Composition of the executive documentation for the section “Water supply and sewerage” (WK)

1. Register of as-built documentation

2. General work log and special work logs:

- General work log

- Welding work log (SNiP 3.03.01-87)

- Journal of anti-corrosion protection of welded joints

- Incoming quality control log

- Author's supervision journal (to be filled out by the responsible person from the design organization)

- As-built surveys of pipeline laying B1, B2, B4, T3, K1 (with marks)

- Executive diagram of the installation of trenches for sewerage outlets (with calculation of soil volumes)

- Executive diagram of the foundation for sewer outlets

- Laying pipelines under floors

- Thermal insulation of pipelines

- Installation of pipeline systems B1, B2, B4, T3, K1 and fastening to building structures

- Installation of passage of KhGSV pipelines through walls

- Anti-corrosion treatment of pipelines

- Construction of a natural foundation for sewer outlets (underground part)

- Construction of an incompressible base for sewer outlets (underground part)

- Installation of sewerage outlets (underground part)

- Thermal insulation device for sewerage outlets (underground part)

- Backfilling of storm sewer outlets (underground part)

- Installation of brackets for fastening fire water supply pipelines to the metal structures of the building frame

- Anti-corrosion protection of welded joints of fire-fighting water supply pipelines

- Installation of fire hydrants included

- Sealing of pipe passages through external walls

- Installation of treatment plants

5.Acceptance and testing certificates:

- Act on the flushing and disinfection of pipelines of KhGSV (with conclusion)

- Report of hydrostatic or manometric leak testing of pipelines B1, B2, B4, T4, K1

- Test report for the internal sewerage system and spillage drains

- Test report for internal fire water supply for water loss

- Certificates of individual testing of equipment (pumps, water heaters, etc.)

- Certificate of acceptance of the system and releases of internal sewerage

- Certificate of inspection of engineering support networks

- Water meter inspection report

- Certificate of completion of installation work

6. Welders’ certificates, welders’ certification protocols

7. Passports, quality certificates, fire certificates, sanitary and hygienic certificates for building materials, products and structures. For all building materials, products, structures and equipment arriving at the construction site, an incoming inspection report must be drawn up and then signed by the responsible persons.

8. A set of working drawings for the construction of the facility presented for acceptance, developed by design organizations, with inscriptions on the compliance of the work performed in kind with these drawings or changes made to them made by the persons responsible for the construction and installation work, agreed with the authors of the project.

9. Documents on approval of deviations from the project during construction

- Installation organization information sheet

- SRO of the installation organization

- Orders for responsible representatives

- Personnel certificates (welders, electrical personnel, etc.)

- Detailed documentation with the Customer’s stamp “In production of work”

- Work production project (title page and familiarization sheet)

*The presented composition of the executive documentation is approximate. Please check with the customer for the exact composition of the as-built documentation.

Work acceptance procedure

When accepting such work, the tests themselves are carried out first, which can be:

- Hydraulic - only non-pressure drainage systems are exposed to them, be it wastewater pipelines or storm sewers. testing is carried out in areas between wells by filling the system with process water. The tests are carried out in two stages - checking pipes and connections before filling the soil and checking the performance of the entire sewer system after filling the soil. Tests are carried out by pumping water into wells or receiving grids for 30 minutes; during the tests, the performance of the system is measured and the tightness of seams and joints is monitored. Tests may also be performed to determine the ability of pipes and connections to withstand the maximum allowable pressure throughout the entire drain.

- Pneumatic - during such tests, the ability of the waste system to withstand the design pressure is checked, according to GOST standards or design documentation. For such a series of studies, specialized organizations with the necessary equipment and licenses are involved; the process itself includes checking the pressure in the system or in its individual sections when supplying air under pressure.

If during the experiments the entire system met the standard indicators of SNIP 3.05.04-85, then an acceptance certificate for the work performed is drawn up, otherwise a defective statement and a drainage troubleshooting report are drawn up.

During periodic monitoring at enterprises with drinking water pipelines, external drainage systems are also tested during disinfection or treatment with special reagents.

Composition of as-built documentation for external water supply and sewerage networks

A19. List of contents of the executive order for the object: “Installation of external water supply and sewerage networks.”

A19.1 Download the general work log.

A19.2 Download the welding work log.

A19.3 Author's supervision journal download.

A19.4 Download incoming quality control log.

A19.5 Download the act for laying out the route with the executive layout diagram.

