Types of presses

There are various devices for making bricks from clay:

- Revolving equipment for pressing bricks. It is intended for the semi-dry method. Allows you to skip the drying phase and immediately begin fire treatment. To do this, special ceramic powder is poured into molds. There are two ways to obtain such a mixture: Slip. When using high pressure and boiled water to crush clay.

- Grinding and drying machine. The labor-intensive process involves grinding, crushing and drying the clay.

Store options

For the production of hyperpressed bricks, you can buy ready-made equipment options:

- Manufacturer Lego Brick press: “Legion-260”;

- "Legion-80";

- "Legion-60";

- "Legion-40";

- "Legion-20".

- TITAN 80S3;

Necessary raw materials

Hyperpressed brick was invented as a material made from wet soil and cement. Due to the low quality of the resulting blocks, the soil filler was replaced with screened shell rock. Modern technology uses quartz sand, screenings of limestone, dolomite, marble, travertine, granite and other rocks as filler, as well as slag, ash, tyrsa, broken brick, concrete and other industrial waste, thus recycling them.

The binder for the filler is cement PC 400. It requires 8-20%. When pressed on both sides, it provides a brick strength grade not lower than M100 (the use of PC 500 cement gives the product strength corresponding to grades M250-M300). To give a variety of colors, iron oxide pigment is added, and water is added to provide the necessary humidity. Its cleanliness, as well as the freshness of the cement, are of great importance.

For production of 1,000 pcs. conventional brick requires 3.5 tons of limestone screenings, half a ton of Portland cement M400, 66 kg of pigment and about 100 liters of water.

How to make a hydraulic press at home?

Materials

Since the cost of pressed bricks is high, you can produce it yourself. Manual settings will help with this. To make it you will need:

- metal sheets;

- drilling machine;

- electrodes;

- welding equipment;

- grinder.

First you need to make the appropriate drawings and measurements, cut out the parts. Using an electrode of the required size and current, you need to weld the main parts. In this case, be sure to take into account the thickness of the sheet; it is different for each part. Parts that must move must be assembled according to the drawing or plan. We must not forget about the correspondence of the parts to each other and to the load that will be carried out.

When working with a press, you need to remember the safety rules; failure to follow them can lead to injury or equipment breakdown.

Device technology

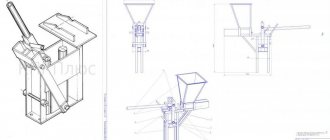

A homemade press is not intended for an automated process and requires manual work. This device consists of four parts. The base holds the machine, preventing it from wobbling and moving during operation. It is desirable that it be heavy for better stability and grip. The mold is made from 8 mm steel sheets. It must be firmly welded to withstand heavy loads. This will allow you to make a higher-quality and durable briquette without damaging the device. The part for filling the material must correspond to the container in which the brick is formed. It is usually made of a thin sheet of metal (2 mm) and has the shape of a truncated cone or pyramid. The press itself is based on two welded thick sheets with a thickness of up to 20 mm. It is subjected to heavy loads and has a major function in brick production.

Home production

The production of hyper-pressed bricks at home for personal needs is a very questionable matter, although with great desire nothing is impossible. To sift raw materials, you can use a construction sieve, instead of a mixer - a concrete mixer, and all loading and unloading work can be done manually.

The problem is the cost of the hyperpress. Just one simple press costs about $4 thousand, and the entire line costs over $16 thousand. The second problem is that the area of the room must be at least 350 m2.

News

Dense silicate concrete according to GOST 25214 is characterized by the following indicators: compressive strength taking into account the requirements of the M75-M700 standard; frost resistance F35-F600; waterproof W 2 to W 10; average density from Pl 1000 to Pl 2400. The abrasion of silicate concrete on dense aggregates should not exceed 0.7-0.9 g/cm2.

Many products used in residential, civil and industrial construction can be made from silicate concrete. High strength properties of products made from such concrete are achieved by autoclave processing of a mixture of fired and unfired materials (finely ground lime, sand, slag, ash, etc.) and quartz and feldspathic sands or industrial waste with a high content of silicon oxide and similar granulometry, which under normal hardening conditions do not have astringent properties. The most effective way is to manufacture hollow products from silicate concrete, including bricks, stones and blocks.

According to their purpose, bricks and stones are divided into ordinary and facing, according to types of production - into hollow, porous (with porous filler), porous-hollow and solid. Facing bricks and stones can be unpainted or colored - painted in the mass or with surface finishing of the front edge.

