Slip composition

The base of the slip is clay with additives, diluted with water. It is usually diluted to the consistency of sour cream or thick cream.

Casting slip composition

The slip is prepared on the basis of one or several types of clay, adding sand, fireclay, electrolytes and dyes. For different types of products, choose the most suitable composition for them.

Slip casting technology

The slip casting process is based on two physical phenomena: the ability of gypsum to absorb water and the ability of clay to release water. It is possible to produce two classes of castings: thin-walled and thick-walled (solid). Compared to the technology of a pottery wheel or hand sculpting, the process looks quite complicated. Its use requires certain skills and experience. Even experienced craftsmen usually have to modify casting molds. The entire technological process from the beginning of developing a sketch to receiving the finished product can take up to several weeks.

Preliminary operations

First you need to develop a sketch. When developing, it is necessary to take into account the requirements of the selected technology, to provide in the form of sprues of sufficient cross-section and in places that ensure the best filling of the mandrel and fit to the model.

Example sketch for slip casting

Based on the sketch, you can begin making the model. The model is an exact copy of the future product, but differs from it in slightly larger sizes. This is an allowance for inevitable shrinkage during firing.

Slip casting model

Models are made from materials such as plasticine, plaster, wood, ceramics or silicone. Using the model, the master makes a collapsible mold from plaster. Other materials available in the workshop are not suitable for mandrels, since only gypsum has the unique property of absorbing water from the slip. The form is disassembled and the model is removed. The mandrel is being prepared for casting. The slip is diluted and thoroughly mixed immediately before casting.

The foundry process itself consists of the following stages:

- Pouring slip into mold

- Removing excess solution

- Drying of the casting

- Separation of the casting from the walls of the mold.

After drying, separate the parts of the mold and carefully remove the product. The casting is dried, and if necessary, insufficiently worked parts are corrected.

Subsequently, the casting must be fired in a muffle furnace, just like a product made on a potter's wheel or by hand. Products made using the slip casting method can also be glazed. Glaze slip is applied to the surface. After this, the products are fired again. The glaze components are sintered to form a thin and smooth glassy layer.

Casting ceramics

Home Articles Briefly about cast ceramics

A little about what cast ceramic production is.

Most often, people are sure that dishes and ceramic household items are made from clay. This is only partly true. From a consumer point of view, pottery is now a fashionable anachronism. This is easy to check by entering the kitchen of any household. Or take your favorite mug - 1000 to 1 that it is not made of clay.

The main materials for the production of modern tableware are ceramics, glass or a combination of both - glass ceramics.

We are interested in the first. Wikipedia states that ceramics are “fired mixtures of inorganic components.” We can agree with this. In a broad sense, a clay whistle, a porcelain vase, and a denture are ceramics. The difference is in their composition or processing methods and, as a consequence, the resulting properties of the finished product.

Everything in the photo below is ceramic.

Let us consciously outline the boundaries of the subject under consideration and concentrate on the so-called. “fine ceramics” is what your dishes and all those products that sometimes appear in the news of this site are made of.

Between the invention of paper and gunpowder, the Middle Kingdom came up with the idea of mixing kaolin (also, by the way, a type of clay), feldspar and quartz sand. It was then discovered that with prolonged exposure to high temperatures, this mixture hardens and becomes impenetrable to water and air. Excellent properties for creating, for example, dishes.

Over the past almost one and a half thousand years, the basic composition of porcelain has not changed, but through experiments with additives and proportions of components, many materials similar to it have appeared. Probably the most common was faience - almost porcelain, but more porous. And to be completely precise, the already mentioned products of our workshop are made from earthenware.

How does this whole kitchen work? The process is quite long if you are not tired yet.

Let's say you come to us with such an original milk jug in the shape of a cow. And they asked to make a figurine of the same shape.

If you needed not a cow, but a dancing elephant, then another stage would be added to the production process - creating a model. The sculptor, based on your sketch or verbal description, would create a model in the shape of which the finished product would be cast. But you came to us with a cow, which means we already have a model.

