimensions | Diameter from 4 to 40 mm, length up to 11.7 m | Diameter from 6 to 80 mm, length up to 12 m |

| Purpose | Reinforced concrete floors, foundations, sidewalks, screeds, arches, greenhouses, columns | Complex bridges, supports, dams, subways, roads, fences |

Metal fittings A240 are an indispensable assistant on any construction site. Properties, compositional features and technical characteristics make it possible to use it both for the production of various steel products of increased strength, and for the creation of decorative elements.

Reinforcing rods A1 and A3

Polished stainless steel

This type of stainless steel is a material with an absolutely smooth surface and a high reflective effect. The technological process of its production differs from other types of stainless steel in the method of surface treatment. It is carried out on special equipment using control and measuring instruments.

Stages of grinding sheet metal.

- Processing with abrasive materials using a special tape.

- Sanding with fine-grained sandpaper or brushes.

- Finish with grinding wheels to a mirror finish.

Areas of application of polished stainless steel:

- Sanded pipes are used to transport oil, gas, liquid foods and alcohol.

- Polished metal products are in demand among designers. It allows you to create creative architectural projects.

- The material is widely used for the manufacture of household appliances, medical equipment and tools, and devices for the food industry.

Polished alloy metals are used in all areas of the national economy where an absolutely smooth and durable material that meets environmental safety standards is required.

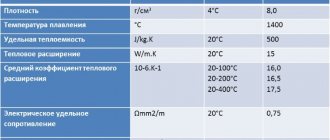

Characteristics of stainless steels

Austenitic steels contain 15-26% chromium and 5-25% nickel, which increase corrosion resistance and are virtually non-magnetic.

It is austenitic chromium-nickel steels that exhibit a particularly good combination of machinability, mechanical properties and corrosion resistance. This group of steels is most widely used in industry and in the production of fasteners: stainless bolts, stainless nuts, stainless studs, stainless screws, and stainless washers.

Steels of the austenitic group are designated by the initial letter “A” with an additional number, which indicates the chemical composition and applicability within this group:

Austenitic structure

| Steel group | Material number | Short designation | AISI number |

| A1 | 1.4305 | X 10 CrNiS 18-9 | AISI 303 |

| A2 | 1.4301 / 1.4303 | X 5 CrNi 18-10 / X 4 CrNi 18-12 | AISI 304 / AISI 305 |

| A3 | 1.4541 | X 6 CrNiTi 18-10 | AISI 321 |

| A4 | 1.4401 / 1.4404 | X 5 CrNiMo 18-10 / X 2 CrNiMo 18-10 | AISI 316 / AISI 316 L |

| A5 | 1.4571 | X 6 CrNiMoTi 17-12-2 | AISI 316 TI |

Steel A2 (AISI 304 = 1.4301 = 08Х18Н10) is a non-toxic, non-magnetic, non-hardening, corrosion-resistant steel. It is easy to weld and does not become brittle. May exhibit magnetic properties as a result of mechanical processing (washers and some types of screws). This is the most common group of stainless steels. The closest analogues are 08Х18Н10 GOST 5632, AISI 304 and AISI 304L (with reduced carbon content).

Fasteners and products made from A2 steel are suitable for use in general construction work (for example, when installing ventilated facades, stained glass structures made of aluminum), in the manufacture of fences, pumping equipment, instrument making from stainless steel. steel for oil and gas production, food, chemical industries, and shipbuilding. Retains strength properties when heated to 425°C, and at low temperatures down to -200°C.

Steel A4 (AISI 316 = 1.4401 = 10Х17Н13М2) - differs from steel A2 by adding 2-3% molybdenum. This significantly increases its ability to resist corrosion and acids. A4 steel has higher antimagnetic characteristics and is absolutely non-magnetic. The closest analogues are 10Х17Н13М12 GOST 5632, AISI 316 and AISI 316L (low carbon content).

Fasteners and rigging made from A4 steel are recommended for use in shipbuilding. Fasteners and products made from A4 steel are suitable for use in acidic and chlorine-containing environments (for example, swimming pools and salt water). Can be used at temperatures from -60 to 450°C.

Strength classes

All austenitic steels (from “A1” to “A5”) are divided into three strength classes, regardless of grade. Steels in the annealed state have the lowest strength (strength class 50).

