Key Features

Stainless steel electrodes TsL-11 are made of cold-drawn wire, the material of which is high-alloy steel SV07X19N10B. A significant amount of alloying additives is designed to compensate for the volume of similar elements that burn out in the base metal when exposed to high temperatures.

Other features:

- the electrodes have a coating of increased thickness (1.45

- rod coating type – basic (calcium fluoride);

- the products provide high stability of the electric arc and minimal metal spattering (up to 5%);

- Due to the characteristics of the coating material (porosity and moisture absorption), the rods must be calcined for 1.5 hours at 320–350 °C before work.

Welding is performed with the shortest possible arc without the use of transverse oscillatory movements of the rod.

Types of electrode coating for manual welding

Let's consider what types of electrode coatings there are, their components and how which one is designated. There are four main types of coatings used in the production of welding electrodes:

- acid coating , designated by the letter A;

- main (B) coating;

- cellulose coating (C);

- rutile (R).

The coating of welding electrodes is selected based on what type of steel is planned to be welded, the load on the structure and other factors.

Sour

The main advantage of acid-type coating is that during welding work, the likelihood of pores forming in the seam area tends to zero , even if the places where the elements are welded to each other are covered with traces of rust or scale. The acidic coating promotes uniform arc burning and easy ignition. This type of electrode is used when the requirements for the finished structure are minimal .

Acid-protected rods work well in both direct and alternating current. The most noticeable disadvantages are welding spatter, toxic fumes, and the risk of hot cracks during welding.

CAREFULLY! Acid coating is toxic when heated!

More information about acid coating >>> [ads-pc-4][ads-mob-4]

Basics

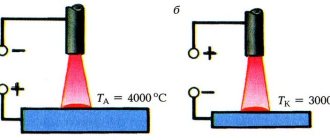

Due to the weak oxidation of such a coating, it facilitates easy removal of oxygen from the melting metal. A seam made using an electrode with a basic coating is protected from hot cracks . An electrode of this type must be calcined before work to eliminate the possibility of pores appearing in the seam. Due to the difficulty of maintaining an arc, welding with basic-coated electrodes should only be done using a direct current source of reverse polarity (this does not apply to all, but to most brands) .

Electrodes with a basic type of coating are used for welding metal parts made of hardening types of steel that are at risk of cold cracks, as well as for welding elements made of metal with a high percentage of sulfur and phosphorus. “Main” electrodes show high efficiency when welding several layers of structures that require high rigidity.

Read more about this coating and electrodes.

Pulp

The use of products coated with cellulose (marked “C” on the packaging) when working with a welding machine gives good high-quality arc burning, mainly at direct current . This variety is used when welding root seams on main pipelines made of low-carbon steel.

Also, cellulose-coated rods are excellent for single-sided welding with high-quality penetration in the root weld area. The use of rods gives good results when welding is carried out in a vertical position.

It is not recommended to use steel containing a high percentage of carbon and other alloying components for welding. Another disadvantage is the high degree of susceptibility to high temperatures and the likelihood of splashes of molten metal during operation.

More about cellulose electrodes here.

TsL-11 – characteristics

Electrodes of the TsL-11 brand allow you to weld parts in all spatial positions with the exception of vertical from top to bottom.

- For 1 kg of deposited metal there are 1.7 kg of consumables.

- Temporary tensile strength – 539 MPa.

- The relative elongation is 22%.

- The impact strength value is 80 J/cm².

- The deposition rate is 11 g/Ah.

The regulatory requirements that apply to the TsL-11 electrode are GOST 9466-75 and GOST 10052-75.

How to learn to cook

Practice and more practice is the most effective way to learn welding. The process, which is simple from a theoretical point of view, requires skill and professional dexterity. At first, you can simply observe how specialists perform the work, so that later you can use their techniques yourself.

The holder must be taken so as not to obscure the view of the welding area. Then you need to tilt the electrode relative to the working surface at an angle of 30 degrees. Several sliding movements are made with the electrode over the part to initiate the ignition of the arc. At this moment, it is important to maintain the distance between the rod and the workpiece so as not to break the arc and prevent the electrode from “sticking.”

