Every residential building has a sewer system. Nowadays it is no longer possible to live without basic amenities. But in any system, failures and malfunctions can occur. In the sewer system, sometimes a situation arises when unpleasant odors penetrate into the room. A solution to this problem can be a sewer valve - also known as a sewer air valve. This valve neutralizes the majority of all air pressure changes in the system.

The most common types of air valve for sewerage

Operating principle of sewer ventilation

Water valves in the siphons of plumbing fixtures are barriers to odor from the sewer system. But when a large amount of water is suddenly drained, the pressure in the pipes decreases and water is sucked out of the siphons. At this moment there are no longer any obstacles to the penetration of the smell and it can freely penetrate into the room. The causes of odor can also be the small size of siphons or prolonged downtime of plumbing, leading to evaporation of water in the siphons.

Sewage ventilation in the form of a drain pipe or air valve helps protect the room from unpleasant odors. The air entering through them equalizes the internal pressure in the pipeline with atmospheric pressure. Under such conditions, gases are not forced out through siphons, but move further through pipes into a collector system or septic tank.

The need to install a drain pipe

Sewer ventilation device.

A private house must be equipped with special ventilation. It is best to use fan products that prevent the air inside from becoming thin during use. Modern siphons are made of compact sizes, the water supply in them is small. If such a siphon is not used for about 3-5 days, then the water in it quickly disappears. And this allows air from the sewer to enter the surrounding space. Unpleasant odors easily begin to spread throughout the system.

Thanks to the drain pipe, it is possible not only to extinguish dangerous pressure drops that appear in the system, but also to ensure ventilation of the sewer system when the siphon is dry . For a city apartment this is rarely relevant, but for a country house, which perhaps no one has used for months, this is not a rare phenomenon. The interior spaces begin to literally become saturated with fetid odors.

Sewage, even if it is not used for a long time, has warm air inside, which rises through the pipe and goes outside. In this case, a small but quite noticeable vacuum is created inside the system. At the same time, an exchange of air occurs through the dry siphon: from the room it penetrates into the pipe, and from the pipe it exits into the rooms, permeating them with the smell of sewage.

Design and principle of operation of the fan valve

The air valve device includes:

- plastic case with a side hole;

- a cover that can be removed to clean the device or carry out repair work;

- rubber membrane or rod;

- a sealing gasket designed to seal the structure and limit the stroke of the rod.

The operating principle of the device is as follows:

- if the pressure in the riser is equal to atmospheric or slightly exceeds it, the valve is closed and does not allow gases from the sewer to pass into the room;

- when draining water from plumbing fixtures, a vacuum occurs inside the pipeline, resulting in the displacement of the rod (membrane) and the opening of the fixture;

- air enters through the valve, which equalizes the pressure. The rod begins to move in the opposite direction and closes the valve.

Based on their operating principle, air valves are divided into three types:

- automatic - used mainly for installation in small private houses, as they are not able to withstand strong water pressure and a significant volume of air. Works only to relieve accumulated air;

- kinetic (anti-vacuum) - designed for the release or intake of air in systems with low pressure levels;

- combined - combine all the best technological capabilities of the two previous devices.

Since the sewer line has vertical and horizontal sections, a ventilation valve with a different design of the operating mechanism is selected for each of them:

- ball aerator. The valve part has the shape of a ball, which is pressed against the bleed hole using a spring. Used for installation on horizontally located sections of small-diameter pipes at the connection point of plumbing fixtures;

- receiving model. The design of the device includes a filter designed to capture solid particles from wastewater and prevent them from passing further into the sewer system. Available with a diameter of 20 cm and used for installation in front of the pump of a horizontal pipeline line;

- Wafer aerator. This is a compact and lightweight device that can be placed both on a vertical riser and on a horizontal pipeline line. Depending on the design of the body, it can be through (the flow of water passes through it without changing its direction) and angular (when passing through the valve, the flow of the transported medium changes direction by 90º). Modifications with a plate-shaped locking organ have a diameter from 1.5 to 20 cm. The diameter of bivalve models ranges from 5 to 70 cm;

- check valve equipped with a rotary or petal mechanism. It has a shut-off element in the form of a spool, which, when the pressure in the system drops, is pressed tightly against the seat. Large diameter aerators can quickly break due to strong impacts of the spool on the surface of the seat. Continued operation of such a damaged device may result in water hammer in the system. To reduce the impact of impact, valves of large diameters are equipped with a damper.

