The influence of alloy impurities on steel welding

Various types of steel can be used for welding structures, but it is worth considering that its weldability depends primarily on the presence of alloyed impurities in its composition. It is the chemical composition that has the main influence on this process.

The table below shows the main alloying impurities that affect the degree of weldability of various types of steel.

| Dopant | Description |

| Carbon (C) | This is the most important impurity on which the strength, elasticity, hardenability and other important qualities of the metal depend. If the composition includes 0.25% carbon, this will not reduce weldability. If its content is higher than this indicator, then this will cause the appearance of hardening structures in the metal of the heat-affected zone and the appearance of cracks. |

| Sulfur (S) and phosphorus (P) | These components are classified as harmful additives. When there is a high level of sulfur in the steel, red cracks appear - red brittleness, and when there is a high level of phosphorus - cold brittleness. Therefore, low-carbon steels contain S and P up to 0.4-0.5%. |

| Silicon (Si) | This is a deoxidizing agent. Its level should be about 0.3%; this indicator does not reduce the clotting properties. If silicon amounts to 0.8-1%, then refractory oxides may form, which will have a negative impact on the weldability of the metal. |

| Manganese (Mn) | When the content of this element is up to 1%, welding does not deteriorate. If the manganese level is between 1.8 and 2.5%, hardening structures and cracks in the metal may form. |

| Chromium (Cr) | Low-carbon steels contain chromium as an impurity up to 0.3%. In the composition of low-carbon steels - 0.7-3.5%. In alloy steels - 12-18%. And in highly alloyed ones - 35%. During welding, chromium causes the formation of carbides, which impair the metal's resistance to corrosion. This substance also causes the formation of refractory oxides, which impair the welding process. |

| Nickel | The component is present in the composition as an impurity. Its normal content should be 0.3%. In low-alloy steels, an increase of up to 5% is possible, and in high-alloy steels - up to 35%. Nickel increases the level of strength and ductility of the metal. |

| Vanadium (V) | In alloy steels, the level of the component reaches 0.2-0.8%. It causes an increase in the viscosity and ductility of steel, improves its structure, and increases the degree of its hardenability. |

| Molybdenum (Mo) | In steels its content should not exceed 0.8%. If the level of the component is normal, then it will have a positive effect on the strength characteristics of the metal. But during welding, this component burns out, which leads to the appearance of cracks in the deposited metal. |

| Titanium and niobium (Ti and Nb) | In steels resistant to corrosion, as well as in metals with high heat resistance, the content of these elements can be 1%. They increase resistance to corrosion, but the niobium in type 18-8 steels causes cracking. |

| Copper (Cu) | In steels its level is 0.3%, in low-alloy steels - from 0.15 to 0.5%, and in high-alloy steels - from 0.8 to 1%. Increases resistance to corrosion, but does not impair weldability. |

Weldability of low alloy steels

To low alloy

include steels that are alloyed with one or more elements with a content of each of them ≤2% and a total content of alloying elements ≤5%. These steels are divided into three groups: low-carbon structural steels; heat resistant; medium carbon structural.

Low carbon low alloy

Structural steels can, in turn, be divided into high-strength and high-strength steels. In high-strength steels (NL1, NL2, 10G2SD, 14KhGS, 10KhSND, 12KhGN, 09G2DT, etc.) the carbon content does not exceed 0.23%. These steels are used in mechanical engineering and construction. They are supplied mainly in hot-rolled form.

Alloying elements - Mn, Si, Ni, Cr, Cu, Ti - dissolve in ferrite, strengthen it and grind pearlite. Thanks to this, the strength characteristics of such steels increase and the tensile strength reaches 55 kg/mm2.

In terms of their weldability, steels of this group differ little from unalloyed low-carbon steels. However, they are more prone to grain growth in the heat-affected zone, and at high cooling rates, nonequilibrium quenching structures may appear in it.

