What are the properties of automatic steel?

Automatic structural steels, unlike structural steels, have lower strength, but at the same time they have increased machinability. In metallurgy, they try to get rid of sulfur and phosphorus - additives that impair performance, while in the production of automatic alloys, on the contrary, their content is increased. For example, sulfur makes the product brittle and brittle, and phosphorus impairs strength and leads to cracks, but at the same time it speeds up the processing of a metal workpiece into a product of complex shape.

What additives are added to automatic alloy steels?

The alloy is enriched with alloying additives, which improve the flexibility of processing and reduce the mechanical characteristics of finished products. The main goal in increasing the sulfur and phosphorus content is to simplify metal processing and reduce the cost of servicing the machine and its consumables.

Depending on what properties the metal should have, various additives are added to alloy it. They allow you to speed up mass production and reduce the cost of finished products.

The alloy differs in the content of various components:

- Sulfur is introduced into the composition in manganese sulfide, due to which the strength of the alloy is reduced, chip cutting is improved and roughness is reduced.

- Phosphorus has a similar effect on metal, as does sulfur.

- Selenium further increases chip breakage without affecting the strength of the alloy.

- Lead allows you to reduce the cost of parts due to the fact that the cutting tool of the machine lasts longer and does not deteriorate as quickly as when processing more durable metals.

- Calcium facilitates the operation of the machine because the chips do not stick to the metal, and the cutting tool can last longer.

- Manganese does not affect the quality of the alloy and is used to introduce sulfur in the composition of manganese sulfide.

Automatic steels

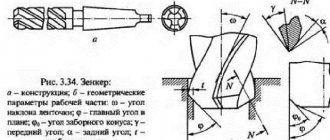

Mechanical cutting is the main technological process for manufacturing most machine parts.

Cutting machinability is determined by the chemical composition and heat treatment of the steel, on which the structure and properties of the workpiece depend. For good heat removal during processing, such a physical property as thermal conductivity is of great importance. High-alloy steels of the austenitic class are characterized by unsatisfactory machinability. They have a low yield strength and high ductility, so when cutting, viscous chips are formed that are difficult to separate from the workpiece. Austenitic steels have low thermal conductivity, which causes overheating of the tool and a decrease in its service life.

Machinability is especially important in those industries that use automatic machining lines. automatic steels have been developed especially for them.

containing microadditives: sulfur S, lead Pb, selenium Se, calcium Ca. These additives improve machinability due to their different effects on the structure of steels:

• sulfur forms chemical compounds - MemSn sulfides, which have a lubricating effect and increase the brittleness of steel, facilitating the separation and grinding of chips;

• selenium forms chemical compounds such as selenides MemSen and sulfoselenides Mem(S,Se)n, which envelop solid particles in steels and eliminate their abrasive effect on the tool;

• lead does not dissolve in steels; it serves as an effective chip crusher and also reduces friction between the workpiece and the tool;

• calcium forms inclusions that can soften and exhibit a lubricating effect; used in steels intended for machining with carbide tools at high cutting speeds, when high temperatures occur in the cutting zone.

Automatic steels are marked according to GOST 1414-75:

— sulphurous

steel (0.08...0.30% S) is marked with the letter A and a number indicating the average carbon content (multiplied by 100) - A11, A20, A35, A40G; the amount of manganese in steels is 0.70...1.55%;

— to the labeling of selenium-containing products

steels (0.04...0.12% Se) add the letter E in carbon (A35E, A45E) and chromium (A40XE) steels;

— in the labeling of lead-containing

steels (0.15...0.35% Pb) add the letter C, followed by the carbon content (multiplied by 100). Steels are divided into carbon steels with a high sulfur content (AC 14, AS40, AS35G2, AS45G2) and alloy steels (AS12KhN, AS14KhGN, AS40KhGNM, etc.);

— calcium-containing

automatic steels (0.002...0.008% Ca) contain the letter C in the marking (AC20, AC40X, etc.).

Depending on the chemical composition, free-cut steels are used for the manufacture of various machine parts (Table 14.13).

Features of physical processing of automatic steels

The alloy enriched with alloying additives is smelted at a temperature of 1300°C. After smelting, or diffuse annealing, all components are evenly distributed throughout the volume of the alloy. Exposure to high temperatures eliminates the fragility of finished metal fragments due to the high accumulation of phosphorus or sulfur in one area. Additionally, the characteristics are improved:

- Cementation - diffuse surface saturation of carbon, increasing wear resistance.

- Cyanidation - saturation with nitrogen and carbon at a temperature of 950°C.

- Quenching and tempering makes the alloy harder, more brittle and less tough.

Properties of free-cut steel

The widespread use of various grades of automatic steels is due to the following advantages:

- slight wear of the cutting tool during material processing;

- easy breaking of steel shavings and quick removal of waste from the treated surfaces;

- ensuring high cleanliness of hardware surfaces.

An important feature is the processing of steels at the highest cutting speeds.

Not only hardware is produced from alloy and carbon steels. The materials are suitable for the manufacture of car and tractor parts, all kinds of shafts and gears.

Technical characteristics of automatic steels

The technical characteristics of alloys are significantly improved when bismuth, manganese, nickel and chromium are introduced into the composition. Adding lead in an amount of no more than 0.3% allows you to increase the speed of mechanical processing by approximately 25-50%. At the same time, the cutting tool becomes more wear-resistant and durable.

