Any work performed with an open flame is especially dangerous, and gas welding is no exception. In addition, this welding method has another danger factor, since the work uses acetylene and oxygen - gases that are classified as explosive.

Safety precautions for gas welding include a set of rules, the implementation of which can significantly protect the work of a gas welder. These rules concern both the behavior of the welder during work and the organization of the workspace, tools and equipment used.

Safety precautions for gas welding

Welding safety precautions contain answers on how to act in certain situations, as well as a list of restrictions and prohibitions when working with gas welding. Safety precautions for gas welding are designed to protect the welder and surrounding people from injury, and will help avoid accidents and destruction.

The welder must follow safety rules when performing work and wear personal protective equipment: overalls, gloves and a mask. Robes and mittens (gaiters) protect not only from splashes of molten metal, but also from thermal and ultraviolet radiation. The welding mask protects the eyes from retinal burns, which lead to loss of vision. It also protects the face and neck from ultraviolet radiation, infrared light and metal splashes.

Preparatory activities before starting work

Fire extinguishing means must be present during welding work. It is prohibited to use steel tools to service gas generators as they may cause a spark. For this, a safe non-sparking tool (copper-plated) is used.

Before starting welding in enclosed spaces, containers and reservoirs, it is necessary to ventilate to remove the accumulation of gases.

Before starting welding, you need to check the equipment:

- strength and tightness of connecting hoses to gearboxes and burner;

- the integrity of the hoses, the condition of the burner and the serviceability of the gearbox;

- connection density and water level in the seal;

- serviceability of pressure gauges.

The preparation and operation of the generator must be carried out by an authorized and qualified person. The following conditions must be met:

- maximum one-time loading of carbide is no more than 4 kg;

- a maximum of 2 burners can be used if there is a separate water seal for each;

- the total power of the burners should not be more than 2000 l/h;

- the room where the work is carried out must be ventilated and have a volume of at least 300 m3;

- the generator with acetylene must be located no closer than 10 m from open sources of fire and the welding site;

- It is strictly prohibited to install a portable generator in boiler rooms, forges and rooms with elevated temperatures. The generator and cylinder are installed outdoors, and gas is supplied to the welding site through hoses;

- >it is prohibited to install the generator near fans and air intakes;

- Warning signs must be posted near the installed generator: “Flammable”, etc.

Cylinders and generators must be painted a certain color, the oxygen cylinder and reducer must be painted blue, the acetylene generator or cylinder must be painted white. Additionally, the acetylene cylinder must have a red inscription “Acetylene”.

Hose requirements

The standard length of hoses should be no more than 20 m, but for installation work it is allowed to use hoses up to 40 m long. It is prohibited to connect tees, plugs and other devices to the hoses to power several burners. The hoses used must not have any defects. It is allowed to join hoses up to 3 m long. The hoses must be tightly secured to the nipples of the reducer and burner using tie wire or clamps.

Do not interchange oxygen hoses with acetylene hoses. Do not bend or flatten hoses when laying or storing them. Under no circumstances should there be any traces of oil on the hoses, as this will lead to oxygen detonation.

Requirements for generators

The acetylene generator must be installed in such a way as to avoid falls, shocks and shocks. The water seal must be in a vertical position and in good working order. Using generators without a water seal is strictly prohibited.

When using generators outdoors or indoors at temperatures below 0°C, it is necessary to prevent water from freezing. If the equipment is frozen: a generator, a water seal or a hose, it is necessary to warm them up in a warm room. It should not be heated by open fire sources and should not be located closer than 10 m to the fire source. It is recommended to warm up with hot water (steam).

It is strictly prohibited to use carbide of smaller granulation than specified in the generator data sheet, as excessive gas emissions may occur. Before loading, it is necessary to screen and remove fine fractions and carbide dust. Carbide may only be loaded into the basket and under no circumstances should it be loaded into the retort.