After a short period of time, a red spot will appear in the welding zone - the result of melting of the flux. After about 2-3 seconds, an orange color will appear in the middle of the red spot. Its brightness will be noticeably higher, and small ripples will appear along the edges. This part is called the weld pool - the place where the metal melts and, after cooling, a weld is formed.

Chemical composition of the deposited metal

As can be seen from the table below, the resulting weld metal contains niobium. The metal is capable of forming superhard carbides. This allows you to obtain a high-strength connection when welding heat-resistant and heat-resistant steels. We also see an extremely low content of harmful impurities in the composition - phosphorus and sulfur.

| Carbon (C) | Manganese (Mn) | Silicon (Si) | Nickel (Ni) |

| 0,05–0,12% | 1–2,5% | <1,3% | 8–10,5% |

| Chromium (Cr) | Niobium (Nb) | Sulfur (S) | Phosphorus (P) |

| 18–22% | 0,7–1,3% | 0,01% | 0,02% |

Types and composition of coating of welding electrodes

For manual arc welding, electrodes are used, consisting of rods 25-45 cm long, on the surface of which a layer of special coating is applied. There are several classes of them on the market:

- stabilizing . They contain elements that perfectly ionize the welding arc. In most cases, the coating is applied to the rods in a thin layer - thin-coated electrodes;

- protective _ The covering is made from a mixture of different materials. The main task of the composition is to protect the melt zone from exposure to atmospheric air. In addition, they promote stable arc burning, refine and alloy the seam;

- magnetic . They are applied to the rod directly during welding. Spraying is carried out under the influence of electromagnetic forces that are formed between a live wire and ferrimagnetic powder poured into a special hopper. The wire or rod is fed into the welding zone through this hopper.

There are the following main types of electrode coatings:

- acid ore . They contain oxides of manganese and iron, silica and a lot of ferromanganese. To create a protective environment, organic substances are included in the composition - starch, wood flour, cellulose and others;

- rutile _ They are becoming increasingly popular thanks to the development of technologies for the extraction of rutile minerals. Its main component is titanium dioxide (TiO2). In addition to rutile, coatings also contain other elements: potassium and magnesium carbonates, ferromanganese, silica;

- calcium fluoride . The composition includes calcium and magnesium carbonates, ferroalloys and fluorspar;

- organic . The composition contains mainly organic compounds. Most often, oxycellulose is used with the addition of slag-forming materials, deoxidizers and alloying additives.

Recommended current values

An inverter machine makes it possible to set precise welding parameters for a particular rod diameter and, as a result, obtain an even and high-quality seam. Below are the recommended (average) current values, taking into account the diameter of the electrode and the spatial position of the weld.

| Electrode diameter, mm | Down position | Top position | Ceiling position |

| 2 | 40...55 A | 30… 40 | 30… 40 |

| 2,5 | 55…65 A | 40… 50 | 40… 50 |

| 3 | 70...90 A | 50… 80 | 50… 80 |

| 4 | 130… 155 A | 110… 130 | 110… 130 |

| 5 | 150… 180 A | 120… 160 | – |

Drying and calcination of electrodes

During transportation or storage, the electrodes may become damp. In this case, preliminary drying is needed, or even better, calcination. This is a very important procedure, which ultimately has a positive effect on arc ignition.

You should not frequently resort to calcining the electrodes, since repeated heating can damage the coating of the rod. It is advisable to undergo the procedure only the number of electrodes required for the current work. Or there should be very few of them left.

Piercing is also practical because it raises the temperature of the electrodes immediately before work. This is important, for example, for welding pipes or when working with thick workpieces. Preheating makes it possible to obtain tight joints during “pressure welding”. But keep in mind that gradual heating is important. With a sharp change in temperature, the formation of limescale cannot be ruled out.

Calcination is associated with the deadlines and duration of storage of the electrodes. According to generally accepted standards, the maximum shelf life of domestic products is five years. In practice, electrodes can be stored slightly longer without losing their characteristics.

Electrodes TsL-11 – application

Products are widely used in various industries - thermal power engineering, mechanical engineering, shipbuilding, aircraft manufacturing, oil refining and petrochemicals, the food industry, etc. We will indicate in more detail, based on the grades of steel being welded.

- 12Х18Н9Т (corrosion-resistant, heat-resistant). Electrodes make it possible to weld pipes, as well as parts of boilers and other containers designed for working environments with temperatures up to 600 °C, and in the presence of aggressive environments - up to 350 °C.

