Microlift - what kind of device?

The main purpose of the microlift is to ensure smooth lowering of the lid to prevent it from falling onto the glazed surface of the sanitaryware with a loud popping sound. Such devices appeared on the market a long time ago and have already gained popularity among connoisseurs of comfort.

The seat cover, supplemented with a microlift, is convenient in that it rises and falls smoothly, and the user does not need to hold it from impact

The operating principle of a microlift is functionally very similar to a door closer, but only made in miniature, which is why it is often called a “smooth lowering device.”

The installed device helps solve three problems at once:

- prevents the lid from falling;

- prevents the spread of unpleasant odors;

- eliminates the formation of cracks and chips on the decorative coating of plumbing fixtures.

This seemingly simple product contains a solution that significantly simplifies the use of plumbing fixtures and increases comfort. Due to the fact that the mechanism operates silently, it is not audible when using plumbing fixtures even at night, when everyone in the household is sleeping.

When you sharply lower the toilet seat onto the toilet, the lid makes a sharp, abrupt popping sound, but with the microlift installed, you definitely won’t hear it

There are both budget options on sale and more expensive ones installed on smart toilets with electronic control. Mechanisms from the expensive category are equipped with a presence sensor, which automatically lifts the lid when a person approaches, and returns it to its original position after using the toilet.

What is a microlift in a toilet?

A microlift is a device that provides silent, smooth raising and lowering of the toilet lid. The operating principle of a microlift is similar to a conventional door closer. Difference in size of structures. A toilet with a microlift is also called a “smooth lowering device”.

The installed device solves several problems at once:

- Prevents the lid from suddenly falling off;

- Makes the lowering of the toilet seat silent;

- Prevents the formation of cracks and chips on the lid itself and plumbing fixtures.

Particularly attractive are mechanisms with a presence sensor. Their feature is to automatically raise the lid when a person approaches the toilet and lower it after he leaves.

Toilet seats with microlift: product advantages

Toilet seats with a smooth lowering system are a simple, modern and affordable solution for the comfort of the whole family. Such toilet seats have a number of advantages:

- noiselessness - the lid will not fall, breaking the silence with a loud knock;

- practicality - microcracks will not form on the toilet at the point of contact due to impacts of the lid made of hard materials;

- durability - the lid will last longer, since gradual lowering will ensure not only longer preservation of the fasteners, but will also prevent the destruction of the lid made of any material due to impacts on the toilet;

- ease of operation - the user does not need to carefully lower the lid; it is enough to apply minor efforts to engage the smooth lowering mechanism.

The disadvantages include

- Plastic structures. Fragile.

- Some products do not require disassembly, which makes them difficult to maintain.

- The product is very rarely subject to repair.

Note! If you find it necessary to remove the toilet seat for cleaning, purchase a model with a dismantling function.

A toilet lid with a microlift has disadvantages, but there are more positive qualities.

Product repair

Parts for a microlift seat

Repair of a seat depends on the type of damage. If the bolts simply loosen and the product is disconnected from the toilet, then repairing the toilet lid microlift with your own hands is possible - you just need to tighten the fastenings. The mechanism itself is simple, but its disadvantage is that the design is not dismountable. Therefore, if, by pressing hard on the cover, the spring is thrown out of balance or the microlift rod is broken, then the seat will have to be thrown away. If you choose a model made from low-quality materials and it cracks, then you will most likely have to throw it away too. But in case of minor damage, you can try to glue it with liquid nails.

Design features of the device

The microlift is sold together with the toilet lid, but it can also be purchased separately. Covers equipped with closers are made of plastic or its modern version - duroplast. Although this polymer looks like plastic in appearance, its quality characteristics are closer to ceramics.

The material for the manufacture of seats equipped with a microlift is duroplast - a modified polymer that can maintain a stable temperature when exposed to heat.

Fix the device to the toilet in a rigid way. The main structural elements of the microlift:

- Rod that reliably fixes a rigid plastic installation.

- Spring to balance the weight of the structure.

- Hinged micro-lift mechanism , providing a change in the position of the lid.