Low carbon high strength

steels (14Kh2GMR, 14KhMNDFR, 16G2AF, 12KhG2SMF, etc.) are classified as heat-hardening steels, which, along with high strength (σв ≥ 80 kg/mm2), are characterized by sufficient ductility, toughness, increased resistance to brittle fracture, corrosion resistance, etc. Application The use of such steels in mechanical engineering and construction can significantly reduce the weight of structures and increase their load-bearing capacity. Strengthening of these steels is achieved by a combination of minimal alloying and heat treatment - usually quenching and tempering. This creates a very fine structure with finely dispersed reinforcing particles of carbides or nitrides.

However, the weldability of high-strength steels is worse than the weldability of low-carbon, low-alloy steels, since:

1) cold cracks may form in the heat-affected zone of welded joints; 2) in the heat-affected zone, a softening area is likely to appear, reducing the strength of the welded joint.

Due to the presence of alloying elements that increase the stability of austenite, these steels are sensitive to the cooling rate. But the danger of cold cracks in the heat-affected zone is less here than in carbon structural steels, since the martensitic (or bainitic) transformation, due to the low carbon content, occurs at relatively high temperatures (> 350 °C) and is accompanied by relatively low stresses of the second kind ( microstresses). In addition, the low-carbon acicular martensite, or bainite structure, is more ductile. Yet. Since these structures have a reduced permeability to hydrogen, hydrogen diffusing from the weld accumulates at the boundaries of grains that have a disordered structure with a higher concentration of defects and distortions, and creates additional microstresses that contribute to the appearance of cold cracks. Reducing the cooling rate in the heat-affected zone, as well as means to reduce the amount of hydrogen dissolved in the metal of the weld pool, makes it possible to obtain a metal that is resistant to cold cracks.

Fig. 190. Distribution curves along the length of zone l of hardness in a welded joint made of heat-strengthened steels.

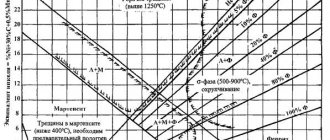

Softening in the thermally affected zone, accompanied by a drop in hardness (Fig. 190), can reach 30% or more. Its appearance is associated with the action of welding heating and concerns those areas of the zone whose maximum heating temperature lies within 500 °C - Аss (areas of recrystallization and incomplete recrystallization). Most often, softening is associated with two processes: 1) decomposition of a supersaturated solid solution and its depletion of strengthening alloying elements; 2) the formation of carbide phases and their coagulation. The degree of softening depends on the chemical composition of the steel and its heat treatment and increases with increasing welding heat input: in Fig. 190 curve 1 is presented for steel 14KhMNDFR (qp - 8000 cal/cm); curve 2 is for 15KhSND (qp - 7500 cal/cm), and curve 3 is for 15KhND steel (qp - 12,000 cal/cm).

Softening can be significantly reduced and even eliminated by increasing the cooling rate during welding. However, in this case, the possibility of the appearance of hardening structures in the heat-affected zone should be taken into account. Therefore, the thermal cycle when welding heat-hardening steels should be regulated very carefully.

Heat-resistant low-alloy

steels (15M, 15KhMA, 20KhMA, 20KhMFL, etc.) have increased technical strength at high temperatures and long-term constant loads. Their heat resistance is assessed by the value of the creep limit (Creep is the ability of a metal heated to a high temperature to gradually deform plastically under the influence of a long-term constant load. Hence the creep limit is the stress at which, after a certain period of time at a given temperature, the creep deformation will receive a predetermined value) and the long-term limit strength (The long-term strength limit is the minimum stress that causes destruction of the metal at a given temperature over a certain period of time (1000 hours, 10,000 hours, etc.)). These steels are used for the manufacture of structures operating at high temperatures (350-450 °C) and significant stresses, as well as in environments that promote chemical and mechanical destruction of the metal (steam boilers, oil equipment, etc.). Usually, such steels are used to increase Their heat resistance is enhanced by special alloying elements (Mo, V, W). which increase the temperature of softening of the metal when heated and the resistance of the metal to softening. To simultaneously increase the heat resistance of steel, Cr is introduced into its composition, which creates a protective film of oxides on the surface of the metal (heat resistance - resistance to oxidation at high temperatures). Heat-resistant steels are used, as a rule, after heat treatment (normalization with tempering, hardening with tempering, etc.).

