Cheese making is not only healthy, but also a very creative activity. There are a great many recipes, and on their basis you can create more and more new variations. To make most types of cheese you will need a press. Today's Crafting School lesson is about choosing a cheese press. The bell has rung - let's start the lesson!

Craft cheese making is a creative activity

What is pressing and why is it needed?

Pressing is a technological stage of cheese preparation, during which intergrain moisture is removed from the product. The cheese takes on a certain shape, becomes denser, and the top layer of grains closes, forming a protective crust.

The easiest way to make homemade cheese is self-pressing.

Self-pressing is the removal of excess moisture from cheese without additional mechanical stress. The liquid leaves under the influence of gravity, flowing through the intergranular channels. The cheese is simply kept in the molds for a certain time, turning regularly to ensure an even outflow of whey.

This is how many types of soft cheeses are obtained. But if you are thinking about making real hard cheese, then the self-pressing stage will only be an intermediate step on the way to the goal. After this, pressing will be required using special equipment - a cheese press.

Manual cheese press: design and principle of operation

Manual cheese presses come in a variety of designs. The most popular among beginning cheese makers are lever and screw presses.

Lever and load presses

The simplest and most accessible is the lever press. Its main structural elements are a frame, a piston, a plate, and a lever mechanism on which the load is suspended. With its help, pressure is created, the piston presses on the plate, and it, in turn, presses on the cheese mass. This press is also called “Danish”. By changing the weight of the load, you gradually increase the pressure on the compressed mass.

Another press that involves the use of additional weight is a platform that moves up and down along columns. Pressing is carried out due to additional weights that are placed on this site. The plate has a direct impact on the cheese mass. Despite its simple design, the press does its job perfectly, providing uniform and constant pressure.

The Danish press is a system of levers and balances

Screw press

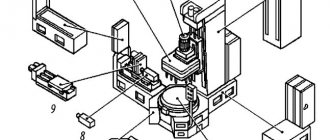

A screw press consists of a frame, a screw pair, a piston, a plate, and a double basket. The inside of the basket may be perforated. This is convenient because there is no need to use special forms.

The screw sets the piston in motion, which presses on the plate, which presses on the cheese mass placed in the basket. Excess whey is removed from the basket through a special drain.

The manual screw press does not require additional weights, which makes it comfortable and easy to use. It’s not for nothing that many consider this design ideal for home cheese making.

Popular Types of Manual Cheese Presses

Cheese press material

The equipment can be wooden or metal. Wooden presses are environmentally friendly, safe, and easy to use. The most popular and inexpensive hand presses are made from wood, which require the use of additional weights. Most models involve the use of cheese molds or napkin pressing, as well as additional weights. But they are inexpensive. The advantage of these designs for a beginning cheese maker is that you can always calculate the pressure on the cheese based on the weight of the load.

Metal presses are made of safe stainless steel and are highly reliable and durable. Most of them are very functional, although their cost is higher than their wooden counterparts.

Cheesemaking dynasties pass down presses like family heirlooms.

How pressure is created in the press

When making a press with your own hands, it is extremely important to pay attention to the issue of creating the required pressure on the cheese mass. In our case, the role of the pressing element is played by springs, so they must be strong enough. For example, the most common option is springs that exert a compression pressure of 10 kg. In the absence of powerful springs, it is possible to use not 2, but 4 levers of similar pressure, placing them between two bars.

The weight platform or lid adapter can be equipped with a scale that allows you to control the pressure. And finally, you need to make several mugs from wood or thick plastic - they act as spacers between the press and the mold.

Be sure to read:

Buttermilk is the basis for making dietary cheeses

The pressure is created quite simply - due to springs, bursa and nuts with lugs.

Pressing process and technology for using a manual cheese press

The pressing process has its own important nuances that a novice cheese maker must know in order to obtain a quality product.

Pressing force and speed

The process of pressing cheese should be smooth, and the pressure on the cheese mass should be increased gradually. The softer your cheese mass, the lower the initial pressure should be.

