Features of welding high-alloy types of steels depend primarily on the quantitative content of Cr in the alloy. One of the types of such alloy steels - austenitic steels, have a Cr component starting from 17%, which makes these steel grades very convenient for welding work. Moreover, such specific quality indicators as elongation, viscosity coefficient and indicators at which steel loses its qualities and begins to become brittle are much higher than those of other representatives of the class of high-alloy steels - ferritic and martensitic types.

Considering the welding process in austenitic alloys, it should be noted that in practical terms they are more suitable for welding work since they do not require additional preparation and processing, and in addition, the weld seam in these types of steels does not tend to form cracks either during welding work (hot cracks) nor in the normal state (cold cracks).

Range of austenitic steel grades and their composition

The main list of steel grades of the austenitic class that can be welded contains steel grades of the 12X..., 15X... series, but the most commonly used grade of austenitic steel with the inclusion of a chromium-nickel component is X18N10.

The characteristics of this type of steel depend on many factors, each of which has its own impact on the quality of the weld and the properties of the steel as a whole. 8% of the nickel content during plastic deformation of steel is transformed into martensite already at ordinary room temperature +21+23 degrees. The heat resistance of such steels is achieved by reaching about 25% chromium in the alloy composition, while the nickel-containing part can reach 38% of the total mass. When carrying out welding work, it is necessary to understand that alloying of this type of steel is carried out by adding silicon or aluminum components in a proportion of about 1% of the mass.

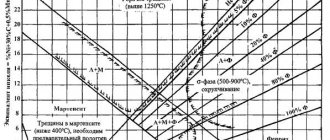

The characteristics of welds depending on the chromium and nickel content are most often determined using the Scheffler diagram. This is a universal diagram for calculating electric arc welding seams. A special feature of working with the graph is the possibility of using, in addition to the existing coefficients, additional methods, for example, using as a calculated equivalent the indicator of copper content (coefficient 0.6) or nitrogen, applicable within the coefficient of 10-30 units. Additionally, you can use other coefficients, for example, tungsten - 0.5 or titanium 2-5.

The use of the Scheffler diagram in calculations is applicable mainly to manual arc welding, since changes in the structure of the weld with other joining methods, for example, using the gas welding method or soldering, are simply not displayed in the diagram.

However, arc welding of austenitic steels, characterized by the quality of the weld and the formation of discontinuities in the form of cracks, both hot and cold periods, largely corresponds to this graph and depends on the proportion of ferrite content. An increase in the ferrite component in a weld from 2 to 6% ensures a significant reduction in the likelihood of cracks forming in the seams. Such positive qualities of the presence of ferrite, on the one hand, also have very negative consequences - a decrease in the viscosity of the metal connection, increases the temperature and reduces corrosion resistance to the main factors of influence.

A feature of the deposited weld, when during the welding process the viscosity of the weld pool is especially high, microcracks, ruptures, peeling and other types of weld defects can occur. The possibility of eliminating these defects is possible by using silicon alloying with a content of 0.3-0.7%. This interval allows you to avoid cracking of the seam, but the need to strictly adhere to this range of values is due to the fact that when this value is exceeded, there is a sharp increase in the processes of crack formation.

By analogy with silicon, manganese also affects the welding seam, although it should be noted that the appearance of cracks is much less. One of the features of austenitic steels of chromium-nickel composition is the specific deformation of the weld during cooling - tempering cracks occur when the joint cools down due to the high carbon content in the steel.

FEATURES OF WELDING OF DISHENIFIC STEEL WITH AUSTENITIC WELDS

The use of fusion welding technology for non-austenitic steels using austenitic welds is continuously expanding. In some cases, this technology is the most convenient, and in others it is almost irreplaceable. The technology of welding non-austenitic steels with austenitic electrodes is especially convenient during installation work and repair of large apparatus, where it is difficult to carry out heat treatment of welded joints after welding with non-austenitic electrodes, which produce a weld metal similar in composition to the steel being welded. But even when welding not during the installation process, but in the workshop, the use of technology with the formation of austenitic welds on non-austenitic steels has advantages over the technology with the formation of a welded joint with seams similar in composition to the steel being welded. For example, when welding high-chromium corrosion-resistant and heat-resistant steels, the use of filler materials that produce high-chromium weld metal is irrational due to its low technological strength and high fragility. When welding medium-carbon, low- and medium-alloy steels that are heat-treated to high strength (ZOKhGSA, ZOKHGSNA, etc.), the use of medium-carbon alloy filler materials is associated with the danger of cracks in the weld, not to mention the fact that the welding technology in this case is complicated the need for heating, slow cooling after welding and heat treatment of welded joints.