The valves differ in the method of fastening:

- for welding. It is used in systems transporting particularly aggressive media of industrial enterprises;

- coupling - threaded couplings are used for fastening;

- flanged - the vacuum valve is clamped between flanges installed at the ends of the pipes;

- flanged with sealing gaskets.

To bet or not to bet

Many people are interested in whether it is possible to install a sewer valve instead of a drain pipe. The fact is that all drain lines work on the same principle. This means that the waste liquid flows by gravity into the septic tank. If you do not install a check valve, an unpleasant odor will appear in the house.

As an alternative to the open hole of the venting structure for the drain line, manufacturers offer vacuum valves. They work in such a way that they only suck in air when draining.

Building regulations do not prohibit the installation of such devices instead of a drain pipe, but when the house has a septic tank, an open ventilation outlet for the waste pipe structure must be present.

In such situations, the valve is not used instead of the specified network; it is assigned the role of an additional device in pipeline areas with a large length. Also, such an installation is only allowed in a heated room, so at sub-zero temperatures condensation collects in the mechanism, which blocks its operation.

If you have any doubts about whether it is appropriate to install a valve instead of a pipe, then it is better to consult with specialists on this issue, and then the comfort in the house will not be spoiled by poor sewerage performance.

Ventilation drainage system in high-rise buildings

A drain pipe for sewerage in a multi-storey building is a necessary attribute. This is a continuation of the drain riser above the roof of the building, and removes the smell appearing in the drain line to the outside.

Such pipe structures can be placed in a multi-story building in different ways: horizontally, vertically, and any other options.

Video

The only thing that the craftsmen say is that such a structure must be present in a multi-storey building. It is in multi-storey buildings that the flow of water passing through the drain riser is very large.

And without such a system, the apartments located below will constantly have troubles in the form of a bad smell and waste liquid returning from the upper floors.

Ventilation drainage system in a private house

A sewer pipe is not always installed in a private house (but depending on objective circumstances, the absence of this product may contribute to the appearance of an unpleasant odor from the sewer system). For the reason that the volume of wastewater in this case is not so large as to create a vacuum in the network.

If you follow the theory, then in a private 1- or 2-story house with one bathroom, you are allowed not to install riser ventilation. But the practical recommendations of professional builders are radically different. Their advice is based on the following facts:

- If the site is equipped with local treatment equipment, then without ventilation the bad smell will spread at ground level and will interfere with the full functioning of the septic tank.

- This solution is very reliable. After all, there is always a risk of the water seal breaking.

- It is not difficult to install this network onto the roof during construction work.

Advantages and disadvantages

Installing an air valve in your drainage system provides many benefits, including:

- saving money that will be required for work on removing the drain pipe through the roof;

- the ability to prevent the penetration of sewer gases into rooms in the presence of an unventilated riser.

The disadvantages of the fan valve include:

- the possibility of the water seal drying out, as a result of which unpleasant odors may enter the house;

- rapid wear of rubber seals, which may result in loss of tightness;

- the difficulty of choosing a place to install the product, since achieving a more complete fit is only possible with sockets;

- the need for regular maintenance of the device and replacement of worn parts.

Preparation for installation of the fan main

To install such a structure, you will need the same structural elements as for installing the drainage communication. Depending on the specific case, it is necessary to calculate the amount of materials and prepare them in advance.

As a rule, plastic pipes and connecting elements are used for installation. This is due to the fact that the installation of such elements is much simpler than metal ones and, in addition, they cost an order of magnitude cheaper. Old lines made of cast iron often fail. There is an opinion that replacing a metal structure with a plastic one is unacceptable, however, this is nothing more than a myth.

Important! Under no circumstances should individual parts of an old cast-iron structure be replaced with plastic ones. Combining materials can cause many problems, so the entire structure needs to be changed.

In addition, experts recommend choosing homogeneous materials both for the installation of fan ventilation and for the wastewater disposal system. For a cast iron system, ventilation from the same material is selected. When combining materials, it is recommended to consult a specialist who will help you calculate the possible risks associated with this installation option.

Let's look at the list of parts that will be required when installing a fan riser:

- pipes with bends;

- special rubber seals, which are necessary for reliable connection of individual structural elements and good sealing;

- transition elements;

- clamps (for fixing the riser to the walls).

