What is sheet metal?

Thin-sheet metal products are made from carbon steel. The thickness of the sheets can be from 0.4 mm. This is a very thin rolled material used in special high-tech work. Modern production technologies and improved chemical composition ensure high quality products. The flawless surface that thin metal sheets have does not require additional processing before applying paint and varnish, which saves time during work.

Metal sheet production

Metal sheets are produced by cold or hot rolling. The hot-rolling method uses low-alloy and carbohydrate steel. In this case, a perfectly flat surface is not obtained due to its uneven cooling. These thin metal sheets are used for the manufacture of household appliances, housings, aircraft, construction and mechanical engineering.

The cold-rolling method involves the use of hot-rolled billets made of carbon and low-carbon steel. After undergoing additional processing to remove scale, the sheet is cold rolled. The result is a thinner metal sheet with high surface quality, a thickness tolerance of no more than ±0.01 mm and improved technological properties. It is subsequently used for the manufacture of various machines and mechanisms. In any case, the production of sheet metal requires the use of specialized equipment.

Sheet steel by rolling type

Based on the type of rolling, products are classified into cold-rolled and hot-rolled. They can then be subjected to treatments such as heat treatment and skin tempering to increase their yield strength or zinc coating to protect against corrosion.

Cold rolled steel

The manufacturing process involves placing a metal alloy between rollers located at the top and bottom. They deform the metal into a thinner piece or sheet than its original size.

The blank for cold-rolled products is hot-rolled. Its properties are improved: the metal is washed with acid at the manufacturing plant before the final rolling is completed. The final stage of obtaining the material consists of heat treatment, known as annealing. Cold rolled steel is harder and stronger than hot rolled steel and looks more presentable. Cold rolled steel sheets and coils are commonly used where dimensional tolerances, strength and surface finish are critical.

Areas of application of cold-rolled sheet metal products: ♦ Metal furniture. ♦ Automotive components. ♦ Electronic equipment. ♦ Household appliances and components. ♦ Lighting lamps. ♦ Construction of buildings.

Hot rolled steel

Products of this type are subjected to rolling processes at temperatures above 750 degrees Celsius. Due to their unsightly appearance, they are usually used where finishing is not critical to the project. This is one of the types of steel most often used for the manufacture of parts of mechanically welded structures, for bending or profiling, assembly by welding, and even for artistic sculptures. The color variations on the steel sheets give character to the entire sculpture.

Properties of metal sheet

Sheets made by hot-rolled and cold-rolled methods differ in their properties. These features are taken into account when using this building material. Hot-rolled sheet has increased rigidity, so it is practically not amenable to stamping and embossing. Welding such a sheet can lead to its thermal deformation.

The popularity enjoyed by thin metal sheets is explained by the presence of a large number of positive characteristics, such as reliability, versatility, strength, durability, ease of installation, etc. Galvanized sheets (coated with one or more layers) are especially in demand in the production of equipment, construction and the medical industry. both sides with zinc). The surface of such a sheet with high-quality galvanization is very clean, smooth, without the slightest cracks.

Application

Rolled sheets are used in a wide variety of production areas. It is almost impossible to name an area where thin metal sheets would not be in demand. This includes the construction of fences, roofs, and wall cladding, the manufacture of stairs and metal structures. Rolled sheets are used for the manufacture of refrigerators, various containers, and drainpipes. This material has recently been in great demand for decorating summer cottages. It is impossible to imagine the creation of cars, airplanes and other equipment without it.

A thin metal sheet with a wavy surface, so-called profiled or corrugated, is used for roofing and fencing. It is made from galvanized steel. Waves can have very different shapes - rounded, trapezoidal and others, and also differ in height and width. Rolled sheets also serve as raw materials for the production of other building materials (corrugated sheets, metal tiles, etc.).

A very thin sheet of metal is called foil. In radio engineering, copper foil has been used as packaging for confectionery products, and aluminum foil has been used for packaging tea. Its thickness is no more than 0.2 mm.

Kinds

Types of thin sheet steel:

- Roofing. Thickness - 0.5–0.8 mm.

- Tough. Thickness - 0.2–0.5 mm.

Types of tin:

- White. Covered with a layer of tin.

- Black. After production, the surfaces of the sheets turn black.

A layer of tin on tinplate is needed to protect metal surfaces from rust. Roofing steel can be coated with a layer of galvanization or oil paint.

Thin sheet metal and wire are used in various fields of activity:

- Production of metal cassettes - perforated, solid, hollow, filled with thermal insulation.