In more expensive functional systems, the basis of the mechanism is not springs and rods, but pistons and cylinders. Structures of this type are classified as non-removable.

Smooth closing/opening of the mechanism and fixation of the toilet lid in the desired position is ensured by a micro-lift hinge mechanism equipped with a spring

Functional systems, in which seats and covers are supplemented with a built-in microlift, are produced by many manufacturers of sanitary equipment. If desired, you can purchase and install a universal system, which includes, in addition to the microlift, other devices.

They are capable of providing several functions at once:

- adjusting the temperature of incoming water;

- possibility of seat heating;

- high-quality washing, enema and massage;

- extraction of unpleasant odors followed by deodorization.

Many models are often equipped with a convenient self-cleaning function, thereby minimizing the participation of household members in the process of using the plumbing fixture. The presence of a microlift is just one way to make your living conditions more comfortable.

What to look for when buying a toilet seat with a microlift

You need to approach the purchase of a microlift responsibly, because it is purchased for more than one year. Therefore, when choosing a suitable model, pay attention to the following:

- Size. The device must be sized to fit the base of the toilet. This is important not only for maintaining an aesthetic appearance, but also for increasing service life.

- Appearance. A toilet seat with a microlift must fit into the interior of the room.

- Material. The parameter also directly affects the operating time of the cover. The best option is Duroplast. It is durable, hygienic, resistant to chips and scratches. It is not advisable to purchase a microlift made of plastic. The material is not durable or wear-resistant, so it will last you a short amount of time.

- Price. There is no need to save money and purchase the most inexpensive lid with a microlift - it will quickly fail. The assortment includes a wide selection of products in the mid-price category - this will be the best option, because they have a full range of necessary characteristics.

- Availability of additional functions. You need to decide on this in advance, because their availability directly affects the cost of the toilet seat. So, there are devices on sale with heating, self-cleaning, and air flavoring. Some of them can reach a price tag of 70,000 rubles.

The toilet lid is an important element of the plumbing fixture. It not only maintains the aesthetic appearance of the room, but also prevents the spread of bacteria and other harmful microorganisms. The microlift system will make visiting the bathroom more comfortable.

How to choose a lid with a microlift: important criteria

In most cases, manufacturers of such products target their products to a specific type of toilet and sell it along with it. But there are also types of lids separate from toilets, when choosing which you need to be extremely careful and pay attention to the following points.

- Compliance of the lid configuration with the shape of the toilet bowl - it should be understood that the service life of the lid with a microlift largely depends on this point. And, in addition, the discrepancy in size leads to a violation of the aesthetic appearance of the toilet as a whole.

- Pay special attention to the reliability of this product. This factor is difficult to determine by appearance, but based on the reputation of the manufacturer it is quite possible. Read reviews on the Internet, chat with happy owners of similar products and make your choice.

- Additional functions. Toilet lids with a microlift, like ordinary seats in general, can be equipped with built-in heating, a self-cleaning function and a smooth lifting device when approaching a person’s toilet.

Toilet with microlift photo

In general, a toilet seat with a microlift is quite easy to purchase at any plumbing store - they provide a large selection of these products, designed for installation on modern toilets. If you are trying to find a similar device for an antediluvian toilet seat, then this may cause problems.

Features of types of toilet seat mounts depending on the material of manufacture

Fastening elements for a toilet seat are of the following types:

- plastic: the most budget option. Plastic is not afraid of moisture, that is, it is absolutely not susceptible to the formation of corrosion and oxides. That is why such a mount will always be easy to replace - it will easily unscrew;

- brass: as a rule, to protect against oxidation, a brass part is coated with a layer of chromium, so the product has a white color (metallic). Brass fasteners are characterized by increased strength and durability. The price of such a set of toilet seat mounts will be higher than that of plastic;

- stainless steel: characterized by good strength and durability, however, rust can still appear on such a surface due to accidental contact with abrasive substances during the cleaning process of the toilet, low quality “stainless steel” (insufficient chromium content), which will cause difficulties when dismantling becomes necessary. The solution to this problem is plastic inserts.

