Greetings, friends.

In this article we will learn how to repair a crane axle box with your own hands.

The main reason for the failure of a kitchen faucet is the breakdown of shut-off valves. Modern cranes are a reliable and durable mechanism, but constant exposure to moisture often leads to failure of the crane and axlebox.

There are three solutions to this problem:

- Completely replacing the faucet is a radical and expensive solution, since a good faucet costs a lot of money. It justifies itself only in case of violation of the integrity of the housing, or replacement of low-quality plumbing fixtures made of silumin. There are times when people simply want to change the design of the kitchen or bathroom - here they also cannot do without replacing the bathroom.

- Replacing the valve axle box is the most common option. Unscrew the broken valve axlebox, buy a new one, and install it in place.

- Repairing the axle box crane - all of the above methods require financial costs, so it makes sense to try to repair the axle box crane.

IT IS IMPORTANT TO KNOW!

Crane axleboxes vary in size and threaded connection. Therefore, my advice to you is to buy a new axle box, take the old one with you. Save time and nerves.

What is an axle box crane

The faucet - axlebox - is a special locking mechanism, rotating which regulates the water pressure. Externally, the crane axleboxes are similar to each other, but structurally different. There are two types of crane axle boxes:

Worm

In common parlance they are called rubber because of the gasket made of the same material located inside. The point of the work is that when the handle is rotated, the rubber band shuts off the water supply to the mixer tap seat.

The main disadvantages of axlebox valves with a rubber seal are their short service life and prolonged rotation of the flywheel.

The advantages include such qualities as:

- low cost - depending on the manufacturer and size, the price ranges from 60 to 400 rubles.

- maintainability - very easy to repair

- Possibility to make the rubber gasket yourself

The main reasons for axlebox worm valve leakage:

- wear of the rubber seal

- mechanical damage

- threaded connection failure

With ceramic liner

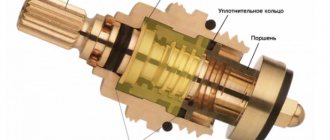

Made of brass and ceramics. Brass is the least susceptible to corrosion. The ceramic faucet axlebox is considered to be very reliable. Let's look at the operating principle:

- The basis of the axlebox crane is a frame with ceramic inserts located inside.

- One of the plates is stationary relative to the other

- The plates have holes, when combined, water flows in

The main disadvantages of ceramic faucet axleboxes are high cost and increased sensitivity to the quality of tap water. Therefore, for faucets with ceramic inserts, it is recommended to install a filter for water purification.

But there are also a number of advantages over worm-mounted crane axle boxes:

- quiet operation

- soft stroke of the faucet valve

- long service life

Let's consider the main reasons for the failure of ceramic faucet axle boxes:

- damage or loss of quality of sealing rubber bands. Even the most expensive faucet axle box uses rubber or silicone seals, which over time can lose their working properties, which will lead to water leakage.

- The ingress of foreign bodies onto ceramic discs can lead to poor sealing. Water will begin to seep into the resulting gap because the tap will not close completely. If the problem is not noticed and corrected in time, the situation will get worse.

- A hole may appear in the rod-body pair. Such malfunctions are very rare and cannot be repaired. Only replacing the axle box valve will help here.

- wear of ceramic plates. This is also a rather rare type of breakdown, and such a crane axle box can only be repaired by purchasing a repair kit.

Selection rules

What should you first of all pay attention to when buying a crane axle box? The ideal option would be to take the old part with you and ask the seller to find you the same one.

If for some reason the seller is unable to help you, pay attention to:

- Length of the body and stem (the difference can be significant);

- Thread pitch (sometimes different);

- Rod head for the flywheel (square or star-shaped).

As for the manufacturer, good crane axle boxes are produced by German, Italian and Russian manufacturers.

Mixer with worm and ceramic valve axle

Major failures of the crane axlebox

How to determine when it’s time to repair a water tap axle box. It's very simple if you notice the following shortcomings:

- the faucet began to leak even with the valve closed

- Water started leaking from under the valve

- The flywheel no longer locks in extreme positions

- the stream of water flows unevenly - “dips” appear

These are general signs of a breakdown, and if you fall under at least one point, then most likely you will be in for repairs. You can repair the faucet and mixer axle box with your own hands, without resorting to the help of specialists. The work is not difficult and even a schoolchild can cope with it.

But before you start, you need to prepare the following tools and materials:

- gas or adjustable wrenches

- fum tape

- special waterproof lubricant

- spanner 17

- knife

- Screwdriver Set

I can’t say right away what materials will be needed, since the cause of the breakdown will only be revealed after disassembling the axle box.

Repair of ceramic crane axle box

Is it possible to repair a ceramic faucet axle box? The answer is yes, although many craftsmen are inclined to believe that it is much easier to change it. But we are not looking for easy ways and will consider step by step how to repair it.

Valve repair

In most cases, the cause of leakage is wear of the sealing gasket. Over time, it loses its working properties and elasticity and must be replaced.

