In ores, copper is found in the form of sulfur compounds (CuFeS2 - chalcopyrite, Cu2S - chalcocite, CuS - coveline), oxides (CuO, CuO) and hydrocarbonates [CuCO3 Cu(OH)2.2CuCO3 Cu(OH)2]

Gang ores consist of pyrite (FeS2), quartz (SiO2), various compounds containing Al2O3, MgO, CaO, and iron oxides.

Ores sometimes contain significant amounts of other metals (zinc, gold, silver and others).

There are two known methods for obtaining copper from ores:

- hydrometallurgical;

- pyrometallurgical.

Hydrometallurgical has not found its wide application due to the inability to extract precious metals along with copper.

The pyrometallurgical method is suitable for processing all ores and includes the following operations:

- preparation of ores for smelting;

- melting for matte;

- matte conversion;

- copper refining.

Varieties of copper ores

There are nine geological types of copper ores of industrial importance:

- Iron-nickel ores occurring in igneous rocks.

- Cuprous sandstones and shales. Stratiform reserves account for 30% of copper reserves and therefore occupy second place in this list.

- Copper-nickel. The deposits are distinguished by a variety of shapes with large inclusions of the desired metal.

- Porphyry copper. They are the undisputed leader and provide 40% of global copper production.

- Carbonatite. They are unique in that there is only one deposit in the world; in addition, they contain alkaline compounds.

- Quartz-sulfide. They do not play a significant role in ensuring production.

- Native. They are located in oxidation areas of copper-sulfide ore mines.

- Skarn. They are located among limestones and are characterized by extreme heterogeneity of morphological structure.

Copper in the listed list of ores can be presented in sulfide, oxide or mixed form, which determines the corresponding types of deposits. Based on their structure in rocks, deposits are divided into disseminated, massive and continuous textures. In the near future, this list may be supplemented by ores lying at the bottom of seas and oceans, as well as nodules of uranium deposits.

RESERVES AND PRODUCTION

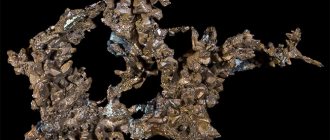

Copper specimen, 13.6 cm. Kinawi Peninsula, Michigan, USA

The average copper content in the earth's crust (clarke) is (4.7-5.5) 10−3% (by mass). In sea and river water the copper content is much lower: 3·10−7% and 10−7% (by weight), respectively. Most copper ore is mined by open pit mining. The copper content in the ore ranges from 0.3 to 1.0%. World reserves in 2000 were, according to experts, 954 million tons, of which 687 million tons were proven reserves; Russia accounted for 3.2% of total and 3.1% of confirmed world reserves. Thus, at the current rate of consumption, copper reserves will last approximately 60 years. Copper is obtained from copper ores and minerals. The main methods for obtaining copper are pyrometallurgy, hydrometallurgy and electrolysis. The pyrometallurgical method involves obtaining copper from sulfide ores, for example, chalcopyrite CuFeS2. The hydrometallurgical method involves dissolving copper minerals in dilute sulfuric acid or ammonia solution; From the resulting solutions, copper is replaced by metallic iron.

Natural minerals containing copper

There are 250 copper-containing minerals in nature, but no more than 20 are used in practice. A list of the most common of them, indicating the percentage of copper:

- Native copper – 88-100%.

- Cuprite – 88.8%.

- Tenorit – 79.9%.

- Khalzokin – 79.8%.

- Covelline – 66.5%.

- Bornite – 52-65%

- Atakamit – 59.5%.

- Malachite – 57.4%.

- Brochantite – 56.2%.

- Azurite – 55.3%.

- Fahl ores – 22-53%.

- Enargit – 48.3%.

- Chrysocolla – 32.8-40.3%.

- Chalcopyrite – 34.5%.

- Cubanite – 22-24%.

Copper ore mining

Copper is one of the very first metals mastered by mankind. At the very beginning, it was mined by collecting nuggets, and then they learned to extract it from ores. Over the years, mining technologies have improved. But the determining factor when choosing a mining method has always been and is the depth of the deposits. However, there are specially developed standards that take into account many factors and allow you to choose the most successful solution from an economic point of view, in terms of choosing the working depth of development and the technologies used.