Universal mounts for toilet seats in the Leroy Merlin catalog

The toilet seat (toilet) is an important element that ensures comfort and ease of use of the toilet. As a rule, the seat comes complete with the toilet, but if necessary, the user can always separately buy a toilet seat and fastenings for its installation, which presents absolutely no difficulties. If it is necessary to replace broken fasteners, you can easily dismantle them and install new ones - thanks to the universal design of the fastenings, you can easily select the required set. The main difference between toilet seat mounts is the material used.

Rules for choosing equipment with a microlift

The choice of a toilet seat with a microlift is based on the parameters of the toilet, the structural features of the devices and the materials from which the component elements are made. The Aquasan store offers products from reliable manufacturers for sale, including a tank with similar functionality to the lid. You can place an order for goods at any convenient time of the day.

Here's what to consider before making a purchasing decision:

- compliance of the accessory with the dimensions of the seating part of the sanitary bowl and the location of the holes for support fasteners;

- use of high quality materials and warranty period of service;

- comfortable use and a design solution that is relevant for the interior.

Another selection criterion is based on hygiene standards. As a rule, they limit the service life of the toilet seat to 6-9 months. You can use stone, earthenware and duroplast longer. But wood is inferior in strength and resistance to moisture. Cracks cannot be restored and are a risk zone for biological damage.

Here is a short overview of the characteristics of popular materials

:

- Plastic is cheap, lightweight, but remains cold, turns yellow, and has low strength.

- Duroplast is comparatively harder and retains its shape and color for 15 years. But it is more expensive and hardly heats up in a warm room.

- Metal is rarely used for installation on earthenware units, but it is durable and practically not damaged during operation. The truth is heavy and must be protected from corrosion.

There are plywood models with soft lining. This chair is comfortable to use. The basis can be fiberboard or chipboard for cheap models, but natural solid wood lasts longer. Materials are subject to mandatory treatment with antiseptics and water-repellent agents.

Upholstery and filling are characterized by poor resistance to moisture, mechanical stress and a relatively short service life. The PVC coating peels off relatively quickly at the ends of the lid or seat and cracks. Due to the violation of the tightness of the finish, a favorable environment for the development of bacteria appears.

Plumbing equipment cannot be returned as it belongs to the group of hygiene products. Therefore, before paying, it is necessary to check the product visually and to ensure that the microlift is working correctly. The component elements should be free of unnecessary inclusions, nicks, irregularities, chips and thread failures.

The presence of sealing gaskets and liners must be monitored. They are needed so as not to damage the ceramic toilet. Such parts are installed in the places of fastening elements, on the underside of the seat and cover.

Design and material of manufacture

Based on their design, seats are divided into soft and hard. Soft models are covered with vinyl or polyethylene on top; they are very inexpensive, have a bright, cheerful design, are easy to use, but will not last long, since the upholstery will quickly tear or crack. Hard models are more reliable, they are not so afraid of mechanical stress, sharp objects and the aggressive effects of detergents. In addition, you can always put a special cover on the hard cover, which can be easily changed. The assortment includes a wide variety of covers made of plush, textile, eco-leather, vinyl, with a zipper or ties.

Today, manufacturers usually use two materials to make lids:

- Plastic;

- Duroplast.

Of course, there are also seats made of wood and MDF, but quite rarely and most often these are designer models that are rarely found in ordinary stores.

Plastic seats are cheaper and lighter, but they are easily scratched and break quickly.

Duroplast is a more modern material, it is stronger, which means this model will last longer. Another plus is that such seats often have an antibacterial coating, which is very important for maintaining hygiene in the toilet. True, such options are more expensive than conventional plastic ones.

Main causes of breakdowns

Closer systems produced by leading manufacturers are renowned for their high quality. But natural wear and tear of functional elements and incorrect operation of a “smart” device lead to disruptions in the operation of the system.

The main sign of failure of the mechanism is the appearance of a loud sound that occurs when the lid is lowered due to its falling

The causes of malfunctions in most cases are attempts to manually close the lid “out of habit.” The mechanism's built-in spring is designed for gradual compression. If physical force is used, the mechanical impact disables the device.