- First you need to remove the faucet valve. To unscrew the locking screw, you will need to remove the plastic decorative plug. This can be done with a knife, carefully picking it up. Removing the flywheel will require some effort.

- Remove the decorative cap - “apron”. To do this, we will use an adjustable wrench, first placing a piece of cloth under it so as not to damage the nickel-plated coating. Often, oxide forms on the threaded connection, preventing normal operation. To make work easier, you can heat the cap with a hair dryer or fill the thread with acetic acid.

It’s not possible to unscrew the axle box valve - read how to do it here.

- After gaining access to the axle box, you need to unscrew it. It unscrews counterclockwise.

- After removing the valve axlebox, it must be thoroughly cleaned of slag and washed. Only after this can you begin repairs.

- If water oozed from under the valve, then the reason was a violation of the rubber seal - the gasket between the body and the valve seat of the axle box.

Replacing it will not be difficult; you won’t have to disassemble the valve axlebox. You can buy a repair kit at any hardware store - for example, in Leroy, its cost is 50 rubles.

IT IS IMPORTANT TO KNOW!

Before replacing the gasket, carefully inspect the seating area on the faucet for signs of cracks or chips. If there are any, you will have to replace the entire faucet.

IT IS IMPORTANT TO KNOW!

If you can’t buy a repair kit or cut the gasket yourself, you can use silicone sealant. Apply a thin layer of sealant to the old gasket and install the valve axle box. This simple technique will temporarily stop the leak, but is not suitable for long-term use.

Replacing the pressure washer

To compensate for the gaps between the ceramic washers, a gasket made of fluoroplastic or caprolon is used. Since it bears a significant portion of the load, it becomes thinner and wears out over time, which immediately leads to water leakage.

- In this case, it is impossible to do without analysis. First, remove the locking half-ring and take out the rod.

- Remove the ceramic inserts and the pressure washer.

- We replace and reassemble in the reverse order, having previously lubricated the surface with a thin layer of grease.

IT IS IMPORTANT TO KNOW!

When reassembling, it is important to correctly install the ceramic inserts with the ground side facing each other and not turn them over.

Cleaning the crane axle box

Tap water contains impurities and foreign bodies that pass through the valve axlebox and settle on the inserts. To remove them you will also need to disassemble them. Then all parts are thoroughly washed. It is also worth carefully inspecting the plates for damage. If they are significant, then it is worth replacing them.

If it is not possible to purchase a repair kit, you can grind the plates yourself. To do this, you need fine abrasive powder, which is used to grind the valves. This powder must be mixed with machine oil and applied to a piece of glass. Then grind the ceramic inserts in a circular motion and assemble the valve axle box. It is also necessary to apply a thin layer of waterproof lubricant.

Damage to metal elements

If the analysis revealed such shortcomings as:

- Chips or cracks on ceramic inserts

- Violation of the integrity of the body of the crane axlebox

- Damage to threaded connections

All these shortcomings cannot be repaired and the valve axlebox assembly will have to be replaced.

Repair of single lever ball mixer

In such a device, the function of a mixing unit is performed by a hollow ball with two inlet and one outlet holes. As in a cartridge faucet, the pressure of hot and cold water is regulated by aligning the holes of the ball and seat.

Replacing the gasket

Replacing the gasket in a ball mixer is carried out as follows:

- It is necessary to remove the lever, as described in the section on ceramic faucets.

- Next, unscrew the screw to gain access to the working part of the device.

- Now you can remove the ball and seals.

- When the new gaskets are installed, the ball returns to its place. After this, the gaskets must be secured with a plastic nut.

All that remains is to reassemble the device in reverse order.

The choice of mixer is carried out taking into account several parameters: appearance, functionality, availability of additional functions. How to choose the right faucet for the kitchen, read on our website.

Read about ways to remove fungus in the bathroom in this material.

How to repair a faucet axle box with a rubber seal

The main reason for axlebox worm valve leakage is wear of the rubber seal. To change it, you need to carry out the steps to remove the axle box described above.

Then you need to unscrew the screw that holds the rubber band and replace it with a new one.

If a new one is not available, you can make it yourself by cutting it out of a piece of rubber.

| Repair of axle box with rubber seal - step by step | |

| We remove the valve axle box, unscrew the screws and dismantle the worn gasket | |

| We install a new rubber band or cut it out of the old rubber. For a better fit into the valve seat, we cut the edge at an angle of 45° to a depth of 2 mm. | |

| We remove the old fum tape, flax or rubber sealing ring from the axle box. | |

| We wind a new seal. | |

| We put the crane axlebox in place | |

Blitz tips

- Ceramic crane axle boxes are quite durable and reliable, but are very sensitive to sand and dirt. Before installing them in your apartment, do not be lazy to install a water filter.

- Ceramics are very durable, but at the same time quite fragile. Closing the tap with too much force can easily break the turn signal.

- When assembling the faucet, clean and lubricate all parts. And lastly, since you’ve already disassembled the faucet, don’t be lazy and replace all the rubber rings. This will significantly extend the life of your mixer, and save yourself time and nerves.