Table 1.24

Types of brick and stone, their sizes

| Product | Length | Width | Height |

| Brick single solid or with porous filler, mm | 250 | 120 | 65 |

| rpich thickened hollow or solid with porous filler, mm | 250 | 120 | 88 |

| Hollow stone, mm | 250 | 120 | 138 |

Note.

The weight of thickened bricks in the dried state should be no more than 4.3 kg.

Based on thermal performance indicators and dry density, bricks and stones are divided into three groups: efficient - brick with an average density of no more than 1400 kg/m3, stones - no more than 1450 kg/m3 and thermal conductivity up to 0.46 W/ (mN°C); conditionally effective - brick with an average density of 1401-1650 kg/m3, stones with an average density of 1451-1650 kg/m3 and thermal conductivity up to 0.58 W/(mN°C); ordinary sand-lime brick with a density of over 1650 kg/m3 and thermal conductivity up to 0.7 W/(mE°C).

For sand-lime brick and stone, there are the following strength grades: 300, 250, 200, 150, 125, 100 and 75. Facing products must have grades: brick of at least 125 and stones of at least 100. Based on frost resistance, brick and stones are divided into grades: Mrz 50, Mrz 35, Mrz 25 and Mrz 15. Frost resistance of facial products should be at least 35 (for the climatic conditions of central Russia).

Dimensional deviations and non-parallelism of facing and ordinary bricks and stones from the nominal ones should not exceed 2 mm. Defects from under-slaked lime are not allowed.

More than one crack on ordinary brick and stone, crossing two adjacent edges of one face and extending up to 40 mm along the beds, is not allowed. There should not be more than 10% of products with such cracks in the batch. In a batch of facial products there should be no more than two halves, and in a batch of ordinary products - no more than 3%.

The total number of repulses in the game should not exceed 5%. The loss of strength of brick and stone samples during compression after testing them for frost resistance should not be more than 25% for ordinary products and 20% for front ones. The water absorption of brick and stone must be at least 6%.

Binder components for sand-lime bricks and blocks (including concrete) must meet the requirements of the standards: lime GOST 9179; sand OST 21-1; slags GOST 3476; ash GOST 25592. Natural or crushed sands that meet the requirements of GOST 8736 and OST 21-1 are used as a filler for silicate concrete.

The most common type of binder in the production of silicate materials (bricks, stones, locks) is calcium air building lime

GOST 9179). In addition, a lime-belite binder is used, obtained by low-temperature firing of natural sandy and marly rocks or artificial ones (waste from acetylene production).

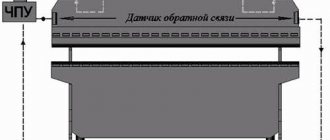

Two technological schemes have been adopted: with centralized preparation of the silicate mixture and its distribution to bins, and a mixed scheme with centralized dosing of components, their primary mixing and individual secondary processing of the mass for each press. The first scheme is preferable for high-capacity plants, the second - for plants with 2-3 presses.

Weight dispensers with a belt conveyor are designed for dosing bulk components of the silicate mixture, ensuring dosing accuracy up to ±1%.

Primary mixing of the binder with sand is carried out with low-speed twin-shaft mixers SM-246 and SMK-126 or high-speed paddle twin-shaft mixers SMS-95. The paddle mixer for primary mixing of components is equipped with perforated tubes for supplying water and live steam. In the SMS-95 and IB-2 7 mixers, water is supplied through sprayers to improve the quality of the mixture.

Slaking of lime mixed with sand occurs in batch or continuous apparatuses. The first includes the extinguishing drum. Its capacity is 15 m3; drive power 14 kW; working pressure 0.5 MPa; the total duration of the lime slaking cycle is 50-60 minutes, including the duration of slaking at high pressure of 30-35 minutes. At modern enterprises and those under construction, lime slaking mixed with sand is carried out in continuous reactor silos. In this case, two technological processes are combined - slaking of finely ground lime and averaging (homogenization) of the silicate mixture. In addition, the silo is a buffer tank that ensures reliable supply of the mixture to the presses. In the reactor, the slaked mixture is lowered through an annular slot between the discharge funnel and the cone onto a fixed bottom, from which it is raked into the hole with a sickle-shaped knife. On the same principle, I developed a reactor, distinguished by the design of the discharge unit and the presence of two sickle-shaped knives. VNIIStrom has developed a silo-reactor design in which the working body of the unloader is vibrating multi-storey gratings located inside a cone.

