Spring manufacturing technology and requirements for them

Spring manufacturing technology plays an important role and is of great importance for their trouble-free long-term operation.

Elastic elements are high-tech products that require qualifications and experience from design engineers and technologists, as well as a good fleet of equipment at the manufacturing enterprise. The operation of the entire unit, where this part will be a component, depends on how correct the calculations of the spring were, the selection of material taking into account the required characteristics and features of its application, as well as the technologies used and manufacturing accuracy.

What types of springs do we produce?

Springs are elastic elements that accumulate and release or absorb energy due to deformation under load. The working element that creates the “springiness” can be metal, liquid or gas. We specialize in the production of metal products. According to the type of load they accept, they are divided into compression, tension, bending and torsion springs; the production of each of these subtypes is possible to order at competitive prices.

According to their design, metal springs are divided into the following types:

- For compression:

- screw (twisted cylindrical);

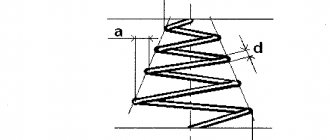

- shock absorbers (twisted conical);

- Torsion:

- torsion bars;

- Disc-shaped;

- From tape and sheet:

- lamellar;

- spiral;

- flat.

We will tell you about the features of the production of each of these types of springs at our enterprise.

What do all spring manufacturing technologies have in common?

In the vast majority of cases, the method of manufacturing a spring directly depends on the purpose, dimensions and characteristics of the material of the product, and what potential energy of the spring is required. For example, small and medium-sized springs with a round cross-section of a rod are made using cold coiling, and to produce larger analogues they resort to the hot coiling method. In some cases, products of the same type can be manufactured in different ways - the number of options depends on the order conditions, intended functionality and requirements for the final product.

The choice of technology is also influenced by the material used - the power, duration and/or need for heat treatment depend on its characteristics.

One of the most common technologies is winding. It is carried out manually (the operator winds the wire or rod on a machine) or automatically (using a winding machine), hot or cold, with or without tempering. The cold winding method is the most common, as it has the lowest cost, but only the hot method is suitable for the manufacture of large-sized springs.

General stages of all spring manufacturing technologies:

- Preliminary preparation of bars of the required diameter (usually performed on rolling machines).

- Editing workpieces (straightening geometry, grinding).

- Calculation of springs when manufactured to order and in standard mode is performed using calculation programs.

- It is possible to coat finished parts with anti-corrosion compounds.

What types of anti-corrosion coating are possible: phosphating + oiling, galvanizing, cadmium plating, chrome plating, polymer powder coating, electropolishing, etc. It is also possible to apply enamels, varnishes with aluminum powder and paint. When producing springs to order, the anti-corrosion coating option is agreed with the customer.

What equipment is used in the production of springs:

- spring-coiling machines;

- bending stations;

- converted lathes;

- grinding machines;

- tempering and hardening furnaces (for heat treatment);

- stands for quality control.

When placing an order for the production of springs with us, rest assured: we carry out all stages of production using high-quality modern equipment that is regularly tested. inspection in accordance with GOSTs and the highest European quality standards. We sell our own products, so we are ready to vouch for every spring made for you, regardless of its size and material.

Twisted compression springs: design and operation features

During operation, this type of spring absorbs loads applied in the longitudinal-axial direction. Compression springs initially have gaps between the coils; the application of external force leads to deformation, characterized by a decrease in the length of the product, and is limited to the moment when the coils touch. When the impact is canceled, the spring must restore its shape and geometric dimensions to what they were before the load was applied.

The main dimensions that determine the type of individual part are:

- — Diameter of wire (rods).

- — Number of turns.

- — Winding pitch.

- — Product diameter.

The most common are cylindrical helical compression springs, in which the diameter of the product is the same along the entire length. These parts are widely used in various industries: instrument and mechanical engineering, mining, gas and oil production, and others.

In general, compression springs can have not only a cylindrical shape, but also a conical, barrel-shaped, or more complex one. The pitch of the turns can be constant or variable, and the winding can be clockwise or counterclockwise.

This introduces features into the generally accepted technology of their manufacture.

Spring requirements

To do their job effectively and correctly, these elements must have good strength, ductility, elasticity, endurance and relaxation resistance.

Achieving these qualities is possible subject to many factors, including:

- — Correct choice of material.

- — Competently carried out calculations.

- — Compliance with manufacturing technology.

High-quality springs must meet the requirements of GOST and the technical specifications of a specific customer.

According to the standard, there are three accuracy groups for controlled deformations:

- — With permissible deviations up to 5% (+/-).

- - To 10%.

- — Up to 20%.

In accordance with this, three groups of accuracy according to geometric parameters are defined.

An important requirement for these parts is a clean surface; scratches and other defects are not allowed here, as they lead to a decrease in strength and reliability.

Material requirements

Springs for operation in certain conditions are selected according to standard sizes, taking into account the nature and magnitude of loads characteristic of operating conditions. The reliability of the operation of these parts is determined by many factors, including the quality and structural state of the metal/alloy after heat treatment, and the presence of residual internal stresses. In addition, the metallurgical quality of the steel/alloy is important. So long-term, trouble-free operation begins with choosing a material with a certain set of properties.

