Description

Currently, stores offer two types of generators, which are designed to work in conjunction with welding machines . It is customary to highlight:

- synchronous;

- welding

The first type is conventional voltage sources that support operation with household appliances and welding inverters.

If we talk about welding generators, then these are small devices, additionally equipped with a built-in welding machine. Due to the fact that they require very little space, they are very convenient to take with you . It is important to take into account that gas generators with a welding machine differ in power indicators. Therefore, consumers need to choose a suitable model with an emphasis on this characteristic.

Design features and operating principle

Some experts distinguish gasoline generators for welding into a separate type of generators that operate on the same principle as conventional devices.

At the moment the arc is ignited, a welding current is supplied to the armature winding, which ensures the stability of the welding arc. The current is generated due to the transformation of energy resulting from the rotation of the crankshaft in an internal combustion engine, which makes it possible to obtain electrical energy from mechanical energy.

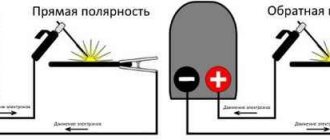

Welding current type: direct (DC) or alternating (AC)

Cooking with constant (or direct, in English - DC) current is simpler: it is easier to hold the arc. Therefore, 99.9% of modern MMA inverter machines produce constant welding current.

But among transformers, previously the majority were AC devices.

Alternating current (in English - AC) is used for welding non-ferrous metals. But not with MMA devices, but with TIG devices. Therefore, an MMA welding inverter that produces alternating current is a rarity.

Selecting a generator for a welding machine

The main characteristic that you should pay attention to when choosing a generator for welding is its power. It is very important that its indicator for the generator is higher than that of the inverter. Thanks to the presence of a power reserve, the device will be able to operate in normal mode and maintain stable performance, provided that the load is correctly selected.

In order to select the optimal power of a gas generator for a welding inverter, you should first find out the maximum current consumption . You can get this information by looking at the device case, where the parameter you need is designated as Imax.

To make it clearer, let's consider this parameter using the example of a generator with an Imax 23A indicator. Power calculation is performed according to Ohm's law.

- You need to multiply the above value by 220, the result is 5060 W.

- You need to additionally add 30% to it, then the final figure will be 6600 W.

- This will be the approximate power of the generator.

When choosing a generator for an inverter, you must also pay attention to the diameter of the electrodes, which must correspond to the power of the device. For example, for a 2.5 kW generator, electrodes with a cross section of 2 mm are perfect. If the diameter of the electrodes is 3 mm, then the generator power should be 3.5 kW. Depending on the generator model you select, power requirements will vary.

It is also necessary to mention another important characteristic that consumers need to take into account - the voltage of the outlets, which must correspond to the type of inverter. If you choose a device for domestic use, then you can limit yourself to a 220 V outlet. For three-phase powerful inverters, you will need a 380 V outlet.

In addition to the above characteristics, there is one more that must be taken into account. We are talking about the body. If you are going to often take the station with you, then it is best to choose a compact model with wheels. One of the main reasons for the popularity of gasoline units compared to diesel ones is their lighter weight and size.

No load voltage

After turning on the device, until the arc is ignited, the voltage at the tip of the electrode is significantly higher than during operation. And the higher it is, the easier it is to ignite the arc. But standards prohibit open-circuit voltage levels on devices delivering direct current above 100V.

To further reduce risks, the so-called VRD blocks. A device equipped with a VRD has only a few volts at the tip of the electrode before the arc starts. And only when you touch the metal, the no-load voltage is restored to the level necessary to ignite the arc.

Selecting a generator with welding function

To ensure that the welding gas generator lasts a long time, make sure that cast iron sleeves are used in its design. Such devices can easily withstand operation for 1500 hours. But their aluminum counterparts are less reliable and can fail three times faster.

In stores today you can purchase inverters with the function of adjusting the power percentage. This is an excellent option for use in conjunction with generators, as they support operation at reduced voltage. If you are interested in just such a model, we advise you to carefully study the markings before purchasing - it must contain the PFC prefix.

Remember that gasoline welding generators are not designed for continuous use. It is necessary to take breaks while working. If you are going to use this device for 5-8 hours a day, then it is best for you to choose a diesel model. A model with a power rating from 0.7 to 5 kW is ideal for relaxation and gardening. They are lightweight, so you won't have any problems with carrying and transporting them.

A generator with a power rating of 10 kW can easily cope with intensive work for 8 hours every day. Features that also need to be taken into account include the size of the fuel tank, as well as the presence of a soundproofing casing. Many experts consider the function that allows you to start a gas generator from an electric starter to be important.

An interesting solution are models with overhead valves. If you have experience working with diesel analogues, then be sure to pay attention to the quality of the energy released. These units have such advantages as compactness, long service life, high performance and low noise level.