To grind lumps of lime, clay and further homogenize the mixture, mixing disintegrators, paddle twin-shaft mixers with normal and increased rotation speed, countercurrent rod mixers, runners, rod mills, and roller mixers-grinders are used. Recently, rod mixers have become most widespread. Mixing and grinding of the mixture components takes place in a rotating drum. It contains metal rods, the cascade movement of which and rotation around its axis provide the necessary

Table 1.25

Technical characteristics of paddle twin-shaft mixers

| Indicators | SMS-95 | IB-27 | SM-2 4 6 | SMK-12 6 | "Buckau-Wolf" (Germany) | F-5 (Poland) |

| Productivity, m3/h | 95 | 60 | 35 | 35 | 50 | 50 |

| Trough or drum length, mm | 4120 | 3500 | 3500 | 3500 | 4000 | 3500 |

| Blade or drum circumference diameter, mm | 850 | 660 | 750 | 750 | 550 | 550 |

| Linear rotation speed, m/s | 4,1 | 4,2 | 1,2 | 1,2 | 2,5 | 3 |

| Weight, t | 6 | 4 | 5,6 | 4,6 | — | 3, 2 |

| Installed power, kW | 55 | 40 | 40 | 40 | 30 | 32 |

Table

1.26

Technical characteristics of rod mixers

| Indicators | S-14 | SK-01 | SK-19 | SK-08 | SK-58 | "Makroom" (Poland) | "^las-Mak" (Germany) |

| Productivity, m3/h | 75 | 15 — 17 | 30 — 35 | 70 — 80 | 100 — 120 | 18 | 25 — 30 |

| Length of trough and drum, mm | 3200 | 1800 | 2500 | 3000 | 3200 | 2500 | 3000 |

| Blade or drum circumference diameter, mm | 1800 | 900 | 900 | 1200 | 1500 | 1700 | 2000 |

| Linear rotation speed, m/s | 1,3 | 20* | 25* | 20-22* | 20* | 2 | 1,95 |

| Weight, t | 15,3 | 3,6 | 4,5 | 12,5 | 14,3 | 13,2 | 16 |

| Installed power, kW | 55 | 22 | 30 | 45 | 55 | 30 | 45 |

Rotation speed, min1.

Effect. The mixer drum can be positioned horizontally or at an angle of up to 10°. Depending on the presence of clay and other inclusions in the mixture and their hardness, the specific productivity of rod mixers ranges from 8 to 14 t/mV4.

One of the important operations in the production process of sand-lime brick is its molding. The strength of the raw material is mainly influenced by the pressure and time of pressing, the content of fine particles in the composition of the molded mixture, the total specific surface of the mixture, its optimal humidity, etc. With an increase in the pressing pressure by 2 times, the strength of the raw material increases by 35-40%. The duration of pressing has a positive effect on the strength of the raw material at low specific pressing pressures. As it increases to 30-40 MPa, the compaction coefficient of raw materials molded at different speeds approaches unity, which leads to an increase in its strength. The introduction of fine particles into the silicate mixture in the form of finely ground lime-sand binder with a specific surface of 5000-6000 cm2/g increases the strength of the raw material from 0.2 to 0.6 MPa.

Coarsening additives in the form of seedings when crushing and sorting granite, limestone and other rocks are introduced when using fine sands of uniform granulometry. The molding moisture content of the silicate mixture is 4-8%, and it is increased in proportion to the specific surface area and kept within 5-6%. Air pressing is one of the reasons for the delamination of raw material, reducing its strength and increasing crack formation. To prevent it, the optimal granulometric composition of the mixture and the design of the mold are selected to quickly relieve the lateral pressure of the raw material on the walls of the mold. For these reasons, some press manufacturers provide for the widening of the molding cavities in the direction of brick ejection.

The main technological equipment of the press departments includes a press for molding raw bricks, an automatic stacker for removal from the press and placement on an autoclave trolley, a pusher for feeding empty trolleys and hauling loaded trolleys in the area of operation of the automatic stacker, and electrical equipment for remote and automatic control.

In turret presses (SM-152, SM-186), the force from the crankshaft through the differential lever and the pressing lever (oscillating on the support axis) is transmitted to the pressing piston and dies, which are located in the molding cavities of the turret table. The dies compress the mixture in the sockets, and it presses on a stationary counter-stamp mounted on a traverse, which is connected with powerful bolts to the press frame. The mixture is fed into the table slots by a filling device equipped with rotating blades. At the same time, two raw materials are filled, pressed and pushed out of their nests in different places on the table. The table is then rotated 45° and the cycle is repeated.