Since austenitic steels are not hardened by hardening, they have the greatest strength in the cold-worked state (strength classes 70 and 80). The most widely used fasteners are A2-70 and A4-80 steels.

Basic mechanical properties of austenitic steels:

| DIN type | A2 | A4 | |||

| ASTM (AISI) type | 304 | 304L | 316 | 316L | |

| Specific gravity (g/cm) | 7.95 | 7.95 | 7.95 | 7.95 | |

| Mechanical properties at room temperature (20°C) | |||||

| Brinell hardness - HB | In annealed state | 130-150 | 125-145 | 130-185 | 120-170 |

| Rockwell hardness - HRB/HRC | 70-88 | 70-85 | 70-85 | 70-85 | |

| Tensile strength, N/mm2 | 500-700 | 500-680 | 540-690 | 520-670 | |

| Tensile strength, N/mm2 | 195-340 | 175-300 | 205-410 | 195-370 | |

| Relative extension | 65-50 | 65-50 | 60-40 | 60-40 | |

| Impact strength | KCUL (J/cm2) | 160 | 160 | 160 | 160 |

| KVL (J/cm2) | 180 | 180 | 180 | 180 | |

| Mechanical properties when heated | |||||

| Tensile yield strength, N/mm2 | at 300°C | 125 | 115 | 140 | 138 |

| at 400°C | 125 | 115 | |||

| at 500°C | 105 |

Types of stainless steel fasteners

The high strength of stainless steel, combined with its other advantages, makes it possible to manufacture almost any type of fastening elements from these alloys. The following types of fasteners are available:

- metric threaded fasteners A4 and A2 - bolts, studs, nuts, screws, washers, etc.;

- blind rivets;

- cassette rivets;

- threaded rivets;

- clamping fasteners, etc.

The most common types of stainless steel fasteners are threaded hardware - bolts, nuts, studs, etc. The properties of the alloys allow us to produce parts of accuracy class A. These are fasteners designed to create the most durable and strong connections. The production of threaded stainless steel hardware is performed on CNC lathes. This ensures stable geometric parameters for the entire batch of fasteners. Thus, in accordance with GOST, after finishing finishing of hardware, a difference in the thread diameters of the nut and bolt of more than 0.25-0.3 mm is not allowed.

Bolts, nuts, studs and other fasteners made of stainless steel are manufactured with strength classes 50, 70 and 80. This gives high mechanical reliability to the connections made with their help. The cost of stainless fasteners is significantly higher compared to similar parts made of carbon steel, even with zinc coating. However, their durability and reliability justify the increased costs, especially when installing critical structures and equipment.

Steel A2 / Auremo

Name Meaning

| Designation GOST Cyrillic | A2 |

| Designation GOST Latin | A2 |

| Translit | A2 |

| By chemical elements | — |

Description

A2 steel is used: for the production of rolled and forged blanks of square or round cross-section intended for the production of axles of locomotives, electric trains, diesel and electric trains, railway cars and subway cars.

Note

Unalloyed steel.

Name Code Standards

| Bandages. Wheels. Axles | B41 | GOST 30272-96, GOST 31334-2007 |

Standard CSP Mn Cr Si Fe Cu V Mo

| GOST 31334-2007 | ≤0.5 | ≤0.04 | ≤0.04 | ≤1.2 | ≤0.3 | ≤0.5 | Remainder | ≤0.3 | ≤0.05 | ≤0.08 |

Fe is the basis.

Mechanical characteristics

Section, mm sТ|s0.2, MPa σB, MPa d5, % kJ/m2, kJ/m2

| Steel A2. Axles of traction and trailed cars in accordance with GOST 31331-2007, ISO 105-3-82. Mode N: Normalize or Normalize + Vacation | |||

| ≥360 | 600-750 | ≥17 | ≥196 |

| Steel A2. Axles of traction and trailed cars in accordance with GOST 31331-2007, ISO 105-3-82. Mode T: Quenching + Tempering | |||

| ≥390 | 620-770 | ≥19 | ≥245 |

Description of mechanical symbols

Name Description

| Section | Section |

| sT|s0.2 | Yield strength or proportional limit with tolerance for permanent deformation - 0.2% |

| σB | Short-term strength limit |

| d5 | Elongation after break |

| kJ/m2 | Impact strength |

www.auremo.org

Stainless steel grades and their characteristics

Popular brands of stainless steel of domestic and foreign production.

