Treatment of the weld after welding

Welding is the most reliable, fastest and economical way to create permanent joints of metals and their alloys. During the welding process, the metal is heated to its melting point. This causes internal tension in him. In addition, slag remains on the surface of the weld. To remove slag and relieve internal stresses in the metal, various weld processing methods are used.

Selection of rolled steel for construction

Selecting materials is not that simple. It is necessary to take into account not only the design plan, but also the likely external factors affecting the metal, and many other characteristics. Therefore, the choice depends on the following factors that directly affect the operation of the metal:

- The average temperature of the environment in which the structure will be installed. It is often necessary to study the weather report and expected changes during construction work. Here the probability of brittle fracture at low temperatures should also be taken into account.

- The nature of the load on the metal during operation. There are three types: dynamic, vibration and variable. It is necessary to take into account the peculiarities of steel operation under such conditions.

- Type of stress state - compression or tension, flat or volumetric; as well as the voltage level of the elements - high or low.

- A method of combining elements (fasteners or welding), which also has a degree of stress concentration. This factor should take into account the properties of the metal in the area where the fasteners are installed.

- Rolled thickness, as this affects the strength characteristics. In addition, an increase in thickness leads to a change in the general properties of steel.

Materials for welded structures must have a high weldability coefficient. It is possible to reduce the requirements for structural elements where there are no welds. The absence of steel stress, welding fields and other factors improves the overall performance of the steel.

Properties of steel after hardening

After hardening, the hardness and strength of steel increases, but at the same time internal stresses increase and fragility increases, provoking the destruction of the material under sudden mechanical influences. A thick layer of scale appears on the surface of the product, which must be taken into account when determining processing allowances.

Attention! Some products are partially hardened, for example, it can only be the cutting edge of a tool or edged weapon. In this case, a clear boundary separating the hardened and unhardened parts can be observed on the surface of the product. The hardened part on the blades is called “jamon”, which translated into modern metallurgy means “martensite”.

Definition! Martensite is the main component of the structure of steel after hardening. The appearance of this microstructure is needle-like or lath-shaped.

To reduce internal stresses and increase plasticity, the next stage of heat treatment is carried out - tempering. During tempering, there is a slight decrease in hardness and strength.

Austenitic

Austenitic steels are materials that contain the high-temperature phase of iron - austenite. They are included, for example, in the group of chromium-nickel steels, which can work in various aggressive environments and at very high temperatures.

The main feature when welding corrosion-resistant steel is the need to ensure resistance to intercrystalline corrosion in the heat-affected zone.

The problem is that even with preheating of the steel, chromium carbides fall out of the crystal lattice along the heating boundaries. As a result of a decrease in the amount of this element in the material, upon reheating, corrosion cracking appears at the boundaries.

In practice, it may be necessary to create structures using austenitic steels with chromium-nickel alloying additives that will operate at high temperatures. To weld such structures, it is necessary to select materials in which the carbon content is as low as possible.

If it is necessary for the percentage of carbon to be higher, and at the same time, steel structures fulfill their purpose in conditions of aggressive environments and high temperatures, you need to choose an alloying additive that is similar in properties to carbon.

Titanium, zirconium, tantalum, vanadium, and tungsten can be used as such an additive. These elements bind carbon, which is released from the steel during subsequent heating, and prevent the depletion of heat-affected areas during the welding process.

Types of steel tempering

The main technical parameter of the OS is the heating temperature. There are 3 types of OS - high, medium and low. Of course, high-temperature tempering is the optimal means of processing, since the higher the heating temperature, the more actively recrystallization of the metal will occur. However, low- and medium-temperature processing methods also have practical benefits that should not be underestimated. Below we will look at each type of OS separately.

High

High tempering of steel is a variant of tempering treatment at temperatures from 500 to 700 degrees. This method is the most effective, since with such heating, polygonization and recrystallization of the material occurs, which eliminates all stress inside the metal. Usually lasts from 2 to 3 hours. In the case of processing complex structures, the recommended time can increase to 6 hours.

The main disadvantage of high-temperature tempering is a slight decrease in the strength of the material. Therefore, the technique is not suitable for processing parts that will experience extremely high loads during operation. The high temperature technique applies to all types of steel, but note that in the case of some alloy alloys, so-called reversible high temperature embrittlement may occur during processing.