Foreign, "Dorstener") produce revolving presses with a knee-lever mechanism. With this design of the pressing mechanism and turret table, the duration of mixture formation can be increased by 2 times and at the same time a specific pressure of 30 MPa or more can be transferred to the raw material. On such presses, up to six standard-sized raw stones per edge or up to four hollow stones with a height of 138 mm are molded.

Domestic enterprises are equipped mainly with revolving mechanical presses SM-481, SM-186 and SM-152. Many sand-lime brick factories have been reconstructed and transferred to the production of thickened hollow sand-lime bricks, carried out by automatic complexes consisting of SMS-152A revolving presses, SMS-19 automatic stackers and SMS-19A 11.00.000 pushers. Dispensing hoppers and a mixture feeding conveyor are installed above the complexes. Near the complexes there are inlet and outlet tracks for transfer carts CMC-168 with a lifting capacity of 3 tons for supplying empty autoclave trolleys and SMS-200 with a lifting capacity of 30 t (or CMC-167 with a lifting capacity of 20 t) for selecting and hauling loaded autoclave trolleys. Along the lines of the complexes in the pit there is a scraper conveyor for cleaning and returning spills and raw brick waste.

VNIISTROM, TsKB Strommashina, VNIISTROM-MASH, based on the SM-1085A press for refractory products, introduced the SMK-74 press for sand-lime bricks and hollow stones. It has a removable multi-cavity mold and is designed for simultaneously molding 9 solid single bricks or 5 silicate stones with a hollowness of 25% “on the edge” “on the bed”. Pressing is double-sided - 50 mm on top and 90 mm on the bottom. The product pressing time is 1.75 s. The complex can be placed in the bays of existing workshops, but requires a deep pit (3.2 m).

All modern presses for molding sand-lime bricks (Table 1.27) are equipped with automatic machines for removing raw material and placing it on autoclave trolleys. Their work is based on the following general principles: removing raw material from the table (sometimes with turning the raw material into the required position) with a special puller with grips; laying the raw material removed from the press table onto a storage device - a belt conveyor with a stepping motion; I remove raw packages from the storage unit using a stacker and place them according to a given program on an autoclave trolley. They use automatic stackers SM-1062 and SM-YUZOA (CMC-19) and its modernized version SMS-19A (Table 1.28), but they also use automatic stackers ABC-1 and ABC-3. The automatic stacker SM-YUZOA (SMS-19) uses a pneumatic gripper to pick up four raw materials radially located on the molding table, rotate them in the air from bed to edge and install them in one line along the width of the drive belt, forming four parallel rows of raw materials on it with the same gaps , with which they should be on the autoclave trolley.

The automatic stacker is equipped with a chain pusher with a movable carriage and an electric drive. The stop-clamp included in the pusher is driven by a standard pneumatic cylinder. These measures, combined with the use of slot trucks and the increased use of four-sided grabs when loading bricks,

Table 1.27

Technical characteristics of presses for molding sand-lime bricks

| Indicators | SM-816 CMC-152 | CMC-I52A SMS-19A | SM-1085A (SMK-74) | "Dorstener" (Germany) | |||

| 104 | 125.02 | 125.12 | 125.05 | ||||

| 203 | 225 | 225 | 225 | ||||

| Productivity, m3/h | 3070 | 4140 | 4860 | 5400 | 3520 | 7350 | 9450 |

| Overall dimensions, mm: dlja Irina height | 4750 3350 3350 | 6500 5800 5815 | 4030 3750 3015 | 4850 3200 4900 | 8300 6800 6000 | 8300 7800 6000 | 9200 7800 6500 |

| Installed power, kWt | 38 | 44,9 | 50 | 40 | — | 160 | |

| Specific pressing pressure, MPa | 30 | 30 | 30 | — | 31,5 | 31,5 | 31,5 |

| Weight, t | 22 | 26,4 | 35 | 30 | 70 | 75 | 80 |

Table 1.28

Technical characteristics of automatic stackers

| Indicators | SM-1030 A | SM-1062 | SMS-19A | VSKO-9 | "Dorste-ner-203" | "Rotomat" | R-550 |

| Productivity in terms of single brick, pcs./h | 3600 | 3600 | 4600 | 4000 | 6000 | 5000 | 5250 |

| Number of simultaneously removed raw materials | 4 | 4 | 4 | 4 | 6 | 6 | 14 |

| Number of simultaneously stacked stacks | 1 | 1 | 1 | 1 | 2 | 2 | 1 |

| Number of raw materials in a stack on a trolley | 907 | 907 | — | — | 800 | 800 | 840 |