To install the drainage structure, the same components are used as for the drainage system.

If it is first necessary to dismantle the old communication, then in this case the following tools will be required:

- sledgehammer;

- drill;

- Bulgarian.

The installation site also needs to be prepared by clearing it of all unnecessary things. It is also worth remembering that there should be no fire hazardous materials near the installation site of the fan riser. During installation work, it is strictly forbidden to use the sewerage system. If you have neighbors, then they must be warned that work will be carried out to replace the fan riser.

Technical characteristics, diameters and manufacturers

The sewer aerator model is selected according to its main technical characteristics:

- diameter - 50, 75, 110 mm;

- throughput - from 7 to 37 l/s (at the rate of 25 l/s per 1 liter of water).

The Russian market of shut-off and control devices for sewerage systems offers products from manufacturers from different countries:

- Austria - the most expensive devices from HL;

- Great Britain - products from the mid-price segment from McAlpine;

- Russia - inexpensive devices from Politek and Sinicon;

- Ukraine - products from the cheap segment of the Europlast enterprise.

Prices and where to buy

The table below contains current offers for today.

How does a vacuum valve work?

It is already clear from the purpose of this device that it must remain closed when there is excess pressure in the sewer pipe or when it is equal to atmospheric pressure. But if a vacuum occurs in the pipe, the valve mechanism must ensure the opening of the passage for air to enter from the outside.

The principle is easily implemented with the “involvement” of ordinary gravitational forces. The diagram below shows the structure of one of the aerator models. Despite possible differences in the design of valves from different manufacturers, the principle remains virtually unchanged.

An example of a device and a demonstration of the principle of operation of a vacuum valve for sewage.

The entire valve mechanism is assembled in a polymer housing (item 1). The device itself implies only a horizontal arrangement, so in its lower part one or another device must be provided for a sealed connection with the sewer pipe. In the example shown, this is an elastic cuff (item 2) for inserting the aerator into a socket or even just into a cut pipe. There may be a connecting unit in the form of a standard sewer pipe socket or other options. But this installation is always simple, reliable and understandable.

Air can enter the aerator through the intake grille or slot-like openings (item 3). They are located at the bottom or on the side of the valve "head", but outside air will almost always be applied to the valve diaphragm from below.

This is very easy to explain. The valve flap (pos. 5) is located in the seat assigned to it (pos. 4) and fits tightly to its edges with an elastic cuff (membrane), preventing air from passing from the pipe into the room. And the fit is ensured by the banal force of gravity of this damper. That is, even if the atmospheric and established pressures in the pipe (riser) are equal, the valve will be closed. This can also be facilitated by some excess pressure in the pipe, since gas formation in the sewer almost never stops. That is, the valve will thereby be pressed even more against the seat (in the diagram it is the left fragment).

But if, for one reason or another, even a slight vacuum is created in the pipe, atmospheric pressure will overcome gravity and lift the valve above the seat. As they say, “nature abhors a vacuum,” and the outside air will rush into the pipe, equalizing the pressure and preventing the siphons from breaking.

To prevent the damper from warping, it may have special guides (item 6). However, many models can do without them - centering is done due to the cylindrical shape of the valve assembly.

Aerator for 110 mm pipe - model with two valve heads. One of them has been disassembled to demonstrate its simple device.

Out of pure curiosity, you can “disassemble” several more vacuum valves of various models. But we still won’t find any fundamental differences there.

The differences in the design of different valve models are not fundamental.

By the way, since the device is being considered, you can immediately draw the readers’ attention to the “Achilles heel” of any valve. This, of course, is the membrane itself, or more precisely, the area of it that is pressed by gravity against the valve seat.

And here we are not talking about wear (if it exists, it is very unnoticeable), but about other obstacles that can prevent the sash from sealing:

- Over time, dust can accumulate on the valve seat or on the membrane itself, which can turn into hard lumps of dirt that prevent the valve from sealing tightly. Often the owners are notified of this by the “aroma” of sewerage entering the premises. The first thing to do when such a “bell” comes up is to check the cleanliness of the membrane and its fit, and carefully clean the assembly from contaminants.

- The second conclusion is that the vacuum valve must be installed only in a heated room of the house. Otherwise, with the onset of cold weather, drops of condensate may freeze on the seat or on the membrane, and the valve mechanism will not fit properly. And in general, too large temperature changes do not benefit the rubber membrane - it begins to “tan” in the cold, losing the necessary elasticity.