Average

The main feature of medium tempering is the active diffusion of carbon without polygonization and recrystallization of the alloy. In the case of medium-temperature treatment, the elasticity of the material improves and its relaxation resistance increases. The steel tempering temperature in this case ranges from 350 to 500 degrees. The average processing time is 2-4 hours. The optimal environment is oily or alkaline. Medium processing is well suited for durable parts of complex shapes - springs, springs, impact structures. However, in practice this technology is rarely used due to a number of limitations:

- In the temperature range from 250 to 300 degrees there is a so-called island of brittleness of the first kind, which should be avoided. At the same time, at temperatures above 500 degrees, there is another island of fragility of the second type (it is also recommended to avoid it). We will discuss the features of these islands below. A slight deviation in temperature up or down during the holidays can lead to fatal consequences.

- The technique has no advantages in comparison with alternative technologies (low and high). At the same time, weak processing furnaces usually cannot heat the working environment to such temperatures, and stronger furnaces can reach higher temperatures, which is inconvenient from a practical point of view.

Short

Low tempering of steel is a method of processing a steel alloy or product in which heating is carried out to a temperature of 100 to 250 degrees. The processing time is usually 1-3 hours depending on the type of part and its dimensions. During low-temperature processing, diffusion of particles of carbon components occurs without polygonization and recrystallization of the atomic lattice. This allows you to increase some of the physical characteristics of the material - strength, ductility, hardness, chemical inertness.

Rating of steels and marking

Regulates the conformity of the properties of structural steel. The requirements are determined according to GOST 27772. According to it, the following brands are used:

- Shaped products (235, C245, C255 and others).

- Sheet metal, bent profiles - S390, S390K, etc.

Whereas the digital designation means the yield strength in MPa (MegaPascal), which is used to measure the compressive and bending strength of steel. The meaning of the letter designations is as follows:

- D - increased copper content to enhance corrosion resistance (C345, C375, C390, C440);

- C - structural steel specifically for construction work;

- T - thermal improvement;

- K - variation in chemical composition.

Rolled metal is sold hot-rolled and heat-treated before sale. Moreover, the manufacturing plant itself decides on the amount of additives for alloying steel and on the temperature of exposure - there is no general standard. So, for example, C345 sheet steel can be made from metal with the chemical composition C245, which has increased resistance to heat treatment. It is in this case that the letter T appears in the name of the alloy.

Marking of sheet metal also includes division into categories, for example, C345-1. There are six categories in total, the differences between which are in the following factors:

- operating temperature conditions of the finished structure;

- degree of probability of destruction;

- Impact resistance at different temperatures.

The category number depends on the last factor - the resistance temperature of all these characteristics. From first to sixth in ascending order.

Structural steel welding also has a joining rating:

- less than 0.4% - easily processed, without defective consequences;

- from 0.4% - 0.55% - welding is possible only if special measures are taken to prevent splitting;

- above 0.55% - difficult to process, high probability of defects: splits, cracks, pits.

Steel marking is regulated by GOST 380-88, according to which it additionally specifies the delivery group, the method of steel oxidation and its category. They also have their own designations:

Grouped delivery:

- A - mechanical properties;

- B - chemical composition;

- B - combined view.

Oxidation state:

- KP - boiling;

- SP - calm;

- PS - semi-calm.

Impact test category:

- The first is that no checks are carried out;

- The second is minimal impact strength;

- The third is a high temperature of +20 degrees Celsius;

- Fourth - low temperature (-20 degrees);

- Fifth - mechanical aging combined with low temperature;

- The sixth is mechanical wear.

Structural steel is marked according to the research carried out.

Selection of steel for hardening

To begin with, let’s conditionally divide all steels into high-carbon and alloyed. All steels are alloys of iron with carbon and various alloying elements; The name of the steel will depend on whether one carbon predominates in it or whether alloying elements are present in significant quantities. It cannot be said that this or that group is worse or better at hardening; They initially have very different characteristics and different tasks, so we will simply talk about the hardening of both steels.

Hardening of carbon steels

We have accumulated vast experience working with this steel, as well as with products made from it. By itself, it requires lower quenching temperatures than those alloyed with various elements - it already has fairly high hardness and strength indicators, which are so valued on the market.

- Low-carbon steels are hardened at temperatures from 727 to 950 °C.

- Medium and high carbon steels are hardened at temperatures from 680 to 850 °C.

It must be remembered that steels with very low carbon content cannot be hardened at all.