- Production of ceiling and facade panels.

- Manufacturing of support pillars, metal structures, parapets, lamellas, fence sections, caps.

- Production of window openings and additional elements.

Other areas include the production of housings for machines, instruments, machine tools, cans, dishes, and drainpipes.

Drainpipes (Photo: Instagram / ventilacia_kms)

Methods for processing thin sheet metal

When manufacturing a product of a certain configuration, it is necessary to carry out appropriate processing of the sheet profile. As a result, the appearance of the material and its quality should not be affected. There are several different processing steps that are used to process thin sheet metal. This includes welding, cutting, bending, etc.

The most common processing method is bending. Performed by stretching and compressing the outer layer. It can be manual, when tools such as a hammer, pliers, vice are used, or mechanical, performed on modern equipment. Manual bending is a rather labor-intensive process, so it is performed only for bending thin metal sheets with a thickness of no more than 0.6 mm.

Welding is used when there are no special requirements for the appearance of the product. A metal sheet less than 3 mm thick can be melted quite easily, resulting in holes that are very difficult to weld. Direct current is used to weld sheets up to 2 mm thick. When it is necessary to weld thinner metal, small currents and electrodes of smaller diameter are used.

The range of metal sheets on the construction market is quite large, which allows you to choose the material that best suits the task.

Blog

Topic: “Thin sheet metal and wire. Artificial materials.

Purpose of the lesson

: to study the types of thin sheet metal and wire.

Lesson objectives:

Introduce the concepts of “thin sheet metal” and “wire”, “metal properties”, part development; with the process of obtaining and using thin sheet metal and wire, with the features of the image of wire products. Development: cognitive interest, research skills, communication skills: ability to listen and hear, tolerance, abstract logical thinking, ability to analyze, generalize, ability to perform a development sketch. Foster independence, responsibility, dedication, mutual assistance. Time:

2 hours.

Lesson type

: combined.

Lesson form

: lesson-game, problem-search.

Interdisciplinary connections

: history, physics.

Forms of work: frontal, group.

Teaching methods: explanatory-illustrative, instruction, problem-search, independent (laboratory-practical) work.

Lesson equipment:

sets of thin sheet metal and wire for laboratory work; samples of thin sheet metal and wire and products made from them, Exhibits of the school local history museum (plates of armor of warriors of the Jurchen state); task cards, projector, screen, computer, painting “In the workshop of a medieval gunsmith.”

DURING THE CLASSES

I. Organizational moment.

Checking students' readiness for the lesson. Mark those who are absent.

II. Preparing students for conscious and active learning of new material.

Before you is the painting “In the workshop of a medieval gunsmith.” What is shown on it? Why does a knight need them? What do you think armor should be like? What do you think the armor is made of? The armor was made of t/l metal. “Thin sheet metal and wire” is the topic of our lesson.

Would you like to take an imaginary journey to the times of the knights?..... Imagine that we are in a medieval gunsmith's workshop. I will be the master, and you will be my apprentices. The workshop received an order from a knight to make armor. Can we do it now? Do you know the types and properties of t/l metals?…. In order to fulfill this order, you and I must study the types of thin sheet metal and wire, the properties of metals and alloys, learn to distinguish between the types of thin sheet metal, so that in the future you can correctly select the material for armor and other products.

III. Repetition.

Frontal survey on the topic of the last lesson.

IV. Learning new material

Metals play a huge role in human life. They are used to make various machines, building structures, and household items.

Metals have different properties: physical, mechanical.

Physical properties: electrical conductivity - all metals conduct current, thermal conductivity, color (demonstration of metals), luster, fluidity.

Mechanical properties of metals: ductility - the ability of a metal to change shape under the influence of loads, strength - the ability of a metal to withstand loads without collapsing; and hardness.

Metals are often used to make products not in their pure form, but in the form of alloys. The most common alloys: steel and cast iron (alloys of iron with carbon), duralumin (alloy of aluminum with copper, magnesium, etc.), bronze (alloy of copper with lead, tin, etc.), brass (alloy of copper with zinc).

Blanks from metals and alloys are produced at enterprises in the form of sheets, rods, pipes, wire, which greatly facilitates the manufacture of various products from them.

Previously, sheet metal was produced by forging (heated blanks were flattened with hammers); this work was very long and painstaking. It was very difficult to obtain the same thickness of the workpiece. One wrong blow from the master could ruin the entire work. In modern enterprises, sheet metal is produced by rolling heated ingots in rolling mills, where the billet, falling between the rolls, is compressed and takes the form of a sheet. By adjusting the gap between the rollers, you can obtain a sheet of the desired thickness.

