To protect the surfaces of steel products from atmospheric and water corrosion, their surface is covered with a thin protective film of metals that are passive to carbon and resistant to oxidation. The most common among them are zinc and cadmium. Galvanizing and cadmium plating of metal is usually carried out using the galvanic method, using various salts of these chemical elements. Cadmium is more stable than zinc and better protects steel parts from corrosion in sea water. But it is tens of times more expensive than zinc and is very toxic in production, so cadmium coatings are used only where there is no alternative. This area of application is the protection against corrosion of metal parts of ship instruments and port equipment.

The metal after cadmium plating is easily soldered, and the coating itself is ductile and does not collapse during bending, rolling and stamping. Chromated cadmium has a beautiful golden color, so cadmium plating is also used for decorative finishing of metal surfaces. The disadvantages of such a coating include the instability of cadmium in relation to oils and petroleum products, which contain sulfur compounds.

Definition and purpose of cadmium plating

The thickness of the galvanic layer when cadmium plating parts made of various metals and their alloys is regulated by GOST 9.303-84. Depending on the operating conditions for carbon steels, it ranges from 12 to 40 microns. The first value of this range is used for products that are periodically exposed to moisture and sea fog, and the last value is used when operating in conditions of evaporation and spray of sea water. The designation of the type of cadmium coating includes letters indicating the metal itself, as well as the type of additional processing and its thickness in microns. For example, KDkhr-12 is a protective and decorative chromated coating 12 microns thick.

The main purpose of cadmium plating is corrosion protection of products operating in humid and salt-saturated environments. Such galvanic processing of parts is most widespread in the defense industry, aerospace industry and shipbuilding. Due to its ductility and ability to retain properties at elevated temperatures, cadmium plating is the main type of corrosion protection for springs and other parts subject to bending and compression under cyclic loads. Another popular trend in electroplating is cadmium plating of fasteners. Here, cadmium is not only a protective material, but also ensures the tightness of the threaded connection due to its plastic deformation.

In addition to protective properties, cadmium plating has a number of other qualities. Cadmium is used to coat iron contacts and similar parts because it can be easily soldered. Unlike copper, it has good galvanic compatibility with aluminum and magnesium, therefore, when pairing copper and alloys of these metals in products, a layer of cadmium is applied to copper parts. Another area of cadmium plating is the finishing of various decorative parts, including furniture fittings. In this case, the galvanic surface is subjected to subsequent chromating to give it a golden hue.

The main disadvantage of cadmium plating, which prevents its widespread use, is the high toxicity of cadmium, which is especially dangerous because it is not excreted from the body and accumulates in it to a critical concentration. Another limiting factor is the high cost of cadmium plating (compared to zinc and tin plating).

In terms of its physical and chemical properties, gold is closest to cadmium, which is also safe for health. But this is an even more expensive metal.

Cadmium plating

Home » Archive library » Other » Cadmium plating All operations that parts undergo before entering the galvanic shop leave traces on their surface in the form of various contaminants.