If we want to make and harden a blade from carbon steel at home, the following brands are suitable for us.

- U7 – U10;

- 65 G.

- O1;

- 1095.

These grades, when properly heat treated, are characterized by great strength and hardness, although low resistance to corrosion.

Hardening of alloy steels

In addition to iron and carbon, such steels contain a significant amount of various alloying elements, which give the alloy special properties needed in a particular area.

- Chromium makes steel corrosion-resistant if its content exceeds 12–16%.

- Molybdenum and nickel increase the strength of steel and its ability to withstand high loads.

- Vanadium improves the wear resistance of the alloy and gives its blades the ability to hold an unusually sharp edge.

Due to the presence of these elements in the alloy, steel has worse thermal conductivity than pure carbon steel, therefore: 1) it will take more time to heat and cool - if the process is artificially accelerated, then cracks may appear in the alloy; 2) for hardening it needs a high temperature - from 850 to 1,100 ° C.

Unfortunately, correct heat treatment of complex alloy steels is quite difficult, since to give the blade high performance properties, both precise temperature and special equipment for deep cooling are needed. Therefore, it will not be possible to harden them qualitatively “by eye”.

The most common brands include the following:

- 420;

- 440A;

- D2;

- ATS34;

- CPM S320V.

We can say about the last sample that it is extremely wear-resistant.

Welding high carbon steels

Demonstration welding of steel from springs with Zeller 655 electrode

The high carbon content in steels of this type makes them, as a rule , unsuitable for the manufacture of welded structures. They are characterized by low ductility and therefore have limited use.

The need for high-carbon steels arises when carrying out repair work, in the production of springs, cutting, drilling, woodworking and other tools, high-strength wire, as well as in those products that must have high wear resistance and strength.

Welding technology for high carbon steels

Welding is possible, as a rule, with preliminary and concomitant heating to 150-400°C, as well as subsequent heat treatment . This is due to the tendency of this type of alloy to become brittle, sensitive to hot and cold cracks, and chemical heterogeneity of the weld.

For your information! Exceptions are possible if you use specialized electrodes for dissimilar steels. See photo and caption below.

- After heating, it is necessary to perform annealing , which must be carried out until the product cools down to a temperature of 20°C.

- An important condition is the inadmissibility of welding in drafts and at ambient temperatures below 5°C.

- To increase the strength of the connection, it is necessary to create smooth transitions from one to another metal being welded.

- Good results are achieved when welding with narrow beads , with cooling of each deposited layer.

- The contractor should also follow the rules provided for joining medium-carbon alloys.

This is a demonstration sample (spring, files, bearing and food-grade stainless steel are welded together). If you do not pay attention to the quality of the seams, the welds were not made by professional welders, the photo confirms that welding of “non-weldable” steels is quite possible.

Video

Features of welding high-carbon steels

The working surface must be cleaned of various types of contaminants: rust, scale, mechanical irregularities and dirt. The presence of contaminants can lead to the formation of pores.

Structures made of high-carbon steels need to be cooled slowly , in air, to normalize the structure.

Preheating critical products to 400°C allows one to achieve the required strength.

Types of welding of high-carbon steels

1. The optimal option for the welding process is manual arc welding using coated electrodes. Working with high-carbon steels has a large number of specific characteristics. Therefore, welding of high-carbon steel is carried out with specially designed electrodes, for example, NR-70. Welding is carried out with direct current of reverse polarity.

2. Submerged arc welding is also used to join this type of alloys. It is quite difficult to evenly coat the work area with flux manually. Therefore, in most cases, automatic technology is used. The molten flux forms a dense shell and prevents the influence of harmful atmospheric factors on the weld pool. For submerged arc welding, transformers are used that produce alternating current. These devices allow you to create a stable arc. The main advantage of this method is the small loss of metal due to small spattering.

It is important to note that the gas welding method is not recommended . The process is characterized by the burning of a large amount of carbon, resulting in the formation of hardening structures that negatively affect the quality of the weld.

However, if ordinary structures are welded, then the use of this method is possible. The connection is made on a normal or low flame, the power of which does not exceed 90 m3 of acetylene per hour. The product must be heated to 300°C. Welding is carried out using the left-hand method , which makes it possible to reduce the time the metal is in the molten state and the duration of its overheating.