AISI 304 is the most common and popular steel grade. It is characterized by high strength, elasticity, resistance to oxidation, and is easy to weld.

AISI 316 and 316Ti steel is an improved version of AISI 304, with increased anti-corrosion resistance and resistance to aggressive environments.

AISI 430 is an economical option for corrosion-resistant material, ideal for stamping, deformation and perforation.

Stainless steel is a type of alloy steel that is resistant to corrosion due to its chromium content of 12% or more. In the presence of oxygen, chromium oxide is formed, which creates an inert film on the surface of the steel, protecting the entire product from adverse influences. The modern market can offer various grades of stainless steel for use in a wide variety of industries.

Not every grade of stainless steel demonstrates the resistance of chromium oxide film to mechanical and chemical damage. Although the film recovers when exposed to oxygen, special grades of stainless steel have been developed for use in aggressive environments.

Thermo-mechanical treatment

Steel D2 is classified as cutting steel. Such grades are subjected to hardening to impart maximum strength (57 Rockwell units in the annealed state, after quenching and tempering 61 units). The bulk of the steel undergoing hardening is heated in an oxidizing atmosphere, but for knives, an unusual technology is used due to the difference in thickness between the edge and the main thickness of the knife. That is, it is important to ensure uniform heating and obtain a uniform structure throughout the entire body of the blade: both in the edge and in the butt. At the same time, avoid warping of the metal.

Heating for hardening in an oxidizing atmosphere leads to partial decarburization of the upper layers, which are removed by final processing. But knife blanks are hardened to exact dimensions, since after heat treatment the steel becomes very strong and therefore the final mechanical processing that is applied to it is grinding and sharpening the cutter.

Heating is carried out in salt baths at a temperature of 850-630 ºC. To heat the entire thickness of the workpiece, a few seconds or minutes are sufficient, after which the metal is cooled in air. In order for the matrix to heat up in a matter of seconds and turn into an austenitic state, the steel is alloyed with molybdenum and vanadium, which not only increase the wear resistance of the knife, but also increase the hardenability.