You should consider such a generator model only if you are going to use it to perform work on a construction site, where you will need to supply a powerful flow of energy from time to time. If you are looking for a unit for a cottage or enterprise, we advise you to choose from generators with a capacity ranging from 10 to 20 kW. Many devices of this type have the ability to start automatically, and, in addition, they can be used as a permanent installation.

Popular models

To choose the right gas generator, you need to not only look at the operating parameters, but also take into account the manufacturer, of which there are plenty on the market today.

Characteristics of the FUBAG WS 230DC ES station

If you are looking for a gas generator for welding , then we advise you to consider the following model as a possible option. With the help of the FUBAG WS 230DC ES generator you can solve a wide range of problems, including those that arise for installation and construction teams. Thanks to the spacious fuel tank, it can operate continuously for 9 hours at a maximum load of 75%.

To start the station, an electric starter is provided, which allows you to quickly start working. It is possible to select the operating current in the range from 50 to 230 A. Using this device, you can weld metal products using arc welding using stick electrodes, which can have a cross-section from 1.6 to 5 mm.

In this generator model, automatic control is not provided. Weighing 112 kg, it is equipped with a 25 liter fuel tank. The model is easy to use and has an oil sensor for this purpose. The power drive used has a power rating of 14 hp. With. During operation, the generator creates noise at a level of 77 dB. With dimensions of 722x530x582 mm, the installed engine with a volume of 439 cm3 can be assessed as the correct decision of the manufacturer. The operation of the device is ensured by a four-stroke motor. The model is not equipped with either a handle or wheels .

Power station FUBAG WS 190 DC ES

This model can be used to connect metal products using arc welding. It supports generators up to 4 kW. For welding work, it is allowed to use only electrodes whose diameter is in the range from 1.6 to 4 mm.

This generator has a reinforced metal frame coated with paint that protects the housing from corrosion. The latter is equipped with special damping pads that reduce vibration during operation. The weight of the device is 97 kg, and the fuel tank volume is 25 liters.

The device has quite compact dimensions - 722x530x582 mm. The operating noise indicator does not exceed 77 dB. The power drive used in this model has a power of 13 hp. With. The generator is powered by a four-stroke engine. Additionally, the design includes a fuel level indicator. To turn on the power plant, you can use either an electric or a manual starter.

Characteristics of Caliber BSEG-5511

To choose the most suitable gas generator model, you should first look at several models. Among the devices on the market, the Caliber generator deserves special attention. This is a universal-purpose device that will be indispensable at car service centers and construction sites.

This unit uses an engine with an increased operating life, which is explained by the presence of a forced cooling system. Operation of the device at a load of no more than 75% without refueling is possible for 9 hours. The model comes with automatic control. The permissible power of the device is 5.5 kW. The fuel tank is quite spacious and has a volume of 25 liters. The weight of the device is 86.1 kg. For this model, the minimum and maximum current are 50 and 190 A, respectively.

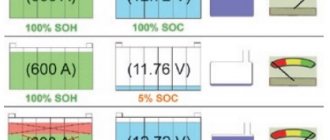

Duty cycle, also known as PV (on period), also known as PN (payload)

PV is indicated by two numbers. The first is current strength. The second is the percentage of time. For example, “130A-50%” means that this device with a current of 130A can cook half the time. And the same amount of time will remain idle, waiting for cooling to operating temperature. If measurements are carried out at the maximum current of the device, the first digit is omitted, leaving only the percentage indicator. For example, if a device with a rating of 160A has the entry “30%” opposite “PV”, this means that with a current of 160 amperes it can operate 30% of the time, and 70% will cool down.

That's right. It only remains to add that the domestic GOST R IEC 60974-1-2004 does not establish a single mandatory method for measuring the PN indicator for MMA devices.

The European methodology, set out in the EN60974-1 standard, suggests measuring on a load stand at an ambient temperature of 40C only until the first shutdown due to overheating. The result obtained is referred to a 10-minute period. It turns out that the thermal protection worked after 3 minutes, the cycle of the device at this current is 30%.

Methodology of the TELWIN concern. To date, it is used by most Chinese manufacturers (those that generally conduct such tests on their cars). The Italian concern itself, when measuring the PV of its devices using its own method, modestly indicates “TELWIN” after the indicator. The vast majority of Chinese manufacturers do not do this.

Finally, there is a Russian, also known as Soviet, methodology. In essence, it is closer to the TELWIN method: all intervals during the control period when the device was working are summed up. But the segment is taken not 10, but 5 minutes. And - most importantly - the device is first put into overheating protection mode, after which measurements begin.

As a result, the same device produces completely different percentages using all 3 methods! Naturally, the most modest “numbers” are obtained using the European method, and the most impressive ones – up to 2 times or more – using the Telwin method.