| Installed power, kW | 2,2 | 1,7 | 2,75 | 2,75 | 16 | 8 | 11 |

| Compressed air consumption, m3/h | 240 | 200 | 180 | — | — | — | — |

| Overall dimensions (LxWxH), m | 3,8×3,3×2,9 | 3,75×4,4×3,9 | 4,2×3,12×3,8 | 3,73×2,7×3,0 | 8.0x2.0x5.0 | 4.0x3.0x3.0 | 8.0x6.0x6.0 |

| Weight, t | 3,3 | 3,3 | 3,46 | 3,0 | 3,0 | 6,0 | 10,0 |

This contributes to the safety of bricks, eliminates the manual movement of rows during stacking, the laying of additional bricks in the bottom row and the need to clear gaps in the stack from debris and spills when shipping finished bricks. During the modernization, significant improvements were made to the details of the SMS-19A.

The automatic machine for removing and stacking raw materials from the R-550 press consists of a puller that picks up a package of pressed raw materials from the table and transfers it in the same position to the storage unit. When molding two rows of seven or eight raw materials at the end simultaneously, a device placed in the middle of the storage conveyor turns both rows of raw materials from end to edge so that one row of raw materials ends up lying on top of the other.

Two automatic machines are installed on the Atlas-Intertechnic hydraulic press, which select a package of raw bricks formed on the corresponding side of the table and place it according to a given program on an autoclave trolley. The absence of a storage conveyor, the elimination of double clamping and transferring contribute to better preservation of raw materials.

It is of interest to form hollow bricks and stones that meet the requirements of GOST 379 and dimensions that are double the dimensions of a single brick (length 250 ± 3 mm, width 120 ± 2 mm, thickness 138 ± 2 mm). The voids in the silicate stone are located perpendicular to the “bed” and are non-through cylindrical, tapering to a cone. Voids with a diameter of 32 mm make up 11, or 14%, the maximum volume of voids is 24.5 and 31%, respectively, relative to the volume of the entire stone. When producing hollow stone, raw material costs are reduced by 20-25%, electricity and steam consumption is reduced, and press productivity increases by more than 1.5 times compared to the production of thickened bricks.

Autoclave processing of raw bricks

carried out with saturated water steam. As a result of the synthesis of calcium hydrosilicates, raw material is converted into artificial stone - silicate brick.

The optimal temperature with a duration of autoclave treatment of 4-5 hours, which, with the lowest cost of binder and short cycles, ensures the production of sand-lime brick with the required strength of 1.2 MPa), is, according to domestic research, 191°C. Increasing the temperature of hydrothermal treatment to 203°C (1.6 MPa) is advisable in the absence of finely ground silica in the charge.

For the production of sand-lime brick, autoclaves with a diameter of 2 m, a length of 19 and 21 m for a working pressure of 0.8 and 1.2 MPa and 40 m for a pressure of 1.6 MPa are used. To avoid significant deformations that cause additional stress in the metal during rapid heating and cooling of autoclaves, they are equipped with converters that provide safe lifting speeds and a decrease in steam pressure. To eliminate electrochemical corrosion of the autoclave walls, cathodic protection is provided.

Autoclave trolleys come with solid and slotted platforms. The latter are composed of four stamped thin-walled box-section profiles. The gaps between them make it possible to remove the mixture remaining on the raw material after it is molded and laid on the trolleys. Bricks after autoclave treatment are easily removed from the slotted platform using grab grips, while with a solid platform, additional operations are required to compact the first row of raw materials due to the presence of spilled mixture residues, burrs, etc. in the spaces between the walls of the charge. Trolleys with raw materials are loaded into autoclaves by pushers: rack, screw, cable, moving along tracks parallel to the front of the autoclaves or placed on transfer carts that transport the trolleys with raw materials to the machines. In some cases, self-propelled trolleys are used, which drive into autoclaves along with pushed trolleys.

Typically, autoclaves with a length of 19 and 21 m are used for hydrothermal treatment of single solid and thickened bricks, and in some industries - for hollow-core stones.

The heat consumption for autoclave processing of sand-lime brick is quite large. It is accepted that the molding moisture content of the raw material is 6%; average specific heat of dry brick (40-200°C) 0.9; metal parts of the autoclave 0.478, water 4.19 kJ/(kg-°C).

