In order to cut threads on a lathe, different tools can be used. Experienced craftsmen most often do this using a cutter.

But you can also use special-purpose working heads, taps, and dies. This operation is also carried out using knurling technology.

In this article we will figure out what types of threads there are, how to obtain them using different methods, and how to check their quality.

Types and properties of cutters

Classification

In practice, cutters for external and internal threads with a rectangular section holder are used. Less common are disc, prismatic, sharpened along the front surface. The working profile of all corresponds to the dimensions of the screw groove. In the direction of the cut spiral, left and right ones are released.

There are solid and prefabricated instruments. The first ones are mainly made of high-speed steel, small section or disk. The bulk is equipped with cutting plates secured by soldering with refractory solder or mechanically, allowing replacement when worn.

Threaded cutters: external (Fig. 1), internal (Fig. 2)

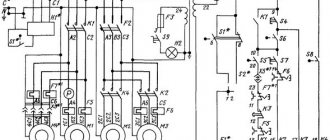

Specification of the main components and controls of the lathe

Main components and controls of the 1k62 lathe

List of controls for the 1K62 lathe

- Switching handle for feed, thread, lead screw and Archimedean spiral;

- Handles for setting spindle speeds;

- Handle for setting increased, normal thread pitch and position when dividing into multi-lead threads;

- Handle for setting right and left threads and feed;

- Handles for setting spindle speeds;

- Button for turning on the rack and pinion gear when cutting threads;

- Handle for indexing and securing the cutting head

- Caliper cross feed handle;

- Push-button station for starting and stopping the main drive electric motor;

- Feed handle for the upper part of the caliper;

- Handle for controlling rapid movements of the carriage and support;

- Tailstock quill fastening handle;

- Cooling pump switch;

- Line switch;

- Tailstock fastening handle;

- Local lighting switch;

- Handwheel for moving the tailstock quill;

- Handles for turning on, turning off and reversing the spindle;

- Handle for turning on the uterine nut;

- Handwheel for manual movement of the caliper and carriage;

- Handles for turning on, turning off and reversing the spindle;

- Handle for setting the feed rate and thread pitch.

Specification of components of the lathe 1K62

- Front headstock (gearbox) - 1K62.02.01

- Bed - 1K62.01.01

- Apron - 1K62.06.01

- Carriage - 1K62.05.01; Caliper - 1K62.04.01

- Cooling - 1K62.14.01

- Rear headstock - 1К62.03.01

- Motor installation - 1K62.15.01

- Feed box - 1К62.07.01

- Electrical equipment - 1K62.18.01

- Slope - 1K62.78.01; Replaceable gears - 1K62.78.02

- Fencing - 1K62.50.01

- Switching - 1K62.11.01

Materials

For the manufacture of the cutting part are used:

- high-speed steels;

- hard alloys;

- mineral ceramics;

- superhard tool materials (STM).

The former are used for thread cutting of steels, non-ferrous metal alloys, and plastics. They are distinguished by high strength, thermal conductivity, but lower, compared to others, hardness, red-hardness, wear resistance, which limit the cutting speed.

The largest proportion of thread cutters used are those equipped with carbide inserts. This is due to high durability, hardness, sufficient strength and rigidity, and reasonable cost. Processing productivity is 2-3 times higher than with rapid. A wide range allows you to select the optimal grade for processing in most cases. Ceramics are relatively cheap, quite fragile, and are used for processing fine pitch threads of steel and cast iron parts, with a rigid AIDS system, with limited allowance removal per pass.

STMs based on polycrystalline diamond (PCD) or cubic boron nitride (CBN) are extremely hard, heat-resistant, but expensive. Indispensable for precision work on difficult-to-cut materials. PCD is used for cutting copper, aluminum, and tungsten carbide. CBN work on hardened steels and hardened cast irons. Successful application requires high rigidity and smooth running of the equipment.

Decoding the writing of threads

Regulatory documents: GOST, OST, MN for a specific type contain samples of conditional recording.

Graphic materials are designed in accordance with the instructions of GOST 2.311-68 “Image of threads”.

A typical designation structure contains:

- the literal part defining the type;

- numbers corresponding to the nominal size in millimeters or inches;

- pitch (mm) is indicated only as fine, after the “×” sign;

- for multi-start ones, instead of the previous paragraph, the stroke (mm) is given, then the step in parentheses;

- direction: right is the default, left is LH;

- tolerance range or accuracy class;

- make-up length other than normal.

