What is a hydraulic cylinder?

A hydraulic cylinder is a mechanism of the hydraulic system, which is an integral working element of equipment for various purposes, the main principle of which is the transformation of hydraulic force into mechanical force - the output link. The process of converting force is carried out using reciprocating or rotary-rectilinear movements.

What does a hydraulic cylinder look like?

The hydraulic cylinder is used in the manufacture of construction, road and agricultural equipment that has drives for raising and lowering mounted structures - manipulator cranes, buckets, shovels, seeders, hydraulic hammers, plows, buckets, etc. Hydraulic cylinders are also often used for wood splitters.

Components

The hydraulic cylinder consists of the following parts:

The chambers in the hydraulic cylinder must be sealed. To achieve this goal, special seals are installed on the piston - cuffs that prevent fluid from flowing through the piston. Also, the cuffs are placed on the axle box, here they act as seals. The axle box is also equipped with a wiper to prevent particles from the external environment of the device from getting into the inside of the cylinder.

Important: The seals on the piston do not work if there are roughness and scratches inside the liner. The inside of the liner is ground by special machines at the factory to achieve a relatively perfectly smooth state.

How does a hydraulic cylinder work?

Structurally, the hydraulic cylinder mechanism looks like a sleeve - a straight pipe with a perfectly smooth and clean inner surface of the product. It is filled with liquid, around which a movable cylindrical rod rotates to pump or pump it out. To prevent the leakage of existing liquid, it is equipped with cuffs made of plastic but durable rubber.

Sectional design of a hydraulic cylinder

The piston is activated when liquid enters the cylinder under sufficiently high pressure. There are protective plugs screwed into the sides of the sleeve to prevent leakage and have special holes for transporting liquid in the sleeve. The force from the cylindrical rod is transmitted by a pre-installed rod, characterized by a polished, and therefore as smooth as possible, surface. Its ground book determines the desired direction.

The main components with which the mechanism is equipped, depending on the field of application of the equipment:

- the sleeve itself;

- piston;

- rubber cuffs;

- wiper;

- rod and its guide bush;

- retaining ring;

- eye.

A part or eyelet adapted for this function is fixed on the threaded side of the rod, which connects it to the moving mechanism.

Operating principle of hydraulic cylinder

The volumetric hydraulic motor is controlled by hydraulic drive adjustment elements or directly by the hydraulic distributor itself. Since hydraulic cylinders operate under high pressure conditions (up to 32 MPa), increased demands are placed on the functioning system. There must be maximum strength and high performance of the system, then reliable operation of the hydraulic cylinder is guaranteed.

Hydraulic cylinder - device, operating principle, force calculation

The performance of many types of power equipment, both industrial and domestic, is ensured by a device such as a hydraulic cylinder. Acting as a reciprocating drive motor, such a mechanism, with minimal energy consumption, ensures a full cycle of operation of power equipment used in construction, in various industries, in agricultural enterprises and in everyday life. Hydraulic cylinders are most widely used as the main element of equipment for pressing equipment, which is actively used to solve various problems.

A hydraulic cylinder is a volumetric hydraulic motor that converts the energy of fluid flow into mechanical energy

Types of hydraulic cylinders

Product variants require different configurations and application options. And for convenience, they are usually divided into specific types.

By type of direction of action of the liquid:

- Single acting;

- Double acting;

- Telescopic models;

- Differential;

- number of rod positions: two positions and many positions;

- by type of travel: telescopic or single-stage;

- in the direction of fluid pressure: single- or double-acting;

- by the presence of braking: with or without braking.

Classification of hydraulic cylinders depending on the working unit used:

- piston with one- or two-sided rod;

- bellows - with a working link in the form of a bellows;

- plunger - in which a plunger is used as a piston;

- membrane - have a link in the form of a membrane.

Based on the type of fixation in the system, units are divided into options with fastenings on hinges or more rigid fasteners.

Single acting

Such hydraulic motors are characterized by a certain direction of movement of the rod in it when the fluid pressure increases. A spring returns it to its normal position, creating certain forces for this.