Most often, the creation of austenitic welds when welding non-austenitic steels is practiced in the following cases:

welding of low-carbon, low- and medium-alloy heat-resistant steels and steels with increased corrosion resistance (12Х1МФ, 15Х1М1Ф, 15Х5М, type 15Х5ВФ, etc.);

welding of nickel cold-resistant steels (type 06N6, 06N9); welding of medium-carbon low-alloy high-strength steels (ZOKHGSA, ZOKHGSNA, etc.); welding of high chromium steels.

For fusion welding of low-carbon low- and medium-alloy heat-resistant steels, there are two features. The first is that these materials contain elements (chromium, molybdenum, vanadium, tungsten, etc.) that give stable

carbides and reducing the activity of carbon in these steels. This means that in welded joints of such steels with austenitic seams during heating, diffusion heterogeneity will develop less actively than in the contact of austenitic seams with unalloyed steels. When welding these steels, you can limit yourself to 25–40% Ni in the weld metal. This can be judged from the data in Table. 11.4, from which it is clear that after severe heating conditions, heat-resistant steel 12Х1МФ has carbon activity not much higher than in austenitic metal 10Х23Ш8 and much lower than in austenitic metal type Х25Н40М7. Probably, for steels with a lower content of active carbide-forming elements (12МХ, 15ХМ), decarburization during heating should not occur when the weld contains ~40% Ni, and for steel 12Х1МФ it can be lower, for example 30%. When welding 15Kh5M steel with austenitic electrodes, the carbon activity in it is even lower than in 12Kh1MF steel (see Table 11.4); according to the conditions for preventing diffusion heterogeneity during heating, a 20% Ni content in the weld metal (10Kh23N18 metal) is quite sufficient. At the same time, taking into account the influence of nickel on chemical heterogeneity in the fusion area caused by the formation of intermediate alloys due to penetration, as well as the rationality of unifying the types of filler materials when welding low- and medium-alloy low-carbon heat-resistant steels, it is advisable for this case to focus on weld metal with 40 % Ni, especially if this metal contains such active carbide-forming elements as molybdenum, tungsten, vanadium, niobium, titanium, which reduce the activity of carbon in solution and require an increase in the nickel content, which increases the activity of carbon.

The second feature that must be taken into account when welding heat-resistant steels is that the operation of welded joints occurs at elevated temperatures (450-600 CQ for a very long time (hundreds of thousands of hours), i.e. under conditions that determine the development of diffusion processes and the formation of chemical and structural inhomogeneities in the fusion area.Therefore, great attention should be paid to the development of diffusion inhomogeneity in welded joints of the type under consideration.

N.V. Kirilichev examined more than 430 thousand joints of pipes made of steels 15Х5М and 12Х2М1 with weld metal of type 10Х25Н13Г2 and 06Х25Н40М7Г2, operating at temperatures from 400 to 550 °C. It was noted that all welded joints had quite satisfactory operational reliability. However, in welded joints with weld metal of type 10Х25Н13Г2, cracks appeared in 0.16% of cases, while at the joints with weld metal of type 10Х25Н13Г2 there were practically no cracks (0.005% of cases).

(In order to save welding materials with a high content of nsl/nickel, they can only be used to deposit the edges of the welded

.evil

heat-resistant steels, and subsequent welding - filling of the groove should be carried out with austenitic filler materials with a lower nickel content. It was also shown that high performance of welded joints of 12Kh1MF steel and a good set of properties at high operating temperatures are achieved by surfacing the edges of the steel being welded with electrodes producing metal of type 08KhN60G7M7T, and welding and filling the groove are carried out with electrodes producing weld metal of type 11Kh15N25M6AG2. For more alloyed heat-resistant steel I5X5M, surfacing of edges with metal of type 06Х25Н40М7Ґ2 and welding with materials that produce weld metal of type 10Х25Н13Г2 should be justified. In terms of nickel consumption, this is close to the use for welding without surfacing the edges of materials that produce weld metal with 25% Ni (for example, type 10Х15Н25М6), and in terms of operational reliability, determined by resistance to the formation of diffusion heterogeneity in the fusion zone, the first option is preferable.

Welding cold-resistant nickel steels 06N6 and 06N9 with the formation of austenitic welds is also associated with certain features. Firstly, the high nickel content in the steel being welded and the low carbon content create the prerequisites for reducing the width of the martensitic section in the penetration and mixing zone. Secondly, the operation of welded joints occurs without heating, and diffusion heterogeneity in the fusion zone does not develop, and the properties are determined only by penetration and the formation of mixing alloys. Thirdly, low operating temperatures (-196 °C) can lead to the decomposition of insufficiently stable austenite both in the weld metal and in the zone of penetration and mixing, therefore austenitic welds must be stably austenitic. The increased stability of austenite in the weld metal also determines an increase in the stability of austenite in the fusion (mixing) zone and, accordingly, a decrease in the width of the martensitic region (Table 11.6).