Corrosion resistant stainless steels

| CIS (GOST) | Euronorms (EN) | Germany (DIN) | USA (AISI) |

| 03 X17 N13 M2 | 1.4404 | X2 CrNiMo 17-12-2 | 316 L |

| 03 X17 N14 M3 | 1.4435 | X2 CrNiMo 18-4-3 | – |

| 03 X18 H11 | 1.4306 | X2 CrNi 19-11 | 304 L |

| 03 X18 N10 T-U | 1.4541-MOD | – | – |

| 06 ХН28 MDT | 1.4503 | X3 NiCrCuMoTi 27-23 | – |

| 06 X18 H11 | 1.4303 | X4 CrNi 18-11 | 305L |

| 08 X12 T1 | 1.4512 | X6 CrTi 12 | 409 |

| 08 X13 | 1.4000 | X6 Cr 13 | 410S |

| 08 X17 N13 M2 | 1.4436 | X5CrNiMo 17-13-3 | 316 |

| 08 X17 N13 M2 T | 1.4571 | Х6 CrNiMoTi 17-12-2 | 316Ti |

| 08 X17 T | 1.4510 | Х6 СrTi 17 | 430Ti |

| 08 X18 H10 | 1.4301 | X5 CrNi 18-10 | 304 |

| 08 X18 N12 T | 1.4541 | Х6 CrNiTi 18-10 | 321 |

| 10 Х23 Н18 | 1.4842 | X12 CrNi 25-20 | 310S |

| 10X13 | 1.4006 | X10 Cr13 | 410 |

| 12 X18 N10 T | 1.4878 | X12 CrNiTi 18-9 | – |

| 12 X18 H9 | – | – | 302 |

| 15 X5 M | 1.7362 | Х12 СrMo 5 | 501 |

| 15 X25 T | 1.4746 | Х8 CrTi 25 | – |

| 20X13 | 1.4021 | X20 Cr 13 | 420 |

| 20 X17 N2 | 1.4057 | X20 CrNi 17-2 | 431 |

| 20 Х23 Н13 | 1.4833 | X7 CrNi 23-14 | 309 |

| 20 X23 H18 | 1.4843 | X16 CrNi 25-20 | 310 |

| 20 Х25 Н20 С2 | 1.4841 | X56 CrNiSi 25-20 | 314 |

| 03 X18 AN11 | 1.4311 | X2 CrNiN 18-10 | 304LN |

| 03 X19 N13 M3 | 1.4438 | X2 18-5-4 | 317L |

| 03 X23 H6 | 1.4362 | X2 CrNiN 23-4 | – |

| 02 X18 M2 BT | 1.4521 | X2 CrMoTi 18-2 | 444 |

| 02 X28 N30 MDB | 1.4563 | X1 NiCrMoCu 31-27-4 | – |

| 03 X17 N13 AM3 | 1.4429 | X2 CrNiMoN 17-13-3 | 316LN |

| 03 X22 N5 AM2 | 1.4462 | X2 CrNiMoN 22-5-3 | – |

| 03 X24 N13 G2 S | 1.4332 | Х2 CrNi 24-12 | 309L |

| 08 X16 N13 M2 B | 1.4580 | X1 CrNiMoNb 17-12-2 | 316 CD |

| 08 X18 N12 B | 1.4550 | X6 CrNiNb 18-10 | 347 |

| 08 X18 N14 M2 B | 1.4583 | X10 CrNiMoNb 18-12 | 318 |

| 08X19AH9 | – | – | 304N |

| 08X19H13M3 | 1.4449 | X5 CrNiMo 17-13 | 317 |

| 08X20H11 | 1.4331 | X2 CrNi 21-10 | 308 |

| 08X20H20TYU | 1.4847 | X8 СrNiAlTi 20-20 | 334 |

| 08X25H4M2 | 1.4460 | X3 CrnImOn 27-5-2 | 329 |

| 08X23H13 | – | – | 309S |

| 09X17H7 Yu | 1.4568 | X7 CrNiAl 17-7 | 631 |

| 1X16H13M2 B | 1.4580 | Х6 CrNiMoNb 17-12-2 | 316Cd |

| 10X13 SJ | 1.4724 | Х10 CrAlSi 13 | 405 |

| 12X15 | 1.4001 | X7 Cr 14 | 429 |

| 12X17 | 1.4016 | X6 Cr17 | 430 |

| 12X17M | 1.4113 | X6 CrMo 17-1 | 434 |

| 12X17MB | 1.4522 | Х2 СrMoNb | 436 |

| 12X18H12 | 1.3955 | GX12 CrNi 18-11 | 305 |

| 12X17 G9 AN4 | 1.4373 | X12 CrMnNiN 18-9-5 | 202 |

| 15X9M | 1.7386 | X12 CrMo 9-1 | 504 |

| 15X12 | – | – | 403 |

| 15X13H2 | – | – | 414 |

| 15X17H7 | 1.4310 | X12 CrNi 17-7 | 301 |

Food grade stainless steel

This type of rolled metal is ground and differs from other types in a special way of treating its surface. The final layer of food-grade material is sanded until shiny. This type of stainless steel is environmentally friendly and does not react with acids, alkalis, or detergents.

Popular brands and their applications:

- 08Х18Н10 – widely used for the production of food equipment.

- 08Х13 – metal suitable for making kitchenware and cutlery.

- 20Х13, 40Х13 are ideal materials for the production of sinks and containers in which thermal and hygienic processing of products is carried out. It is used to produce equipment intended for the production of wine, alcohol, and food.

- 08X17 is a popular material for cookware exposed to high temperatures.

The optimal amount of alloying elements included in the composition of stainless steel forms a protective film on the surface of the metal. The use of this type of steel is necessary for the production of products that are exposed to long-term exposure to water vapor, heating and boiling of liquid food products. Due to the properties of food grade steel, when cooking food, there is no chemical interaction between the products and the container in which they are located.

Chemical composition

In terms of chemical composition, D2 belongs to high-carbon alloy steels, and more precisely, cutting steels. Initially, it was developed for the manufacture of cutting teeth based on high-carbon metal with a carbon content of 1.4-1.6%.

The main alloying elements that impart such qualities as red brittleness (the metal breaks at temperatures above 725 C, when it takes on a red color) and wear resistance are vanadium and molybdenum, the content of which is:

- V-0.9-1.1%;

- Mo- 0.8-1.2%.