A19.6 Executive diagram of the trench for laying pipelines.

A19.7 As-built survey of the plan and longitudinal profile of underground networks download.

A19.8 Download diagram of welded joints with distances indicated on it.

A19.9 Conclusion on the quality of welds from the pump.

A19.10 Download the report on hydraulic testing of the pressure pipeline for strength and tightness.

A19.11 Download the report on conducting a hydraulic test of a gravity pipeline for leaks.

A19.12 Download the pipeline flushing (disinfection) report.

A19.13 Conclusion of the sanitary-epidemiological service.

A19.14 Download the test report for the external fire-fighting water supply system for water yield and operability of fire hydrants.

A19.15 Certificate for checking the laying of non-pressure pipelines by looking at the light.

A19.16 Download the certificate of inspection of engineering support networks.

A19.17 Download the act of hidden work for the development of a trench for laying pipelines.

A19.18 Download the act of hidden work to prepare the foundation for pipelines.

A19.19 Download the act of hidden work for laying pipelines.

A19.20 Act of hidden work on pipeline insulation download form.

A19.21 Act of hidden work on the construction of wells and cameras download.

A19.22 Download the act of hidden work for backfilling.

A19.23 Download the act of hidden work for inspection and testing of fittings.

A19.24 Act of hidden work to seal passages through the walls of wells and chambers.

A19.25 Certificates of certification of welding technology, welding equipment, welding materials.

A19.26 Documents on certification of the laboratory for quality control of welded joints.

A19.27 Certificates and certification protocols for welders.

A19.28 Certificates and passports for the materials and equipment used, sanitary and epidemiological reports, fire safety certificates (can be downloaded here).

A19.29 A set of working drawings for the construction of an object presented for acceptance, developed by design organizations, with inscriptions on the compliance of the work performed in kind with these drawings or changes made to them made by the persons responsible for the construction and installation work, agreed with the authors of the project.

See executive examples in the section: “Executive Examples”

See the composition of the executive in the section: “Composition of the executive”

Download acts, protocols and more in the section: “Acts and other”

Download useful books, GOSTs, SNIPs in the section: “GOSTs and books“

in Ivanovo

About the company+7 Pumping out sludge, cleaning car washes, pumping out wells, septic tanks and cesspools.

21 May '19

Guarantee of the best price for new MTKs in stock* Economy from RUB 14,000.

(incl. VAT) | Standard from 17,000 rub. (including VAT) Rental of dry toilets Short-term and long-term rental of dry toilet cabins Liquids for dry closets Universal environmentally friendly products for dry closets Sewage pumping Pumping of septic tanks and toilets, removal of reinforced waste by sewage truck from 800 rubles Any type of rental and maintenance of toilet cabins in Ivanovo and region B The cost of short-term rental includes: delivery and installation, unloading and loading, special refueling. liquid and toilet paper, waste removal for disposal.

from 13,900 rubles Sale of mobile toilet cabins in Ivanovo and Ivanovo region Sale of mobile toilet cabins with delivery and the possibility of further maintenance, as well as sale of shower cabins and portable washbasins.

from 300 rubles Portable dry toilets and consumables for them Portable dry closets for country holidays, as well as a wide range of consumables

from 400 rubles per 1 m3 Sewage disposal: pumping out cesspools, septic tanks and settling tanks We have a license for the collection and transportation of liquid household and industrial waste of hazard class 4, we enter into contracts with organizations for the removal and disposal of solid waste.

RUR 15,000/month Autonomous wheel washers for construction sites The installation allows for recycling water supply for wheel washing without polluting the natural environment and does not require connection to a water supply.

Laying water supply and sewerage

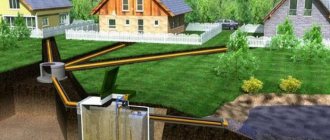

The DVN-Stroy company carries out complex installation of water supply and sewerage networks on a turnkey basis, with the transfer of water supply or sewerage networks to the balance of the operating organization. We carry out work for cottages, multi-storey residential buildings, industrial and public buildings and structures.