The easiest way to solve the problem is to completely replace the cover with a new one, since reinstalling damaged mechanisms is not always advisable. But still, in order to save on expenses, you can repair a broken toilet lid microlift on your own, by trying to disassemble the device and replace its failed elements.

DIY repair

Fastening for the lid

Perhaps the most common breakdown occurs when the base with the elevator rotates and detaches relative to the toilet. This rotating mechanism is located at the rear of the seat, secured with two bolts made of plastic.

Plastic is a fragile material, so it is only a matter of time before they break. It is enough to replace the bolts with new ones and secure the rotation mechanism.

Also quite often the spring fails. It may weaken over time or even break down, therefore, it ceases to cope with its task. To repair, you need to buy a new part and fix it.

Some breakdowns can be fixed on their own. For example, if the structure begins to creak, it has run out of lubricant. The shortage is filled and the microlift works like new.

You can also fix some mechanical breakdowns yourself. As a rule, we are talking about the toilet lid. For example, it may crack if you sit on it or put something heavy on it.

Of course, because of a crack, it would be a pity to completely change the entire structure, especially if it was expensive. If the lid is made of plastic, it is recommended to pour dichloroethane or acetone along the crack. If it is made of another material, the best option is liquid nails.

Problems with the rod are already difficult to repair. As a rule, it is possible to eliminate the breakdown only if a similar device with an intact rod is found or a suitable repair kit is found in a specialized store. But unfortunately, most often you have to purchase a new toilet lid with a microlift.

Repair

Adjustment is required when the product does not hold and falls. For repairs you will need a screwdriver and a hexagon.

- Remove the system from both sides.

- Pull out the piston.

- Remove old grease.

- Pour new ultra-high viscosity polymer silicone grease (PMS 1000000) into the capsule.

- Insert the piston.

- Tighten the screw.

- Return the microlifts to their place.

Bushing repair

The easiest way to repair the mechanism is if the bushing stops functioning. You need to proceed as follows:

- Unscrew both nuts.

- Remove the seat.

- Pull out both bushings and swap them.

After this the system works normally.

A new bushing can be made to order, or independently by printing a drawing using a 3D printer.

Nut repair

If the toilet seat is detached from the body, the cause of the breakdown may lie in the nuts - they are attached to bolts at the bottom. In order to create a tight fastening of the microlift, it is necessary to replace the bolts.

If the nuts cannot be reached without removing the toilet, you will need to do the following:

- Dismantle the housing.

- Disconnect it from the drain hose.

- Remove the bolts and replace them with others.

- Place new bolts in place of the old ones.

Toilet closer repair

If the microlift breaks down, it is better to contact specialists with the proper experience. They will help determine the cause and type of malfunction, and will also professionally make a replacement and fully restore the functionality of the “smart” system.

Work on self-repair of the built-in mechanism should be carried out with extreme caution, having thoroughly studied the instructions for the product before starting work.

This is especially true if you have to deal with a design that is equipped with several additional functions at once.

Replacing failed bolts

The most common malfunction that can be fixed on your own is broken fastening bolts.

Work to eliminate the defect is carried out in the following sequence:

- Dismantling the device (you can take the installation instructions and repeat the steps, but in reverse order).

- Replacing broken bolts , screwed on the back side with nuts, which connect the back of the cover to the elevator mechanism.

- Assembling the system is carried out in the reverse order with strict adherence to the installation of each part in its original place.

The nuts are screwed onto the plastic bolts from the underside of the toilet. The work is carried out carefully so as not to damage the fasteners.

If you have to screw in brass parts to prevent damage to the surface, you should use intermediate plastic or rubber washers that soften the pressure of the fastener

If it is necessary to dismantle the seat, it is convenient to unscrew the holders manually or using pliers.

Tightening up loose supports

To tighten one of the metal supports securing the seat cover to the toilet body, you need to remove the caps on each leg of the fastener. They are equipped with hexagon holes, although some models do not have holes in these caps.