Due to the fact that they are very refractory and it is not possible to obtain them using the usual method, these substances are introduced into the melt in the form of fine powders. Getting into liquid steel, the elements form the strongest carbide compounds (VC) and (WC), destroying iron carbide (FeC) and chromium carbide (CR23C6). This provides high strength at high temperatures and good hardenability of the steel.

Molybdenum increases the hardenability of steel to a greater depth and uniform distribution of internal stresses that arise during hardening. Vanadium, in turn, prevents the blade from becoming brittle and brittle.

Chromium is the only element that gives the alloy resistance to chemical corrosion. But since for complete protection a minimum chromium content of 13% is required, and D2 steel contains only 11%, it is classified as low-rust. In addition, the high carbon content contributes to the formation of a fairly large amount of chromium carbide, which affects intercrystalline corrosion when reacting with acids.

Carbon content is an indicator of very high strength, which is inherent to a much greater extent than steels such as cord or wire rope. With proper heat treatment, the surface takes on a hardness of 61 Rockwell units, when it is 55-58 units. that's more than enough.

It is mandatory to add silicon and manganese in a ratio of 1:1 and an amount of 0.60%. Silicon has a grain boundary strengthening effect. Being a non-carbide-forming element and at the same time refractory, one of the first to crystallize, silicon pushes carbon to the grain boundaries, thereby giving them greater strength.

Manganese, as a rule, is added in a ratio of 1:1.1 and higher, but in this case it is maintained at 1:1. It stabilizes the structure of the metal, both in the austenitic state and in tempered martensite. Although it increases the hardness of steel, but without compromising its toughness.

The harmful impurity phosphorus is reduced to a limit of 0.04%, sulfur to 0.03%. These are not the minimum limits of their content, but when this content increases, they can negatively affect it, and in this range they do not have a negative effect.

Compound

The mechanical, physical and technological features of A2 stainless steel are ensured by the optimal combination of alloying components. The composition of steel includes the following elements that affect the characteristics:

| Carbon, C | Silicon, Si | Sera, S | Phosphorus, P | Nickel, Ni | Manganese, Mn | Molybdenum, Mo | Chromium, Cr |

| 0,1-0,5 | 1,0 | 0,3 | 0,05 | 8-19 | 2,0 | Up to 5.0 | 15-20 |

The table shows the percentage of elements included in A2.

When replacing nickel with vanadium, an identical grade of steel is obtained, but characterized by increased strength and wear resistance. The main difference between the A2 steel grade and other austenitic grades of this category (A) is the increased copper (Cu) content, up to 4% (not indicated in the table)

Properties

The content of alloying components and the total content of chemical elements directly affect the properties of steel.

Steel A2 has the following properties:

- Strength. The strength class of grade A2 is determined by the percentage of carbon, manganese and silicon. The minimal presence of sulfur and phosphorus is also one of the factors in obtaining high strength characteristics. Strength indicators are maintained when using products made from steel of this grade at temperatures from -200ºC to +425ºC.

- Suitable for all types of mechanical processing (drilling, cutting, broaching, rolling);

- Connections using various types of welding have a sufficient margin of safety. When welding, at the joints (welding seams) there is practically no change in the crystalline structure of the metal, which ensures the plasticity of the joint.

- Does not require additional heat treatment (hardening).

- It has an increased coefficient of resistance to various chemical compounds. Exceptions include concentrated acid compounds and liquids with a high chlorine content.

- Steel does not have magnetic properties. Small manifestations of magnetism may appear after machining of workpieces.

In terms of its technical and technological indicators, A2 steel is similar to domestically produced stainless steel (08X18H10) and the brand of foreign manufacturers (AISI 304, AISI 304L, USA).

INPO: Technical Library

Chemical composition of stainless steel and compliance with standards

Stainless steels include a group of corrosion-resistant steels containing at least 10.5% chromium and low carbon content. As an example, here is a simple table of various alloys with iron.

| Cast iron | Fe + C > 2% |

| Carbon steel | Fe + C 5% |

| Stainless steel | Fe + C 10.5% |

In addition to Chromium as the “main stainless component,” stainless steel may contain Nickel, Molybdenum, Titanium, Niobium, Sulfur, Phosphorus and other alloying elements that determine the properties of steel.