Next, the foundry worker gets down to business. His task is to make injection molds for the model. A mixture will be poured into them, which also has its own name - slip. Roughly speaking, slip is liquid porcelain (faience in our case).

Have you ever wondered how hollow ceramic products with irregular geometric shapes are made? After all, a cow is not a body of rotation, and it cannot be molded on a potter’s wheel. The answer lies in the fact that the mold is made of gypsum, a hydrophilic material that easily absorbs water.

The slip layer, in direct contact with the inner surface of the mold, gradually releases moisture, becoming more viscous and hard. As the mold absorbs water, the hardened layer thickens, forming a “shard” of the product. At the appointed hour, you only need to drain the liquid fraction.

Our raw material is ready, what next? Now you need to carefully remove it from the mold.

The semi-finished product, although it stands on its own, is very plastic and easily deformed from a slight impact. It requires careful adjustment (removal of seams and possible defects) and natural drying for several more hours.

Perhaps the most important process in production is firing. His time has come. The dried products are sent to an oven, in which, at high temperatures, the remaining moisture is evaporated from them, and physical and chemical processes of sintering the slip components into a single mass occur. The temperature in the oven at this stage is 1200 degrees or higher. For example, the temperature of boiling deep fat is about 200 degrees, and at 660 degrees. The aluminum spoon will melt.

Firing at this stage is a long (about a day) algorithm of heating, calcination and cooling of products and is called waste. After it we will receive the so-called. “biscuit” - a piece that has been fired but not yet covered with anything.

It should also be added that during the firing process the product lost part of its mass and volume due to evaporation and sintering, i.e. has undergone shrinkage. Therefore, strictly speaking, we will not get an entirely exact copy of our cow, but a 7-10% smaller one. The shrinkage percentage is calculated at the stage of creating the model, but we started with a ready-made sample.

Due to its smooth, semi-matte “biscuit” color, it is sometimes used as is. For example, porcelain dolls are made from it. However, your sample is shiny, and ours is matte. The situation will be corrected by glaze.

Glaze is another component of ceramic production. The basis of the glaze is frit - a finely ground glass mass. To put it simply, glaze is diluted glass powder.

The glaze is used to cover the scrap product. And it is sent for firing again. The second firing is called watering. This time it is made so that the frit crystals melt and, after cooling, form a continuous glass-like coating on the shard.

The glaze serves both decorative purposes—for example, adding color to the product—and utilitarian purposes—it protects the crock from the penetration of moisture and gases. It is neutral to organics and any other substances that dishes come into contact with in everyday life.

The photo below shows a fracture of a glazed shard. A layer of both colored glaze (above) and colorless glaze (bottom of the product) is visible.

After coming out of the oven and cooling, our cow is finally ready.

But the customer suddenly wanted the cow to become not white, but with black spots. This can be arranged. We can decorate the resulting white cow in different ways. And more about this next time.

Equipment and materials for casting

For casting, a slip of a certain consistency is used. It should feel oily to the touch. The composition of the slip, in addition to clay and water, includes various additives that change the consistency and other properties of the suspension. Used as additives

Slip for the future product

- Other types of clay

- Sand

- Chamotte

- Electrolytes

- Dyes

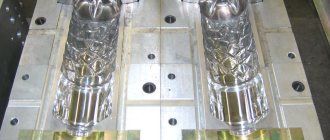

The most important equipment is the casting molds. The quality of the final product directly depends on the thoughtfulness of the design and quality of workmanship. Slip casting uses gypsum molds. The mandrel is usually made of two parts. To accurately align the two parts, protrusions are provided on one of them, and depressions corresponding to them in profile are provided on the other. In artistic casting, characterized by small series, parts of the mold are held together with rubber bands. The gypsum mold for slip casting has a limited service life, and when planning the production of large batches (for example, tiles), it is necessary to provide for the production of several mandrels for each product.

Slip casting molds

Important! The mold must be made only from high-quality sculptural plaster. The plaster must be fluffy and free of foreign inclusions and lumps. Mandrels made from high-quality gypsum can withstand more than a hundred castings. If the gypsum is of low quality, then after a dozen castings the walls begin to crumble and crumble.