Example 1: М16×1.5LH–6H. Explanation:

- M – metric cylindrical;

- 16 – nominal diameter, mm;

- 1.5 – fine pitch, mm;

- LH – left;

- 6Н – tolerance range, where 6 – degree of accuracy; H – main deviation. Capital letters are used for internal (nuts), hence the threads in the hole.

The screw-in length is not indicated, which means it is normal.

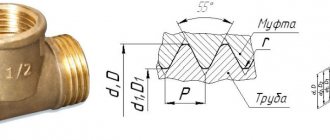

Example 2: G1/2–A

- G – cylindrical pipe;

- 1/2 – thread size, inches; corresponds to the internal diameter of the pipe;

- A – accuracy class.

The designation options are illustrated below.

Slicing rules

The quality of the profile depends on many factors:

- Workpiece errors. Underestimation or overestimation of the diameter of the rod and hole, respectively, is the reason for the incomplete height of the turns. The difference in height along the length is a consequence of the taper of the original surface.

- A torn surface is caused by a dull tool, high speed, or incorrectly chosen lubricant.

- Shrinkage of the nut along the average diameter is typical with similar wear of the tap.

- The stretching of the coils occurs due to the braking of the self-extending mandrel.

- Breaking the nut along the average diameter is possible from a large rake angle, which facilitates the pressing of the tap feathers.

To avoid this you must:

- Choose the equipment and cutting method wisely.

- Prepare the workpiece according to the technological documentation or the instructions in the reference tables.

- Select the correct cutting modes and coolant.

- Set up the machine for processing, calculate and assemble the guitar if necessary.

- Control sharpening and installation of the cutter according to the template.

- Check the first finished parts, make adjustments, and periodically repeat the check in the future.

- Monitor the serviceability of devices and sharpen tools in a timely manner. Thread quality control Providing the required service characteristics of the connection is determined by the compliance of the actual values: outer, inner, average diameters, half of the profile angle, pitch. Checks are performed:

- Calibers. They control thread diameters in mass production.

- Pedometers (threaded templates), micrometers with replaceable inserts. The first to check for clearance are P and α/2, the second are equipped with a set of replaceable inserts for different ratings and are designed to measure the average diameter of bolts. They are used in small-scale workshops, measurements are not accurate.

- Accurate measurement of the average screw diameter is performed using three wires, a micrometer or an optimometer. The error of the latter is up to 2 microns.

- Particularly important parts are checked using instrumental microscopes, which make it possible to reliably determine diameters, pitches, and angles.

How to cut on a lathe?

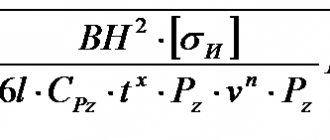

For example, cutting on a lathe using a cutter will look like this: the cutter moves along the axis of the rotating part, which moves back and forth in relation to the cutter, and with its pointed tip draws a screw-type line.

The helical line differs in the angle of its rise or increase. The magnitude of this angle is perpendicular to the axis of rotation, it is measured between the tangent and is determined by: the amount of feed of the cutting tool, which moves along the axis, with the rotational speed of the part.

Cutting internal and external

To cut internal or external threads, you need to use a rod cutter. Their production differs only in the shape of the cutter. For external applications, straight or bent incisors are used.

And for the internal ones, curved or straight incisors. The location of the cutter edge must coincide with the profile of the thread being processed.

Cutting with taps and dies

External threads are cut using dies. The part area is pre-processed. The diameter of the surface to be machined should be slightly smaller than the outer diameter of the thread.

First, a chamfer corresponding to the height of the thread profile is removed. Then the die is installed in the chuck (die holder).

And the speed is selected in accordance with the desired thread (it is indicated on the back of the machine).

Taps are often used for internal metric threads. As a rule, machine taps are used on the machine, this allows the part to be completed in one pass.

For threads made of hard, viscous materials, sets of 2–3 taps are used. In a set of two, the right one does 75% of the work, and the second one only brings it to the desired size.

In a set of three taps, the right or roughing one does 60% of the work, the middle (semi-finish) 30% of the work, and the third 10%.

Using Die Heads

Threading heads are used for pipes and bolts. They are installed in the machine, then the desired diameter is adjusted and moved along the pipe. They are able to carry out work with high precision.

Universal heads allow you to install dies from different companies. It is also possible to lubricate the combs and adjust the sizes; manual clamping is often found.