Steels of this group have satisfactory weldability. However, in this case it is necessary to obtain a weld metal that is close in composition to the base metal in order to prevent the development of diffusion processes under high temperature conditions. This ensures the required strength of the weld metal and the base metal.

Heat-resistant low-alloy steels are characterized by increased sensitivity to hardening. Therefore, metastable brittle martensite structures and cold cracks can form in the heat-affected zone. To create conditions in the metal being welded under which the heat-affected zone would cool at a rate not exceeding the permissible rate, preheating of the product is used. The heating temperature and welding mode are determined by appropriate calculations. Typically, the heating temperature of chrome-molybdenum heat-resistant steels lies in the range of 200 - 300 °C. After welding, all products made from heat-resistant low-alloy steels are subjected to heat treatment (usually normalization with tempering, sometimes high tempering to level the structure and relieve welding stresses).

Medium carbon low alloy

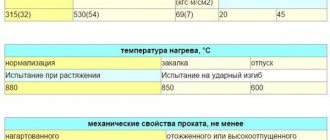

Structural steels (25KhGSA, ZOKHGSA, 35KhM, etc.), most widely used in mechanical engineering, are used mainly in heat-treated form. Such steels have high mechanical properties, especially strength characteristics (σв = 80 ÷ 110 kg/mm2).

The weldability of medium-carbon low-alloy steels is significantly worse than the steels of the previously considered groups, which is associated with the increased tendency of the weld metal and heat-affected zone to form cracks. The weldability of these steels has many similarities with the weldability of medium-alloy pearlitic steels.

Factors determining the curlability of steel

Welding carbon steels depends on the impurity content and other properties. Typically, welding is assessed based on the content of the main substance - carbon equivalent Seq. This is a conditional coefficient that will allow us to take into account the degree of influence of the carbon content and the main alloying components on the characteristics of the weld.

The degree of welding of steel for the manufacture of welded structures may depend on the following factors:

- carbon content indicator;

- the presence of harmful impurities;

- degree of alloying;

- type of microstructure;

- environmental conditions;

- level of thickness of the metal base.

Classification of steels by weldability

Welding steel 45, 40, 20 and other grades, depending on the important qualities of the metal base, can have different characteristics.

Depending on the degree of weldability, steel is divided into several groups:

- good weldability, while the carbon equivalent indicator SEq. must be at least 0.25%, more is allowed. It does not depend on weather conditions, the size of the thickness of the products, or the presence of preparatory work;

- satisfactory weldability indicator - the SEq indicator should be more than 0.25%, but not higher than 0.35%. At the same time, there are restrictive standards for environmental conditions and for the diameter dimensions of the welded product. Welding steel 20 should be carried out at air temperatures down to -5 in calm weather, and the diameter size should not exceed 20 mm;

- limited. Indicator Seq. should be from 0.35% to .45%, but the main thing is not more. To obtain a high quality seam, preheating is required. Due to this, it is possible to achieve smooth austenitic transformations, as well as the formation of stable structures;

- poor weldability, at which the indicator Seq. is more than 0.45%. In order to obtain a high-quality and mechanically stable welded joint, preliminary temperature preparation of the edges of the metal base is required. Also, after welding, the structure should be heat treated. To obtain the required microstructure during welding of steel 40, additional heating and cooling must be performed.

Features of welding low-carbon steels

Low-carbon metals contain 0.25% carbon. This indicator provides positive features of the foundation:

- good elasticity;

- high plasticity properties;

- significant impact strength;

- The base is ideal for welding.

Low carbon steel is used for welded structures. Also used in the manufacture of products using cold stamping.

How low carbon steel is welded

The technology of welding low-carbon steels is carried out using manual arc welding using coated electrodes. Be sure to remember a few nuances:

- First of all, you need to choose the brand of electrodes. This ensures a uniform structure of the deposited metal;

- welding must be performed quickly and accurately;

- Before starting the work process, you need to prepare in advance the parts that will need to be connected.