Table 1.29

Technical characteristics of autoclaves

| Indicators | Autoclave length, m | |||||

| 17 | 17 | 19 | 19 | 21 | 40 | |

| Autoclave type | Passage | Dead end | Passage | Dead end | Phkd-sy | |

| Working steam pressure, MPa | 1,2 | 1,2 | 1,2 | 1,2 | 1,6 | 1,6 |

| Rail gauge, mm | 750 | 750 | 750 | 750 | 750 | 750 |

| Lid opener drive | ||||||

| Overall dimensions, mm: length width height | 18670 2690 3830 | 18160 2690 3830 | 20730 2690 3830 | 20225 2690 3830 | 23200 2560 3720 | 40400 2560 3720 |

| Weight, kg | 23070 | 21600 | 25707 | 23440 | 32150 | 47400 |

Table

1.30

Cycle duration for autoclave processing of silicate products, h

| Duration of operation, h | Cycle at pressure P, MPa | |||

| P = 0.8 | P = 1.2 | P = 1.8 | P = 1.6 | |

| Solid brick | Lightweight brick | Hollow and solid brick | Hollow stone | |

| Raw loading | 1 | 1 | 0,25 | 1 |

| Closing the lids | 0,2 | 0,2 | 0,15 | 0,15 |

| Steam pressure rise: without bypass with bypass | 1,1 1,3 | 1,15 1,4 | 1,5 1,6 | 1,15 1,4 |

| Holding time at maximum pressure (P) | 6 | 5 | 4 | 4,5 |

| Steam release: without bypass with bypass | 0,8 1,1 | 0,9 1,1 | 1,1 1,3 | 1 1,1 |

| Opening the lids | 0,2 | 0,2 | 0,15 | 0,15 |

| Unloading a train with bricks | 0,25 | 0,25 | 0,25 | 0,25 |

| Cleaning the autoclave | 0,15 | 0,15 | 0,3 | 0,15 |

| Total duration: without bypass with bypass | 9,7 10,2 | 8,85 9,3 | 7 7 | 8,35 |

Steam bypass is usually carried out until its pressure in the autoclave decreases to 0.25-0.35 MPa. The bypassed steam heats the loaded raw material in another autoclave, raises the pressure in it to 0.15-0.25 MPa and thereby reduces steam consumption by 20-25%. To ensure the possibility of steam bypass, it is necessary that loading of autoclaves with raw material, unloading and its processing mode are carried out according to a schedule, while regular steam bypass is most effective if the enterprise has at least five autoclaves.

PRESSES FOR THE PRODUCTION OF SILICATE BRICK CJSC "KHARKIV MACHINE BUILDING"

The presses are designed for molding silicate single and thickened bricks from a moistened mixture of sand and lime.

Revolving press for sand-lime brick SMS 294

The SMS 294 revolving press is designed for molding thickened (250x120x88) hollow sand-lime bricks, as well as single 250x120x65) made from a moistened mixture of sand and lime (with or without porous additives). The press is a crank-lever type of machine with periodic rotation of the table. Brick pressing is one-time, one-sided bottom with preliminary pressing. The press is a four-position automatic machine: in the first position, the molds are filled with silicate mixture; on the second - pre-pressing; when turning the table from the second to the third position - cutting off excess mixture; on the third - pressing two bricks; on the fourth - pushing out and eating. The table and dies are cleaned by moving the table from the fourth to the first position. A full cycle of press operation occurs in one revolution of the crankshaft.

At the customer's request, the SMS 2 94 press can use a crankshaft with a crank radius R = 140 mm. Together with the pre-presser, this design ensures a reduction in peak current by approximately 25%, correspondingly reducing power consumption and the required pressing force; the durability of loaded press mechanisms increases. The press works smoother.

The new press lubrication system is automatic, centralized under pressure.

The press is also equipped with a silent pneumatic friction clutch. The pneumatic coupling allows you to smoothly turn on and off the press when the electric motors are turned on, thereby avoiding large starting torques when starting the engines.

This press can be equipped with dies for molding both hollow and solid bricks. The working surfaces of the lining plates of molds, dies and working bodies of void formers are made of wear-resistant materials.

The press comes with a modern electrical control system. The new electrical control cabinet is additionally protected from dust with special seals and is equipped with components.

The design of the press allows it to work in conjunction with a serial automatic stacker.

A distinctive feature of the SMS 294 press is the presence of a pre-pressing mechanism that ensures high dosing accuracy, the replacement of the mixer with a hopper storage device, the elimination of the hydraulic stabilizer and the mechanism for automatically adjusting the filling depth, the split connecting rod has been replaced with a blind one, and the hydraulic cylinder has been eliminated, etc.

In addition to the serial press SMS 2 94, a modernized version of the press SMS 2 94 M is offered, the following technical innovations have been added to the design:

— Pressure stabilizer — stabilizes the press pressure and avoids over-pressing, which is harmful to the press;

— New lubrication system;

— Improved filling system;

— A mechanism for cleaning the stamp legs has been introduced;

— Heating of the pressing piston plates is being developed.