The work includes the following construction stages:

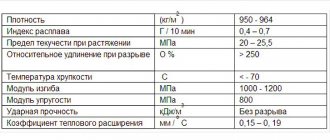

- Excavation work, foundation installation, pipe laying (HDPE, PVC, steel, cast iron, reinforced concrete pipes, corsis, pragma), backfilling of trenches and pits with layer-by-layer compaction;

- Laying water pipelines using the trenchless method, including HDD drilling, punching steel casings, and auger drilling;

- Installation of prefabricated reinforced concrete wells and monolithic chambers;

- Filling of sewerage trays;

- Installation of fire hydrants, valves, PFRK, transitions, bends and other shut-off valves;

- Welding of HDPE pipes using the butt method and electric couplings;

- Carrying out pressure and non-pressure testing of pipelines, flushing water supply systems;

- Insertion into existing water supply and sewerage networks;

- Restoration of landscaping.

- Delivery of the package of executive documentation.

How to properly detect apartment flooding

It is not always the neighbors above who are at fault.

There are situations when the riser bursts between apartments, i.e., in the ceiling. Here the management company on whose balance sheet the house is located is considered guilty. To sue her, you will need to collect as much evidence as possible. So, in addition to the drawn up act, it is recommended to take photos and videos. It is recommended to record the fact of flooding on the same day. The maximum time you can invite the commission is the day after the flooding. Remember, the sooner this is done, the better for the injured party. But there are situations when the management company does not provide the appropriate commission. There may be several reasons for this. For example, there simply aren’t enough employees. Or this is done deliberately, because after a few days traces of flooding may be insignificant. In such a situation, it is necessary to conduct video and photo recording, and draw up a report yourself, having previously invited several witnesses.

There are situations when a neighbor admits his guilt and is ready to fully compensate for the damage. It would seem that in this case there is no need to draw up an act. But you need to understand that in a few days the neighbor may refuse his promises, but there will be no document drawn up. Lawyers recommend filing a home flood report in any case. Even if the culprit is ready to compensate for the damage, he must put his signature on the act. Now he will know that if he delays with compensation for damage, the victim may go to court.

Pre-trial proceedings often lead to a dead end, and the victim still has to contact the relevant authorities. Usually, if the amount of damage does not exceed 30 thousand rubles, the case is heard in the magistrate's court. You will have to resort to the services of a federal court in cases where damage in the amount of more than 30 thousand rubles has been caused.

If the injured party expects to receive compensation for material damage, drawing up this act is mandatory. This also applies to cases where flooding was not immediately detected. For example, the owner of the home was on vacation, returning from which he discovered signs of flooding. In this case, the damage should be immediately recorded by drawing up an appropriate report.

( Video : “Everything about the Bay Act. How to get the correct act?”)

Requirements for laying water supply and sewerage systems.

The laying of water supply and sewerage is carried out in strict accordance with the work project and technological maps after checking the compliance of the trench dimensions with the design, the fastening of the walls, and the marks of the bottom of the trench. The results of inspections are recorded in the work log.

Socket-type pipes are laid with the socket up the slope. The straightness of sections of free-flow pipelines between adjacent wells is controlled by looking “up to the light” using a mirror before backfilling and after backfilling the trench. If the pipe is laid correctly, the circle visible in the mirror has the correct shape. The acceptable horizontal deviation from the circle shape should be no more than 25% of the pipe diameter; vertical deviations are not allowed.

Deviations from the design position of the axes of pressure pipelines should not exceed +-100mm in plan, marks of trays of non-pressure pipelines +-5mm, and marks of the top of pressure pipelines +-30mm.

Laying polyethylene pressure water pipes along a flat curve without the use of bends is allowed for socket pipes with a rotation angle at each joint of no more than 2 degrees. for pipes with a diameter of up to 600mm.

Flange connections of various fittings and shut-off valves are installed in compliance with the following requirements: flange connections must be installed perpendicular to the axis of the pipe, the planes of the connected flanges must be smooth, the bolts are tightened evenly crosswise.

Methods for testing sections of internal sewerage

What and how is checked when checking the compliance of the internal network with the project and established standards is described in SNiP “Sewerage. Internal and external networks and structures." According to this fundamental construction document, the following parameters of the sewer system are subject to inspection inside the building and then reflected in the final document (inspection report):

- testing network pipes for strength and their connections for tightness;

- compliance of the location of installed instruments and elements of the outlet pipeline with the design documentation;

- correct installation of plumbing fixtures in relation to the floor surface (the distance from the floor to the upper edge of the receiver of each plumbing fixture is specified in the above-mentioned SNiP);

- the presence of a slope in the horizontal sections of the pipe and the degree of verticality of the risers.