The technology of welding carbon steels can be performed by gas welding. Important features include:

- in this case, the process is carried out without the use of additional fluxes;

- for the filler base it is worth using metal wire with a low carbon level;

- when welding is performed correctly, the formation of pores is prevented;

- Important products must be welded with argon.

Once welding is completed, the finished product must be subjected to heat treatment using the normalization method. During this process, the product is heated to 4000C, then cooled and kept in the open air. This procedure makes the structure of the product uniform.

Main features

Welding 30 steel with a low carbon base has several important features that are worth paying attention to:

- high-quality welding of structures made of this material ensures equal strength of the welded joint with the base metal. It also protects against the formation of defects;

- the metal base of the compound has a low carbon content, but the indicators of components such as silicon and manganese are increased;

- During manual arc welding, the heat-affected zone may be subject to overheating. This helps to slightly strengthen the seam;

- the seam, which is made using multilayer welding, has increased fragility;

- Due to the fact that the seams contain a low level of carbon, they have increased resistance to intercrystalline corrosion.

Welding Varieties for Low Carbon Steel

Welding of low-carbon steels can be done using several methods. Moreover, each of them has important features that must be taken into account during welding.

| View | Characteristic |

| Manual arc welding with coated electrodes | In order to accurately select consumables for welding using this method, several important conditions must be taken into account - the finished weld must be without damage, uniform strength of the joint, optimal chemical composition of the metal base of the seam, resistance of the joint to impacts. Welding of steel 45 and other grades is performed with an electrode. In this case, various brands of electrodes can be used. |

| Gas | The process is carried out in a protective argon environment. Additionally, metal base wire is used as a filler base. |

| Electroslag | During this process, fluxes are used. Wire and plate electrodes are selected depending on the main alloy. |

| Automatic and semi-automatic welding | The welding process is carried out in a protective environment. During it, argon or pure helium can be used, but mainly carbon dioxide. |

| Automatic submerged | Welding is performed using electrode wire with a diameter of 3 to 5 mm. Welding 45 steel (20, 30, 40 and other grades) with a semi-automatic machine - 1.2-2 mm. Welding occurs due to electric current with reverse polarity. |

| Welding using flux-cored wires | It is considered the most suitable. The current strength is usually in the range from 200 to 600 A. |

Low carbon steel: welding technology

As mentioned above, low-carbon steels lend themselves best to the welding process. They can be welded using gas welding in an oxy-acetylene flame without additional fluxes. Metal wires are used as an additive. Hydrogen, which can form pores, can negatively affect the welding process. To prevent this problem, it is recommended to carry out the welding process with a filler metal containing a small amount of carbon.

After the welding process, the structure must be thermally treated to improve the mechanical properties - ductility and strength will be the same. Heat treatment of welded structures is carried out by a normalization operation, which consists of heating the product to a certain temperature, approximately 400 degrees, holding and further cooling in air. As a result, the structure is equalized, carbon in the form of cementite in the metal diffuses into the grains, due to which the structure becomes uniform.

Gas welding is carried out in the presence of argon, which creates a neutral environment. Structures that are welded in an argon environment have a more important purpose.

Welding of low-carbon steels can be done manually; arc welding of such materials requires the correct choice of electrode. When choosing an electrode, it is necessary to take into account the following factors, which will ensure a uniform weld structure without defects. Before carrying out the welding process, it is necessary to calcinate the electrodes in order to prepare them for further work and remove hydrogen. Welding low-carbon iron alloys must be precise and fast, and the metal parts must be prepared before starting the process.

Welding medium carbon steel

Metals with medium carbon content are usually used in the production of products with high mechanical properties. The alloys are suitable for forging. They are also often used for structures that are produced using cold plastic deformation.

Steels that contain carbon from 0.4 to 0.6% are often used in the mechanical engineering industry. They can be used to make wheels and axles of carriages, and railway rails.

How to do it

The technology of welding medium-carbon steels is not so simple. It's all about some difficulties:

- the main and deposited metal do not have equal strength;

- there is an increased risk of large cracks and non-ductile structures appearing near the joint;

- low resistance to corrosion.