Checking hardness after hardening metal at home

The word familiar to everyone in everyday life is a precise term and is applied mainly to solid products. To check, a ball or cone made of tool steel is pressed into the surface, and then a calculation is made using formulas depending on how deep the mark is left and what force was applied. There is another option - a Rockwell device, but using it at home or in an apartment is almost impossible.

The unit of hardness measurement is HRC. To compare values:

- kitchen knife, strong, expensive - from 55 to 63;

- small gears in cars - from 52 to 58;

- tips, drill tools, drills - from 60 and above.

Requirements

When welding carbon steels, to achieve maximum parameters, the following requirements must be met:

- Welding electrodes and wires must have a low percentage of carbon to avoid unnecessary defects;

- It is necessary to ensure that carbon from the metal does not transfer into the weld under the influence of high temperature; for this, wire is used for welding steels with an average carbon content and higher, for example Forte E71T-1, Bars-71. These types are ideal for welding steels with a carbon content above 0.3%;

- When carrying out the welding process, fluxes should be added, which contribute to the formation of refractory formations;

- Reduce chemical heterogeneity of the seam by subsequent heat treatment;

- Reduce the hydrogen content by calcining the electrodes, using electrodes with low hydrogen content, etc.

Heat treatment when welding metal

Heat treatment oven

Heat treatment (HT) is the process of heating metal products to a critical point, above which the microstructure and characteristics of the metal change; holding and subsequent rapid or slow cooling. The question is often asked: can heat-treated steel be welded? Heat treatment does not affect weldability. You can cook both hardened and “raw” steel, or annealed steel. Maintenance is allowed before, during and after welding work.

Commonly used heat treatments for steel

Annealing – relieves stress, improves ductility, and forms fine grains. Temperature (650±10) oC. The holding time is calculated depending on the maximum thickness of the part and averages 2.5 minutes. At 1 mm thickness. During annealing, the parts are always cooled along with the furnace. When fully annealed, the parts are heated to 800-900 °C. Recrystallization and strengthening of the weld occurs. Holding time and cooling conditions are the same as in the previous case. The data given here is for informational purposes; exact data can be obtained from the reference book. Normalization is a process very similar to annealing, with only one difference - cooling is done in air (self-tempering). Rest is carried out at low temperatures of 200 ... 300 ° C for 2 ... 3 hours. This procedure reduces the content of diffusion hydrogen and reduces the amount of internal stress. All types of maintenance are carried out in furnaces with electrical resistance heating in an air atmosphere.

Heat treatment of aluminum

Preheating of aluminum is necessary due to its high thermal conductivity. The formation of a normal weld pool and the formation of a weld will be difficult due to the lack of temperature, which is constantly “taken away” by the body of the aluminum alloy. If we are talking about small-sized parts, the lack of heating will not be catastrophic, but when you are dealing, for example, with welding defects in a large casting body, then the difficulties will become obvious even to a person not privy to the intricacies of welding art. You can heat the entire product, or perform local (local heating) of the area being welded using oxygen-acetylene, propane and other burners. It is also possible to preheat directly during the welding operation, provided that this is technically feasible. Preheating is also used for some types of steels prone to cracking (for example, 30KhGSA). Post-weld heat treatment for aluminum is hardening + aging. True, such maintenance is fraught with large warping. If the products being repaired have ready-made drawing dimensions, such a procedure becomes impossible. In this case, you will have to do without any maintenance at all, or use half measures: heating to the aging temperature and holding for a certain time (the mode is selected based on the grade of the aluminum alloy). The impact of such a measure is debatable, but it is better than doing nothing at all. If after welding it is necessary to increase ductility and reduce hardness, it is advisable to perform partial or complete annealing . You also need to understand that if you are welding heat-treated aluminum, the weld, even with subsequent complete maintenance, will be soft (significantly different from the hardness of the base metal). Write in the comments if there are filler rods that may experience polymorphic transformations.

High strength steels

The group of steels has a fine-grained surface structure, which is created using nitride. During production, such steels are alloyed and treated at high temperatures. These include alloys from C440 to C590.

Such metals have practically no yield area, therefore their plastic properties are significantly reduced. Therefore, when installing a structure made of these steels, you can not take into account possible plastic defects - they simply do not exist.

But it is worth taking into account the structural changes that occur as a result of uneven heating (welding) and subsequent cooling. The following defects may occur:

- rigid layers - a combination of increased strength and fragility;

- soft layers, on the contrary, have low strength and high ductility.