Testing of pipes and connections for leaks in a gravity system, regardless of the material of the pipeline and fittings, is carried out using the spill method. The essence of the technique is that part of the main pipeline (bed) is fenced off in a certain area from the rest of the system. This is done with special plugs through inspection holes. The separated area is checked by filling it with water through the pipes of plumbing fixtures. According to SNiP, the results of a spill deserve attention if the pipeline was filled with the participation of at least ¾ (or 75%) of all devices connected in a given isolated section. Testing of the pipeline using the spill method is considered positive if the connections after filling the system did not give the slightest leak within 10-15 minutes (depending on the volume of the area filled with water).

According to the regulatory documentation, a spill, that is, testing a sewer system by filling it with water, is informative when the air t˚ is above 5˚. If the temperature is lower, a pneumatic leak test of pipes and connections is carried out (compressed air). The integrity of the riser, sometimes of external sections of the pipeline, is also determined by air. We will use the pneumatic testing method to assess the performance of a pressure sewerage system, when wastewater is forced out, under pressure created by pumping equipment.

The location of installed plumbing fixtures and its compliance with project documentation is determined visually. The height of the receiver of each device, the correct connection of the toilet drain, siphons of the washbasin, bathtub, sink, etc. are objectively assessed and reflected in the report. The condition of the plumbing fixtures themselves is also visually assessed. They must be free of visible dirt and mechanical damage.

The correct slope of the pipes inside and outside the building is controlled using a building bubble level. If the slope of the internal sewer network is allowed to be at least 1 cm per linear meter, then on the outside this figure must be increased to 2 cm per meter.

The installation position of the riser (this data is also reflected in the final report) is checked with a plumb line. A deviation from the vertical of 3˚ is allowed. A water tightness test of the riser is also carried out. The pressure should be about 0.8 MPa.

Filling out a report on hidden work in the sewer system

After the free-flow sewer system and water supply system have been completely installed and have been tested for sealing by pouring the system, it is also necessary to inspect the communications before closing the entire system. Such work is called hidden and is carried out inside the sewer network. The documented inspection is certified through an inspection report of the sewer pipes before closing.

Such a test (research) is carried out for external pipelines of water supply and free-flow sewerage in order to identify the slightest defects that could ultimately lead to depressurization of the sewerage system and subsequent environmental disaster on a district/city/region scale.

Important: an inspection of the sewerage/water supply system for the purpose of its final commissioning must be carried out as part of a full commission. About who should participate in the inspection and how exactly the sewer network inspection report is filled out, see our material below.

For a detailed explanation, attached is a sample form for an inspection report of the wastewater system after a major pipeline spill to identify violations in the sealing of the system.

Verification stages

To identify defects in the operation of the sewerage system, a series of tests are carried out, which includes:

- Checking the operation of the internal part of the communication using the spill method;

- Full check of the tightness of all pipeline joints along its entire length;

- Identification of possible defects in the operation of all sewerage wells (inspection, rotary, inspection, etc.);

- Storm sewer testing.

Stages of filling out the act

The document form must be filled out strictly according to the form without deviations from the standards. Only in this case will the document be considered legally valid.

The header of the document on sealing the free-flow sewage network must be filled out in accordance with the available columns. That is, information about the city in which the inspection of the external and internal networks of the collector is being carried out, the name of the ministry and trust, the name of the customer organization and the contractor organization (the latter is fully responsible for the tightness of the collector) is entered. Also in the header of the study document it is worth indicating the date of inspection of sewer networks before putting them into operation.

Important: a hidden inspection of pipeline tightness is carried out only after testing the system using the spill method.

Sample report on sewer clearance. Persons - members of the commission

After completing the installation work of internal sewerage systems and drains, the installation organization must carry out their tests and draw up a report in accordance with Appendix “D” “Internal sanitary systems of the building” (updated edition of SNiP 3.05.01-85). These tests must be carried out by pouring water by simultaneously opening 75% of the sanitary fixtures connected to the area being tested. The test method gives rise to the “everyday” name of the act – sewer spill act or sewer spill act.

However, the name of the act, according to the regulatory documentation, is the following: act of testing internal sewerage and drainage systems. We have figured out the correct name of the act and its purpose.

Now let’s take a closer look at the form of the test report for internal sewerage and drainage systems and the method of filling it. First, fill in the name of the system on which the tests were carried out.

We take the name of the system from the design documentation.

For example, this could be “domestic sewerage K1”. Next, you need to fill in the name of the capital construction project.

There is nothing complicated here. We take information about the name from the design documentation or construction permit. After this, we enter information about the city in which the capital construction project is located and the date of the tests.