But if you follow important recommendations, all these problems can be avoided:

- welding of 30xgs steel should be carried out with electrodes and wire with a low carbon level;

- welding rods must have an increased deposition rate;

- to ensure a small degree of penetration of the base metal, it is recommended to separate the edges, set a suitable welding mode, and also use filler wire;

- welding of 35xgsa steel must necessarily involve pre-heating of the workpieces. They must also be heated during the welding process to ensure uniform strength of the welds.

Types of welding of medium carbon steel

Welding medium carbon steel pipes and other products is a complex procedure. Welding of this material can be done in several ways. Moreover, each of them differs both in the process of work and in the finished result.

Steel grade 35 hgsa has a medium carbon content; its welding is usually done by manual arc welding with electrodes. But at the same time, they must contain a small level of carbon; the following brands of consumables are considered the most suitable - UONI-13/55, UONI-13/65, OZS-2, K-5a.

The technology of gas welding of medium-carbon steels having a thin-sheet format is carried out using the left-hand method using wire. It is also necessary to use a normal welding flame, which allows reducing gas consumption to an average of 75-100 dm3 per hour. On average, acetylene consumption is 120-150 l/h per 1 mm of thickness of the alloy being welded.

Products with thick walls with a thickness of 3 mm or more must be welded using the right gas welding method. This option has high performance. In this case, the calculation of acetylene is the same as with the left-hand welding method - 120-150 l/h. General heating should reach 250-300 degrees, and local heating should reach 600-650 degrees.

Welding steel 35, 20, 40, 45 and other grades under submerged arc is accompanied by the use of welding wire and fused fluxes. When welding there is a small impact of current. This increases the content of silicon and manganese in the deposited metal base.

Gas welding of carbon steels

Low-carbon steels (up to 0.25% C) can be welded using gas welding without much difficulty. Welding is carried out with a normal flame and, as a rule, without flux. The torch tip for the left-hand welding method is selected based on the acetylene consumption of 100-130 dm3/h per 1 mm of the thickness of the metal being welded, and for the right-hand method - 120-150 dm3/h per 1 mm of metal thickness. Edges for welding are prepared depending on the thickness of the product being welded. The diameter of the filler wire is also selected depending on the thickness of the metal being welded according to the following formula:

- with the left welding method dn =S/2+1 mm;

- with the right welding method dn = S/2 mm, where dn is the diameter of the filler wire, mm; S—thickness of the metal being welded, mm.

Highly qualified welders use a high-power flame; the tip is selected based on an acetylene consumption of 150-200 dm3/h per 1 mm of the thickness of the metal being welded, using a filler wire of a larger diameter; The burner flame should be normal. This increases the productivity of gas welding. For non-critical structures, welding wire Sv-08 and Sv-08A is used as an additive. When gas welding with these wires, some of the components, such as C, Si and Mn, burn out, and the weld metal acquires a coarse-grained structure. The tensile strength of such a connection is lower than the tensile strength of the base metal.

To obtain a connection of equal strength with the base metal when gas welding critical structures, it is necessary to use silicon-manganese welding wire Sv-08G, Sv-08GA, Sv-10GA or Sv-14GS. During gas welding, it is necessary to ensure that the edges of the metal being welded and the end of the filler wire melt at the same time. The end of the filler wire should be immersed in the molten metal pool. Drops of molten metal should not be allowed to fall on the unmolten edges of the base metal, as this leads to lack of penetration, which reduces the mechanical characteristics of the joint. To prevent the molten metal from flowing down during the left-hand welding method, the product is tilted 10-15° against the movement of the torch. If the end of the filler wire sticks to the edges of the base metal being welded, this means that they are not yet heated enough. During the welding process, it is necessary to avoid deflection of the welding flame from the pool of molten weld metal, as this can lead to oxidation of the weld metal by atmospheric oxygen. Welds must have a uniformly scaly surface, a uniform width and height of the weld bead along the entire length of the weld. The transition from the base metal to the deposited metal should be smooth, without undercuts. During the welding process, the torch produces uniform and continuous oscillatory and translational movements. Oscillatory movements are selected depending on the thickness of the metal being welded.