Otherwise, the mechanism is extremely simple, and it is difficult to come up with any circumstances that would lead to a breakdown of the vacuum valve.

How to choose the right valve?

When choosing an air valve for sewerage, they are guided by the location of the pipe (vertical or horizontal) in the place where it is planned to be installed. The device must correspond to the nominal pressure in the network and have appropriate installation dimensions.

You also need to consider:

- how the aerator will be attached;

- strength of the material, its anti-corrosion properties;

- possibility of manual adjustment in case of mechanism failure;

- availability of protection for rodents.

Installation of a vent riser

The fan riser is mounted from the lowest sewer communication or from the base. The second option is relevant for private houses. It is best to install the pipe in a straight vertical line, however, in some cases it is not possible to avoid side pipe branches. In these cases, special fittings are used:

- fan tee;

- crosspiece;

- revision.

When installing a vent riser in each restroom, a large tee is installed, which is connected to the toilet drain pipe. In addition, there is one important rule - the design must have as many tees as there are areas for volumetric wastewater discharge. Installation of a separate fan tee in the bathroom is not required. Also, each such system, without exception, is equipped with fan pipe crosses. The crosspiece connects to the drain pipes of sinks, bathtubs and various equipment (washing machines and dishwashers).

After installing the fittings and connecting the central drain riser to the side pipes, it is necessary to connect it to the external sewerage system. The sewer line is connected to the central sewer pipe using a special fitting - revision.

The fan riser must be equipped with an inspection; fastening is done using clamps

Fan ventilation outlets are connected to the outlets of plumbing equipment and are securely fixed. In order to achieve the required tightness indicators when connecting vent ventilation to the riser, it is recommended to use special rubber seals. Experts recommend installing seals using silicone. This installation results in truly reliable connections.

Note! To fix the clamps in the wall, you need to make holes. It is advisable to choose steel clamps. This is due to the fact that they are very durable and reliable products and are able to provide good fixation of the fan riser.

An important point is the arrangement of sound insulation. Not every person enjoys listening to the sounds that are generated when transporting wastewater through a sewer riser. Construction foam is excellent for such purposes. You just need to apply the foam to the pipe and let it harden. The result is good sound insulation, however, this method has some disadvantages: unaesthetic appearance and difficulty in maintaining the sewer line.

When arranging a complex system that includes branches, it is recommended to use special mineral slabs or mineral wool as a soundproofing material. In addition, there is another way to arrange sound insulation - a special box. Such boxes have windows in order to monitor and, if necessary, carry out repairs on the highway.

Where and how to install the valve correctly?

When installing the valve, it is necessary to follow a number of rules that will allow it to fulfill its purpose as efficiently as possible, namely:

- Aerators may only be installed in rooms with constant heating.

- The device should be placed in a place where there is easy access to avoid problems with future maintenance.

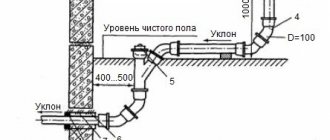

- If there is a grate in the floor of the room, then the distance from the floor level to the device must be at least 35 cm.

- Installation of the automatic valve should be carried out at a point in the system that is 10 cm above the maximum level of flow into the main riser, in order to prevent clogging of the aerator with waste and feces passing through the system.

- The device must be mounted in a vertical position directly in the socket of a straight line of a sewerage pipeline at a distance of at least 0.2 m to the nearest siphon.

Possible locations for installing the device

Aerators of modern design can be installed:

- into a vertical riser with an exit through the roof;

- cylindrical aerator models with a lid are placed on a drain pipe; simple valves are suitable for individual plumbing fixtures: toilet, sink, bathtub or washbasin;

- devices with a diameter of 50 mm are mounted on long horizontal pipes or on lines with a transition of sections of one diameter to another. Maintaining a slope when installing pipelines will promote the natural flow of wastewater and prevent the occurrence of stagnation and foul odor;

- devices with a diameter of 110 mm are mainly installed on a drain pipe; installation on an auxiliary riser is possible.

About the need to use a valve

After water is flushed down the drain, it interacts with the air inside the pipe, creating a pressure difference. Draining large volumes of water with insufficient air supply, which equalizes the pressure, leads to the formation of an area of rarefied pressure. In the absence of ventilation, air is sucked into the pipe, thereby creating negative pressure.

