The chimney is an important part of heating appliances running on gas, solid or liquid fuel. In fireplaces, stoves, baths and boilers, it is important to maintain a certain level of draft in order to clean the air from combustion products. The correct choice of chimney pipe is the basis for the safe operation of the heating device. Errors in chimney construction can lead to life-threatening situations.

Advantages of a steel chimney pipe

Chimney pipes are made of metal, ceramics and brick. Metal pipes are currently in greatest demand. Of all the varieties of this material, it is recommended to choose steel. Steel pipes for chimneys are coated with special solutions that make the material resistant to all adverse effects of the internal environment of the chimney.

When choosing a pipe, it is necessary to take into account the parameters of the heating devices and the fuel used. The material from which the pipes are made must withstand higher temperatures than the fuel can create.

When using some types of heating devices, chemically active substances are found among the under-oxidized combustion products. They can damage a chimney that is not sufficiently resistant to chemicals. Some unburned particles can ignite, creating sparks. Therefore, the material from which the pipe is made must be fireproof.

This is interesting! When choosing a pipe, you need to pay attention to the melting point of the material from which it is made. The melting point of steel exceeds 1000 0C - the highest possible indicator encountered when operating heating appliances powered by coal.

The advantages of steel pipes are:

- Easy to install. Steel pipes do not require the installation of a special foundation; they do not require complex engineering solutions or special installation tools. You can install them yourself without prior preparation. Due to the plasticity of the material, complex technical structures can be created.

- Light weight. They are easy to transport, you can lift and move them yourself without a team of workers, which also simplifies installation.

- High temperature resistance. Steel products are suitable for appliances operating on any fuel. They do not melt at maximum temperature loads.

- Chemical inertness. Steel does not interact with chemical reagents that can form as under-oxidized combustion products. These substances are not capable of destroying it.

- Corrosion resistance. This advantage applies to pipes that have a special coating and stainless steel. The material itself quickly corrodes. It is worth considering that in addition to the internal environment, the chimney pipe is affected by external unfavorable factors, for example, precipitation. Preference should be given to coated pipes.

- Smooth inner walls. Combustion products settle on the rough surface, turning into soot, which gradually reduces the clearance. This reduces the draft in the chimney. Steel is completely smooth, the risk of soot settling on their surface is minimal.

Production of thick-walled pipes

Thick-walled pipes are manufactured in accordance with the established TU 14-3r-50-2001. This type of pipe is produced on special pipe rolling machines. Thick-walled pipes in Moscow are manufactured using welded-seam and seamless-drawn methods. Thick-walled seamless pipes are produced both by cold rolling and by hot rolling. Seamless is usually used when laying gas and pipelines.

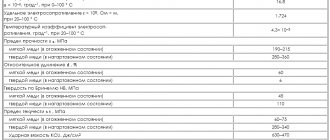

As a rule, non-magnetic, biologically inert steel is used to produce thick-walled pipes. The stainless steel thick-walled pipe contains the following elements:

- nickel;

- titanium;

- chromium.

All presented chemical elements give the product high strength without loss of ductility, as well as reliability in contact with alkalis and acids. Thick-walled pipes are usually subjected to a thermal hardening process upon completion of production. This ensures resistance to any chemical reagents and ensures reliability even at high internal pressure.

To produce thick-walled pipes, not only steel is used, but also copper, brass and aluminum.

Categories of thick wall pipes

B - products that will more often come into contact with an aggressive environment.

B - products that may be frequently subjected to mechanical stress.

D - pipes for which chemical and mechanical protection is not important.

E - pipes without heat treatment.

Classification of thick-walled pipes

- brushed;

- polished;

- matte;

- polished.

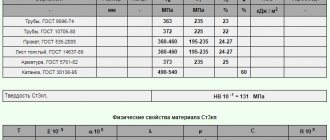

Thick-walled pipes are produced from the following steel grades: st20, st45, st09G2s, as well as 08x18N10. The pipe is thick-walled, the price of which is inexpensive, and is made from inexpensive steel grades.