The table shows that with almost the same total width of the fusion zone, which was determined by the same welding conditions, the austenitic-martensitic zone 1 and the purely martensitic zone 2 (see Fig. 11.2) are different for different welds. It is the smallest in extent where the weld metal was nickel-based with the most stable austenitic state. Noteworthy is the fact that in all cases the martensitic zone turned out to be larger than the austenitic-martensitic one. Apparently, this occurred due to the decomposition of insufficiently stable austenite formed in the fusion upon cooling to a temperature of -196 °C.

The size of the martensitic region in the fusion zone affects the properties of this region. With an increase in the length of the yangite section, the impact strength KS1 and the strength of the fracture B decrease (Fig. 11.18). A]

Table 11.6

| Type weld metal | Total width of the fusion zone, microns | Section width, µm (see Fig. 11.2) | |

| i | 2 | ||

| 11Х15Н25М6AG2 | 42 | 10 | 17 |

| 10Х25Н40М7 | 40 | 8 | 13 |

| 10Х20Н70Г2М2Б2В | 40 | 5 | 7 |

| Dimensions of various sections of the fusion zone when welding 06N9 steel with various electrodes after cooling to -196 °C |

When welding medium-carbon steels (ZOKHGSA, 30KhGSN2A, etc.) with austenitic seams, treated to high strength (1300-1700 MPa), it is also necessary to take into account some features. The technology for producing austenitic welds (for example, type 10Kh16N25AM6), on the one hand, should make it possible to abandon the heat treatment of welded joints and obtain weld metal with a sufficiently high toughness (1.2-1.6 MJ/m2), on the other hand, weld metal must have a strength level close to the strength level of the steel being welded (austenitic welds of type 10Kh16N25AM6 are characterized by R < 700 MPa). Therefore, in this case, purely austenitic weld metal cannot meet the requirements. To obtain the required combination of properties in the weld metal, they resort to the use of filler materials that produce an austenitic-martensitic weld. V. E. Lazko, M. T. Borisov and V. G. Fedorov, based on a study of the properties of welded joints of dissimilar steels (steel 30KhGSN2A and high-strength maraging steel 03Kh12N5M6K13), obtained using various austenitic-martensitic filler materials, recommend argon-arc welding with an additive that produces metal of type 06Х12Н6М5КУ in the weld. This ensures high properties of welded joints (Table 11.7).

For welding high-chromium steels, both corrosion-resistant and heat-resistant, austenitic filler materials are widely used. Austenitic seams. obtained by welding heat-resistant high-chromium steels of type 13Х11Н2В2МФ, make it possible to avoid heat treatment after welding. Welding corrosion-resistant high-chromium steels with austenitic welds makes it possible to obtain weld metal with high toughness, while when using

for welding electrodes that produce high-chromium weld metal, the weld has low impact strength.

Features of welding high-chromium steels to obtain austenitic welds are as follows. The first was considered in paragraph 11.1, it is connected with the fact that changing the nickel content in the weld metal within a wide range gives austenitic-ferritic alloys for steels with 17 and 25% Cr in the fusion zone metal, or for steels with a chromium content of 13% - austenite-martensite-ferrite and ferrite-martensite. In this regard, it is not advisable to use welds with a very high nickel content for welding high-chromium steels. Typically, the nickel content in the weld is limited to 25%.

The second feature of welding is due to the fact that the high chromium content in the steel being welded greatly reduces the activity of carbon in it, bringing it closer to the activity of carbon in weld metal alloyed with 20-25% Ni. As a result, heating of such welded joints is not associated with active movement of carbon at the fusion boundary. This circumstance also makes it possible to limit the nickel content in the weld metal to 25%. Often, for welding high-chromium heat-resistant steels, electrodes that produce weld metal of type X16N25M6 are used; for welding corrosion-resistant high-chromium steels, electrodes that produce weld metal of type X23N18 and even 08X17N10 are used.

Recommendations for welding dissimilar steels are given in table. 11.8.

| Table 11.7 Properties of welded joints of dissimilar high-strength steels 30ХГСН2А and 03Х12Н5М6К13 KCU, MJ/m* | ||||

| Weld metal type | aw, MPa | fusion zones on the steel side | ||

| seam | 30ХГСН2А | 03X12H5M6KI3 | ||

| 10X16N25AM6 06Х12Н6М5КУ | 630 1100 | 1,84/1,57 1.17/0,74 | 1,42/4,10 0,45/0,24 | 1,58/1,37 1,65/1,42 |

Note. The numerator contains data obtained at 20°C, the denominator - at -70°C.