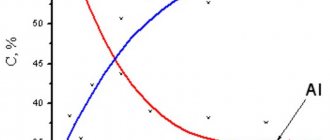

With a thickness of even thousandths of a micrometer, they sharply reduce the adhesion strength of the coating to the base metal, and as their thickness increases, the adhesion strength drops almost exponentially. The quality of galvanic coatings largely depends on the quality of surface cleaning. Contaminants on the metal surface can be different in nature and properties. Thermal scale, corrosion products, sulfide or oxide films that arise as a result of the interaction of the metal with the environment and are quite firmly bound to it by forces of chemical affinity are removed by etching, during which their chemical bond with the metal is broken. Contaminants in the form of fats, preservative lubricants, residues of polishing pastes, abrasives, cooling emulsions, bound to the metal by adhesive forces, are removed during the degreasing process, which destroys these bonds. The method of cleaning parts from grease contaminants is determined by their nature. Fats of plant or animal origin are practically insoluble in water, but interact with solutions of alkalis or alkali metal salts, forming water-soluble soaps. Fats of mineral origin, which include mineral oils, greases, polishing pastes, etc., also do not dissolve in water. Therefore, to remove them, aqueous solutions of surfactants (surfactants) or special organic solvents are used. 1. Properties, scope and composition of the electrolyte Cadmium plating, unlike galvanizing, cannot be carried out by immersion in molten metal, due to the volatility of cadmium at a temperature of 400 ° C with the release of vapors harmful to health. In an industrial atmosphere, cadmium and cadmium coatings corrode at a rate 1.7-2 times higher than the corrosion rate of zinc and zinc coatings. Despite the fact that cadmium is much more expensive than zinc, thin cadmium coatings are used to protect against corrosion and to give the surface a beautiful appearance to various steel parts in aviation, to protect against sea corrosion, etc. Assemblies made of various metal parts, such as steel and brass, are subjected to cadmium plating , aluminum and stainless steel, etc. in order to prevent or reduce the electromotive force of operating galvanic cells. Electrolytic cadmium plating from cyanide electrolytes came into industrial use about 50 years ago. Subsequently, various brightening agents and methods for subsequent processing of cadmium-plated products were proposed in order to brighten them. The most common cadmium cyanide electrolytes consist of an alkali cadmium cyanide complex, free sodium or potassium cyanide, free alkali and an organic or inorganic additive. The exact composition of the complex has not been established; it is written as NaCd(CN)3 or Na2Cd(CN)4. The electrolyte can be prepared by dissolving cadmium oxide in sodium cyanide so that there is enough free sodium cyanide, adding the necessary additives. Below are approximate electrolyte compositions (g/l) for stationary (I) and drum (II) baths: The higher the cadmium concentration in the electrolyte, the higher the cathode current density. The optimal salt concentration is selected depending on the electrolyte capacity, the frequency of loading and unloading, the shape of the products being coated and the associated amount of electrolyte carried away. Free cyanide plays an important role, which increases the electrical conductivity of the electrolyte and ensures normal dissolution of the anodes. Often the concentration of free cyanide is maintained within the range of 60-75 g/l. The appearance of the coatings to a certain extent depends on the ratio of the total cyanide content to the content of metallic cadmium in the electrolyte, which they try to maintain within the range of 3.71-3.79. The alkali concentration is usually determined by the cadmium oxide introduced into the electrolyte. Its purpose is mainly to increase electrical conductivity, which is especially important when coating products in drums. Excess alkali should be avoided, as this leads to a narrowing of the permissible current densities for obtaining shiny coatings. Brightening agents on both an organic and inorganic basis are introduced into cadmium plating electrolytes. Of the organic brighteners, condensation products of high molecular weight nitrogen-containing compounds, aluminum piperonal and some sulfonic acids deserve attention. Other patented brighteners produce an effect only in electrolytes diluted with cadmium. As the cadmium concentration increases and the current density increases, it becomes more difficult to obtain smooth, shiny coatings—small amounts of inorganic salts must be introduced into the electrolyte. For this purpose, nickel or cobalt salts are used, and nickel in some quantities coprecipitates with cadmium at a low concentration of cadmium and alkali in the electrolyte. Cobalt salts have the same effect as nickel salts, but cobalt does not coprecipitate with cadmium. 