The cross-section of the presented pipe model can be rectangular, square and oval.

Disadvantages of a steel chimney

In addition to the advantages, steel pipes have a number of disadvantages. Their main disadvantage is the rapid absorption of heat. Steel heats up quickly, so they need to be insulated. If this is not done, the pipe may heat the materials it comes into contact with and cause a fire. In addition, when it gets hot, it loses its ability to extinguish sparks that occur in the chimney.

Another disadvantage of steel pipes is the large formation of condensate. This feature of the material can vary in severity depending on the coating and type of structure. The least condensate falls on straight pipes without horizontal outlets.

Regulatory documents (standards) for thick-walled pipes and steels for their production

According to the assortment tables (in the appendices of each standard), there is a clear definition of thick-walled pipes, depending on the ratio of wall thickness and outer diameter:

Ø

In the range from 6.0 to 12.5 - standard thick-walled pipes;

Ø

Less than 6.0 - especially thick-walled pipes.

Basic standard dimensions according to all DIN and EN standards:

- Outer diameter: ranging from 26.9 mm to 711.2 mm.

- Wall thickness ranges from 10.0 mm to 100 mm.

Particularly thick-walled pipes are produced in the following sizes:

- Outer diameter: ranging from 76.2 cm to 81.2 cm.

- Wall thickness ranges from 20.0 mm to 80.0 mm.

The most common standard tubular products with large wall thicknesses and the main steel grades used for their manufacture are regulated by the following standards:

Seamless thick-walled carbon steel pipes

| Standard | Steel | Size chart | |

| EN 10210-1.2 | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S355NH, S355NLH | ||

| EN 10216-1 | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 | ||

| EN 10216-2 | P195GH TC1, P235GH TC1, P265GH TC1 | ||

| EN 10216-3 | P275NL1, P275NL2, P355N, P355NH, P355NL1, P355NL2 | ||

| EN 10216-4 | P215NL, P265NL, P255QL | ||

| EN 10225 | S355G1+N, S355G14+N, S355G15+N | ||

| EN 10297-1 | E235, E275, E315, E355, E275K2, E355K2 | ||

| DIN 1629 | St 37.0, St 44.0, St 52.0 | ||

| DIN 17121 | RSt 37-2, St 44-2, St 37-3, St 44-3, St 52-3 | ||

| ISO 3183 | L245NE, L290NE, L360NE, L415NE | ||

| ASTM A53 | Grade B | ||

| ASTM A106 | Grade B, Grade C | ||

| ASTM A252 | Grade 2, Grade 3 | ||

| ASTM A333 | Grade 1, Grade 6 | ||

| API 5L | Grade B, X42, X46, X52, X56, X60 | ||

Thick-walled boiler pipes

| Standard | Steel | Size chart |

| EN 10216-2 | P195GH TC2, P235GH TC2, P265GH TC2, 16Mo3, 14MoV6-3, 13CrMo4-5, 10CrMo9-10, 15NiCuMoNb5-6-4, X10CrMoVNb9-1 | |

| DIN 17175 (DIN 2448) | St35.8/III, St45.8/III, 15Mo3, 14MoV6-3, 13CrMo4-4, 10CrMo9-10 | |

| ASTM A335 | Grade P1, Grade P2, Grade P5, Grade P11, Grade P12, Grade P22, Grade P91 |

Seamless thick-walled stainless steel pipes

| Standard | Steel |

| EN 10216-5 | 1.4301, 1.4306, 1.4541, 1.4571, 1.4401, 1.4404, 1.4466, 1.4462 |

| ASTM A312 | TP304, TP304L, TP316, TP316L, TP310S, TP317L, TP317LN, TP317LNM, TP321, TP347, TP410, TP410S, S31803, S32304 |

These same types of steels are suitable for the production of thick-walled pipes used for the construction of underwater pipeline systems.

Assortments of manufactured pipe products according to various standards are compiled according to various criteria, taking into account certain characteristics:

- manufacturing methods;

- diameters of thick-walled pipes;

- Wall thickness;

- section type;

- general dimensions and dimensions of the finished pipe;

- intended area of application for thick-walled pipes.