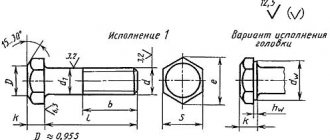

Drawing of a single-acting hydraulic cylinder

It resists the standard elastic force of the spring during the smooth movement of the cylindrical rod. The functions of a return type mechanism in such a mechanism are performed by a spring. A slightly different method of operation is observed in jacks that do not have a return spring. When the mechanism is activated, the rod is returned by engaging the functions of another hydraulic motor or the force of gravity of the load being lifted or lowered.

Double acting

During normal piston movement, the force on the rod is achieved by providing increased pressure of the available fluid in the cavities of the rod and piston type cylinder.

Drawing of a double-acting hydraulic cylinder

The forward stroke, compared to the reverse stroke, is characterized by increased reinforcement on the rod and low speed of movement. This is due to the difference in areas to which the pressure force of the available fluid is applied. This type of hydraulic motor is used to lift and lower blades in many brands of bulldozers.

Telescopic

They are named so due to the structural features of the structure, visually reminiscent of a small telescope and due to the characteristic operating principle.

Drawing of a telescopic hydraulic cylinder

Structurally, the mechanism looks like several cylinders of different diameters inserted into one another. It is relevant to use such mechanisms in situations in which a large stroke of the cylindrical rod is required, but the size of the product itself must be small. This type of mechanism can be found in the form of single- or double-acting. Actively used in dump trucks.

Differential

This type of mechanism is characterized by a complex design, where pressure is applied to the piston pushing the liquid from both sides at once. The areas of pressure on the cylindrical rod are different from different sides. The speed of movement in relation to the forces in strokes of different directions is commensurate with the ratio of the areas of the piston. Accordingly, there is a relationship between effort and speed: the higher the speed, the lower the effort and the lower the speed, the higher the effort.

Drawing of differential hydraulic cylinder

When operating a hydraulic motor, the dimensions of the pistons, which have a ratio of 2 to 1 (differential), provide identical speed and rod stroke options in two directions. Similar functions are not found for hydraulic cylinders with a one-way piston without auxiliary elements or special adjustments.

Design features and principle of operation

The design of any hydraulic cylinder includes the following elements:

Plunger hydraulic cylinders are somewhat different in design, in which the plunger simultaneously performs the functions of a piston and a rod.

Hydraulic cylinder diagram

The operating principle of any type of hydraulic cylinder is based on the pressure of the working fluid on the piston. As a result of the impact on the hydraulic cylinder piston, the rod begins to perform cyclic work, transmitting force to the working unit of the equipment served by the device. Such a working unit, the functioning of which is ensured by a hydraulic cylinder, depending on the type and purpose of the equipment, can be a compacting platform, a bending or pressing mechanism, as well as a device of any other type that ensures the transmission of the force of the hydraulic cylinder to the final recipient of power energy.

Sliding hydraulic cylinder device

Since the force created by a hydraulic cylinder, as mentioned above, is formed due to the pressure exerted by the working fluid on the piston, the properties of this fluid have a significant impact on the efficiency of use, technical and operational characteristics of the cylinder itself. As a working fluid for piston or plunger type hydraulic cylinders, as a rule, a special oil is used, which must meet certain requirements for a number of parameters:

- chemical composition and density;

- temperature values at which the working fluid retains its original characteristics;

- the tendency of the working fluid to develop oxidative processes.

To operate hydraulic cylinders of various types and models, working fluid is pumped into their internal chamber using a manual or electric pump.

Technical characteristics of hydraulic cylinders

The scope of application of the mechanism, as well as the period of its trouble-free operation, depend on the characteristics and parameters of the unit. It is important to know what it consists of so that, if necessary, you can easily purchase a replacement for the faulty part.

Main operating parameters:

- The diameter of the rod is a fairly important parameter that determines the scope of operation of the product. When choosing, it is important to focus on the type of equipment in which it will function. When designing a hydraulic system for a specific vehicle, it is imperative to take into account the dynamics of the load on the mechanism, as well as its load-carrying capacity. This eliminates bending of the rod during operation of the hydraulic cylinder.