- 08Х18Н12Т (corrosion-resistant ordinary). The alloy is used to make ship hull elements, pipes and pipe fittings designed to work in aggressive environments (salt solutions, alkalis), seamless pipes for furnaces and for oil refining.

- 08Х18Н12Б (corrosion-resistant ordinary). By welding, components and parts of machine bodies, special-purpose and aviation equipment, as well as parts of high impact strength designed to operate at low temperatures (refrigeration equipment) are manufactured. The minimum temperature at which such structures can be operated is -253 °C.

- 12Х18Н10Т (calibrated corrosion-resistant, heat-resistant and heat-resistant). Products obtained by welding are resistant to alkaline and acidic solutions, dilute solutions of acetic, phosphoric, and nitric acids. Units and elements can operate at temperatures up to 600 °C, in the presence of aggressive environments - up to 350 °C. These are housings, pipes, exhaust manifolds, heat exchangers, parts of furnace equipment and much more.

In all listed brands, the predominant alloying element is chromium (18%). The share of nickel ranges from 9 to 12%. Also, the composition may contain no more than 1.5% titanium (letter T in the marking) and up to 1.3% niobium (letter B).

Purpose of welding electrodes

The role of electrodes is reduced to forming an arc in electric arc welding. The quality of the electrodes directly affects the efficiency and results. How stable the arc will be, how deeply the metal will heat up, how easy it is to ignite the arc and other nuances during welding are determined by the choice of electrodes. They have to:

- maintain a stable arc during operation;

- melt evenly;

- form a neat seam with the desired chemical composition;

- create conditions to minimize the splashing of hot metal;

- help improve the efficiency of welding work;

- ensure joint strength;

- have a low degree of toxicity.

In addition, the slag that is formed during the welding process should be easily removed.

Crap. 1

kernel; 2 - transition section; 3 - coating; 4 — contact end without coating

Damn.1

2.2, 2.3. (Excluded, Amendment No. 1).

2.4. The structure of the electrode symbol is shown in the diagram (Fig. 2).

2

| The nominal diameter of the electrode, determined by the diameter of the rod, | Nominal electrode length (limit ±3) with welding wire rod | Length of the end stripped from the coating (limit deviation ±5) | |

| low carbon or alloy | highly alloyed | ||

| 200 | 150 | ||

| 1,6 | 250 | 200 | 20 |

| (250) | |||

| 250 | 200 | ||

| 2,0 | (300) | 250 | |

| (300) | |||

| 250 | 250 | 20 | |

| 2,5 | 300 | (300) | |

| (350) | |||

| 300 | 300 | ||

| 3,0 | 350 | 350 | |

| (450) | 25 | ||

| 4,0 | 350 | 350 | |

| 450 | (450) | ||

| 5,0 | |||

| 6,0 | |||

| 8,0 | 450 | 350 450 | |

| 10,0 | |||

| 12,0 | 30 | ||

Notes:

1. The dimensions indicated in brackets are not recommended.

2. It is allowed to produce electrodes with a nominal diameter of 3.15; 3.25; 6.3 and 12.5 mm.

3. By agreement between the manufacturer and the consumer, a different length of electrodes may be established.

4. By agreement between the manufacturer and the consumer, the coating on the end of the electrode along the length may not be stripped. In this case, both ends of the electrode must be cleaned as contact ends.

5 and 6. (Excluded, Amendment No. 1).

7. On individual electrodes, the total number of which should not exceed 10% of the total number of monitored electrodes, it is allowed to increase the maximum deviations of the electrode length to ±4 mm.

8. The shape of the stripping of the coating on the side of the contact end of the electrode should be conical, round, or transitional between conical and round. In this case, the cone angle and radius of curvature are not regulated, however, in any case, the contact end of the electrode must be free of coating.

9. On individual electrodes, the total number of which should not exceed 10% of the total number of monitored electrodes, flat stripping of the coating on the contact end of the electrode along the entire perimeter or in individual areas is allowed, provided there is no coating on the surface of the contact end.

10. A layer of ionizing substance can be applied to the contact end of the electrode, facilitating the initiation of the welding arc, the composition of which must comply with that provided for in the standard or technical specifications for electrodes of a particular brand. (Changed edition, Amendment No. 1, 2).