Due to this phenomenon, water from the weakest water seal is sucked into the drain pipe. This is the so-called “hydraulic seal failure”. And the pressure in the pipe is compared with atmospheric pressure only when air enters the valve. And this happens through the path of least resistance - the siphon. When air is drawn in, water is drawn out at the same time, thereby destroying the water seal device.

As soon as the water leaves the siphon, odors from the sewer begin to flow freely into the room. Such gases can not only be unpleasant, but also harmful and toxic. Often they contain only methane, but along with it spores, bacteria, and fungi can enter the apartment.

To prevent such incidents, the common riser is led to the roof. At the same time, it may not cope with its task, for example, in winter or if it is installed incorrectly. To eliminate this possibility, a special device was developed that would equalize the pressure in the sewer system, namely a vacuum valve.

Why do you need a sewer vacuum valve (video)

Types of valves

According to their purpose, valves can be divided into 2 categories: a check valve for sewerage and a ventilation sewer valve.

According to the laws of physics, water always moves along the path of least resistance. Even with a small clog, there is a chance that the direction of the water will change. This flow can, rising through the riser, gush from various plumbing products - toilet, sink. All this is fraught with flooding of the premises and problems with neighbors. Installing a check valve will help prevent this, as well as the possible penetration of rodents through the drain riser. For the manufacture of such devices, a variety of materials can be used: plastic, cast iron, bronze, stainless steel and others.

In turn, check valves are divided into 4 categories:

- wafer. They are light weight and small in size. In such devices, flanges are not installed for connection to the pipeline. If problems are detected, you will have to replace not only the product itself, but also the sewer section;

- rotary, otherwise - petal. The membrane is played by a flap or spool operated by a lever. There are simple and unstressed ones. The difference between impactless and simple ones is that after passing water, the spool smoothly returns to its place. In simple cases, it is possible to disable the entire system;

- ball They are used in pipes of small diameter and with a riser of less than 110 mm. The metal ball acts as a membrane, and the spring acts as a lever. The most common type of valve, which was due to ease of dismantling. To do this, just unscrew 2 bolts;

- lifting Such products are installed in areas where regular repair work is difficult. The valve can be dismantled and repaired without disassembling the pipes. A significant disadvantage is rapid contamination.

Non-return valve for sewerage

The vacuum valve for sewerage prevents the appearance of odors from the sewer pipe, and also eliminates the noise of the sewerage system. There are 3 main types of such devices:

- automatic vacuum. It is used mainly in the construction of private houses or installed on individual elements of the system. Works to release air from the system;

- anti-vacuum. Can ventilate a large number of sewer pipes. Can both let in and let out air;

- combined vacuum. It has all the best technological features of the two previous types.

Where is a vent pipe needed, and where can you do without it?

According to SNiP, in low-rise construction (in one-story and two-story private houses), the sewerage system does not necessarily have to have a drain pipe. The reason is that in such houses the volume of simultaneously drained wastewater is small, and in rare cases it can completely block the diameter of the sewer riser.

In a private house, there is a need for such a ventilation duct if:

- the house has two or more residential floors, and both (or more) floors have a bath and toilet;

- the house will have 2 or more bathrooms that can be used simultaneously;

- the house has a swimming pool (or any other source of a large amount of waste, for example a jacuzzi);

- the diameter of the sewer riser is small (less than 100-110 mm);

- There is a septic tank (cesspool) located near the house.

Scheme of the passage of the riser through the house

If you are building a house of 1-2 floors, in which there will be 1 toilet and a bathtub (sink, shower), you can do without a ventilated riser, or limit yourself to installing a sewer valve. This is true for dachas and small cottages.

Is a drain pipe needed in an apartment in a multi-storey building? Yes, it is needed, and it is always available. The reason is that in apartment buildings the volume of wastewater is always large (especially during the hours when people are in the apartment: in the evening, early in the morning, on weekends).

How can I determine if installation is required?

The drain pipe is an optional, but highly desirable element of the sewer system, which perfectly stabilizes its operation. It is considered that installation is necessary for all houses with a height of more than one floor. However, when designing a sewer system, it is important to take into account other minor factors:

- Diameter of sewer pipes. If the diameter of the sewer riser pipes is less than 110 mm, then sewer pipes must be installed, since to fill the full volume of the riser, it is enough to drain the toilet and bathtub at the same time.