In career

If the seam of the mineral being developed is located at a depth of no more than 500 m, the most appropriate is the open-pit mining method. It is with its help that most copper ores are extracted. Despite a number of problems associated with the development of a large area, the movement of huge masses of waste rock, the use of a significant amount of technical equipment and the harmful impact on the environment, the method is characterized by fairly high efficiency and the absence of significant losses of minerals. The ratio of metal yield to mined ore is: 1:200.

After conducting preliminary geological studies at the site of the future quarry or open-pit mine, the upper layers of rock are removed and disposed of in dumps. Very often this is accompanied by drilling of solid rock masses and blasting operations. The fossil mineral is extracted in layers with the further development of new massifs. Ore is picked up by bucket equipment (excavators, loaders) and loaded onto vehicles (conveyors, dump trucks) for transportation to processing plants.

In the mines

If the desired ore is located at a depth of about 1 km, then a closed mining method is used, that is, the construction of a mine and the organization of vertical, inclined or horizontal workings. Using mining equipment and drilling equipment, copper-bearing layers are developed. After which the extracted rock is loaded and removed to the surface. For this purpose, underground structures are equipped with elevators, lifting equipment, and railway tracks.

Copper

The method is quite expensive, but at the same time it provides access to deep-seated deposits.

Drilling of the wells

There is a third method for extracting copper ores - by pumping leaching solutions of acids and alkalis deep into a pre-drilled well. The result is a semi-liquid mixture, extracted to the surface by powerful pumps and subjected to further processing.

Extraction methods

How is copper mined from ore deposits? The low concentration of metal in the rock requires processing of a large amount of material. To obtain a unit of metal mass, you need to process 200 units of ore.

Copper, which is mainly mined using the open-pit method, is located at a depth of up to 1000 m. The depth of open-pit mining reaches 150–300 m, and in some cases up to 600 m. Deposits located at a depth of up to 1000 m are developed using the underground method.

Processing ore in search of copper.

Certain standards regulate the feasibility of deepening developments in order to extract ore raw materials. This is due to production technology, additional costs and reduced equipment productivity, which increase the cost of raw materials.

Therefore, the metallurgical industry widely uses the open method, which is characterized by insignificant losses during development. Although there are also disadvantages associated with storing waste rock.

For example, in 2013, a landslide occurred at the Kennecott Utah Copper Bingham Canyon Mine in the United States. The depth of the Bingham Canyon quarry is about 1 km, and the diameter is about 4 km. Ore was mined here for 150 years.

Delivery of raw materials to the processing site was carried out by vehicles with a carrying capacity of 231 tons. The miners were warned about the dangerous phenomenon and were prepared for developments. The quarry wall was moving at a rate of several inches per day, and attempts to strengthen it did not produce the desired result. The conditions for the extraction of raw materials require the use of sequential development technology using:

- self-propelled equipment;

- conducting work during the extraction of raw materials;

- filling the mined-out space with special materials for the purpose of safety of further development.

Each technological process involves reducing losses during deposit development and improving ore output.

By extracting ore in layers, full use of reserves is ensured. In deep quarries, cyclic-flow technology is used, taking into account the peculiarities of ore occurrence.

Copper production

After mining the ore, the next problem arises: how to extract the necessary material from it? There are several ways.

One of the oldest technologies involved burning malachite ores with limited air access. The mass placed in pots, mixed with coal, burned, releasing carbon monoxide. Which led to achieving the desired result - obtaining copper that was sufficiently pure for its time.

It is clear that over the past centuries, methods and methods of ore processing have undergone major changes, driven by the goal of achieving the most optimal results for any type of primary raw material. That is why modern metallurgy is based on three main methods for producing copper.

Pyrometallurgical method

Based on high-temperature processes, the pyrometallurgical method is ideally suited for sulfide ores, which are sometimes quite poor in copper concentration. It allows you to extract metal even with a content of 0.5%.

But first of all, the feedstock is enriched during the flotation process. Its essence lies in thoroughly grinding the ore, filling it with water, and adding complex organic flotation reagents. They envelop mineral particles containing copper alloys, giving them non-wetting.

At the second stage of this process, foam is created in the solution, the bubbles of which pick up particles coated with organic matter. This happens under the influence of air flow, as a result of which the formations float to the surface, from where they are later taken up. The foam saturated with copper compounds is collected, squeezed out and dried.