Recommendations for welding dissimilar steels

| Table 11.8 Weldable become | Conditions work | Weld metal | Heat treatment |

| Multi-alloyed pearlitic | No heating | Must match less alloy steel | Designed for welded joints made of higher alloy steels |

| Heating up to 580 °C | With intermediate content of alloying elements | ||

| Pearlitic and ferritic or semi-ferritic | No heating | Pearlitic or austenitic type X18N10, X25N13 | With pearlitic metal, high tempering (mode for pearlitic steel) |

| Heating up to 580 °C | Austenitic with > 15% Ni content | — | |

| Unalloyed martensitic | No heating | Non-austenant, corresponding to less alloy steel | High holiday |

| Austenitic with 20–40% Ni | — | ||

| Heating up to 520 °C | Non-austenitic, corresponding to less alloy steel | High holiday | |

| Cooling below -20 °C | Austenitic with 40–60% Ni | — | |

| Same | — | ||

| Multi-alloyed austenitic | No heating | Austenitic, corresponding to less alloy steel | — |

| Heating up to 650 °C | Austenitic intermediate composition | Austenitization, stabilizing tempering | |

| Pearlitic and austenitic | No heating | Austenitic type X25N13 or austenitic steel type | — |

| Heating up to 580 °C | Austenitic with >35% Ni content | — | |

| Multi-alloy high-strength | No heating | Austen-open-hearth - sieve with Mo and Co | — |

| High chromium ferritic and semi-ferritic | Same | Austenitic with a content of 20-25% No. | — |

Features of changes in metal structure during welding of austenitic steels

A feature of arc welding of austenitic steels containing chromium is an increase in grain volume. This process proceeds evenly with gradually increasing grains, in contrast to unalloyed grades of structural steels. A natural obstacle to this process is the carbide phase of welding, during which grain growth does not occur.

The carbide phase, the dissolution of which occurs in the overheating zone, forms two types of carbides - chromium carbide Cr23C6 and titanium carbide; the formation of other types of carbides, for example, niobium and vanadium, occurs to a slightly lesser extent. In addition to carbides, Cr2N nitrides also appear in the zone. Chemically, the dissolution of small amounts of these compounds results in the formation of a film of dissolved carbides along the grain boundaries. Subsequently, these processes act as places of formation of foci of internal intergranular corrosion.

The problem of corrosion can be solved by stabilizing the steel, but even if certain types of welding are used, such as submerged arc welding or electroslag welding, stabilizing the steel will not prevent corrosion. The only way to increase the strength of a weld when arc welding austenitic steels is to use nitrogen during welding.

Methods of heat treatment of welded austenitic steels

Most often, to relieve internal stresses before welding, heating the steel to 200°C is used as one of the processing methods. Heated steel, when the weld cools, allows you to relieve stress, but it is not possible to finally solve the problem of corrosion not due to stress at the welding site.

To solve the problem of corrosion manifestations due to internal stresses, we apply the tempering method. The optimal temperature for this is around 800-850 °C. For structures used in aggressive environments, this temperature can be increased to 950-1050°C. This increase in temperature contributes to the rapid destruction of the carbide film.

But with respect to steels of the X18N8 - X25N20 type, the formation of cracks is typical when released.

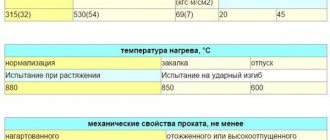

Preheating and heat treatment when welding austenitic steel

When welding austenitic steels, preheating, from the point of view of structural transformations, is not necessary. But, in some cases, heating to a temperature of 200°C is used in order to reduce internal stresses.

The magnitude of residual stresses in such steels is quite large, which creates a risk of corrosion failure of the steel. In order to avoid this, heat treatment of welded joints is performed.

If it is only necessary to reduce the magnitude of internal stresses, then choose a tempering temperature of 800-850°C. If welded joints are in contact with an environment that promotes the formation of intergranular corrosion, then annealing at a temperature of 950-1050°C would be appropriate. Annealing promotes the dissolution of carbide films.

When performing heat treatment, it must be taken into account that steels of the types X18N8, X18N8M2, X18N8T, X18N9B, X25N12, X25N20 have a tendency to form temper cracks.