Sheet steel is divided into thick sheet (thicker than 2 mm) and thin sheet (thinner than 2 mm).

In turn, thin sheet steel comes in several types

Tin (0.2 to 0.5 mm thick) comes in black and white.

Tinplate is sheet steel coated on both sides with a thin layer of tin. This type of tin has a smooth, shiny, stainless surface; it is used to make tin cans, lids for glass jars, and toys.

Roofing steel (0.5 to 0.8 mm thick) that does not have a coating is called black. To protect it from corrosion, it is coated with paint; it is used mainly in construction: covering roofs, finishing balconies, building fences, sheathing wooden buildings.

To prevent the surface of the sheets from rusting, it is coated with a thin layer of zinc (galvanized steel). This semi-finished product is used to cover roofs; buckets, drainpipes, and cornices are made from it.

Cold-rolled steel (0.8–2 mm thick) is produced by repeated rolling of sheet steel; it is used for the manufacture of car body parts and refrigerators.

Very thin sheet metal is called foil (less than 0.2 mm thick). Copper foil is widely used in radio engineering, and aluminum foil is used for packaging chocolate, sweets, tea, and in cooking.

In addition to sheet metal, wire is also widely used in industry, which is long and thin. Copper and aluminum wire are used to make electrical wires and rivets. Nails, screws, screws, rivets are made from soft steel wire, and springs, strings and other products are made from hard wire.

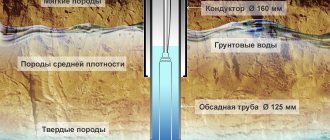

Wire with a thickness of more than 5 mm is obtained by rolling heated blanks between rollers with grooves. This wire is called wire rod.

Thinner wire is obtained by drawing - pulling wire rod through dies - parts with a hole made of very hard materials and even diamonds. Drawing mills are serviced by drawers.

In the days of the knights, wire was drawn in forges while swinging on swings. The drawer, sitting on a swing, rested his feet on the die, grabbed the end of the wire with pliers, pushed off and thus pulled the wire through. This wire was used mainly in the manufacture of chain mail.

Tinsmiths manufacture products from thin sheet metal at enterprises. Workers in these specialties must know the structure of the equipment they work on, the properties of metals, and be able to read drawings.

In factories, rolling mills for producing sheet metal are serviced by rollers.

Tinsmiths manufacture products from thin sheet metal at enterprises. They must know the structure of various machines and devices for sheet metal processing and be able to work on them using various tools.

V. Independent work of students (work in pairs)

Induction training:

Have you forgotten about the order from the knight? We need to choose the right material for the armor. And for this, now we will do laboratory and practical work with you

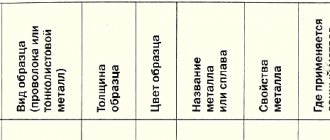

Consider several samples of thin sheet metal (roofing, black and galvanized steel, black and white tin). Determine the color of each sample and the name of the material. Try to bend each sample. Think about where the material you are studying is used. Record the results of your observations in the table. Final briefing

Frontal survey on the following questions:

What metal is best to make armor from and why? What is the difference between black tin and white tin? How is thin sheet metal obtained? Where is foil used? How is the wire obtained? Where is wire, t/l metal used? VI. Image of thin sheet metal products.

So, we have chosen the material for the armor and we can start making it. What do you think - where should we start making armor? How did we start making wood products? From the construction of a drawing or sketch.

Images of products made of thin sheet metal have some differences from images of parts made of wood. If you need to make a three-dimensional product from thin sheet metal, for example a scoop or a box, then you first need to cut out a flat piece and then bend it. Therefore, the drawings do not show an image of the product, but its development. Fold lines on developments are indicated by a dash-dot line with two dots. The outline is outlined with a solid thick main line. The center of the hole is shown by dash-dot lines with one point intersecting at right angles.

Products made of wire less than 2 mm thick. depicted with one solid thick main line. If the wire thickness is more than 2 mm. that product is depicted by two parallel solid thick main lines between which a dash-dotted line is drawn.

In the drawings you will often encounter various symbols.

S – flight thickness; R – arc radius; L – part length; Ф – hole diameter. VII. Lesson summary. Giving assessments and justifying them.