Correspondence table of the main grades of stainless steels and chemical composition

Technical features of D2 steel

The D2 grade is an American marking that is also used here, indicating precise use. The existing Russian analogue is X12MF steel. Both in chemical composition and mechanical properties, these brands are similar. There is only a difference in the range of components used. But more properties depend on thermal processing.

This brand has become very famous in its country; many companies use it for their products: cutting tools for equipment, knives. It is in demand thanks to:

- low cost;

- good machinability;

- sharpening resistance;

- high cutting characteristics;

- corrosion resistance;

- homogeneity of the structure after hardening.

Classification of stainless fasteners according to strength indicators

According to GOST, all austenitic steels are divided into three classes based on tensile strength:

- the lowest class 50 is assigned to hardened stainless steel;

- class 70 includes cold-deformed steel grade A2;

- class 80 is also a steel obtained by cold deformation, containing, in addition to chromium and nickel, molybdenum.

The standard requires that the steel grade and strength indicator be denoted by a hyphen:

- A1-50 is a soft metal endowed with a tensile strength limit of ≤500 N/mm2 or 500 MPa;

- A2-70 – cold-drawn stainless steel with a tensile strength value ≤ 700 N/mm2 or 700 MPa;

- A4-80 is a high-strength alloy with a tensile strength limit of ≤ 800 N/mm2 or 800 MPa.

The designation must be applied to the head of the fastener next to or parallel to the manufacturer’s mark. Marking of studs is carried out on a smooth area or at the end. Some manufacturers practice additional color coding of steel grade. For A2 the tone is green, for A4 - red.

Classification of fittings

The production standards for fittings are defined in DSTU 3760-98, which replaced the old GOST 5781-82 and GOST 10884-94.

Regulatory standards for fittings

- The diameter of the reinforcement in a periodic profile, otherwise the profile number is the cross-sectional diameter of the rod corresponding to the parameters of its area;

- The strength class of the product is the conditional, physical yield strength of steel, this parameter is regulated by standards;

- Nominal cross-sectional area - characterizes the cross-sectional area of a round smooth rod, which corresponds to its diameter;

- The height of the transverse projection is the distance from the center of the profile rod and the highest point on the groove, which is measured perpendicular to the longitudinal axis;

- The pitch of the transverse protrusion is the distance between two adjacent corrugations, which is measured along the longitudinal axis;

- The angle of inclination of the transverse protrusion is the angle formed between the longitudinal axis and the transverse protrusion on the reinforcement product;

In accordance with DSTU, classes of reinforcement have the following designations: A240S, A300S, A400S, A500S, A600, A600K, A800, A800K, A1000, where the number means the conditional yield strength in N/sq.mm, the index C is an indicator of the weldability of the reinforcement , and the K index indicates its corrosion resistance.

Table 1. Profile numbers, weight of 1 m length of reinforcing steel of smooth and periodic profiles, maximum mass deviations for periodic profiles.

| Profile number | Weight of 1 m profile | |

| Theoretical, kg | Maximum deviations, % | |

| 6 | 0,222 | +9,0/—7,0 |

| 8 | 0,395 | |

| 10 | 0,617 | +5,0/—6,0 |

| 12 | 0,888 | |

| 14 | 1,21 | |

| 16 | 1,58 | +3,0/—5,0 |

| 18 | 2 | |

| 20 | 2,47 | |

| 22 | 2,98 | |

| 25 | 3,85 | |

| 28 | 4,83 | +3,0/—5,0 |

| 32 | 6,31 | +3,0/—4,0 |

| 36 | 7,99 | +3,0/—4,0 |

| 40 | 9,87 | |

| 45 | 12,48 | |

| 50 | 15,41 | +2,0/—4,0 |

| 55 | 18,65 | |

| 60 | 22,19 | |

| 70 | 30,21 | |

| 80 | 39,46 |

According to the standards, reinforcement is classified into 6 classes, depending on the thickness and grade of steel used, as well as the mechanical properties available in connection with this:

- Reinforcement A-I (A240) smooth bars;

- Armature A-II(A300);

- Fittings A-III (A400);

- Armature A-IV(A600);

- Armature А-V(А800);

- Armature A-VI(A1000);

| Reinforcing steel class A-II (A300) in standard design | Reinforcing steel class Ac-II (Ac300) for special purposes |

| Reinforcing steel class A-III (A400) and classes A-IV (A600), AV (A800), A-VI (A 1000) | Reinforcing steel classes A-IV (A600), AV (A800), A-VI (A 1000) for special purposes |

A1 fittings are available in diameters from 6mm to 40mm, made from steel grades 3SP, D16, and St3 (StZkp; StZps; StZsp;). It is used in conditions that require increased tensile elongation, ductility and good tolerance to low temperatures. Class A1 can be used for welding load-bearing structures and meshes.