After this, all that remains is to remove the seat and cover without making excessive efforts. To do this, when open, simply gently lift it up.

The metal fasteners move freely in the holes, so to adjust the position of the lid relative to the tank, you just need to move them slightly forward or back, and then carefully tighten the caps or fastening nuts. In this case, the microlifts themselves do not need to be disassembled.

The spring burst

If the spring fails, then it can only be replaced. Then the microlift will have to be completely disassembled and reassembled. The process can be complicated by two points:

- the mechanism cannot be reconstructed due to the integrity of the structure;

- it is necessary to find a part in strict accordance with the faulty one in terms of size and stability relative to the load.

How to repair a toilet

The main signs of a broken toilet are water leaking from the tank into the toilet, an inactive start button, a leaking toilet, noisy operation, and so on. Moreover, all these malfunctions can be classified into two types - tank failure and toilet leakage. Do-it-yourself toilet repair using our video, which can clearly demonstrate breakdowns and how to fix them.

If you notice that water is flowing continuously, then most likely the reason is in the float lever, it is either skewed or displaced.

This problem can be fixed very simply, you just need to adjust the lever into place.

If this is not the cause of the leak, check the float, because the slightest damage could cause it to fill with water. This leads to the weight of the float and, accordingly, it does not block the access of water.

- To fix this problem, you need to remove the float and find damage on it (water will flow out from there).

- Then drain all the water from the float, seal the hole and install the float back.

You can also repair the toilet yourself if the flush button breaks. Often, button failure is caused by a damaged rod.

- Therefore, it is worth removing the broken rod and installing either a temporary or a completely new rod in its place.

- If no measures help eliminate the breakdown, then it is necessary to replace the entire mechanism of the tank; you can also do this yourself.

Broken toilet bowl

Breakage of the toilet bowl is a fairly rare occurrence, but very unpleasant. Often they consist in the lack of a tight fixation of the toilet to the floor, or in leaking drain pipes.

- Before you fix the toilet or repair the pipes, you need to carefully inspect both the toilet and the tank.

- Only after you have discovered the unmistakable cause of the leak can you begin repair work.

Replacing the seat cover

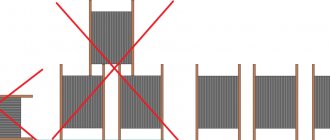

One of the significant reasons for fatal mechanism failure is the wrong choice of model and errors during its installation.

Therefore, when purchasing a new cover, you should be guided by the following rules:

- take into account the dimensions of the plumbing fixtures;

- pay attention to the shape and configuration of the toilet;

- give preference to products from trusted manufacturers.

The seats on sale with a lid are suitable for toilets of any design: floor-standing, side-mounted, wall-hung. Work on installing a new device is carried out in the standard manner.

When choosing a new model, it is important to take into account the features of the plumbing fixture and pay attention to ensuring that the distances between the system fasteners coincide with the seat fastening locations

To replace a broken cover with a closer with a new one, you will need a set of tools:

- hacksaw;

- pliers;

- socket wrench.

The materials you will also need are silicone or oil to process dried elements. Ideally, it is better to use a special lubricant that, penetrating into the cracks, freezes the rust.

Traditionally, the lid with the toilet seat is secured with two bolts. But in some models a metal pin may be used instead. To dismantle you just need to lower/raise the cover and then unscrew the pins.

If the cover has been used for quite a long period, there is a high probability that the bolts have become clogged, and the fastening points have become coated and “fused” to the body.

To ensure easier unscrewing and simplify your task, the bolts will have to be pre-coated with oil or silicone, but this is not always effective

Using pliers, carefully, trying not to damage the decorative surface of the toilet, unscrew the clamp and bolts. To protect your plumbing from possible damage when working with pliers, it is better to cover the surface with rags or pieces of cardboard.

You should not neglect this recommendation, otherwise if you make the slightest mistake you will have to change not only the lid, but also the toilet. The following article will introduce you to the rules for installing this plumbing fixture, the contents of which we recommend that you familiarize yourself with.