The block in which data about the commission that conducted the tests is entered includes the following information: the name of the customer’s organizations, the general contractor, the installation (construction) organization, as well as the positions, initials and surnames of representatives of these organizations. In paragraph 1 of the test report for internal sewerage and drainage systems, data (name) is entered on the design organization, design documentation code, drawing numbers in accordance with which installation work was performed.

In paragraph 2 we indicate the number of simultaneously open sanitary fixtures and the time during which the tests were carried out. Sanitary fixtures include bathtubs, washbasins, shower trays, drains, bidets, toilets, closet bowls, urinals, sinks, sinks, and drains.

Further filling out the act

Following the header, the research (test) document contains data on the members of the commission participating in the inspection of the integrity of the pressure-free communication. Here it is necessary to indicate the positions of each of the commission members, as well as their initials and surnames.

The members of the commission should be:

- Representative from the customer organization;

- A person representing the contractor organization;

- Representative of a government organization from RosTechnadzor.

All persons listed in the document must sign.

After the information about the members of the commission has been indicated, it is necessary to enter reliable information about the properties and features of the sewer network at the time of the work. Information is taken from project documentation and written down on paper without any distortion.

Important data are:

- Total pipeline length;

- The material from which the internal and external pipelines are laid;

- Place of installation of the sewer system.

The next section of the act is the “Inspection Result”, divided into paragraphs.

- In paragraph 1, enter information that a visual inspection of the sewer pipes confirms/does not confirm (select the appropriate one) the compliance of the installation of the collector pipes with the existing drawing number such and such. The drawing number is taken from the design documentation.

- In paragraph 2, enter data on the absence or presence of deviations of the installed system from the existing design drawings as a result of installation and after testing the collector using the spill method. If there are deviations after the trial work, it is necessary to indicate with whom the actions to change the sewer network design were agreed upon and the number of the new drawing according to which changes were made in the communication project.

- Point 3 contains data on the method of connecting sewer pipes into a single system between themselves and wells.

- In paragraph 4 it is necessary to indicate data on the results obtained after the examination. If the system and all wells do not have any damage or visible defects, then information is entered into the research form that the sewer system has an optimal bending radius of the pipeline in the required places. There were also no dents, creases, damage or leaks in the pipeline and wells.

Testing of external sewer network

Testing of external sewerage is also carried out in most cases using a hydraulic method. The check includes:

- testing the pipeline for leaks (carried out as described above. For testing, sections of pipes located between wells or other elements of the system are taken);

- checking the pipeline slope level;

- testing of wells and other equipment;

- checking the performance of storm drains.

A level is used to check the level of pipe laying required for a gravity sewer system.

If a pressure sewer test is being carried out, then water must be supplied to the pipeline system at the pressure specified in the design documents.

The test of pressure sewerage pipelines is considered successful if the pressure value in the flow into the network and at the exit from it is the same.

Well inspection

Leak testing of wells is carried out in various ways, depending on the equipped waterproofing:

- if the well has internal insulation, then the test consists of determining the volume of leakage;

- if the well is equipped with external insulation, then to check it is necessary to determine the level of liquid inflow.

In both cases, to test a well it is necessary to fill it with water to a certain level.

Testing of other devices included in the external sewage system (for example, septic tanks) is carried out in a similar way.

Storm drain inspection

To check the functionality and tightness of storm drains you need:

- install a plug at the wastewater outlet;

- fill the system with clean water to the maximum level (this includes drainage systems installed around the perimeter of the roof and drains);

- wait at least 10 minutes for metal pipes and at least 20 minutes for plastic pipes.

If, as a result of the check, the water level in the system has not decreased, then it can be put into operation.

Plastic pipes can only be checked after 24 hours have passed after the last joint has been sealed.

Testing the sewer network is a mandatory procedure carried out before its operation. Carrying out an inspection allows you to detect all construction defects in a timely manner and correct them in a timely manner. It is recommended that all work on checking the system be carried out before the final finishing of the house and digging of trenches for the outer part of the system.

After installing the sewer system, before moving on to finishing work inside and backfilling trenches outside, the drainage network must be tested to ensure the tightness of the nodes, pipelines and their connections. The external system and internal network are checked in various ways, regulated by the fundamental document of builders - SNiP. How to test the tightness of pipes and sewer connections by pouring, filling, and other methods, and what data is entered, if necessary, into the inspection report, you will learn by reading the article.