- If the septic tank is located in close proximity to the house. Even if the house is one-story, but the wastewater tank is too close to it, you need to protect yourself with the help of a vent valve.

- If the layout of your home means there will be multiple bathrooms or baths that could potentially be used at the same time, then it is best to reduce the risk of a vacuum in the system.

- If the house has plumbing fixtures that have a large volume of waste water, for example, a swimming pool, jacuzzi, large bathtub.

Remember that the amount of wastewater is affected not only by the number of plumbing fixtures, but also by the intensity of their use. If the building has two bathrooms located above each other, but only one family lives in it, then it is unlikely that a drain pipe will be needed, but it certainly will not be superfluous.

When designing sewer systems for private houses, it is necessary to take into account many factors, ranging from the number of floors and devices that drain water into the riser, ending with the diameter of the pipes. Fan pipes are divided into categories based on shape, diameter and material used to make them. The diameter of the drain pipe depends on the diameter of the sewer riser. Based on the material, they are divided into the following types:

- Metal. Traditionally, the communication elements of the sewer system were made of cast iron. This is a fairly strong, durable and relatively inexpensive alloy. The disadvantages of this material are heavy weight and low ductility.

- Plastic. Nowadays, cast iron fan pipes are gradually being replaced with plastic ones, since this material is much more plastic and easier to process. Plastic models are lighter, cheaper and much more practical than cast iron, so they have almost displaced cast iron from the plumbing market.

Please note! When installing or replacing a drain pipe, you can connect cast iron sections with plastic ones; the main thing is to choose the correct diameter of the pipes so that in no case is there a reduction in the cross-section in the system.

Fan pipe - when to use

Today, according to existing building codes, it is possible to abandon the use of waste pipes only for one-story construction, since in such cases the amount of wastewater discharged at a time will be small.

But there are situations when even during the construction of one-story buildings it is impossible to do without them. They will be especially useful for large volumes of one-time flushing, for example, in cases of simultaneous use of a toilet and a bathtub.

In most cases, a sewer pipe with a diameter of 110 mm is used to install a toilet. In this case, the flush tank has an opening cross-section of 70 mm. The bathtub and riser are connected using a 50 mm pipe. Based on this, we can say that the cross-section of the siphon reaches about 110 mm. This means that if the bathtub or toilet is not used at the same time, the diameter of the riser does not completely cover.

It is worth noting that various types of household appliances do not have a special effect on the volume of drainage, therefore the use of a drain pipe is done solely at will. If the house is equipped with several bathrooms that can be used simultaneously, the drain pipe for the sewer is a mandatory part of the drainage system.

In addition, it should be noted such cases when the introduction of waste pipes into the sewer system is required:

- The diameter of the sewer riser is less than 50 mm;

- The building has two or more floors in height, each of which has separate working bathrooms;

- The house is equipped with a swimming pool or other plumbing systems that can cause high-power drains.

How to install drain pipes yourself

When installing it yourself, you need to clearly understand what a sewer pipe is, and also not forget about the following details:

- It is necessary to purchase a drain pipe with the same cross-section as that of the riser - 110 mm, otherwise difficulties will arise during installation;

- The riser, or rather its outer section, must be located in such a way that odors arising in it quickly and easily dissolve in the atmosphere;

- To create the most favorable conditions for removing unpleasant odors from the house, the required temperature difference should be achieved. Therefore, the beginning of the sewer system should be in a warm room, and the end in a cold room.

The main cause of unpleasant odors is the small volume of siphons mounted on sanitary fixtures. As a result of this, if the plumbing equipment is not used for three to five days, the water in the siphons quickly evaporates, so unpleasant odors can easily penetrate the room. In some cases, the installation of large-volume siphons is impractical, which is why it is necessary to resort to replacing vent pipes.

In situations where vent pipes made of plastic are used, this problem can be solved in several ways:

- As a result of the air in the riser rising up and leaving the pipes, a vacuum occurs in the sewer system;

- If the water in the siphons has dried, air is drawn from the apartment into the sewer, and not from the sewer into the apartment;

- Even if the plumbing is not used for a long time, the air remains clean.

