Description

Steel 35L is used : for the production of castings of rolling mill beds, gears, rods, runners, valves, balancers, diaphragms, rollers, rolls, brackets and other parts operating under medium static and dynamic loads; castings of parts for steam, gas, hydraulic turbines and axial compressors operating at temperatures from -40 to +350 °C; castings of groups 2 and 3 of parts for pipeline fittings and drive devices for them (parts of increased strength and hardness, except for bodies and covers), with a working medium temperature from -30 to +400 ° C without limiting the nominal operating pressure; castings of parts of mining and metallurgical equipment; investment castings for the aircraft industry Group I - loaded parts with certain requirements for density and mechanical properties: highly loaded brackets, sealed instrument housings, gyroscope frames, stabilizers, etc. and Group II - unloaded and lightly loaded parts: rings, flanges, connecting parts parts, leaking instrument housings, etc.

Note

Pearlitic grade steel. Castings of pipeline fittings parts made of steel 35L are supplied only for non-weldable structural elements.

35L Ekaterinburg

| Brand: | 35L |

| Substitute: | 30L, 40L, 45L |

| Classification: | Unalloyed casting steel |

| Application: | rolling mill beds, gears, rods, runners, valves, balancers, diaphragms, rollers, rolls, brackets and other parts operating under medium static and dynamic loads. |

| Foreign analogues: | Known |

Chemical composition in % of material 35L

GOST 977-88

| C | Si | Mn | S | P |

| 0.32- 0.4 | 0.2- 0.52 | 0.45- 0.9 | up to 0.06 | up to 0.06 |

| Note: The proportion of phosphorus and sulfur impurities depends on the group of castings and the type of steel smelting |

The temperature of the critical points of the material is 35L.

| Ac1 = 730, Ac3(Acm) = 802, Ar3(Arcm) = 795, Ar1 = 691 |

Technological properties of material 35L.

| Weldability: | limited weldability. |

| Flock Sensitivity: | not sensitive. |

| Tendency to temper brittleness: | not inclined. |

Foundry and technological properties of material 35L.

| Linear shrinkage: | 2.2-2.3 % |

Heat treatment modes for material 35L

| Normalization 860-880 ° C, Vacation 600-630 ° C |

| Quenching 860-880 ° C, Tempering 600-630 ° C |

Mechanical properties at T=20oC of material 35L.

| Assortment | Size | Eg. | sв | sT | d5 | y | KCU | Thermal change |

| — | mm | — | MPa | MPa | % | % | kJ/m2 | — |

| Castings, K25, GOST 977-88 | up to 100 | 491 | 275 | 15 | 25 | 343 | Normalization 860-880oC, Vacation 600-630oC, | |

| Castings, KT35, GOST 977-88 | 540 | 343 | 16 | 20 | 294 | Quenching 860-880 ° C, Tempering 600-630 ° C |

| Hardness 35L, | HB 10 -1 = 137-229 MPa |

Physical properties of material 35L.

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

| hail | MPa | 1/Grad | W/(m deg) | kg/m3 | J/(kg deg) | Ohm m |

| 20 | 2.12 | 53 | 7830 | 172 | ||

| 100 | 2.06 | 11.1 | 51 | 470 | 223 | |

| 200 | 2.01 | 12 | 49 | 491 | 301 | |

| 300 | 1.92 | 12.9 | 45 | 512 | 394 | |

| 400 | 1.76 | 13.5 | 42 | 533 | 497 | |

| 500 | 1.63 | 13.9 | 39 | 554 | 623 | |

| 600 | 1.51 | 14.5 | 35 | 580 | 771 | |

| 700 | 1.31 | 14.8 | 31 | 613 | 935 | |

| 800 | 1.18 | 11.9 | 27 | 710 | 1115 | |

| 900 | 12.5 | 27 | 701 | 1154 | ||

| T | E 10- 5 | a 10 6 | l | r | C | R 10 9 |

Foreign analogues of material 35L

Attention!

Both exact and closest analogues are indicated. 1.0552

| USA | Germany | Japan | France | England | China | Bulgaria | Hungary | Poland | Romania | Czech | Finland | Norway |

| — | DIN,WNr | JIS | AFNOR | B.S. | G.B. | BDS | MSZ | PN | STAS | CSN | SFS | N.S. |

Gr1

| ||||||||||||

| GS-52 | ||||||||||||

| S355JRC |

| SCC |

| A2 |

| ZGD290-510 |

| 35LI |

| Ao500FK |

| LII500 |

| OT500-3 |

| G-30-57 |

Designations:

| Mechanical properties : | |

| sв | -Short-term strength limit, [MPa] |

| sT | - Proportional limit (yield strength for permanent deformation), [MPa] |

| d5 | -Elongation at break, [%] |

| y | -Relative narrowing, [%] |

| KCU | -Impact strength, [kJ/m2] |

| HB | -Brinell hardness, [MPa] |

| Physical properties: | |

| T | -Temperature at which these properties were obtained, [Deg] |

| E | -Elastic modulus of the first kind, [MPa] |

| a | -Coefficient of thermal (linear) expansion (range 20o-T), [1/degree] |

| l | -Thermal conductivity coefficient (heat capacity of the material), [W/(m deg)] |