To compact and increase the ductility of the deposited metal, forging and subsequent heat treatment of the weld are used. It is recommended to start forging at a light red heat temperature and end at a dark red heat temperature. Forging at a lower temperature can lead to the appearance of microscopic cracks in the weld metal or heat-affected zone. When gas welding critical and thick-walled products, heat treatment of welded joints is used. Acetylene or propane-butane is used as a combustible gas for low-carbon steel; They are welded with a propane-butane flame in such a way that the distance from the end of the flame core to the welded surface is 8-10 mm. Propane-butane is used for welding non-critical parts.

The flame power is selected based on the acetylene consumption of 75-90 dm3/h per 1 mm of the thickness of the metal being welded. Gas welding is recommended to be performed with a normal or slightly carburizing flame. In order to reduce overheating and the time the weld pool remains in the molten state, the left-hand welding method is used. For gas welding of high-carbon steels, fluxes of the same composition are used as for medium-carbon steels.

weldering.com

Welding high carbon steel

Welded products are not produced from high-carbon metal. The fact is that this material has a low level of ductility; it is this property that limits the use of metal.

High carbon steel is used for the following purposes:

- during repairs and construction;

- for the manufacture of springs;

- for the production of tools and products that are used for cutting, drilling, woodworking;

- High-strength wire is made from metal;

- structures that have high wear resistance and strength.

How to do it

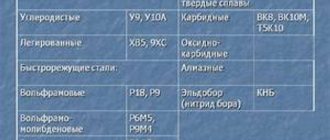

Welding of high-carbon steels is usually performed using preliminary and concomitant heating of the deposited metal to 150-4000C. Also, after welding, additional heat treatment is carried out to improve strength.

This is necessary because the alloys from the material have high fragility, increased sensitivity to cracks with a hot and cold structure, and also because of the chemical heterogeneity of the welded joint.

Welding technology for high-carbon steels is carried out taking into account the following recommendations:

- After heating, annealing is performed. It is carried out until the structure cools down to 2000C;

- welding 40x, 20x, 30x should not be performed in drafts, or at temperatures below -50C;

- in order to increase the strength properties of the weld, it is necessary to make a smooth transition from one to another metal being welded;

- To obtain a high-quality connection, it is worth using narrow beads when welding. In this case, each layer being deposited must be cooled;

- The rules that apply to compounds made from a medium-carbon base must be followed.

Types of welding

The welding process of high-carbon steels can be performed in several ways, which may differ in some features:

- manual arc welding using coated electrodes. The working process of high-carbon steels has many specific characteristics. For this reason, welding of steel 40x, 30x, 45x and other grades should be carried out using special electrodes, for example, HP-70. And welding of seams is carried out with a current of reverse polarity;

- To connect this type of metal, submerged arc welding can be used. Due to the fact that in manual mode it is very difficult to evenly coat the work area with flux, therefore welding is carried out using automatic technology. When melted, the flux turns into a dense shell, which protects the weld pool from harmful atmospheric factors. Welding of 30xgsa steel using flux is carried out using transformers.

High alloy

Highly alloyed alloys usually contain at least 16% chromium and at least 7% nickel, in addition to other impurities. Thanks to these and other additives, high-alloy alloys are highly resistant to low temperatures, corrosion and high temperatures.

But each brand has its own specialization, in which it has extreme characteristics. According to their purpose, high-alloy steels can be divided into heat-resistant, heat-resistant and corrosion-resistant.

After heat treatment they increase their strength and ductility. When hardened, their ductile properties improve.

Specificity

High-alloy alloys have such outstanding characteristics that they are used wherever the feasibility and price of the product allows.

But each specific product has different requirements. Accordingly, when carrying out welding work, different requirements for strength and ductility are imposed on welded seams, which leads to different approaches to welding work. That is, everything here is individual.

The presence of a large number of approaches in welding high-alloy steels is due to the fact that they have very specific thermophysical properties.

They have a low coefficient of thermal conductivity and a high coefficient of thermal expansion. In combination, they place conflicting demands on the welding process.