How to install a vent pipe on the roof

The main task of the internal sewerage system is to deliver wastewater from the premises to the external sewerage system. Based on this, a sewer drain pipe device is being developed. And the operation of such a system will be effective only if there is a high-quality ventilation system, the arrangement of which is carried out using risers equipped with vent pipes.

The installation of the drain pipe will be correct, and the structure itself will last longer if the following requirements are observed:

- The optimal height of the vent pipe on the roof is about 50 mm. If the roof is actively used, the riser should have an outlet about three meters high;

- The diameter of the sewer pipe must match the diameter of the riser (110 mm);

- One similar pipe can be used to connect several risers;

- Under no circumstances should a riser with a waste pipe be removed together with the stove chimneys or ventilation system;

- The horizontal distance between the drain pipe and openable windows and balconies must be at least 4 meters.

It is worth noting that the installation of any additional hoods after installing and leading to the roof of the sewer riser is not required, since their use can lead to the formation of condensation, the freezing of which, in turn, will lead to blocking of the outlet openings.

It is also extremely undesirable to route the ventilation drain pipe under the roof overhang, since it can be damaged in winter by snow sliding from the roof. Ventilation equipment for the sewer system is also carried out using drainage pipes of different diameters, but the most common are pipes with a diameter of 110 mm.

Is it possible to vent the ventilation into the attic?

In a one-story or two-story private house, most owners install and replace toilet pipes with their own hands. In some cases, you can get by with one hood, but in large buildings where there are 2 or more bathrooms, it is necessary to install 2 ventilation risers. But each option has one thing in common - a ventilation outlet. Is it best to install the exhaust riser on the roof or in the attic?

Output to the roof

First things first. If the house is two-story, and the toilets on each floor are placed one above the other, then the design itself predicts that you can get by with one common riser. Although it is not recommended to take it out into the attic.

Even with the optimal diameter, sewer “odors” will be heard throughout the space. After some time, unpleasant odors can be felt in the attic. Plus, a lot of warm, moist air will be released from the riser, which will easily turn into condensation during contact with the roof.

Over time, fungus will begin to appear in the wood, and moisture in winter will turn into icicles. That is why it is necessary to carry out the drain pipe to the roof.

This option has its own characteristics:

- it is enough for the riser to rise 25-35 cm above the roof. A hood that is too high will contribute to the appearance of ice plugs, since warm air escapes through it. It is not recommended to cover the end with deflectors or weather vanes, as they help trap warm air;

- You cannot install the outlet very close to windows or ventilation hoods, because the smell will be everywhere after a while. When the riser is removed to the opposite end of the roof, away from ventilation, the sewer “odors” will not be drawn back into the room. An option with a non-return air valve for waste pipes is possible if there is only one bath.

Important! When constructing multi-story buildings, the sewer riser has an outlet to the roof. This is ventilation. In this case, it serves as a funnel pipe.

Multi-angle roof outlets

A vertical riser can enter the atmosphere in three ways: at a slope of 90 degrees, 45 degrees, and without a slope - immediately vertically upward through the roof.

Thermal insulation and sound insulation of pipes

When installing plastic elements, we must not forget about important measures to protect the system - noise insulation and thermal insulation of the pipe. Thermal insulation is carried out using a tubular cover made of foam insulation, which is worn from the outside.

To arrange the sound insulation of the system, the contact point between the interfloor slab and the pipes is filled with polyurethane foam or other sealed material.

The fan pipe is surrounded by a sealed material with excellent sound insulation properties. Due to this, vibration from movement through the sewage pipe does not transfer to the walls of the house

Sound insulation of a fan pipe can be carried out using a mineral slab or special polyurethane foam. Polyurethane foam is more often used, which is easier to use, however, if the structure is dismantled, it will not allow it to be put back together.

Is it necessary to do thermal insulation and sound insulation?

When installing plastic parts of the main, it is necessary to carry out noise and heat insulation of the risers.

Materials for insulation must be non-flammable and differ:

- ease of installation;

- possibility of reuse;

- low cost.

- fairly low thermal conductivity;

- property of maintaining operating temperature;

- long service life;

- poor moisture absorption.

The best option for thermal insulation is a foam-insulated cover, in which the sewer outlet part should be “dressed”. This method will help get rid of frost, which will contribute to the reliable, high-quality functioning of the entire structure. Glass wool, “basalt fiber”, and polystyrene foam are often used.