The sand-lime brick press SMS 294 M is supplied with a pressure stabilizer, which maintains the press pressure at a given level when the properties of the mixture and the mass of the backfill change by changing the height of the brick within the permissible standard range of ±2 mm. In this case, the operating mode of a toggle mechanical press approaches that of a hydraulic press. The principle of operation of the stabilizer is based on changing the equivalent length of the connecting rod during each pressing cycle. To do this, the press lever is connected to the connecting rod by an eccentric shaft, which can be rotated by levers in contact with the stabilizer pneumatic cylinders.

The speed of the stabilizer is ensured by a pneumatic system. The operation of the stabilizer is monitored by an indication system.

The pneumo-mechanical press pressure stabilizer allows you to realize the following advantages:

— to increase the quality of manufactured bricks by reducing the variation in its strength;

— improve the quality of bricks by increasing the effective duration of pressing and eliminating under-pressed samples;

— reduce operating costs for repairs by increasing the service life of wear parts, due to the elimination of over-pressing, each of which, in terms of wear, is adequate to dozens of cycles of press operation in normal mode;

— reduce labor costs for press operators and increase productivity by reducing losses from defects.

An additional advantage of a press with a stabilizer is the ability to directly control the pressing force. The press also features a new heating system for the pressing piston plates, which eliminates mass sticking to it, and a device for cleaning the die legs, which as a result eliminates the formation of wedge-shaped bricks.

Specifications

Product performance according to GOST 530-95

or DSTU B V.2.7.61-97, pcs./h:

bricks……………………………………………………………………………….. 3070

thickened brick…………………………………………… 3070

the same, in terms of single brick……………….. 4100

Design force, MN (t):

pressing……………………………………………………………………. 1.8 (180)

pre-pressing………………………………………………………………. 0.02 (2)

Number of simultaneously pressed bricks, pcs. . . 2

Number of molds, pcs…………………………………….. 16

Design pressure, MPa (kgf/cm2):

pressing …………………………………………………………………… 30 (300)

pre-pressing…………………………………………………… 0.5 (5)

Depth of filling molds, mm………………………………. 145

Installed engine power of the pressing mechanism (excluding engine power

auxiliary mechanisms), kW, no more than………………. 37

Overall dimensions, mm, no more: ……………………………..

length……………………………………………………………………. 4730

width …………………………………………………………………. 3090

height above o…………………………………. 1900

total height……………………………………………………….. 3100

Weight, kg…………………………………………………………… 21 700

Press SMK 491-01 for the production of sand-lime brick

The semi-dry pressing press SMK 491-01 is designed for the production of sand-lime bricks with a height of 65 mm, thickened bricks with a height of 8–8 mm and stones with a height of 138 mm from a moistened mixture of sand and lime.

The press is characterized by double-sided pressing due to the vertical movement of the frame of the pressing mechanism. It carries out the processes of pressing, pushing and dispensing pressed products from the press area for their subsequent selection by the planter (stacker).

The press cycle is carried out in one revolution of the crankshaft. Changing the rotation speed of the latter is carried out by reinstalling replaceable pulleys on the motor shaft.

The press is a type of mechanical toggle-lever machine of continuous action.

Specifications

Product productivity according to GOST 530-95 or DSTU B V.2.7.61-97, pcs./h:

bricks……………………………………………………………………………….. 4500

hollow stones…………………………………………………………….. 2400

the same, in terms of single brick……………….. 5000

Pressing force, MN…………………………………………… 4.5

Number of simultaneously pressed products, pcs.:

brick (hollow) …………………………………………… 6

thickened (hollow) bricks………………………. 6

Maximum depth of filling molds, mm,

with double-sided pressing………………………………… 240

Installed power, kW, no more than ………………….. 34.2

incl. press drive……………………………………………………………. 28

filling mechanism……………………………………………………. 4

backfill adjustment mechanism…………………………….. 2.2

Overall dimensions, mm, no more:

length………………………………………………………………………………4365

width …………………………………………………………………. 3780

height above o…………………………………. 3635

total height……………………………………………………….. 5400

Weight, kg………………………………………………………………………………… 34 800

Back to section

Presses for the production of sand-lime bricks

Designs of a revolving crank-lever press

For the production of single and one-and-a-half silicate bricks, a revolving crank-lever press with a rotary table is used. This press is a three-position revolving semi-automatic machine, in one of the positions of which two forms are filled with lime-sand mass, in the second - pressing two bricks, in the third - pushing out two bricks.