Low thermal conductivity leads to an increase in the depth of steel penetration. A high coefficient of thermal expansion causes deformation, including warping of parts. To reduce warping, it is necessary to concentrate thermal energy as much as possible. Laser welding does this well.

When manual electric welding of high-alloy alloys, the same measures are carried out as when welding medium-alloy alloys. The main task is to minimize the entry of hydrogen into the welding zone, otherwise it causes the appearance of pores and cracks.

Choice of technology

For high-alloy alloys, gas welding is not recommended for acid-resistant steels, as it causes intergranular corrosion. Even when heat-resistant steels are used in welding, warping of products occurs.

Submerged arc welding has great advantages over manual electric arc welding due to the fact that the welding process takes place under protection in a constant environment with the same components. There is no need to change electrodes, which causes crater formation.

Submerged arc welding ensures a uniform weld with specified characteristics due to the protection of the weld pool from the external environment in the form of hydrogen.

In addition, preliminary work is reduced, since cutting edges is only necessary for thicknesses of more than 12 mm, and manual arc welding requires cutting edges for metal thicknesses of more than 5 mm.

Laser welding is the most effective for alloy steels due to the high concentration of energy in a small area. This allows you to virtually eliminate warping and deformation. Many alloyed alloys can be welded together, regardless of type, only when using laser welding.

Types of stainless steel

Welding dissimilar stainless and regular steels depends not only on the properties of the material, but also on its type. For this reason, in order to choose the appropriate welding method, you should first determine the type of steel.

Based on their main properties, stainless steel is classified into the following types:

- austenitic;

- martensitic;

- ferritic.

Austenitic materials contain a high content of nickel and chromium. Stainless steels are used for the manufacture of welded structures, for the production of tableware, architectural components, chimneys, and cutlery. This type of steel has high ductility, chemical resistance and resistance to mechanical damage.

Martensitic steels contain low levels of carbon and chromium, up to 12%. Metals of this variety are highly brittle, but very hard. They are used to produce cutting devices, household products, turbines, and fasteners that are used in environments with a low level of aggressiveness.

Ferritic steels contain medium levels of chromium. They are not hardened and have increased resistance to aggressive environments. They are mainly used in the mechanical engineering sector for the production of bushings, shafts, and fittings.

Types of stainless steel welding

Welding of martensitic, ferritic and austenitic steels is carried out by almost all known and common welding methods. The most popular methods include:

- manual arc MMA;

- tungsten electrode in an argon atmosphere TIG;

- using semi-automatic welding technologies in an inert atmosphere - MIG/MAG, laser.

Welding of austenitic steels and other types of stainless metal is usually done carefully, taking into account the complex chemical composition and physical properties of the metal. The main qualities that complicate the welding process include:

- when welding stainless steels, the temperature should be lower, in contrast to welding carbon metals;

- welding of dissimilar steels is accompanied by high thermal expansion;

- low level of thermal conductivity.

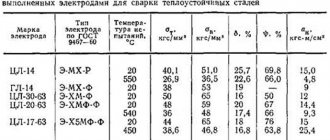

Welding of heat-resistant steels

Welding of heat-resistant steels is usually performed using arc welding using a tungsten electrode. The entire process usually takes place in a protective gas environment - argon or helium.

Welding of steel 15x5m and larger sizes can be carried out using argon arc welding using non-consumable or consumable electrodes or using automatic submerged arc welding.

Argon welding of steel 20x, 30x, 40x compared to welding in a helium protective environment is accompanied by lower gas consumption, low arc voltage and high welding current. For this reason, it is the most popular.

Welding heat-resistant steel 40x, 20x, 30x, the technology of which requires joining the metal in a state after hardening, has several features. During the welding process, the metal warms up to 1050-1100 degrees and then cools sharply.

Welding of steel pipelines from any type of metal (low-carbon, medium-carbon, stainless, heat-resistant) can be performed in different ways. The most popular are manual arc, automatic, and gas welding. But in any case, before welding of 30xgsa steel and other grades is carried out, the technology must be fully studied.