Forms that have become unusable can be crushed with a hammer, sifted through a fine sieve and added to the gypsum solution for casting new mandrels in a ratio of no more than 1:10.

The main problems in slip casting

Thickening of the solution in the mold

The solution may thicken just by being in the mandrel. Therefore, before draining, it is better to activate the slip poured into the mold by lightly shaking, rotating or shaking

Hammering the sprue

If you are using a mold with a small sprue, you need to clean the hole with a thin spatula before draining.

Cleaning the hole with a thin spatula

The sprue hole is clogged

Some novice craftsmen cut out the crater of the sprue without touching the hole for fear of harming the casting. To keep the sprue hole free, you can insert scraps of cocktail tubes into them.

The sprue hole is clogged

You need to turn the mold over the drainage container and blow evenly and strongly into the tube. It is important to achieve complete drainage. Particular attention must be paid to complex relief forms.

After the slip is drained, the piece of tube must be filled with water. In the same position, with the sprue facing down, the mandrel should be placed on a plastic surface.

Installing the mold after draining the slip to its original position

After draining the solution, the mold must be placed in an inverted position. If you return it to its original state, slip drips form along the walls of the product, and the thickness of the walls changes. Different wall thicknesses will lead to an increase in stress during firing and even the appearance of cracks along the drips. The casting may be hopelessly damaged.

Incomplete drainage of slip from the mold

Incomplete draining can also lead to drips and cracks during firing. If a product with an intricate configuration is being drained, it is better to shake the mold at different angles when draining, ensuring that the slip is completely drained.

Obtaining slips

The slip method is used in the manufacture of sanitary construction and other products from multicomponent masses.

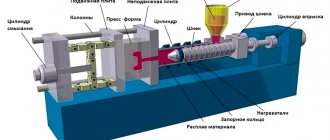

Slip masses are prepared according to the following technological scheme: dosing (box feeder); coarse grinding of components and cleaning of raw materials (plane, disintegrator rollers, crushers, runners, stone-excreting rollers, electromagnets); dosing (automatic scales DST-10, DA-10, automated installation BB-198, etc.); fine grinding and moistening (wet grinding ball mill); filtering and electromagnetic separation (vibrating sieve D-511, magnets, ferrofilters); storage; transportation (diaphragm pumps).

Slip is a suspension - a dispersed system with a moisture content of 35-80%, in which solid particles are suspended. The quality of casting products depends on the properties of the casting slip, which must have good fluidity, stability, and good filtering ability.

The fluidity of a slip characterizes its mobility, i.e., its ability to evenly fill gypsum molds with a low water content.

The stability of a slip is determined by its ability to keep solid particles in suspension.

The filtering ability of a slip determines its water loss upon contact with the surface of the mold.

The slip is prepared in two ways: pressless and pressed. With the non-press method, raw materials are jointly ground in a ball mill, electromagnetic cleaning, and filtering are carried out. For 5–6 days, the slip is kept in mixers with constant stirring and heating to 40–60 °C. The slip prepared in this way is pumped by a membrane pump into consumable mixers, from which it is supplied to the casting of products.

The quality of the slip obtained by the press method is higher than the quality of the slip obtained by the non-press method. Therefore, it is used for casting especially critical products. It is prepared as follows. The slip obtained by the non-press method is fed from the collection pool by a membrane pump into a frame filter press for dewatering to a moisture content of 22-23%. It is recommended to keep the resulting cakes for 2-4 weeks in basements. Then they are loaded into horizontal mixers for dissolving, while adding water in the amount necessary to obtain a slip with a moisture content of 31-32%, and electrolytes (soda ash up to 0.1%, liquid glass up to 0.07% by dry weight). Next, the slip is subjected to electromagnetic cleaning, filtered through sieve No. 025 (250 holes/cm2) and pumped into a propeller mixer. From it, the slurry, cleaned and filtered through vibrating sieve No. 0071 (6400 holes/cm2), is pumped into a collection basin with a mixing device, where it is kept for 3-5 days. Next, the slip is pumped into the feed mixer. This method of preparing molding casting masses is more expensive and complex than the non-press method, but it allows one to obtain slip with better properties.