The processed area of the part does not overheat due to the addition of bismuth. The presence of calcium promotes the formation of a special layer in the cutting zone, which prevents the formation of adhesion and is an internal lubricating component. All alloying elements are added to the composition based on the GOST 1414-75 standard. The requirements of this document must be fully complied with, since even if the amount of additives is slightly exceeded, the properties of free-flowing steel deteriorate.

To improve the characteristics of produced steels, the following effective methods are also used:

- carburization with diffusion surface saturation of the metal with carbon, which significantly affects the increase in wear resistance of the finished product;

- diffusion annealing, eliminating heterogeneity caused by the inclusion of sulfur. The annealing temperature is about 1150°;

- hardening and high tempering. As a result of such heat treatment, automatic steel becomes less viscous and ductile. Having acquired increased fragility, the material has increased hardness;

- cyanidation, in which steel is saturated with nitrogen and carbon. To perform the operation, it is necessary to create a temperature of about 950°.

Consumers are mainly supplied with cold-worked automatic steel. Distinctive features are considered to be the most convenient workability and high mechanical characteristics.

Advantages and disadvantages of metal

Automatic steel is characterized by:

- simplified and fast cutting;

- easy chip separation;

- high thermal conductivity

- low hardness;

- minimal wear of the cutting tool.

Increased machinability, easy chip release and low roughness can increase production productivity several times, reduce costs and increase profits. The disadvantages include the presence of sulfur and phosphorus, which reduce the viscosity and ductility of parts.

What marking is applied to automatic steel?

Automatic steel must comply with GOST 1414-75. It is marked with a large letter A, judging by which you can understand what the steel is intended for. Additional additives that are included in the alloy are designated in the alloy by different letters. The numbers indicate carbon concentration, measured in hundredths of a percent.

Classification by alloy additives:

- A - sulfur steel;

- AC - lead added;

- E - selenium;

- C—calcium;

- G - manganese;

- X - chromium;

- N - nickel

Marking of automatic steels

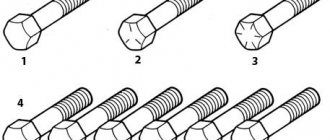

A characteristic feature of free-cut steels is their good machinability on metal-cutting machines. This is achieved primarily by increasing the sulfur content in automatic steels to 0.15-0.35% and phosphorus to 0.10-0.15%. Of course, these elements worsen the mechanical properties of steels, but production benefits from machining costs, since it gets the opportunity to produce non-critical fasteners (bolts, screws, nuts) and small parts in mass production on high-speed automatic lines. Automatic steels include both carbon and alloy steels.

Automatic steels are marked with the letter “A”, which is placed at the beginning of the mark before indicating the amount of carbon: A12, A20, A30, A40G.

In addition to these basic elements (S and P), lead, selenium, and calcium are introduced into automatic steels. The introduction of these elements is reflected in the brand's writing. Lead is designated by the letter “C”, and calcium by the letter “C”. Both of these letters are placed after the letter “A” and before the number indicating carbon in the stamp. Lead-containing grades: AS14, AS40, AS35G2, AS45G2, AS30ХМ, AS40ХГНМ . Lead is introduced in an amount of 0.15¸0.30%. Calcium-containing brands: AC20, AC40, AC60, AC40X, AC35G2, AC30ХМ , etc. The amount of calcium in the brand is negligible: 0.001-0.007%, i.e. does not exceed one hundredth of a percent. And selenium, designated in the stamp by the letter “E”, is placed at the end of the stamp: A35E, A45E, A40XE . The amount of selenium does not exceed a tenth of a percent.

Automatic steels are supplied in accordance with GOST 1414-75.

Bearing steels

Bearing elements (rings, rollers, balls) operate under conditions that require steel to have high hardness, wear resistance and contact fatigue strength. High-carbon (>1%) chromium steels are used as ball bearing steel, and for massive bearings, increased (up to 1%) amounts of manganese and silicon are added to chromium steel.

Bearing steels are supplied in accordance with GOST 801-78. Features of marking steels for bearings: the letter “Ш” is placed at the beginning of the mark, followed by the index of the main alloying element chromium and the subsequent number indicating the chromium content in tenths of a percent. The remaining alloying elements are marked as is customary for alloy steels.

Table 7.1. Composition of bearing steels (GOST 801-78)

| Steel grade | Chemical composition, % | |||

| Carbon | Manganese | Silicon | Chromium | |

| ШХ15 | 0,95-1,05 | 0,20-0,40 | 0,17-0,37 | 1,30-1,65 |

| SHH15SG | 0,95-1,05 | 0,90-1,20 | 0,40-0,65 | 1,30-1,65 |

The main brands in the production of automatic steels

The grade of metal determines the scope of application. Sulfur grades are used in production:

- A11 - bolts, nuts, chains, forks for clutches in cars;

- A12 - axles, screws, bolts, nuts and products of complex shapes;

- A20 - small parts of complex shape;

- A30 - hardware and parts that are subject to precision processing.

From brands containing various additives the following are produced:

- A35E - matrices and bandages;

- AS19KhGN - gear transmission mechanisms;

- AS35G2 - oil pump rollers;

- AC40X - car axle rings.