Well done! I am very pleased with your work in the lesson. Did you like the lesson? What did you learn new and interesting for yourself today? Now you have become masters and, as real masters, you are supposed to have your own mark, which the masters put on their products.

(document)

Thin sheet metal and wire Technology lesson in 5th grade. Lesson two in the section “TECHNOLOGY FOR CREATION OF METAL PRODUCTS BASED ON DESIGN AND TECHNOLOGICAL DOCUMENTATION” Technology teacher at Kalinin Secondary School - Malafeev Egor Nikolaevich. Chelyabinsk region, Bredinsky district, Kalininsky village, st. Shkolnaya, house 9. Form - a combined lesson (lecture with elements of conversation, practical part) using ICT.

Page 1

Thin sheet metal with a thickness of several hundredths to 4 mm is stamped mainly in a cold state, and thick sheet metal with a thickness of over 4 to several tens of millimeters is often stamped in a hot state.

Thin sheet metal must be cut using low cutting oxygen pressure. The center nozzle of the torch should not have any expansion at the outlet. To maximize the oxidation of molten iron in the slag, cutting must be carried out at relatively low speeds and with a minimum power of the preheating flame.

Thin sheet metal is widely used in various branches of mechanical engineering for the manufacture of critical parts such as thin-walled shells of complex shapes. In this case, the process of plastic deformation of workpieces occurs under complex loading conditions.

| Macrostructure of the root of a butt joint weld. |

Welding thin sheet metal in a horizontal position is similar in technique to welding in a vertical position. After the arc is excited, the electrode is positioned below the horizontal to keep the metal of the weld pool from flowing down.

The amount of thin sheet metal in brackets is indicated for vertical devices.

For thin sheet metal, pulsed welding is advisable. For thick sheet metal (610 mm), three-phase welding with a non-consumable electrode gives good results.

For thin sheet metal (2-5 mm), it is advisable to use pulse welding without filler wire. The mechanical properties of titanium during plasma welding are close to those obtained during argon arc welding.

For thin sheet metal, pulsed welding is advisable. For thick sheet metal (610 mm), three-phase welding with a non-consumable electrode gives good results. Welding with a consumable electrode in inert gases is performed at thicknesses of more than 4 mm at direct current of reverse polarity / CB (120 - f - 160) da, where da is the diameter of the welding wire. The disadvantage of consumable electrode welding is increased porosity.

Lesson type: combined.

Lesson form: game lesson, problem-search lesson.

Purpose of the lesson: to study the types of thin sheet metal and wire.

Lesson objectives:

- Introduce the concepts of “thin sheet metal” and “wire”, “metal properties”, part development; with the process of obtaining and using thin sheet metal and wire, with the features of the image of wire products.

- Development: cognitive interest, research skills, communication skills: ability to listen and hear, tolerance, abstract logical thinking, ability to analyze, generalize, ability to perform a development sketch.

- Foster independence, responsibility, dedication, mutual assistance.

Interdisciplinary connections: history, physics.

Forms of work: frontal, group.

Teaching methods: explanatory-illustrative, instruction, problem-search, independent (laboratory-practical) work.

Lesson equipment:

- sets of thin sheet metal and wire for laboratory work;

- samples of thin sheet metal and wire and products made from them, Exhibits of the school local history museum (plates of armor of warriors of the Jurchen state);

- task cards, projector, screen, computer, painting “In the workshop of a medieval gunsmith”;

Progress of the lesson

I. Organizational moment.

Checking students' readiness for the lesson. Mark those who are absent.

II. Preparing students for conscious and active learning of new material.

Before you is the painting “In the workshop of a medieval gunsmith.” What is shown on it? Why does a knight need them? What do you think armor should be like? What do you think the armor is made of? The armor was made of t/l metal. “Thin sheet metal and wire” is the topic of our lesson ( Appendix 2, Presentation

,

Slide 1.

)

Would you like to take an imaginary journey to the times of the knights?..... Imagine that we are in a medieval gunsmith's workshop. I will be the master, and you will be my apprentices. The workshop received an order from a knight to make armor. Can we do it now? Do you know the types and properties of t/l metals?…. In order to fulfill this order, you and I must study the types of thin sheet metal and wire, the properties of metals and alloys, learn to distinguish between the types of thin sheet metal, so that in the future you can correctly select the material for armor and other products.

III. Repetition.

Frontal survey on the topic of the last lesson.

IV. Learning new material

Metals play a huge role in human life. They are used to make various machines, building structures, and household items.

Metals have different properties: physical, mechanical. (Slide 2.)