When installing a soundproofing system, the place where the floor slab contacts the riser must be filled with foam or other sealing materials. That is, it is necessary to apply a high-quality noise-insulating substance to the drain pipe from the toilet. Only with such enclosure will vibrations from the movement of wastewater along the risers not be transmitted to the walls of the building.

Important! By making noise insulation, you will ensure comfortable living for your family, since the appearance of invisible, inaudible, but dangerous and insidious acoustic effects will be completely excluded. You can also use a mineral plate, which is a good sound insulator. Most people prefer polyurethane foam, which is reliable and easy to use.

As you can see, without fans, it is impossible to install a sewer system, since the design

:

- connects the sewer system with the surrounding atmosphere;

- prevents the formation of wastewater stagnation;

- removes unpleasant odors from the sewer line;

- promotes uninterrupted operation of water valves.

How well the system functions, how comfortable your life in the house will be.

Video

Valve for sewer pipe

Anyone can handle the installation of a vent pipe, since it is carried out in a channel that is provided in advance in the ventilation shaft. If there is a relatively small number of risers in the ventilation circuit, such a pipe can be discharged horizontally, which will in no way affect the interior design of the room.

One of the parts of the pipe is a non-return valve for sewerage. With its help, the incorrect position of the sewer pipe is corrected.

In addition, it serves to protect the sewer system from:

- Reverse movement of wastewater;

- Rodents entering the system;

- Various impurities entering the system.

The valve can be installed not only in the inside of the drain pipe, but also in the outside. In the case of internal installation, the pipe must first be thoroughly cleaned and degreased. After this, a special insert is mounted. It is worth noting that the check valve for the sewer pipe is sold with this insert separately. It must be installed in such a way that it is located in the opposite direction to the drains. In this case, its petals should be bent towards the plumbing.

In the process of laying a drain pipe, the diameter of which is 110 mm, the installation of a check valve cannot be carried out without the use of a special adapter. If fan pipes are connected to gray pipes that have a sawn-off socket, the valve is installed directly into the pipe.

Vacuum valve option

If repairs are being made and drain pipes need to be replaced, it is not always possible to bring them to the roof.

This problem sometimes arises when installing the system in a new house or apartment.

In this case, you can install a vent pipe from the outlets indoors, but to protect against unpleasant odors you will need a vacuum valve.

The principle of its operation is simple. Special petals do not release the foul odor from the pipe into the room, but when the pressure in the system drops, they bend inward and allow a portion of room air into the pipe.

The system is very compact, the cost of materials is low, the valve can be placed next to the riser, and there is no need to fence off a complex and long air channel.

But you should be prepared that a small amount of sewer air will still leak through the valve.

Therefore, it cannot be placed in a living space; the room must have a good ventilation system.

Modern models are made with bodies made of the same material as the pipes; the connection will not cause problems. Typically, this unit is equipped with a grille that prevents small rodents from getting through, and also prevents small children from inserting any object into the valve.

Fan pipe or vacuum valve

Due to a number of positive characteristics of vacuum valves, they are increasingly used in private construction. What is this device? It is a special aerator with the help of which all unpleasant odors are quickly removed from the sewer risers. If individual developers are faced with the question of which device is more profitable and efficient for them - a vent pipe or a vacuum valve, then the majority choose the second option. Vacuum valves, depending on the manufacturer, have different technical characteristics. The principle of operation of the products is the same.

Designs are preferred in 2 cases:

- the house lacks high-quality sewer ventilation;

- You cannot lead the drain pipe from the toilet to the roof.

Like all devices, the vacuum valve has a number of advantages.

It is different:

- ease of installation and maintenance. There is no need to watch his work often, since it is impeccable;

- quiet operation;

- reliability of operation.

Photo of vacuum sewer valve

During installation:

- the roof remains intact and unharmed. Its installation does not involve an outlet to the roof, as is the case with a vent pipe;

- minimal damage is caused to the appearance of the home, since the device does not extend beyond the building;

- money is saved on the purchase of materials when removing risers through the roof or wall.

Flaws:

- the device is designed to connect one toilet;

- a cost that is considered relatively high. If you count the money spent on installing a riser through the roof with the outlet of the vent riser on the roof, then a vacuum valve is a more profitable option.

Correct connection diagramImportant! In the case of installing a non-standard type of vent riser, which must be equipped with bends, corners, and transitions, there may be a mismatch in the diameters of the products in different parts of the system.