As a rule, thick-walled pipes are subjected to further mechanical processing to produce cylindrical and hollow elements and structures used for various engineering and technical solutions.

Types of steel chimneys

Steel chimneys vary in pipe material and type of construction. Steel is used in several varieties:

- Black without coating. This material is the cheapest, but at the same time the least durable. Such steel is susceptible to corrosion and quickly becomes unusable.

- Low alloy steel. Chromium, zinc, nickel, and molybdenum are used as impurities for this material. This alloy is less susceptible to corrosion than ordinary black steel.

- Stainless steel. The best possible option. Pipes made of this material have all the advantages of steel chimneys.

- Corrugated steel. It is the least reliable option, since due to the corrugated wall, soot quickly settles on the pipe. Such a chimney will have to be cleaned frequently. Corrugated material is used for lining.

This is interesting! Restoration work on old stove chimneys is called lining. In this case, a new, usually steel, pipe is placed inside the existing brick frame. Lining can significantly improve the aerodynamics of an old chimney.

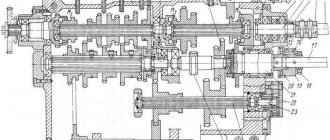

Based on the type of structure, the following types of chimneys are distinguished:

- Single-walled. Such pipes have one wall, with a diameter of 0.6 to 1 mm. They do not have thermal insulation, so it is dangerous to use them for heating appliances in the house. They have found application in bathhouses, where water can be heated using a constantly hot pipe.

- Single-walled for sleeving. Such pipes may be no different from ordinary single-wall pipes; they may be corrugated or have an oval shape. Their distinctive feature is their location inside an old brick chimney.

- Sandwich systems. The most common and reliable of all options. They consist of inner and outer pipes, between the machines there is a layer of insulating material. This design avoids heating the outer surface of the pipe and the formation of condensation.

- Pipe-in-pipe design. This system differs from the previous version by the absence of an insulating layer. Such chimneys are called coaxial. The inner pipe in them is needed to remove combustion products; air moves through it from bottom to top. Along the outer pipe, that is, the layer between two pipes, air flows move in the opposite direction. They are necessary to maintain fuel combustion. This design helps to increase draft in the inner pipe, but it cannot be used in low temperature conditions due to freezing of condensate on the walls.

Calculation of the required cross-section and height of the pipe

To ensure good aerodynamics and adequate traction, it is necessary to comply with the rules prescribed in the relevant SNiP. They regulate the standards for the height and diameter of the pipe section for chimneys.

The height of the pipe depends on the type of roof. Its minimum possible value is 5 m, if measured from the heating device to the head. In addition, it is necessary to calculate the height of the part of the pipe protruding above the roof.

Above a flat roof, the pipe must rise no less than 50 cm. If the roof has a slope, the height of the pipe depends on its location in relation to the ridge of the roof. The location options are as follows:

- Up to 1.5 m from the ridge. In this case, the recommended pipe height is 50 cm higher than the most protruding part of the roof.

- From 1.5 to 3 m from the ridge. With this arrangement, the head should form a straight horizontal line with the roof ridge.

- More than 3m. In this case, the height of the protruding part of the pipe should be such that the angle between the ridge and the head is 10°. In this case, the pipe is located below the ridge.

Special formulas have been invented to calculate the cross section. They are very complex and to use them you need to know how much fuel is burned per hour of operation of the device, what the inlet and outlet temperatures are, as well as the coefficient for each type of fuel. To simplify the task of calculating the pipe cross-section, simplified rules are used:

- For devices with a power of less than 3500 W, the pipe cross-section must be at least 140 mm x 140 mm.

- For devices with a power from 3500 to 5000 W, the cross-section must be at least 140 mm x 200 mm.

- For devices with power from 5000 W to 7000 W - 140 mm x 270 mm.