Crap. 3

1 — electrode coating; 2 — electrode rod

Damn.3

(400±10) °C - for the main coating; (180±10) °C - for acidic and rutile coatings; (110±5) °C - for cellulose coating. For other and mixed types of coatings, as well as for acidic and rutile coatings containing cellulose, the temperature is taken in accordance with the instructions of the standards or technical specifications for electrodes of the controlled brand. The moisture content in the coating () as a percentage is calculated with an error of 0.1% using the formula

,

where is the initial mass of the coating, g; — constant mass of the coating, g. The mass is determined by weighing with an error of 0.01 g. It is possible to determine the moisture content in the coating by other methods that provide the required accuracy. (Changed edition, Amendment No. 1).

5.6. The coating mass coefficient () in percent is calculated with an error of 0.1% using the formula

,

where is the mass of the coated part of the electrode, g; — mass of the rod of the same part of the electrode, g. The mass is determined by weighing with an error of 0.1 g.

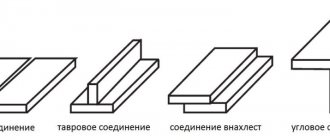

5.7. When checking the welding and technological properties of electrodes intended for welding steels, one single-sided welded T-sample and one double-sided welded T-sample are made with the electrodes of the controlled batch. In cases established by standards or technical specifications for electrodes of a specific brand, instead of a one-sided welded T-type sample, a pipe welded butt sample is made. Notes:

1. On double-sided welded T-type samples, the tendency of the seams to form cracks is checked.

2. If the standard or technical specifications for electrodes of a controlled brand provide for a more stringent test to check the tendency of seams to form cracks, performing double-sided welded T-type samples is not mandatory.

3. In cases established by the standard or technical conditions for electrodes of a controlled brand, it is allowed not to make double-sided welded T-type samples, however, the manufacturer is obliged to ensure that there is no tendency to form cracks in the welds made by the electrodes of this batch, in accordance with the requirements of this standard. (Changed edition, Amendment No. 1, 2).

5.8. To produce welded samples when checking according to clause 5.7 of electrodes for welding carbon structural steels, plates made of steel grade St3sp in accordance with GOST 380 and pipes made of steel grade 20 in accordance with GOST 1050 should be used. If the electrodes are intended for welding both carbon and low-alloy structural steels, The steel grades of plates and pipes must correspond to those specified in the standard or technical specifications for electrodes of the controlled grade.

5.9. To make welded samples when checking electrodes for welding low-alloy, alloy and high-alloy steels according to clause 5.7, you should use plates and pipes made of steel for which electrodes of the controlled grade are intended for welding. If the electrodes are intended for welding several grades of steel or for welding steel from which rolled sheets and pipes are not made, the steel grades of the plates and pipes must correspond to those specified in the standard or technical specifications for the electrodes of the controlled grade.

It is allowed to replace plates made of low-alloy and alloy steels with plates made of steel grade St3sp according to GOST 380 and plates made of high-alloy steels with plates made of other steels of the same structural class, provided that the plates are pre-fabricated with controlled electrodes in at least three layers at the places where welds are applied and at adjacent to them in areas with a width of at least 25 mm with mechanical processing of the deposited surfaces. Note. Surfacing with electrodes of other batches of the same brand (including a different diameter) is allowed.

5.8, 5.9. (Changed edition, Amendment No. 1).

5.10. The shape and dimensions of welded T-type samples must correspond to those indicated in Figure 4 and Table 7.

ACCEPTANCE RULES

4.1. To verify compliance of electrodes with the requirements of this standard, the manufacturer must conduct acceptance tests of each batch of electrodes. At the same time, they check the compliance of the electrodes with the requirements of clauses 3.9 and 3.12, as well as with the requirements of the standard or technical specifications for electrodes of a specific brand in terms of the chemical composition of the deposited metal, mechanical and special properties and characteristics of the deposited metal, weld metal or welded joint. The need to check electrodes for compliance with the requirements of clauses 2.1, 3.3-3.7, 3.11, as well as checking the moisture content in the coating and the mass coefficient of the coating is established in the standard or technical specifications for electrodes of a specific brand. However, the manufacturer must ensure that the electrodes comply with these requirements. (Changed edition, Amendment No. 1, 2).