2. Electrolysis mode Depending on the composition of the electrolyte, its temperature and the intensity of stirring, current density can be used in the range of 0.5-5 A/dm2. On average, the current density is maintained within the range of 1.5-2 A/dm2 at a concentration of 20 g/l Cd and 3-4 A/dm2 at a concentration of 40 g/l Cd. The anodic current density, which ensures a constant composition of the electrolyte in the usually used mode, should not exceed 2 A/dm2. The temperature is often maintained within 20-35° C, but if necessary it can be increased. Current output varies within 85-98%; More often its values correspond to 90-95%. The current efficiency increases as the concentration of cadmium in the electrolyte increases, the temperature and the intensity of stirring increase. With an increase in the content of cyanide and brightening agent, the current output of the metal decreases slightly, and with an increase in the alkali content, it increases slightly. The anodic current efficiency is almost 100%, except when using excessively high current densities (anodic) and excessively reducing the concentration of free cyanide. The dispersion and covering power of cadmium cyanide electrolytes are of great importance. At a high cadmium content in the electrolyte and a given current density, the dissipative ability decreases with increasing temperature, and at a given temperature, the dissipative ability improves with increasing average current density. Constancy of the dissipative power can only be achieved by increasing the current density in accordance with the increasing temperature. Dissipation ability improves with high free cyanide content in the electrolyte and low metal content. The resistivity of cadmium cyanide electrolytes is low, approximately 5.6 Ohm*cm. Cadmium electrolytes are sensitive to a number of impurities that discolor the coating. The most harmful impurities are thallium, lead, arsenic, antimony, tin, and silver. These impurities can be removed by treating the electrolyte with freshly deposited cadmium sponge or zinc dust, followed by filtration. Electrolysis can also be used at low current densities. Cathode depolarizers (nitrates, chromates) significantly reduce the current yield of the metal. In a diluted electrolyte, 1.6 g/l ΝΟ3 reduces it to 60% without any visible effect, and 40 g/l ΝΟ3 reduces the current efficiency to 30%, and the shine weakens somewhat. Very small amounts of CrO3 cause peeling of the coating, and 0.5; 1.0 and 1.9 g/l CrO3 prevent uniform surface coverage, and the current efficiency from 95% decreases to 85, 22 and 1%, respectively. Poor quality coatings can be removed by immersion in a solution containing 120 g/l ΝΗ4ΝΟ3; coatings can be removed from steel anodicly in a solution containing 90 g/l NaCN and 15 g/l NaOH at 25 ° C and a voltage of about 6 V or in a pyrophosphate solution. As in all cyanide electrolytes, carbonates accumulate in cadmium electrolytes, which are harmless in small concentrations, but as they accumulate they are removed by freezing or by treatment with calcium sulfate. Anodes. Cadmium plating in cyanide electrolytes is carried out using soluble cadmium and insoluble steel anodes. Cast cadmium anodes have the following composition: Cd>99.9%; impurities % no more than: 0.005 Ag+Pb+Sn; 0.0005 As+Sb+Tl. Anodes made from bearing scrap typically contain higher levels of silver and tin, as well as nickel and lead. At high current densities, these impurities cause an uneven course of the cathodic process, and at low densities, sludge is formed, which settles on the surface of the coated products, resulting in a rough, spotty coating. The anodic polarization curves of cadmium in cyanide electrolytes resemble the polarization curves of other metal anodes soluble in cyanide solutions. Initially, the polarization slowly increases to 0.2-0.3 V as the current density increases; the anodes have a normal gray color. Subsequently, with a very slight increase in current density, the polarization increases to 2.6-3.2 V. At this voltage value, the anode has a black powdery or polished shiny appearance; there is a slight release of oxygen. With a further increase in current density, the anode is covered with white salt, the layer of which gradually thickens and abundant release of oxygen begins. In this state, the anode becomes an oxygen electrode and with a further increase in the current density, the polarization increases very slowly. Since we are interested in dissolving cadmium anodes with 100% current efficiency, we can visually regulate the process by the anodic current density (anode surface) and the concentration of free cyanide in the electrolyte so that the anodes have a normal gray color. This must be especially carefully monitored when cadmium plating the internal surfaces of small-diameter tubes or large recesses. The anodic limiting current is highly dependent on the content of free cyanide - the excess over and above the amount associated with the Na2Cd(CN)4 salt. Increasing the free cyanide content from 15 to 75 g/l in an electrolyte with 19.5 g/l Cd and 14.3 g/l NaOH increases the limiting current from 2 to 3 A/dm2. Increasing the carbonate content from 0 to 150 g/l in the electrolyte from 19.5 g/l Cd; 14.3 g/l NaOH and 60 g/l free NaCN reduces the limiting current from 3 to 2 A/dm2. Strong oxidizing agents—chromates, nitrates, etc.