Seamless steel pipe GOST 8732-78, GOST 8734-75

View price - Pipe BS

Seamless steel pipe GOST 8732-78, GOST 8734-75 - a pipe made from a steel billet without longitudinal and transverse seams.

Seamless pipes are used in pipelines and boiler plants, machines and units; in shipbuilding, automotive and aircraft industries. When it is impossible to use welded pipes, seamless ones are used, because... the latter are distinguished by high strength, quality and durability, wear resistance and are able to work in operational conditions. Increased strength is important when water flows through the pipeline at high pressure and temperature. Seamless pipes also have increased anti-corrosion properties - a special coating that protects against aggressive influences. Production of seamless pipes.

There are 4 methods for producing seamless pipes: rolling, drawing, forging and pressing. Seamless pipes , according to the manufacturing method and production temperatures, are: hot-deformed (rolled in a hot state) , heat-deformed (steel is heated to a temperature not exceeding the recrystallization temperature) and cold-deformed (rolled without preheating); by wall thickness: thick-walled and thin-walled .

Hot-deformed seamless steel pipes GOST 8732-78

- Seamless steel pipes for general purpose, manufactured according to outer diameter, wall thickness and length.

The production of seamless hot-deformed steel pipes occurs by hot rolling, after which the pipes are subjected to additional cold rolling. These pipes have increased strength and heat resistance, and therefore this type of pipe is used when installing pipelines with water, gas, steam or oil products. They are also widely used in aircraft and mechanical engineering, and in the construction of boiler structures.

The mass of 1 m of pipes is calculated by the formula: M = 0.02466 x S (Dn - S), where Dn is the outer diameter, mm; S - wall thickness, mm

Assortment of hot-deformed seamless steel pipes

The outer diameter of these pipes ranges from 25 to 700 mm inclusive. Wall thickness ranges from 2.5 mm to 75 mm. Seamless hot-formed steel comes in different thicknesses and diameters. Depending on the ratio of these quantities, pipes are distinguished: extra-thin-walled, thin-walled, thick-walled, extra-thick-walled.

Along the length of the pipe, seamless hot-deformed pipes are manufactured:

- unmeasured length (4-12.5m)

- measured length - within unmeasured

- length, a multiple of the measured length - within the unmeasured length with an allowance for each cut of 5 mm

- approximate length - within unmeasured length

Seamless hot-deformed pipes are represented by steel: steel 10, st 20, st35, st 45, st40Kh, st09G2S, 30KhGSA. The curvature of any section of the pipe per 1 m of length should not exceed: - 1.5 mm - for pipes with a wall thickness up to 20 mm - 2.0 mm - for pipes with a wall thickness above 20-30 mm - 4.0 mm - for pipes with a wall thickness more than 30mm.

Buy seamless pipe

From us you can purchase seamless pipes from all manufacturers from branch warehouses, warehouses in the Moscow region or directly from the factory. We provide pipe cutting, delivery and assembly services. the availability, range and price of seamless pipes on our website. It should also be taken into account that the price of metal depends on the required quantity. More detailed information on the price per 1 meter or per length, clarify the weight of the seamless pipe and make a quantity calculation , issue an invoice and fill out an application , clarify payment options and request a certificate for a seamless pipe - you can contact the manager by contacting him at

(8452) 57-00-18, e-mail: [email protected] .ru

Table . Seamless hot-deformed steel pipe. Dimensions, main diameters and thicknesses of seamless hot-deformed pipe according to GOST 8732-78. Weight of 1m of pipe, number of meters per ton .

Cold-deformed seamless steel pipes GOST 8734-75 - seamless steel pipes with a diameter of 5 to 250 mm, produced by cold rolling. Seamless cold-deformed pipes are used for pipelines, boiler equipment, machine parts, structures and other products, in shipbuilding and mechanical engineering, where the accuracy and quality of the material is important.