Since they form in separate areas, the structure of the structure is disrupted. It is these areas that may cause collapse in the future. Different strengths can reach a difference from 5% to 30% within one element. Therefore, it is necessary to consider the characteristics of steel before designing and welding work. The effect of deformation can reduce the introduction of molybdenum and vanadium into the alloy.

Resistance to brittle fracture is ensured due to the correctly selected chemical composition and heat treatment regime of the steel. Impact strength is also high, maintained even at extremely low temperatures (down to -70 degrees).

This group still has a drawback: high strength and low ductility require the use of specialized equipment. Construction work cannot be carried out without powerful equipment for cutting, straightening and drilling high-strength steels.

It is advisable to use high-strength heat-treated steels in the construction of powerful structures, including the foundations of buildings.

How to avoid scale formation and decarburization during quenching

Many steel parts are hardened after they have been finished. In such cases, it is unacceptable for the surface of the parts to be decarburized or for scale to form on it. There are methods for hardening steel products that avoid such problems. Hardening, carried out in a protective gas environment, which is injected into the cavity of the heating furnace, can be classified as the most advanced of these methods. It should be borne in mind that this method is used only if the heating oven is completely sealed.

The photo shows the moment of hydrobeating at the hot rolling mill - descaling

A simpler way to avoid decarburization of the metal surface during hardening is to use cast iron shavings and used carburizer. In order to protect the surface of the part when heated, it is placed in a special container into which these components are previously poured. To prevent ambient air from entering such a container, which can cause oxidation processes, the outside of it is thoroughly coated with clay.

If, after hardening the metal, it is cooled not in oil, but in a salt bath, it should be deoxidized regularly (at least twice per shift) to avoid decarburization of the surface of the part and the appearance of oxide on it. Boric acid, brown salt or charcoal can be used to deoxidize salt baths. The latter is usually placed in a special glass with a lid, the walls of which have many holes. Such a glass should be lowered into the salt bath very carefully, since at this moment a flame flares up on its surface, which dies out after a while.

There is a simple way to check the quality of deoxidation of a salt bath. To do this, a regular stainless steel blade is heated in such a bath for several minutes (3–5). After the salt bath, the blade is placed in water to cool. If after such a procedure the blade does not bend but breaks, then the deoxidation of the bath was successful.

Volumetric hardening of thick-walled workpieces

Low alloy

These alloys are called low-carbon alloys. The inclusion of alloying components in such metals is no more than two to three percent. Most of the composition is occupied by iron, in addition to which there is a small percentage of carbon and other inclusions.

The low-alloy type of alloys includes a whole list of metals. This includes silicon, aluminum, copper, nickel, tungsten, and others. Most varieties of low-alloy alloys have a high heat resistance threshold - up to 200°C.

It is used to produce medical, jewelry and engraving instruments, blades, and razors. Adding a small amount of chromium increases the strength of the metal. The alloy with chromium will last longer than usual.

Hardening equipment and features

The houses can be used:

- electric or muffle furnace;

- soldering iron;

- big fire outside.

The choice must be made according to the size of the part, the type of alloy, and the maximum heating temperature.

Increased hardness over open fire

If you don’t want to make a forge with a blower, you can use a regular barbecue or fireplace, let’s see how they do it in the video:

In the article we told you how to make hardened steel. Since the procedure is risky, please follow safety precautions.

Structural

This type is more common than the previous one. It is used to create more things. Industrial machines, small elements, and parts are made from structural steel. This type includes categories 40x, 30xgsa, 35xgsa and similar brands.

This type of steel has a rather interesting composition. It contains many different impurities, among which you can find phosphorus and sulfur. However, too much inclusion of other elements leads to a deterioration in the quality of steel, so the percentage of impurities should be in small quantities.

There are four main types of this alloy:

- Regular

- High quality

- High quality

- Particularly high quality.

The distribution is based on the amount of impurities, from higher to lower percentage. That is, the fourth type has a minimum amount of impurities, and therefore has a high quality and strength indicator. The first type contains the maximum number of inclusions. In this category, steel alloys are more short-lived.

In addition to the main division into four categories, structural steel has subgroups that are sorted by the inclusion of certain additional elements. However, in this article, the analysis of subgroups will not be discussed in order to avoid confusion.

How to harden steel at home?