Helical compression springs, depending on the size, work performed and other factors, are made of various steels/alloys, including structural spring-spring, stainless steel, and others.

The most widely used materials are steel 60S2A GOST 14959-79, as well as 50KhFA, 51KhFA, 60S2KhFA and similar alloys. Of the stainless steels, the most widely used steel is 12Х18Н10Т.

Features of the technology

Depending on the intended purpose of such parts and their specifications, it is appropriate to talk about the features of their production technology. The manufacture of products from materials with a round cross-section can be done by cold or hot winding. The first method usually produces small/medium springs (from wire up to 8 mm in diameter), and the second - large ones.

In addition, the difference is determined by the use of different types of heat treatment, which is associated with the need to give the products certain characteristics.

Technology of cold coiling of springs without hardening

The coiling of the blanks is made from wire, which was previously patented by the manufacturer. This process involves heating to a temperature above the transformation range, which perfectly prepares the material for subsequent cold plastic deformation.

The blanks formed by coiling ensure compliance with such mandatory parameters as:

- Diameter (this parameter can be internal, middle or external).

- Number of turns provided (working and general).

- Step and height dimension of the manufactured part (changes possible as a result of subsequent processing are taken into account).

- The correctness of the compression of the outer turns.

The next stage is mechanical finishing (facing), during which the end turns (non-working) are processed until a surface is formed perpendicular to the axis. After this, heat treatment is carried out - in this case - only low-temperature tempering. This imparts permanent elastic properties and eliminates the stresses created during winding. An important technological point is to correctly determine the temperature and exposure time, focusing on the diameter of the selected material and the requirements of the standards. Heat-treated springs are subject to control and testing to ensure that the parameters comply with the requirements of the drawings.

If, according to operational requirements, an anti-corrosion coating is provided, its application becomes the last stage in the production of such parts. Only if galvanization was used are the parts heated to dehydrate them.

Technology of cold coiling of springs with quenching and tempering

The difference between this technology and the previously described one begins only at the heat treatment stage. Previous steps: winding and the necessary mechanical processing are performed in exactly the same way.

The first stage of heat treatment is hardening: heating to a certain temperature (depending on the material used), holding the part for a specified time and forced (rapid) cooling in a special environment, mainly in oil (sometimes in water, saline solution, etc.). Important: to heat the springs for hardening, they are placed horizontally to avoid subsidence under their own weight.

The heat treatment is completed by tempering - heating to a relatively low temperature and holding for a strictly defined time to impart the necessary qualities.

After this, parameters such as hardness and correct compression/recovery are monitored. If provided for by the manufacturing technology of a specific part, sandblasting, shot hardening, and application of a corrosion-preventing protective coating are used.

Technology of hot coiling of springs with quenching and tempering

Hot winding involves preheating the material in an electric or gas oven (a possible option is the use of high-frequency currents).

The workpiece prepared in this way is subjected to winding according to the requirements of the technical specifications, layout, as well as trimming and finishing of geometric values using tools. After this, the part is submitted for hardening, the parameters of which are determined by the material used, and then for tempering.

At the end of the heat treatment, parameters are monitored and, if necessary, crimping, capping, other additional operations and surface treatment are carried out. The production process ends with dyeing and drying.

Cold coiling technology with quenching and tempering

The first stages of the technology coincide with the previous process. Changes begin at the heat treatment stage. It is carried out in several stages:

- Hardening. The workpiece is heated to a given temperature and held for 2 to 3 hours. Next, it is subjected to rapid cooling by immersing it in a container with mineral oil or saline solution. During the hardening stage, the workpieces must be in a horizontal position. This will avoid deformation

- Vacation. The workpiece is heated to 200-300° and kept for several hours to relieve internal stresses and improve elastic properties.

Further measuring and control operations are also carried out. The workpieces that have passed the inspection are sent for sandblasting to remove scale. If necessary, shot blasting should also be done to increase the strength of the surface layer of the metal.

The process is completed by applying a protective coating.

Equipment and fixtures used

Making springs requires a variety of equipment to best suit the requirements of each step of the process.

Winding is carried out either on special spring-coiling machines, or on turning equipment converted for these purposes. It is also possible to use manual equipment or specialized semi-automatic machines. Further processing - mechanical - is carried out by face grinding machines, and thermal - in hardening and tempering furnaces. Important: to prevent warping during heat treatment, special mandrels are used. For small parts they are used during tempering, while large parts are hardened on a mandrel.

Quality control is also carried out on special equipment designed specifically for this process.

Hot coiling technology with quenching and tempering

Before winding, the workpiece is heated to plasticity temperature using one of the following methods

- muffle furnace;

- gas-burner;

- high frequency heating.

Next, the workpiece is supplied to the coiling equipment. The geometry is adjusted and flat ends are formed.

Heat treatment includes hardening and low-temperature tempering.

Heat treatment schedules are constructed based on the properties of the material and the dimensions of the workpiece.

Operating mode of the quenching and tempering furnace line

Next comes the control and measuring stage. Manufacturing is completed by applying anti-corrosion protection.