The most popular are pipes with an outer wall diameter from 8 to 450 mm; the wall thickness can reach 20 mm. Depending on the thickness of the outer diameter (Dн) to the wall thickness (s), the pipes are made:

- extra-thin-walled with Dн/ s more than 40 and pipes with a diameter of 20 mm or less with a wall of 0.5 mm or less,

- thin-walled with Dн/s from 12.5 to 40 and pipes with a diameter of 20 mm or less with a wall of 1.5 mm,

- thick-walled with Dн/s from 6 to 12.5,

- extra-thick-walled with Dн/ s less than 6.

The length of seamless cold-deformed pipes is from 1.5 m to 11.5 m, depending on the diameter and wall thickness. The range of steel grades for the manufacture of these pipes is extensive: steel 10, seamless pipes steel 20 , 35, 45, 10G2, 15Х, 20Х, 40Х, 30ХГСА, 15ХМ in accordance with GOST 1050, GOST 19281-89, GOST 4543-71.

In each batch of pipes of measured length, no more than 5% of pipes of unmeasured length and shorter than 2.5 m are allowed

Dimensions, main diameters and thicknesses of seamless cold-deformed pipe according to GOST 8734-75, weight of 1 m of pipe, number of meters per ton can be found in GOST 8734-75 .

Installation features

When installing a chimney, it is recommended to follow a number of rules.

The basic rule is that all objects surrounding the pipe should heat up by no more than 50 °C. Steel ones tend to heat up, so when installing them it is recommended to lay an additional layer of thermal insulation. This problem can be solved using ready-made sandwich systems.

The chimney must be located at a safe distance from electrical wiring, gas pipes and trees.

Where the pipe passes through walls or roofing, there should be a thick layer of heat-resistant sealant between it and the appropriate material. The same sealant is laid between the pipes at their joints.

When connecting, they are guided by one more rule: one pipe must enter another at a distance that is equal to the radius of the outer section of the pipes.

When assembling the structure, it is worth considering that the chimney should not have any narrowing areas, otherwise the aerodynamics of the pipe will suffer.

Horizontal sections should not be longer than 100cm.

An inspection window is installed at the bottom of the chimney - a removable nozzle. The upper part ends with a head with a spark arrester and a cone.

Operation, repair and cleaning of steel chimneys

Steel chimneys are easy to use. It is recommended to check the condition of the traction in them using the inspection hole left during installation. This must be done once every three months. The chimney must be cleaned at the same frequency.

Mechanical cleaning methods can scratch steel pipes, so they are best left to professionals.

At home, chemical methods are often used using special substances that are placed in the firebox. Burning chemical compounds in the form of gases rise up the chimney and dissolve the soot that has accumulated in it.

Condensation often forms in steel chimneys, which can be drained through a left inspection window.

Repairing a steel chimney most often involves replacing the entire structure or a section of it with new pipes. This is the most reliable method of fixing the problem.

Designed for removing flue gases from stoves and fireplaces. Made from structural steel 2.5 mm thick. Covered with a special heat-resistant silicone enamel, which polymerizes upon first use and forms a durable anti-corrosion coating.

Thanks to a wide range of elements, our modular system allows you to assemble a chimney of any height and complexity.

The chimney is a circle in cross section. Such a chimney removes gases much better than a square or rectangular one, since it does not impede the movement of flue gases and prevents the formation of soot. Since the inner surface of steel pipes is smoother than that of brick pipes, there is no additional resistance to exhaust gases. The draft in round pipes is 1.8 times better than in square pipes of the same cross-sectional area.

A steel chimney heats up much faster than a brick one, which means that the threshold for condensation formation is overcome faster, and the less condensate affects the pipes, the longer the chimney system lasts. It is also important to note that metal chimneys do not absorb combustion products, which, when in contact with condensate, form sulfuric acid, which significantly reduces the service life of the chimney system.

Chimneys made of steel are noticeably cheaper than brick ones, and even more so much easier to install. Due to their light weight, our chimneys do not require a separate foundation and can be easily installed in an already built house, even if the project did not include stove heating.

Features, types and purpose of the chimney

A steel chimney made of ferrous metals, which is based on zinc, is an integral component for any furnace or boiler that uses solid fuel, which requires the timely removal of all combustion and decay products to the street.