4.2. Each batch must consist of electrodes of the same brand and diameter. All electrodes included in a batch must be manufactured using the same technological process, on the same type of equipment, using wire rods of the same brand with a constant coating composition from components of the same batches. A batch of electrodes with alloyed or high-alloy wire rods must be manufactured using wire from the same batch. Notes:

1. Determination of the wire batch - according to GOST 2246.

2. In cases established by the standard or technical specifications for electrodes of a specific brand, with the consent of the consumer, it is allowed to manufacture a batch of electrodes using rods made of alloyed or highly alloyed wire of two or more batches that are similar in the chemical composition of the metal. In this case, the batches must consist of wire of the same brand, the same diameter, the same purpose and the same type of surface.

4.3. The mass of a batch of electrodes, depending on their purpose and diameter, should not exceed the values indicated in Table 6.

Table 6

| Purpose of electrodes | Diameter of electrodes, mm | Weight of the batch of electrodes, t |

| Welding carbon and alloy structural steels | Up to 3.15 | 10 |

| St. 3.15 | 20 | |

| Welding of alloy heat-resistant steels | Up to 3.15 | 5 |

| St. 3.15 | 10 | |

| Welding of high-alloy steels with special properties, surfacing of surface layers with special properties | Up to 3.15 | 3 |

| St. 3.15 | 5 |

Note. By agreement between the manufacturer and the consumer, it is allowed to increase the mass of a batch of electrodes with acidic, cellulose and rutile coatings, but not more than twice.

4.4. To check the compliance of the electrodes with the requirements of clauses 2.1, 3.3-3.7, 3.13, 0 is taken from different packaging places, but not less than ten, or at the exit from the calcination furnace (at least ten selections from the conveyor at regular intervals or from different carts). .5% of electrodes from each ton included in the batch, but not less than 10 and no more than 200 electrodes from the batch. Note. If the test results are positive, the electrodes selected under this paragraph can be used for other types of tests.

4.2-4.4. (Changed edition, Amendment No. 1).

4.5. (Deleted, Amendment No. 1).

4.6. To check the compliance of the electrodes with the requirements of paragraph 3.9, at least 5 electrodes from each ton included in the batch are selected from different packs or boxes, but not less than 10 and no more than 50 electrodes from the batch.

4.7. To check the compliance of the electrodes with the requirements of clause 3.11, the mass coefficient of the coating and the moisture content in the coating for each type of test, at least three electrodes from each ton included in the batch are selected from different packs or boxes, but not less than five and no more than 25 electrodes from the batch .

4.6, 4.7. (Changed edition, Amendment No. 1, 2).

4.8. From each batch of electrodes that have been tested according to clauses 4.4, 4.6 and 4.7, electrodes must be selected to check the welding and technological properties, the chemical composition of the deposited metal and the mechanical properties of the weld metal, deposited metal or welded joint, as well as the special properties and characteristics of the deposited metal , weld metal or welded joint (ferrite phase content, resistance to intercrystalline corrosion, etc.) - in the quantity necessary to carry out the relevant tests and samples provided for by this standard and the standards or technical specifications for electrodes of a particular brand.

4.9. If unsatisfactory test results are obtained according to clause 4.6, as well as according to clause 4.7 in terms of strength or mass coefficient of the coating, a re-check is carried out on a double number of electrodes selected from the batch. The results of the re-inspection are final and apply to the entire batch.

If unsatisfactory test results are obtained according to clause 4.7 in terms of moisture content in the coating or according to clause 4.8 in terms of the size and number of pores (clause 3.12) identified in the weld metal or deposited metal when checking the welding and technological properties, it is allowed to re-calcinate all electrodes of the controlled batch with subsequent verification of the corresponding indicators. If unsatisfactory test results are obtained according to clause 4.8 in terms of the chemical composition of the deposited metal, the mechanical and special properties and characteristics of the weld metal, deposited metal or welded joint, it is allowed to repeat the corresponding tests and double the number of samples to check the indicators for which an unsatisfactory result was obtained. The results of the re-test are final.

4.8, 4.9. (Changed edition, Amendment No. 1).