Under significant pressure from the press, the cheese grains are deformed, and in the upper layer they are compacted so much that they form a crust layer, which is important for the preservation of the cheese. The layer prevents bacteria and microorganisms from penetrating into the cheese head and also helps the product maintain its shape.

There is no need to rush the pressing process. If you start to “press” too hard on the cheese mass, the whey will quickly leave the surface layers. A crust forms quickly. It will block the channels between the grains and prevent liquid from escaping from the inside of the cheese mass. This will cause your cheese to be overly wet and taste unripe. This type of cheese does not store well and spoils too quickly.

Simple and effective - the motto of the screw hand press

Napkin and non-napkin pressing

In order for the surface layer to be uniform and of high quality, an important condition is the correct removal of whey from the surface of the formed cheese head.

If you use regular cheese molds, then the drainage fabric in which the cheese is wrapped effectively removes moisture. This method is called napkin pressing.

When using napkin pressing, you need to change the fabric in which the cheese mass is wrapped several times. Then the folds of the fabric will not interfere with the formation of an even surface layer. This process is called “dressing” the cheese or repressing. The number of repressings depends on the recipe you are preparing. As a rule, their quantity is indicated in the cheese recipe.

If you purchased a press with perforated forms, then there is no need to use drainage materials - the top layer will already be smooth. This type of pressing is called napkin-free.

How to use a hand press

Pressing in the technological chain of cheese preparation comes next to self-pressing. When the whey stops being released from the mass, it’s time to put the cheese under the press. To do this, it is placed in a special cheese mold or in a press basket with a perforated mold. Then the press plate is lowered onto the cheese mass. If the design requires it, then secure the load.

The amount of force required to press depends on the type of cheese you are making. If you want to make real hard cheese, then the main part of the pressing must take place under serious pressure. So, you will get Swiss cheese at a load of 64 kPa, and the classic Dutch variety and its analogues at a pressure of 35 kPa.

Pressing takes place in several stages, with regular turning of the cheese. The average process time varies depending on the recipe you follow. The required pressure on the cheese mass ranges from 2 to 16–18 hours.

After pressing is completed, the cheese is removed from the press, the equipment is thoroughly washed and dried.

Double press is ideal for large families or small home production

Features and benefits of manual cheese presses

I highly recommend purchasing a manual cheese press at the beginning of your cheesemaking career. It has a lot of advantages and opportunities.

- Ease of use.

- Low price. A hand press can be purchased at a price of 1,800 rubles.

- Efficiency. A head of cheese is formed in 2 hours.

- Reliability of the design. The equipment is made of natural materials, durable and resistant to stress.

- Autonomy of work. You don't need to connect the press to an electrical outlet or look for batteries for it.

- Compactness. The press will not take up much space in the kitchen, especially the screw model with a perforated basket.

- Ease of use. Equipment parts are easy to clean and do not require additional care.

- Versatility. If desired, you can use the press not only for cheese, but also for squeezing juice from vegetables and fruits, as well as for squeezing cottage cheese when making it at home.

High-quality raw materials and adherence to technology are the main conditions for good cheese.

Which press do you prefer?

The Danish press and all other designs that require the use of additional weights have their own set of advantages. You can easily calculate the pressure, and this is important for following the recipe. The low price also speaks in favor of such models. So you can safely buy these presses if you are taking your very first steps as a cheesemaker.

If you already have some experience and can calculate the pressure even without a load, then you can buy a screw press. Its main advantages are efficiency and convenience. It does not require additional accessories. Just a press and cheese mass. I myself use just such a press.

Cheese press: manual screw or pneumatic?

A special feature of the pneumatic device is the ability to press cheese and simultaneously regulate the pressure thanks to a special regulator. Only constant pressure readings make it possible to obtain cheese of the same density and a beautiful surface of the product.

The screw press is convenient for home cooking or small production, has a simple design and convenient use. The force of the cheese press in kg depends on the location of the product and its weight. Manual equipment allows you to perform pressing quickly and comfortably. The products are made of stainless steel, are not subject to corrosion, and are equipped with a handle for easy pressing.