Physical properties: electrical conductivity - all metals conduct current, thermal conductivity, color (demonstration of metals), luster, fluidity.

Mechanical properties of metals: ductility - the ability of a metal to change shape under the influence of loads, strength - the ability of a metal to withstand loads without collapsing; and hardness.

Metals are often used to make products not in their pure form, but in the form of alloys. The most common alloys: steel and cast iron (alloys of iron with carbon), duralumin (alloy of aluminum with copper, magnesium, etc.), bronze (alloy of copper with lead, tin, etc.), brass (alloy of copper with zinc).

Blanks from metals and alloys are produced at enterprises in the form of sheets, rods, pipes, wire, which greatly facilitates the manufacture of various products from them.

(Slide 3.)

Previously, sheet metal was produced by forging (heated blanks were flattened with hammers); this work was very long and painstaking. It was very difficult to obtain the same thickness of the workpiece. One wrong blow from the master could ruin the whole work (here are the details of the armor of a warrior of the Jurchen state, which were found by the same guys as you at the Krasnoyarovsky settlement in the village of Utesnoye, Ussuri region. These are armor plates made in the 12th century, that is, they are more than 800 years old years)

.(Slide 4.)

In modern enterprises, sheet metal is produced by rolling heated ingots in rolling mills, where the billet, falling between the rolls, is compressed and takes the form of a sheet. By adjusting the gap between the rollers, you can obtain a sheet of the desired thickness.

Sheet steel is divided into thick sheet (thicker than 2 mm) and thin sheet (thinner than 2 mm).

In turn, thin sheet steel comes in several types

(Slide 5.

) Tin (0.2 to 0.5 mm thick) comes in black and white.

Tinplate is sheet steel coated on both sides with a thin layer of tin. This type of tin has a smooth, shiny, stainless surface; it is used to make tin cans, lids for glass jars, and toys.

Roofing steel (0.5 to 0.8 mm thick) that does not have a coating is called black. To protect it from corrosion, it is coated with paint; it is used mainly in construction: covering roofs, finishing balconies, building fences, sheathing wooden buildings.

To prevent the surface of the sheets from rusting, it is coated with a thin layer of zinc (galvanized steel). This semi-finished product is used to cover roofs; buckets, drainpipes, and cornices are made from it.

(Slide 6.)

Cold-rolled steel (0.8–2 mm thick) is produced by repeated rolling of sheet steel; it is used for the manufacture of car body parts and refrigerators.

Very thin sheet metal is called foil (less than 0.2 mm thick). Copper foil is widely used in radio engineering, and aluminum foil is used for packaging chocolate, sweets, tea, and in cooking.

(Slide 7.)

In addition to sheet metal, wire is also widely used in industry, which is long and thin. Copper and aluminum wire are used to make electrical wires and rivets. Nails, screws, screws, rivets are made from soft steel wire, and springs, strings and other products are made from hard wire.

Wire with a thickness of more than 5 mm is obtained by rolling heated blanks between rollers with grooves. This wire is called wire rod.

Thinner wire is obtained by drawing - pulling wire rod through dies - parts with a hole made of very hard materials and even diamonds. Drawing mills are serviced by drawers.

(Slide 8.)

In the days of the knights, wire was drawn in forges while swinging on swings. The drawer, sitting on a swing, rested his feet on the die, grabbed the end of the wire with pliers, pushed off and thus pulled the wire through. This wire was used mainly in the manufacture of chain mail.

Tinsmiths manufacture products from thin sheet metal at enterprises. Workers in these specialties must know the structure of the equipment they work on, the properties of metals, and be able to read drawings.

In factories, rolling mills for producing sheet metal are serviced by rollers.

Tinsmiths manufacture products from thin sheet metal at enterprises. They must know the structure of various machines and devices for sheet metal processing and be able to work on them using various tools.

V. Independent work of students (work in pairs). (Slide 9.)

Induction training:

Have you forgotten about the order from the knight? We need to choose the right material for the armor. And for this, now we will do laboratory and practical work with you

- Consider several samples of thin sheet metal (roofing, black and galvanized steel, black and white tin).

- Determine the color of each sample and the name of the material.

- Try to bend each sample.

- Think about where the material you are studying is used.

- Record the results of your observations in the table.

(Annex 1.

Laboratory work.)

Final briefing

- What metal is best to make armor from and why?

- What is the difference between black tin and white tin?

- How is thin sheet metal obtained?

- Where is foil used?