It is advisable to carry out hardening and tempering under industrial conditions using special equipment and instruments. However, home craftsmen often practice this in their own workshops. To heat the product, electric stoves, ovens, hot sand, blowtorches, and a fire are used. Self-heat treatment is justified if it is necessary to harden the cutting edge of the tool.

How to make hardened steel:

- before heat treatment, the product must be cleaned of oil and rust;

- heat evenly;

- cool and temper in accordance with the conditions recommended for a specific steel grade.

If it is necessary to carry out heat treatment at home in the absence of instruments, the temperature of the metal is approximately determined by the colors of tarnish. Condition: the room should not be illuminated by the sun.

Definition! Tarnish is the name given to oxide films formed without the participation of water molecules on iron-based alloys during heating. Each temperature interval corresponds to a specific color:

- dark brown – 530-580°C;

- brown-red – 580-650°C;

- cherry – 650-730°C;

- cherry red – 730-770°C;

- cherry-scarlet – 770-800°C;

- light cherry-scarlet – 800-830°C;

- bright red – 830-870°C;

- red – 870-900°C;

- orange – 900-1050°C;

- dark yellow – 1050-1150°C;

- light yellow – 1150-1250°C;

- yellow-white – 1250-1300°C;

Possible difficulties when welding

During the work, the contractor may encounter the following problems:

- Arc deflection (magnetic blast). The field can be created by the workpiece or nearby cables. To prevent this phenomenon, the parts are first demagnetized and the work area is fenced off with screens. With direct polarity, you should cook in the direction of the mass clamp, with reverse polarity, away from it.

- The appearance of defects such as lack of penetration or through-burning of the workpiece. Explained by setting the wrong current value. In the instructions for consumables, the recommended amperage is indicated as a range, for example 80-140 A. The exact value is selected experimentally. Lack of penetration occurs when the indicator is underestimated, burn-through occurs when the indicator is too high.

- Flowing out of the melt from the weld pool when making vertical and ceiling seams. To avoid this phenomenon, it is necessary to reduce the welding current and use special consumables that produce viscous slag.

- The appearance of defects in the form of crystallization hot cracks and brittle hardening inclusions. This is explained by the increased concentration of carbon.

We recommend reading: How to cook non-ferrous metal correctly

The welding process depends mainly on the carbon content of the steel.

The amount of carbon in the weld is affected by:

- Node design.

- Joint shape.

- Preheating of workpieces.

- Metal composition.

It follows that the following measures will help prevent cracking:

- Reduction of tensile stresses in the seam.

- Formation of a joint of the correct shape with a homogeneous chemical composition.

- Reducing the concentration of harmful elements.

How to weld stainless steel to carbon steel

Stainless and carbon alloys differ greatly in their characteristics.

Welding is carried out according to the following rules:

- Preliminary and concomitant heating up to 600°C is used. This ensures uniformity of the seam structure.

- The finished structure is subjected to heat treatment to prevent the appearance of cracks.

The following methods are used:

- Cooked with nickel or high-alloy consumables.

- The edges are fused with alloyed electrodes. Then welding is done with stainless steel consumables.

Particularly critical structures are welded using the argon arc method.

How to prepare for welding

Before performing work you must:

- Prepare personal protective equipment: a shield with dark glass, overalls, boots, mittens. The damaging factors are splashes of molten metal and hard ultraviolet radiation, which cause burns to the retina and skin.

- Clean the edges of the parts to be joined (remove dirt and rust). The grease is neutralized with a degreaser.

- Secure the workpieces to the table with clamps or other clamps.

- Heat the consumables in the oven. Temperature and duration are indicated in the instructions.

The last operation is needed to remove moisture from the coating. Without this, the seam does not receive protection from oxidation and is saturated with hydrogen.

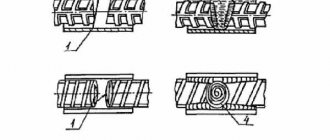

Working with two-layer steels

The use of 2-layer technology makes it possible to reduce the consumption of alloy alloys and at the same time ensure high performance characteristics of the product. The base is made of carbon steel, its thickness can reach 150 mm. A cladding made of a high-alloy alloy is fused on top with a layer of up to 12 mm.

Welding of each part is carried out separately, using appropriate materials (fluxes, filler wire, consumables).

They operate in the following order:

- carbon layer;

- highly alloyed.

With this sequence, the cladding is not subjected to reheating, which eliminates the appearance of cracks.