| r | -Material density, [kg/m3] |

| C | -Specific heat capacity of the material (range 20o-T), [J/(kg deg)] |

| R | -Specific electrical resistivity, [Ohm m] |

| Weldability: | |

| no limits | -welding is performed without heating and without subsequent heat treatment |

| limited weldability | -welding is possible when heated to 100-120 degrees. and subsequent heat treatment |

| difficult to weld | - to obtain high-quality welded joints, additional operations are required: heating to 200-300 degrees. during welding, heat treatment after welding-annealing |

35L-Steel for castings, unalloyed 35L-chemical composition, mechanical, physical and technological properties, density, hardness, application

Affordable metal products

Steel sheets

Standards

| Name | Code | Standards |

| Castings with special properties (iron and steel) | B83 | KSt 81-033:2009, TU 4112-78269737-008-05 |

| Steel castings | B82 | GOST 977-88, OST 108.961.04-80, OST 26-07-402-83, OST 24.920.01-80, OST 3-4365-79, OST 1 80059-83, OST 5R.9285-95, TU 108.11 .352-87, TU 108-11-539-87, ST TsKBA 014-2004 |

| Hard alloys, metal-ceramic products and metal powders | B56 | OST 107.750001.001-91 |

| Classification, nomenclature and general norms | IN 20 | OST 84-218-85 |

| Welding and cutting of metals. Soldering, riveting | B05 | RTM 108.020.122-78 |

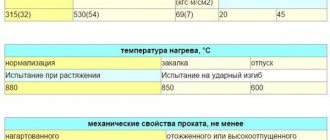

Mechanical characteristics

| Section, mm | sТ|s0.2, MPa | σB, MPa | d10 | y, % | kJ/m2, kJ/m2 | Brinell hardness, MPa |

| Sand castings. Annealing at 850 °C, furnace cooling | ||||||

| 30 | ≥255 | ≥530 | ≥19 | ≥34 | ≥490 | 146 |

| Normalization at 860-880 °C, cooling in air to 300-350 °C, holding for 2 hours at 300-350 °C + tempering at 600-620 °C, holding for 1 hour in an oven to 500 °C, cooling at air (the place where the sample was cut is indicated) | ||||||

| 100 | 245-250 | 350-510 | 13-20 | 16-25 | — | 136-156 |

| 200 | 295-310 | 560-590 | 17-27 | 19-40 | — | 163-196 |

| Castings of gas turbine parts. Normalization at 860-880 °C + tempering at 600-630 °C, air cooling | ||||||

| — | ≥275 | ≥490 | ≥15 | ≥25 | ≥343 | 137-166 |

| Normalization at 860-880 °C, cooling in air to 300-350 °C, holding for 2 hours at 300-350 °C + tempering at 600-620 °C, holding for 1 hour in an oven to 500 °C, cooling at air (the place where the sample was cut is indicated) | ||||||

| 10 | 235-275 | 550-590 | 22-28 | 28-43 | — | 143-156 |

| Castings for shipbuilding. Normalization at 860-890 °C + tempering at 630-670 °C, air cooling | ||||||

| — | ≥280 | ≥500 | ≥17 | ≥27 | ≥350 | 137-166 |

| Castings. Hardening from 860-880 °C + tempering at 600-630 °C | ||||||

| 100 | ≥343 | ≥540 | ≥16 | ≥20 | ≥294 | — |

| Normalization at 860-880 °C, cooling in air to 300-350 °C, holding for 2 hours at 300-350 °C + tempering at 600-620 °C, holding for 1 hour in an oven to 500 °C, cooling at air (the place where the sample was cut is indicated) | ||||||

| 100 | 245-250 | 400-520 | 13-20 | 16-25 | — | 143-156 |

| 200 | 275-295 | 530-550 | 13-18 | 14-28 | — | 163-170 |

| 30 | 235-295 | 540-570 | 23-28 | 33-42 | — | 137-156 |

| 50 | 290-450 | 570-590 | 22-27 | 56-64 | — | 154-186 |

| After normalization and tempering, quenching in oil from 860-870 °C + tempering at 620-630 °C, holding for 3 hours, cooling in air (the place where the sample is cut is indicated) | ||||||

| 100 | 345-380 | 570-600 | 22-33 | 36-58 | — | 170 |

| 200 | 300-335 | 550-600 | 18-26 | 25-36 | — | 156-170 |

| 10 | 330-370 | 620-660 | 24-28 | 44-49 | — | 162-206 |

| 100 | 345-365 | 560-580 | 24-29 | 28-48 | — | 170 |

| 200 | 300-330 | 550-580 | 16-25 | 21-34 | — | 156-170 |

| 30 | 365-400 | 610-640 | 23-29 | 47-57 | — | 156-187 |

| 50 | 365-550 | 590-640 | 22-31 | 33-66 | — | 162-178 |

Electrodes for carbon and low alloy steels

The widest range of electrodes is used for welding both carbon and low-alloy steels. This group includes carbon steels with a C content of up to 0.25%, as well as low-alloy steels with a tensile strength of up to 590 MPa. Both have a high carbon content. This reduces the oxidation of the metal and makes it easier to obtain oxide-free compounds. Their plasticity is increased by preliminary heat treatment or subsequent heating.