As a last resort, if the processing did not give the desired result and the plastic bolts do not give in, they can be sawed with a hacksaw or cut off with a hot knife blade. There is no need to worry that melted plastic will stain your plumbing fixtures. After hardening, it will not be difficult to remove from the surface.

Having dismantled the old lid, the remnants of dirt, accumulation of rust and limescale are removed from the grooves on the toilet, after which bolts are inserted into the fastening points and the structure is fixed.

Installation of the new cover is carried out in the following sequence:

- Rubber inserts are inserted into the new seat cover. They provide a soft fit of the product to the seat.

- Fasteners are installed in the holes on the toilet. They are screwed using rubberized seals.

- Fix the cover to the seat using metal or plastic bolts.

- The structure is centered and the seat is checked for fixation strength.

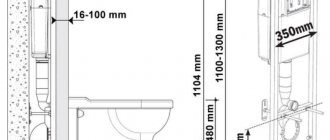

Installation

Installation begins with measuring the parameters of the upper part of the plumbing. First the width is measured. Then you need to measure the depth.

Next, you need to measure the distance between the bolts that are located in the area where the toilet seat and cover are attached. How to install a microlift on a toilet? The general instructions, regardless of the type of plumbing, look like this:

- Compare mounts. This is to ensure that the mechanism is suitable for installation.

- Install 2 rubber inserts. They are inserted into the recesses that are located at the bottom of the seat.

- “Arm yourself” with a bolt and bushing. Using these tools, connect the toilet seat to the body.

- Adjust the height using the adjustment cup screwed onto the mounting bolt. The fit should be as tight as possible - this will help avoid breakage.

- Place the gasket.

- Install the bolts.

- Tighten the nuts at the bottom.

The mechanism is installed on any type of toilet. How to install a seat with a microlift on a floor-mounted plumbing fixture? The system is mounted both in the lid (on the right) and in the seat itself (on the left).

Algorithm of actions:

- Insert plastic bushing seals into the mounting holes.

- Insert rubber sealing gaskets.

- Place microlifts over the mounting holes of the plumbing fixture.

- Place washers on the mounting bolts.

- Insert washers into holes.

- Adjust the distance.

- Secure the mounting position of the bolts using a screwdriver.

- Place protective cups on top of the fasteners.

- Install the seat studs into the mounting holes. The right pin is marked with the letter R. It must be inserted on the right. The left pin is marked with the letter L and is inserted from the left.

The bolts must be tightened very carefully, otherwise there is a risk of injury to the fasteners made of plastic.

In order to ensure better safety for polymer threaded connections, it is necessary to thoroughly lubricate them with silicone.

Installation on a wall-hung toilet has some features. How to install a cover with a microlift on a suspended housing if the holes in it are not through, but are located only on top? In this case, spacer dowels should be used. If the design is designed for such fastening, then they are included in the kit.

When the screw is tightened, the dowels expand. The rest of the algorithm will be exactly the same.

Preventive measures

To prevent malfunctions from occurring, you must follow the rules for using the mechanism. The first thing to remember is that you cannot put additional pressure on the lid or seat. It should work at a slow pace initially.

Every 2-3 months it is necessary to monitor the position of the toilet seat. If deviations occur, adjustments are made. To do this, you need to loosen the supporting fasteners, align them and fix the structure again.

Cleanliness must be maintained. Blockages provoke corrosion of parts, interference with movement, and as a result, failure of individual elements or equipment in general. In addition, pollution becomes a comfortable place for the development of bacteria and the appearance of an unpleasant odor.

Is it worth buying a toilet seat with a microlift?

Strengths of a microlift for plumbing:

- silent lowering/raising;

- absence of scratches, chips, cracks on the installed structure, thanks to the smooth,

- neat operation of the mechanism;

- long service life with proper use;

- simplicity and speed of installation;

- Some models have a presence sensor.

However, along with the advantages, the microlift mechanism for the toilet lid also has weaknesses:

- easy to break due to physical impact;

- cannot close quickly if necessary, since only one mode works - smooth;

- difficult to repair and restore, and some elements cannot be replaced or repaired at all;

- During disassembly, damage to internal parts and connections may occur.