A2 fittings are produced with diameters from 10mm to 80mm, made of steel, grades: St5sp; St5ps; - for class A2 with a diameter from 10mm to 40mm. 18G2S - for class A2 with a diameter from 40mm to 80mm. The scope of application of rolled rod of class A2 differs little from the scope of application of class A1.

A3 fittings are produced with diameters from 6mm to 40mm, made of steel grades: St3, 25G2S, 35GS, A400, A500S. The steel used for the manufacture of this class has good weldability. This makes A3 class rods suitable for the manufacture of reinforced concrete structures, therefore products of this class with a diameter of 10mm, 12mm and 14mm are most often used in industry and civil construction.

A4 fittings are available in diameters from 10mm to 32mm, made from steel grades: 80C - for class A4 with a diameter from 10mm to 18mm. 20ХГ2Ц - for class A4 with a diameter from 10mm to 32mm.

Reinforcement of class A4 and higher classes is used as a prestressed reinforcement. But the technical features of A4 class rod are such that it can also be used for non-stressed structures. The weldability property of the steel used for the manufacture of this class is such that it is preferable to use the crimped ferrule method for joining it.

A5 fittings are available in diameters from 6mm to 36mm; steel grade 23Х2Г2Т (AT800) is used for its manufacture. Rolled metal of this class is used in conditions suitable for prestressing rods and structures with long spans.

A6 fittings are available in diameters from 6mm to 32mm, made from steel grades 22Kh2G2AYU, 22Kh2G2R, 20Kh2G2SR. Class A6, like class A5, is used in conditions suitable for prestressing rods

Mechanical properties of material 1.4401

The mechanical properties of 1.4401 alloy steel are described below.

| Temperature, °C | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 |

| Yield strength | 175 | 158 | 145 | 135 | 127 | 120 | 115 | 112 | 110 | 108 |

| Tensile strength | 210 | 190 | 175 | 165 | 155 | 150 | 145 | 141 | 139 | 137 |

| Steel group | steel grade | Steel strength class | Diameter range, mm | tensile strength Q min, N/mm2 | Tensile yield strengthQ min, N/mm2 | elongation at breakmin, mm |

| austinitic | A2, A4 | 50 | ≤ M39 | 500 | 210 | 0.6 d |

| 70 | ≤ M24 | 700 | 450 | 0.4 d | ||

| 80 | ≤ M24 | 800 | 600 | 0.3d |

Approximate values of tightening torques and pre-tightening forces for screws made of stainless and acid-resistant steel A4:

| Thread | Strength class 70 | Strength class 80 | ||

| Pre-tightening force, N | Tightening torque, Nm | Pre-tightening force, N | Tightening torque, Nm | |

| M5 | 3.000 | 3,5 | 4.750 | 4,7 |

| M 6 | 6.200 | 6 | 6.700 | 8 |

| M 8 | 12.200 | 16 | 13.700 | 22 |

| M 10 | 16.300 | 32 | 22.000 | 43 |

| M 12 | 24.200 | 56 | 32.000 | 75 |

| M 16 | 45.000 | 135 | 60.000 | 180 |

| M 20 | 71.000 | 455 | 140.000 | 605 |

| M 30 | 191.000 | 1.050 | 255.000 | 1.400 |

Application

The listed advantages contribute to maintaining a leading position in the rolled metal market. Anti-corrosion alloys are an indispensable material in heavy engineering, energy, oil and gas and agricultural sectors.

The material is in demand in the following areas of the national economy:

- Construction, architecture;

- production of equipment and medical instruments;

- pulp and paper production;

- food industry;

- transport engineering;

- chemical industry;

- electrical power and electronics;

- production of household appliances and household items.

The decorative qualities of stainless metals and the high level of anti-corrosion properties make it possible to use parts and elements made from them for facades, advertising installations, shop windows, and fountains. Railings, doors, stairs, and elevators are made from alloyed material.