The Giprostroymaterialy Institute has proposed a new technological scheme for the continuous mass preparation of slip, according to which all operations are carried out using program control.

Features of thin-walled slip casting

If you need to get a thin-walled product, it is important to remember that after pouring, the gypsum will immediately begin to suck water from the slip. Depending on the time the solution is in the mold, the thickness of the walls of the vessel or figurine changes. Clay is deposited on the walls of the mold at a rate determined for each specific configuration and specific composition of the solution. Accordingly, the thickness of the shard increases.

Thin-wall slip casting

During the test pouring, the slip is poured into the mandrel to the top. Every 5 minutes, the thickness of the deposited layer is measured with a caliper. Based on the measurement results, the master can calculate the time required to obtain the specified wall thickness. When plaster is completely saturated with moisture, it stops absorbing water, but in the case of thin-walled vessels, due to the relatively small volume of the shard, this should not be feared.

From casting to waste firing: making faience monkeys

In this master class I want to show and tell how earthenware products are created by slip casting into plaster molds, and what happens before the first firing.

The process of manufacturing ceramic products by slip casting takes place in several stages.

For now, I’ll skip creating a plasticine model of the figurine, casting the plaster molds themselves, and preparing the slip. Let me remind you that slip is clay diluted with water to a state reminiscent of thick cream.

So, about working with forms and clay.

Since the gypsum mold into which the slip is poured absorbs water. After each casting, the mold is thoroughly dried, and subsequently assembled for further casting. In the photo, the molds have just been taken out of the dryer, all its parts are assembled and secured with ordinary money rubber bands.

Since plaster molds have cast holes. Liquid clay is poured there.

This is what molds filled with clay look like.

After the clay is poured into the mold, it is left for 12-16 hours to increase the thickness of the walls of the product. When the time comes to open the molds, the clay in the molds must also be hard so that it can be handled without crushing the product.

We remove clay deposits after casting.

Open the plaster mold.

We take the figurine out of the plaster mold and cut off the casts.

We smooth the bottom, make a recess for stability and make a technical hole.

Now the figurine can be placed in a plastic container so that it does not dry out while the next plaster molds are opened. It is convenient for me to divide the work into stages. So I immediately open all the molds filled yesterday to put them in the dryer. And while they dry, I can easily modify the figures by removing them from the container.

Now I pick up a tool - stacks. I will use each of them.

So that all the details stand out sharply on the figure, I outline them, lightly touching the clay with a stack.

We press out the grooves in the ears.

We form clear balls of eyes.

We deepen the holes in the nose and make the pupils.

I tighten the corners of my mouth and the smiles near my eyes. I press through the navel . I really like this process; it’s as if they begin to come to life from an indefinite clay disc and acquire their own characters. I'm not a robot, and they all turn out differently.

I press through the navel . I really like this process; it’s as if they begin to come to life from an indefinite clay disc and acquire their own characters. I'm not a robot, and they all turn out differently.

The next stack is the marigolds.

I highlight the phalanges of the fingers.

With a slight movement I lower my lip. And now the monkey has a lively expression. Funny and slightly tricky :)

In this form they go into the dryer and dry naturally.

Next stage. I cut off the seams left from the plaster molds with a knife.

With a brush dipped in water, I finally smooth out all the unevenness on the figure.

When the clay is completely dry, it can be fired. So we got to the scrap.

I call scrap the first firing of a clay product. It is also called scrap. Then comes the work of painting and coating the product with glaze. After which a second glaze firing takes place. The glazed monkey is still in the working process. .

Application of slip casting

Slip casting from clay is used quite widely both in industry and in artistic crafts.

Industrial production includes sanitary ceramics, the production of figured elements for interior decoration, tiles and stove tiles.

High voltage insulators

Separately, it is worth noting the production of high-voltage insulators. Porcelain insulators combine an affordable price with excellent electrical characteristics, resistance to temperature changes and excellent durability. Their disadvantage is their high fragility. Recently, they have begun to lose their position in the market to products made from modern plastics.