—also lead to a sharp increase in anodic polarization, even when their content in the electrolyte is insignificant. The oxygen overvoltage on steel at a current density of 0.0047 A/dm2 is 0.49 V, and at 0.47 A/dm2 it is 1.95 V against an unpolarized cadmium electrode in an electrolyte containing 19.5 g/l Cd and 15 —75 g/l free NaCN; practically these data do not depend on the content of free cyanide. Since the oxygen overvoltage at a given current density is significantly higher than the potential of the soluble cadmium anode, the simultaneous use of soluble and insoluble anodes must be ensured by an individual anode voltage controlled by isolated rheostats. Since the oxygen overvoltage on a fully polarized cadmium anode is higher than on steel (3 versus 2 V), the cadmium anode cannot become inert if it is connected in parallel with the steel anode. This circumstance makes it possible to use cadmium anodes in the form of balls and load steel parts as anodes (along with cadmium ones) into drums. It is necessary to avoid getting chlorine ions into the electrolyte, as they corrode steel anodes, which eliminates the possibility of using them as intermediate conductors. When a large current flows through anode-enabled steel, the surface oxidizes and becomes coated with a film resembling rust. This film prevents the further passage of current without increasing the voltage, so it must be periodically removed from the surface. It should be taken into account that if you use only steel anodes (without cadmium), they oxidize cyanide to carbonate. 3. Subsequent processing of cadmium products In some cases, cadmium products are used in the form in which they are unloaded from the bath, limited to washing in cold and hot water and drying. However, more often the products are additionally processed in order to give them a beautiful, shiny appearance. To do this, cadmium-coated products are immersed in solutions of acids containing oxidizing agents. The cadmium coating partially dissolves without evolution of hydrogen, apparently similar to a semi-polarized cadmium anode, at a high enough potential to prevent surface corrosion. For this purpose, the product can be immersed in 0.5-1% (by volume) nitric acid with a density of 1.4 or in a mixture of acids and oxidizing agents. Quite often, compositions are used by mixing 100 g/l CrO3 with 1 ml of concentrated sulfuric acid (density 1.84) or 7% (by volume) 30% hydrogen peroxide with 0.3% (by volume) concentrated sulfuric acid (density 1.84). The duration of stay of the product in these solutions ranges from 2 to 30 s depending on the concentration of the solution. The chromic acid solution is characterized by a high degree of passivity imparted to cadmium. The nitrate solution has the disadvantage that cadmium-plated products processed in it become stained, especially small ones stored in small containers. An acidified solution of hydrogen peroxide has the advantage that during the washing process no stains or other defects associated with this treatment remain on the surface of the products. Any post-processing method requires thorough rinsing. 4. Acid cadmium electrolytes Attempts to introduce acid electrolytes for cadmium plating into industry were unsuccessful. Coatings made from acidic electrolytes had a large structure, significant porosity, poorly adhered to the base, and the electrolytes had poor dissipation ability. Therefore, cyanide electrolytes have become the only ones used in the industry for cadmium plating. It has long been known that high-strength steels become embrittled after cadmium plating in cyanide electrolytes and, according to numerous studies, heating was used to combat this phenomenon. However, this did not give positive results for all steel grades. Thus, with a steel strength of 16,000 kgf/cm2, 24-hour heating at a temperature of 175° C was sufficient, while with a steel strength of 19,000 kgf/cm2, it was not possible to de-brittle it for any duration of heating. It has been suggested that in high-strength steels, hydrogen, which is included in the coating and partially in the base during cadmium plating in cyanide electrolytes, is in an irreversible state at a temperature of 175 ° C (at which the coating is not damaged). In comparative tests of cadmium plating in acid sulfate, perchlorate, sulfamate and fluoroborate electrolytes, the most encouraging results were obtained in fluoroborate electrolytes, at least from an industrial point of view.