- How is the wire obtained?

- Where is wire, t/l metal used?

VI. Image of thin sheet metal products.

So, we have chosen the material for the armor and we can start making it. What do you think - where should we start making armor? How did we start making wood products? From the construction of a drawing or sketch.

(Slide 10.)

Images of products made of thin sheet metal have some differences from images of parts made of wood. If you need to make a three-dimensional product from thin sheet metal, for example a scoop or a box, then you first need to cut out a flat piece and then bend it. Therefore, the drawings do not show an image of the product, but its development. Fold lines on developments are indicated by a dash-dot line with two dots. The outline is outlined with a solid thick main line. The center of the hole is shown by dash-dot lines with one point intersecting at right angles.

Products made of wire less than 2 mm thick. depicted with one solid thick main line. If the wire thickness is more than 2 mm. that product is depicted by two parallel solid thick main lines between which a dash-dotted line is drawn.

In the drawings you will often encounter various symbols.

- S – flight thickness;

- R – arc radius;

- L – part length; – hole diameter.

VII.

Independent work of students. (Slide 11.)

You and I will restore the armor of the warrior of the Jurchen state. To do this, first make a sketch of the armored plate in notebooks. What is a sketch and how is it done?

1. What is a sweep? 2. What lines show the places where the workpiece is bent in the drawing? 3. How to show the center of a hole in a drawing?

VIII. Lesson summary. Giving assessments and justifying them.

Well done! I am very pleased with your work in the lesson. Did you like the lesson? What did you learn new and interesting for yourself today? Now you have become masters and, as real masters, you are supposed to have your own mark, which the masters put on their products.

Rice. 1. Master's mark.

Metals play a huge role in human life. They are used to make various machines, building structures, and household items.

Metals have some physical properties that wood does not have: electrical conductivity, magnetizability, thermal expansion, melting point. The mechanical properties of metals, such as strength and hardness, are significantly higher than those of wood. Unlike wood, metals have plasticity - the ability to change shape under the influence of external forces without collapsing.

Metals are often used to make products not in their pure form, but in the form of alloys.

The most common alloys:

steel

and

cast iron

(alloys of iron with carbon), duralumin (alloy of aluminum with copper, magnesium, etc.), bronze (alloy of copper with lead, tin, etc.), brass (alloy of copper with zinc).

Blanks from metals and alloys are produced at enterprises in the form of sheets, rods, pipes, wire, which greatly facilitates the preparation of various products from them.

Sheet metal is produced by rolling

heated ingots in rolling mills (Fig. 56), where the billet, falling between the rolls, is compressed and takes on the shape of a sheet. By adjusting the gap between the rollers, you can obtain a sheet of the desired thickness.

Sheet steel is divided into plate steel

(thicker than 2 mm) and

thin sheet

(thinner than 2 mm).

In turn, thin-sheet steel comes in several types: roofing steel

(thickness from 0.5 to 0.8 mm),

tin

(thickness from 0.2 to 0.5 mm).

Roofing steel that is not coated is called black. To prevent the surface of the sheets from rusting, it is coated with a thin layer of zinc (galvanized steel).

Tin comes in black and white. Tinplate is sheet steel coated on both sides with a thin layer of tin. This tin has a smooth, shiny, stainless surface.

Machine and instrument casings, dishes, and cans are made from sheet metal.

Very thin sheet metal is called foil

. Copper foil is widely used in radio engineering, and aluminum foil is used for packaging chocolate, sweets, tea, etc.

In factories, rolling mills for producing sheet metal are serviced by rollers

. They must have a good knowledge of the properties of metals at different temperatures and understand the design of rolling equipment.

Tinsmiths manufacture products from thin sheet metal at enterprises

. They must know the structure of various machines and devices for sheet metal processing and be able to work on them using various tools.

wire is also widely used in industry.

, which is distinguished by its large length and slight thickness. Copper and aluminum wire are used to make electrical wires and rivets. Nails, screws, screws, rivets are made from soft steel wire, and springs, strings and other products are made from hard wire.

Wire with a thickness of more than 5 mm is obtained by rolling heated blanks between rollers with grooves (Fig. 58, a). This kind of wire is called wire rod

.

Thinner wire is obtained by drawing

- pulling the wire rod through

dies

- parts with a hole made of very hard materials and even diamonds (Fig. 58, b).

Drawing mills are serviced by drawers, who must have a good understanding of the behavior of metals and alloys during drawing and know the design of drawing equipment and devices.