Both carbon and low-alloy steels have relatively low heat resistance and hardenability.

The share of alloying elements (cobalt, nickel, molybdenum, aluminum, tungsten, copper and others) can reach up to 5% in low-alloy steels. In comparison with carbon materials, they are characterized by a reduced susceptibility to mechanical aging, higher wear resistance, corrosion and cold resistance, and yield strength.

Depending on the proportion of alloying elements, the parameters by which electrodes are selected for welding carbon steels are determined. These parameters include:

- mechanical characteristics of the weld metal;

- required properties of the welded joint;

- temporary tensile strength;

- impact strength;

- relative extension.

ANO-4 (NAKS) Current - alternating or constant of any polarity

170.64 rub. ? with VAT per 1 kg.

ANO-21 (NAKS) Current - alternating or constant of any polarity

180.36 rub. ? with VAT per 1 kg.

MK-46.00 (NAKS) Current - constant reverse polarity, alternating

RUB 230.88 ? with VAT per 1 kg.

OZS-12 (NAKS, RRR) Current - alternating or direct polarity

RUB 183.84 ? with VAT per 1 kg.

physical characteristics

| Temperature | E, GPa | G, GPa | r, kg/m3 | l, W/(m °С) | R, NOM m | a, 10-6 1/°С | C, J/(kg °C) |

| 0 | 212 | 82 | 7830 | 53 | 172 | — | — |

| 20 | 212 | — | 7830 | 53 | 172 | — | — |

| 100 | 206 | 80 | — | 51 | 223 | 111 | 470 |

| 200 | 201 | 78 | — | 49 | 301 | 12 | 491 |

| 300 | 192 | 75 | — | 45 | 394 | 129 | 512 |

| 400 | 176 | 68 | — | 42 | 497 | 135 | 533 |

| 500 | 163 | 63 | — | 39 | 623 | 139 | 554 |

| 600 | 151 | 58 | — | 35 | 771 | 145 | 580 |

| 700 | 131 | 50 | — | 31 | 935 | 148 | 613 |

| 800 | 118 | 45 | — | 27 | 1115 | 119 | 710 |

| 900 | — | — | — | 27 | 1154 | 119 | 710 |

| 1100 | — | — | — | — | — | 125 | 701 |

Technological properties

| Name | Meaning |

| Weldability | Limited weldability. Welding methods: RDS, ADS under gas protection, ESW. Preheating and subsequent heat treatment are recommended. |

| Tendency to temper brittleness | Not inclined. |

| Flock sensitivity | not sensitive. |

| Welding defects | Welding of defects in castings after cutting is carried out with preliminary and accompanying heating to 150-200 °C. For semi-automatic welding in a carbon dioxide environment, Sv-08G2S wire with a diameter of 2 mm is used at a current strength of 380-420 A. Welding of defects by manual welding is carried out with electrodes of type E50A (GOST 9467) brand UONI-13/55. Before mechanized welding of large defects, it is recommended to line the edges of the samples with electrodes of the indicated brands. The thickness of the cladding layer is 8-10 mm. After brewing, slow cooling is required at a rate of 50 °C/h. |

Material 35L Ekaterinburg

Not a single production can operate without steel, be it heavy engineering or the manufacture of household electrical appliances. There are many brands of this product, as well as a large number of dispensing forms. Our company sells 35L material in large quantities and with a minimal margin. To clarify the properties and characteristics of a particular brand, you can contact the company’s managers.

Like all products, material 35L is purchased from leading manufacturers. Therefore, we are ready to provide a quality guarantee with full responsibility. The minimum number of intermediaries determines the low cost. Coupled with fast delivery, this enables our business partners to conduct stable and mutually beneficial cooperation.

In addition to tempering, in the form of one or another part (blank), our company carries out metal processing. All events undergo strict control for compliance with GOST and rules. The specialists of our company carry out such work as galvanizing, creating parts according to customer drawings, producing castings, manufacturing various profiles and much more.

Having the latest equipment and vast experience in our arsenal, we can offer product testing for a number of parameters, such as strength characteristics, chemical composition, alloy purity, and so on.

Each buyer is offered a huge range of products in various formats, as well as current services and works. To quickly understand and choose a product that meets your needs, you need to contact the company manager and receive detailed information on all issues of interest.