Process technology

The cadmium plating process, in addition to the electroplating itself, includes several preparatory technological operations.

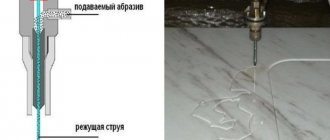

Even before entering the galvanic shop, parts are cleaned using abrasive blasting units or drum and vibration devices. The next stage of cleaning is chemical or electrochemical etching in an alkaline electrolyte, which removes rust and other oxides from the surface, and also degreases it. Next, if necessary, scale is removed, for which the part is first treated with a solution of hydrochloric acid, and then, to remove etching sludge, with a solution of a mixture of caustic soda, soda ash and sodium orthophosphate. Then, after activation in a hydrochloric acid solution for several minutes, the part is washed with water, dried and sent to the cadmium plating site. Before immersion in a galvanic bath, parts are placed on special equipment: hooks, frames, baskets. Although during cadmium plating the deposition rate largely depends on the type of electrolyte used, it is mainly determined by the current density. After galvanic treatment, the part is brightened in a solution of chromium anhydride, and then, if provided for by the technical specifications, it is passivated (chromatized), immersed for some time in a solution of chromium salts. Chromating enhances the protective properties of the surface layer, since in chromic acid solutions, cadmium is partially replaced by harder chromium. At the same time, the surface of the part acquires a beautiful color: from rainbow to various shades of gold and brown. The hue and color saturation depend on the composition of the solution used and the processing time.

Cadmium plating of parts can be used in combination with other types of galvanic coatings to enhance their protective capabilities or impart special mechanical properties. Cadmium is used as a sublayer during galvanic galvanizing to increase the corrosion resistance of the surface of parts. For the same purpose, cadmium plating can be performed over copper and nickel galvanic coatings.

Applying tin to a cadmium coating improves its soldering properties and also increases ductility in threaded connections.

Oxidation of fasteners

Oxidation is the creation of a kind of film of oxidized materials on the surface of a metal fastener or part. Oxide coating is comparable to phosphate coating in terms of corrosion protection, adhesion characteristics and other parameters. Depending on the specifics of production, oxidized products can have different shades: from deep gray to glossy black.

Fasteners protected by phosphating or oxidation are used primarily in simple conditions where there is no overly aggressive environment. If the parts are additionally oiled or hydrophobized, then they can be used in more severe conditions. In order to use them in the most difficult environment, they must also be painted, providing the greatest degree of protection.

Bath composition

The galvanic equipment used for cadmium plating does not have any special features and is no different from installations for other types of electroplating. As a rule, these are rectangular propylene vessels, the dimensions of which depend on the dimensions of the parts and the productivity of the process. The composition of the active bath, in addition to the container itself, usually includes:

- devices for supplying and pumping out electrolyte and rinsing water with a filtration system;

- electrical equipment for regulating and supplying cathode current;

- heating elements for heating the electrolyte, cooling system and temperature sensors;

- supports and rods for hanging parts with a swing device;

- electrolyte mixing mechanism;

- service ladders, guardrails and covers.

The main groups of electrolytes for cadmium plating are cyanide, pyrophosphate, ammonia and acid (sulfate and fluoroborate).

The former are more stable and generally provide better coating quality, therefore they are more common. In addition to the substance containing cadmium, the electrolyte contains up to a dozen different components. For this reason, there are many varieties within the main groups, each of which has its own technological focus and special characteristics. Some craftsmen carry out cadmium plating of parts in their home workshops. Is this really a dangerous activity or does it pose no health risks if the prescribed precautions are followed? What do you think about this? Please share your opinion in the comments to this article.