The press (Fig. 6) consists of the following components: cast frame; a rotary table with stamps installed in it; pressing mechanism; table rotation mechanism; brick ejection mechanism; mixer feeder. In the base plate 1 of the frame there is a central column 2, which serves as an axis for rotating the table 3. Sixteen radially arranged forms with stamps 4 inserted into them are placed in the table. At the bottom of the stamp

there is a roller 5. A half-ring 6 made of a steel strip is attached to the plate 1 on the brackets, which holds the dies after pushing out the pressed brick in the required height position. Table 3 is covered by a ring 7 lying on the balls. The ring can move freely around the table. Plate 1 is connected with two coupling bolts 8 to the cross-beam 9, securing the column 2. A metal brush shaft 11 is installed in the bearings of the box 10. A counter-stamp 12 is mounted on the lower surface of the cross-beam with wedges. A crankshaft 13 is installed in the sliding bearings of the foundation plate, on the neck of which there is a connecting rod 14 , which is a differential lever: the second end of the connecting rod is connected to the press lever 15. The other end of the lever 15 is mounted on the axis 16 and can rotate on it. The press lever transmits pressure through the elbow 17 to the piston 18 with a press plate attached to it. The press drive consists of an electric motor and a gearbox 19, connected to each other by a coupling 20. The gearbox is connected to the drive shaft 21 by a coupling.

Friction clutch 1 is rigidly fixed to the drive shaft of the press (Fig. 7) and gear 2 is mounted, which has the ability to rotate on this shaft. When the clutch is engaged via lever 3, the gear drives the press mechanism through gear 4 and crankshaft 5.

Periodic rotation of the press table (Fig. is carried out from a spur gear 1. A crank pin 2 is attached to the gear wheel, which is pivotally connected to a ring covering the table 4 using a connecting rod 3. In the boss of the ring there is a pin 5, pressed upward by a spring 6. On the bottom parts of the table in the annular groove there are eight inserts that form an assembled ratchet. During the forward movement of the connecting rod 3, the table is motionless and the forms are filled with the mixture, pressing and pushing out bricks. During the return movement of the connecting rod, the finger pressed by the spring to the ratchet rests on its protrusion and turns table by 1/8 turn.Fixation of each table position is carried out by a brake.

is carried out from a spur gear 1. A crank pin 2 is attached to the gear wheel, which is pivotally connected to a ring covering the table 4 using a connecting rod 3. In the boss of the ring there is a pin 5, pressed upward by a spring 6. On the bottom parts of the table in the annular groove there are eight inserts that form an assembled ratchet. During the forward movement of the connecting rod 3, the table is motionless and the forms are filled with the mixture, pressing and pushing out bricks. During the return movement of the connecting rod, the finger pressed by the spring to the ratchet rests on its protrusion and turns table by 1/8 turn.Fixation of each table position is carried out by a brake.

The ejector mechanism of the press (Fig. 9) is formed from a double-armed lever 1, an ejector piston 2 and a cam 3 cantilevered onto the crankshaft. When the shaft rotates, the cam presses on one end of the double-armed lever, which, when lowered, raises two stamps to table level with the help of ejector piston 2. When two bricks are pushed out, the dies continue to be held in the raised position by the half-ring 6 (see Fig. 6).

Rice. 6. Press for the production of sand-lime brick : a - general view; b - kinematic diagram; 1 - plate; 2 - column; 3 - table; 4 — stamp; 5 - roller; 6 - half ring; 7 - ring; 8 - bolts; 9 — traverse; 10 - box; 11 — brush; 12 — counter-stamp; 13 - crankshaft; 14 — connecting rod; 15 — lever; 16 - axis; 17 - knee; 18 - piston; 19 — gearbox; 20 - coupling; 21 - drive shaft

The productivity of the press is 1 brick per second, the highest pressing force is 12 Mn, the highest specific pressure is 20 Mn/m2; power of the electric motor of the press is 20 kW, the electric motor of the mixer feeder is 10 kW.

Rice. 7. Press drive device : 1 - friction clutch; 2 - gear; 3 - lever; 4 - gear; 5 - crankshaft

Rice. 8. Press table drive : 1 - gear wheel; 2, 5 - finger; 3 — connecting rod; 4 - table; 6 - spring

Rice. 9. Ejector mechanism : 1 - double-arm lever; 2 - cam; 3 - piston

When the press is equipped with additional devices with void formers, it is possible to produce hollow bricks.