- The diameter of a cylindrical rod, the main function of which is to determine the value of pulling and pushing forces;

- characteristics of the stroke of the cylindrical rod - a parameter that determines the movement of the piston and the dimensions of the mechanism in working condition.

- design features that allow you to determine how to attach the hydraulic cylinder.

- pulling force (kg).

- non-operating distance on centers that provide an effective assessment of the connecting dimensions of the unit.

- nominal pressure, calculated in MPa.

- pushing force (kg).

- the mass of the product itself.

Permissible values of hydraulic cylinders

| Name | Meaning |

| Rod stroke | no more than 10000 (mm) |

| Rod diameter | no more than 500 (mm) |

| Working norm | no more than 70 (Mpa) |

| Rod force (pushing/pulling) | no more than 70 (N) |

| Ambient temperature | from -40° to +40° |

| Working environment | water, water-oil imulsion, mineral oils. |

Features of plunger models

Take a look at the hydraulic cylinder catalogue. Among the power units of standard rod, telescopic, single-sided or double-sided ones, you will probably notice plunger modifications. Let’s say right away that they also have a wide range of applications and have proven themselves well in production equipment, such as lifts for heavy trailers. They contain, as the name implies, a plunger. Let us recall that this is a cylindrical rod, extended under the influence of the working medium pumped through the valve system. Under the weight of the object or due to external influences, the monolithic displacer returns to its original position and is recessed in the tube.

In addition to the base (sleeve) and plunger, the product includes a sliding support, sealing collars, and a wiper ring.

How are they different from piston

In plunger hydraulic cylinders, as you understand, there is no piston, that is, the rod is directly affected by the guide sleeve, which is displaced by the pumped medium. If there is no place for the piston, then there are no sealing rings; as a result, the inner surface of the cylinder may not contain a special chrome coating, and without it the drive is able to function properly. This is the main difference; other nuances relate to performance indicators. Plunger devices have a greater load capacity and are equipped with valve protection, which is activated when overloaded, but they have a significant disadvantage - the movement of the output link in one direction.

Main advantages

Among the obvious advantages, we highlight reliability, relatively simple production (no need to treat the inner surface, apply protective layers for perfect smoothness), and, accordingly, reasonable cost. But the advantages are not limited to this; here are some significant points:

- Power;

- Wear resistance;

- High efficiency with small dimensions;

- Durability;

- Possibility to choose products for different brands of cars.

Let's add simple maintenance to the above. Nothing special is needed. Those who have dealt with hydraulic systems are familiar with the basic requirements: maintaining fluid levels, avoiding overload, and periodically replacing seal materials.

Purpose of hydraulic cylinders

The use of units of this type is relevant in road, cleaning, construction and repair equipment, in earth-moving, unloading, lifting and cargo-transporting machines. Machines that cut metal, perform forging work, and operate as a press are also equipped with hydraulic motors.

In these systems, hydraulic cylinders are one of the most important units, ensuring increased functionality of the hydraulic system, as well as operation under high load conditions.

Hydraulic cylinders - manufacturing and repair in Nizhny Novgorod

Even if you know the structure of a hydraulic cylinder very well, repairing it at home or assembling your own cylinder is quite a difficult task. This requires special equipment and skills. Therefore, it is better to turn to experienced professionals with such questions. specializes in the repair of hydraulic cylinders, as well as the manufacture of hydraulic cylinders according to your orders.

Our company deals with the full range of work related to hydraulic cylinders. Our workers repair hydraulic cylinder rods, repair hydraulic cylinders for special equipment, such as loaders, asphalt pavers, excavators, concrete pumps, truck cranes, manipulator cranes, other construction and municipal equipment and production machines. We can also manufacture a hydraulic cylinder according to the drawings or samples you provide. We guarantee high quality and short terms of work.

Buy hydraulic cylinders : single-acting, double-acting, plunger, telescopic, double-rod and tandem, outriggers, hydraulic cylinders with stroke damping. Low prices.

Hydraulic cylinder repair : professional, fast, quality guaranteed.

“>