Before you buy black steel chimneys, you need to think about where exactly such a structure will be installed, identify all its features, dimensions, and select suitable materials and fittings for successful implementation.

The chimney pipe, black steel, for the manufacture of which is very popular among stove makers, can be made of the following materials:

Photo of chimney pipes

Description and features of materials

The most common material is steel. They have a lot of advantages, first of all, it is an affordable price, as well as light weight, which together allows you to create a durable and effective design, with the help of one person.

A steel chimney quickly warms up and cools down quickly; there is no need to equip it with an additional foundation, it does not have a significant and negative impact on the walls and ceiling of the house.

An expensive material from which stoves with high efficiency and good heat capacity are often made.

Pipes from which chimneys are assembled are also made from cast iron.

The main disadvantages of this option include high cost, as well as heavy weight.

The advantages are good retention and accumulation of thermal energy.

This variety was in great demand and popularity for another 20-30 years. However, today it has been proven that pipes consisting of materials based on zinc are dangerous to human health.

When heated and there is a sharp change in temperature, they begin to release harmful and hazardous products into the air. Therefore, today it is strictly forbidden to make chimneys from galvanized components.

A stainless chimney, Moscow and the region for which are the main delivery regions in our online store, will serve you for many years and will not cause problems or unpleasant moments during its operation, maintenance and cleaning.

So what is the difference between this chimney and those made of stainless steel? The fact is that pipes based on stainless steel are more durable and of higher quality, they retain heat very well, do not freeze in the winter and do not form a large amount of condensation on their inner walls if they are properly insulated.

If we talk about the features of black steel chimneys, they, in turn, are not made of simple stainless steel. They contain a carbon base, which is inherently completely safe for human health, even with strong heating, it does not emit harmful decomposition products. Also, such pipes are more affordable and budget-friendly, compared to stainless steel pipes and sandwich systems. However, for all their advantages and positive qualities, such hoods also have several disadvantages. The fact is that they are not so durable, much less durable and wear-resistant than those made of stainless steel.

However, this option is ideal for a number of specific cases when unnecessary spending is inappropriate. This option can be installed in a country house, in a bathhouse where there are other sources of heat, as well as in places where there is no need to frequently and daily light a fireplace or boiler. The best option would be to install and buy pipes based on low-alloy steel, which has increased resistance to plaque, rust and corrosion.

If you want this design to serve you for as long as possible, we recommend giving preference to pipes made of thick-walled steel, which will not thin out so quickly. Also, the best option would be to assemble a chimney from long pipes and similar connections. Which in turn form a minimum number of seams and joints, with which the very first and most serious problems arise.

General information

The production of rolled thick-walled pipes (wall thickness from 30 mm), with increased characteristics of strength and resistance to sub-zero temperatures and various negative influences, is a rather complex process. This is due to several reasons, the main one of which is a specific physical phenomenon in which the strength properties and fracture resistance indicators significantly decrease with increasing pipe thicknesses. This phenomenon is provoked by a number of factors accompanying production:

- lower cooling rate;

- longer time required for exposure;

- lower overall degree of deformation, etc.

Special steels for the production of thick-walled pipes are characterized by resistance to the negative effects of chemically aggressive environments and corrosion damage at high temperatures over long-term operation. Therefore, for the manufacture of these pipes, alloys with a special chemical composition are used, which is regulated by standards. It is permissible to add non-ferrous metals in the calculated ratio.

In general, steels and alloys are used for the manufacture of thick-walled precision pipes:

- stainless austenitic steels;

- stainless duplex steels;

- Nickel alloys;

- alloys with additions of non-ferrous metals.

Seamless thick-walled pipe products are produced with surfaces subjected to various types of processing:

- polished,

- polished,

- shiny (glossy) with annealing,

- pickled;

- light-etched;

- without descaling/with descaling.

All thick-walled pipes are characterized by a low expansion coefficient and high resistance to temperature changes. When produced, rolled pipes are subjected to a special treatment process with anti-corrosion mixtures and solutions.