After which the resulting concentrate is fired at a temperature of 14,000 C. This is necessary to remove sulfur and oxidize sulfides. Then high-temperature (14,0000 - 15,0000C) smelting is carried out in shaft furnaces to produce an alloy of iron and copper - matte. Next, in the process of Bessemer smelting in a converter under the influence of oxygen, the oxide is obtained, and then the blister copper itself, containing 90.95% of the metal. In this case, sulfur turns into an acid residue, and iron into silicate slag.

You can obtain pure copper from a rough substance using:

- fire refining,

- electrolysis,

- exothermic reduction reaction under the influence of hydrogen.

Hydrometallurgical method

To extract copper and a number of other metals from polymetallic ores containing less than 0.5% of the desired mineral, the hydrometallurgical method is used.

The extracted minerals are dissolved using non-concentrated sulfuric acid or ammonia. Copper is obtained from the resulting liquids during the displacement reaction. Metallic iron is used to carry out the reaction.

Electrolysis method

The method is designed to obtain pure copper through an electrolytic reaction.

Its technology is to produce pure copper thin sheet cathodes and thick plate anodes from blister copper. Placed then in a bath filled with copper sulfate, they react under the influence of electric current. Copper dissolves on the anodes and is deposited on the cathodes. Released impurities are removed by chemical methods.

Copper pipes

Copper production methods

Currently, several methods for producing copper have been developed. The main ones are:

- pyrometallurgy;

- hydrometallurgy;

- electrolysis.

The largest quantity is produced using the first method. With its help, almost 90% of all metal is obtained. It is quite labor-intensive and time-consuming. The technology for producing copper using this method includes several stages that enrich the incoming material and sequentially obtain the finished material. Each stage contains a strict sequence of technological tasks. Typically, a copper smelter performs the full range of operations.

To obtain the so-called copper cathode, a third method is used. This method is completely called electrolytic refining with subsequent deposition of the finished product on the surface of metal plates.

Areas of use

There are many industries where this oldest of metals finds its application:

- Metallurgy. It is this industry that produces many finished products in the form

- rolled products: sheets, plates, strips, pipes, rods, tires, wire;

- alloys: bronze, brass, cupronickel, constantan, nickel silver manganin.

Both products and intermediate materials are widely used in technical industries, in the production of weapons, and in the arts and crafts. The distinctive features of the alloys are the preservation of mechanical properties, a high level of slip in a paired combination and anti-corrosion resistance.

- Mechanical engineering. A significant portion of copper-containing products obtained as a result of metallurgical processes is used here. These are high-strength alloys with aluminum, tin, silicon, and zinc. As well as various parts of machines and mechanisms. One of the directions is the production of hard solders, which again find application in the mechanical engineering industry.

- Chemistry. The catalyst for the polymerization of acetylene is again copper.

- Electrical engineering. Due to its high electrical conductivity, this metal has become indispensable as a conductor in the manufacture of buses, cables, wires, and printed circuit board tracks. They, in turn, are part of many electrical products, which also contain copper structural elements and alloys of this metal. In addition, copper is used in chemical current sources and in the manufacture of high-temperature superconducting materials.

- Energy. One of the important areas of using copper is the production of pipes based on it, which are an integral part of gas supply systems, water supply, heating, cooling, air conditioning and supply of process fluids.

- Jewelry making. The specifics of manufacturing precious items that serve as jewelry require a combination of a number of contradictory factors. To give strength to gold, copper is added to it. The pliability of the material does not decrease, but the service life and resistance to mechanical stress increase significantly.

Features of copper: its composition, structure and production technology

Copper, which belongs to non-ferrous metals, has been known for a long time. Its production was invented before people began to make iron.

According to assumptions, its active use occurred as a result of its availability and fairly simple extraction from copper-containing compounds and alloys.

So, let's look today at the properties and composition of copper, the world's leading countries in copper production, the manufacture of products from it and the features of these areas.

Copper has a high coefficient of electrical conductivity, which has increased its value as an electrical material. If previously up to half of all copper produced in the world was spent on electrical wires, now aluminum is used for these purposes as a more affordable metal. And copper itself becomes the most scarce non-ferrous metal.

This video discusses the chemical composition of copper:

The structural composition of copper includes many crystals: nickel, gold, calcium, silver, lead and many others. All metals included in its structure are distinguished by relative softness, ductility and ease of processing. Most of these crystals, when combined with copper, form solid solutions with continuous rows.