Only after assessing the positive and negative qualities of a microlift can you make a choice for or against the purchase.

Set of smooth lowering mechanisms (microlift) 27 mm for Dino Plast seats

Set of smooth lowering mechanisms (microlift) 30 mm for Dino Plast seats

Set of smooth lowering mechanisms (microlift) for lid and seat for VITRA toilets

Set of soft lowering mechanisms for toilet lid and seat for SenSea Borneo

Set of microlift smooth lowering mechanisms for the toilet seat lid Gustavsberg Estetic

A set of smooth lowering microlift mechanisms for the toilet seat cover Gustavsberg Nautic

Set of microlifts for seat cover Sanita Luxe 30 mm

Set of microlifts for toilet Sanita Luxe Classic 35 mm

Features of the mechanism

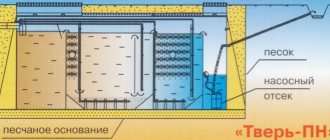

The modification of the lid is called a microlift. The device allows you to smoothly lower both components of the seat. How does a microlift work? The principle of its operation is the same as that of a door closer. Another name is “soft close device”.

The system includes the following elements:

- toilet seat;

- Micro-lift mechanism (hinge);

- Spring (its force corresponds to the weight of the seat);

- A rod designed to secure the structure.

After soft operation, the closed lid fits tightly to the plumbing fixtures.

In expensive models equipped with thermal sensors, automatic operation is observed: when a person enters the bathroom, the seat rises. When a person leaves the room, the lid lowers itself.

Advantages

The main advantages look like this:

- Quiet operation. The lid lowers gently, without knocking;

- Possibility of installation on any product;

- Increased service life. Thanks to smooth operation, the likelihood of constant mechanical impact on the surface is eliminated. Against this background, the risk of chips and other damage is reduced.

Flaws

- Difficulty of repair. When restoring a microlift, there is a possibility of damage to internal parts;

- Fragility. With strong pressure, the product falls apart;

- Excessive smoothness. The system does not involve physical impact. Otherwise it fails.

Additional functions

A high-quality device is made of duroplast. This material is hygienic and resistant to mechanical damage. Some products are complemented by:

- heating function;

- air freshener;

- "Quick Release" function. Thanks to it, the product can be easily dismantled.

Inexpensive plastic lids with micro-lift function

They do not have a long service life and require special, careful handling.

If you have small children, you should not buy this unit. With several forced lowering of the lid, and children will do this out of curiosity, the structure will become unusable.

Duroplast

Products made from Duroplast are popular. The material is durable, easy to clean, antibacterial, and tolerates chlorine and cleaning agents. In combination with metal fasteners, one of the best options.

Tree

Wooden lids are more expensive; the microlift mechanism is always made of metal.

Important! Wood is a heavy material; if the seat is unsuccessfully lowered or the lid hits the cistern, it can easily damage the toilet. This product simply needs a microlift.

Important to remember!

The seats of the toilet seats based on the microlift for the toilet are secured with adjustable hinges. They are made from high-strength steels, which ensure reliability and strength of the connection. They not only fix the equipment, but also regulate the operation of the structure. The adjustment is made by rotating them.

If the system is incorrectly adjusted, as well as if additional force is applied to accelerate the lid rebate, the service life of the entire product is significantly reduced.

Models of Russian and foreign brands

Santek and Kirovskaya Keramika are considered popular domestic brands. All their products are manufactured using high-quality European equipment. The cost of the products is quite reasonable.

Another famous manufacturer is the Roca Group. A couple of years ago she linked up with Santek. This has had a noticeable impact on the style of the products and has led to improved quality and reliability of the products.

Foreign manufacturers whose products have proven themselves in the domestic market:

- Portu is a Chinese company that works with nanocoatings and produces products in different styles and colors;

- Orsa is an Italian company that produces exquisite models of the highest quality;

- Gustavsberg is a Swedish company that produces high quality models at reasonable prices.