Gas welding of austenitic steels

The structure of steel containing chromium is very sensitive to the use of gas welding technologies; the oxygen-acetylene method is the most acceptable for this type of steel, since, unlike the oxidizing type of flame, it does not burn chromium. The recommended welding wires are grades with low carbon content and alloyed with niobium or titanium. When working with sheet material, the diameter of the welding wire is selected equal to the thickness of the base material.

The use of fluxes in gas welding work is carried out by treating a flux solution with liquid glass onto the edges of the surfaces being welded. Work begins after the flux has dried.

Features of electrodes

The key task of electrodes for MMA welding of dissimilar steels is to obtain an equal-strength welded joint. Most of these products are used for welding high-alloy and high-strength alloy steels. Features of such filler materials:

- minimal hydrogen content, which reduces the risk of rapid formation of pores and intergranular cracks in the weld metal;

- high nickel content: its expansion coefficient is close to that of low- and medium-alloy steels, which ensures a stable fusion zone.

Another feature: the presence in the composition, in addition to nickel, silicon, zinc and other alloying additives - in a wide range of cases, they make it possible to suppress the growth and even completely prevent the formation of the above-mentioned fragile intermetallic layers.

Arc welding of austenitic steels

Considering that alloy steels themselves have excellent structural properties and are easy to weld, austenitic steels are no exception to this list. The only point that requires thorough study is the need to use the most suitable consumables.

One of the most important conditions for welding using manual electric arc welding is the absence of a ferrite component in the welding electrodes. For welding austenitic steels, I often use austenitic electrodes UONI-13/NZh, using the composition TsL-2 or TsL-4 as a coating.

The use of argon arc welding for joining thin sheet materials of steel 12Х18Н9Т gives good results using flux. At the same time, it is necessary to control the welding process, since a situation may arise when the amount of carbon in the weld increases sharply, which will dramatically affect the durability of the metal.

For almost the entire range of austenitic steels, austenitic electrodes UONI-13/NZh are most often used; this is an almost universal electrode for this type of steel. The current strength is calculated from the proportion of 30-35 Amperes per 1 mm of electrode diameter. When welding, the polarity is reversed, and the seam is applied in small sections.

Post-weld intergranular corrosion

Austenitic steels are often positioned as resistant to various types of corrosion. Intergranular corrosion, which occurs along the grains, often does not occur in the weld itself, but near the connection line and even at a considerable distance. In general, the physical aspects of the development of corrosion do not differ from each other - the only difference is in the cause of its occurrence.

Intercrystalline corrosion of the base metal occurs when a certain local area is simply overheated. For the weld material, from a physical and chemical point of view, everything is much more complicated. The thermal cycle of welding, as already mentioned, disrupts diffusion processes, as a result of which active carbon and alloying chromium are released onto the surface. They form one of those carbides that lead to increased brittleness of the weld. Obviously, in parallel with this, depletion of other alloying components occurs (carbon compounds with titanium and niobium are also formed to a lesser extent), and the material becomes more vulnerable to intergranular corrosion.

An obvious solution to reducing the susceptibility of the weld and heat-affected material to intergranular corrosion is austenitization at 1050-1100°C

An indirect solution to the problem is the introduction of austenitic-ferritic materials, which are more resistant not only to intergranular corrosion, but also to unfavorable thermal cycles. The special structure - up to 4% molybdenum and 25% chromium - is distinguished by smaller grains and, accordingly, an increased length of intercrystalline boundaries. An increase in the area of carbide precipitation leads to a decrease in their dispersity. Local depletion of chromium occurs to an insignificant depth. In addition, austenitic-ferritic materials have an increased rate of diffusion processes.

There are several ways to reduce the susceptibility of the weld and heat-affected material to intergranular corrosion. The obvious solution is to carry out austenitization, which is already known to us, at 1050-1100°C (can be replaced by stabilizing annealing for 2-3 hours at a temperature of 850-900°C). However, you can always come to terms with the precipitation of the carbide phase, neutralizing its consequences through additional alloying until an austenitic-ferritic structure is formed. The disadvantage of this approach is not only the excessive consumption of chromium and other metals, but also a decrease in the resistance to general corrosion that spreads over the entire surface of the product. In this light, some manufacturers prefer to use titanium, tantalum or vanadium as an alloying component instead of chromium. At the same time, more expensive metals also turn out to be more demanding in terms of the protective environment. If you do not use inert gases or fluoride fluxes instead of acidic ones, titanium, which is close to oxygen, burns out by 70-90%.

Additionally: it is necessary to debug automated processes that guarantee the continuity of obtaining a seam with a stable electric arc, the repeated excitation of which makes the thermal cycle unfavorable.