The unit cell of this metal is cubic in shape. For each such cell there are four atoms located at the vertices and the central part of the face.

Chemical composition

The composition of copper during its production may include a number of impurities that affect the structure and characteristics of the final product. At the same time, their content should be regulated both by individual elements and by their total quantity. Impurities that are found in copper include:

- Bismuth. This component negatively affects both the technological and mechanical properties of the metal. That is why it should not exceed 0.001% of the finished composition.

- Oxygen. It is considered the most undesirable impurity in copper. Its maximum content in the alloy is up to 0.008% and rapidly decreases when exposed to high temperatures. Oxygen negatively affects the ductility of the metal, as well as its resistance to corrosion.

- Manganese. In the case of the manufacture of conductive copper, this component negatively affects its conductivity. Already at room temperature it quickly dissolves in copper.

- Arsenic. This component creates a solid solution with copper and has virtually no effect on its properties. Its action is largely aimed at neutralizing the negative effects of antimony, bismuth and oxygen.

- Nickel. Forms a solid solution with copper and at the same time reduces its thermal and electrical conductivity.

- Tin. Creates a solid solution and enhances thermal conductivity.

- Selenium, sulfur. These two components have the same effect on the final product. They form a fragile connection with copper and amount to no more than 0.001%. As the concentration increases, the degree of ductility of copper sharply decreases.

- Antimony. This component is highly soluble in copper and therefore has minimal impact on its final properties. It is allowed no more than 0.05% of the total volume.

- Phosphorus. Serves as the main deoxidizer of copper, the maximum solubility of which is 1.7% at a temperature of 714°C. Phosphorus, in combination with copper, not only promotes better welding, but also improves its mechanical properties.

- Zinc. Contained in a small amount of copper, it has virtually no effect on its thermal and electrical conductivity.

The process and proper sequence of copper production will be discussed next.

Deposits in Russia and the world

On the territory of Russia there are many fairly large deposits of copper ore:

- Allarechenskoye, Monchegorskoye, Pechenga - Murmansk region.

- Gayskoye - Orenburg region.

- Mikheevskoye, Tominskoye – Chelyabinsk region

- Yubileiny, Sibayskoye, Podolskoye, Zapadno-Ozernoye, Uchalinskoye, Novo-Uchalinskoye, Oktyabrskoye - Republic of Bashkortostan.

- Bystrinskoye and Udokanskoye - Transbaikalia.

- Oktyabrskoye, Talnakhskoye - Krasnoyarsk Territory.

The following deposits of this mineral are highlighted on the world map:

- Chuquicamata, Escondida, Collahhuasi, Antamina, El Tesoro - Chile.

- Bingham Canyon, Keweenaw, Pebble - USA.

- Vale Salobu - Brazil.

- Nurkazgan - Kazakhstan.

- Uyu Tolgoi - Mongolia.

- Grazberg - Indonesia.

Copper mining countries

The leading positions in global copper production (2021 data in quantitative terms of the metal mined for the year) are occupied by:

- Chile – 5.8 million tons.

- Peru – 2.4 million tons.

- China – 1.6 million tons.

- USA – 1.2 million tons.

- Congo - 1.2 million tons.

Judging by expert estimates, the total volume of as yet unexplored copper reserves in the world is 3.5 billion tons. These reserves should be enough for the next century and a half.

Author: Yuri Florinskikh All articles by this author

Latest articles by the author: The largest producers of milk and dairy products in the world Diamonds: properties, mining methods and applications

Copper and healthy diets.

The body's needs for all the substances it needs must be met mainly from foods during nutrition. Food in nutritious forms contains everything you need, including: vitamins, minerals, dietary fiber and other natural substances that have a positive effect on human health.

In some cases, fortified foods and dietary supplements may be helpful in providing the required amount of one or more nutrients.

Dietary recommendations include:

Consume a variety of vegetables and fruits, whole grains, low-fat or low-fat milk and dairy products, and butter.

Some vegetables, fruits, grains and dairy products contain copper.

Eating a variety of protein foods, including seafood, lean meat and poultry, eggs, legumes, nuts, seeds, and soy products.

Some meats, seafood, and nuts and seeds are rich in copper

Limit saturated and trans fats, added sugars and salt in your diet.

Stick to your daily calorie intake plan.

, for today 1