Requirements for cylinders

After removing the metal cap from the cylinders, you must immediately check the fitting and valve for serviceability or mechanical damage. If the cap cannot be removed, then it is strictly forbidden to unscrew it using an impact tool (hammer, chisel), this can lead to a spark and detonation.

Before connecting the gearbox, you should inspect the fitting and nut for damage, make sure that the threads are in good condition and that there is no oil or grease. Before connecting, the fitting must be purged by opening the valve a quarter turn for a short time. When opening the valve, you need to be careful so that the stream does not hit people. It is prohibited to use a gearbox with damaged threads or faulty pressure gauges (pressure gauges that have expired and have not been tested).

It is strictly forbidden to repair or disassemble cylinder valves yourself; for this there are special services and stations that carry out repairs and replacements.

The cylinders are installed either vertically or on special racks, to which they are firmly attached with clamps and chains, protecting them from falling. Cylinders should not be brought closer than one meter to heating devices and closer than 5 meters to a source of open fire, especially welding. Cylinders and hoses must not come into contact with live wires.

Welding safety precautions

During operation, the cylinder and the generator must be separated by a distance of at least 5 meters. Hoses must be suspended during operation to avoid damage. If gas welding is carried out in a room where other people are working, then protection should be placed around the perimeter. Before igniting the burner, the oxygen valve is opened slightly, then the acetylene valve, and after purging the hoses, the combustible mixture is ignited. Do not operate the burner with contaminated channels; this will lead to popping noises and backfires.

It is strictly forbidden to touch the torch or gearbox with oily hands and completely avoid contact of the welding equipment with oil, as it can provoke detonation. If a backfire occurs, you must immediately close the valves on the cutter, cylinders and water seal. The rate at which fire spreads through the hoses is low, and if this is done instantly, an explosion can be avoided.

To avoid kickback during welding, the following must not be allowed:

- a sharp decrease in oxygen pressure, which occurs when the oxygen in the cylinder runs out, the reducer freezes, the injector becomes clogged, etc.;

- bring the working mouthpiece closer to the object (reduces the rate of gas flow);

- excessive heating of the mouthpiece and cutter pipes;

- clogging of the mouthpiece (the flow area decreases and the gas flow rate drops sharply).

If the working torch overheats, then welding work should be stopped and cooled in a vessel with water. Do not empty the acetylene generator until it is completely empty, as this may lead to backfire.

While operating the generator, it is prohibited to:

- load carbide into wet containers;

- exceed the pressure more than indicated in the passport;

- turn off the regulator (in those models where it is);

- use boot devices that are faulty.

During operation, you need to ensure that there are no gas leaks from taps or plugs; this can be determined using a soap solution.

Welding of containers and pipelines under pressure is prohibited. Welding of containers, pipelines containing flammable materials, acids is carried out only after complete cleaning, washing and steaming with open hatches and covers.

During a technical break, the valves on the burner are tightly closed, and during a long break, the valves on the cylinders are also closed. In summer, cylinders should be protected from direct sunlight.

Completion of work

Extinguishing the burner is carried out in the following sequence: close the acetylene valve then the oxygen valve. After completing the welding work, be sure to close the valve on the oxygen cylinder and remove the reducer. The retort on the generator must be unloaded. If the carbide has not cooled down, the retort cannot be opened until it cools completely.

Then you need to clean the generator and rinse the housing with water. For cleaning, you can use a brass, aluminum scraper or hair brush. After completing all work, it is necessary to thoroughly ventilate the room in which the generator was located.

Fire safety requirements

The minimum distance of the generator from the place of welding work and the fire source is 10 m. If the hose catches fire, bend it on the side of the gearbox or generator and immediately close all the valves. The gas welding station must be equipped with individual fire extinguishing equipment. Acetylene can only be extinguished with a carbon dioxide fire extinguisher (dry sand); extinguishing with water is strictly prohibited.

Share with your friends

0

0

0

0

svarkalegko.com

Safety precautions for gas welding

Carrying out welding work most often involves a high level of danger to humans. To avoid unpleasant consequences and preserve your own health and even life, you must follow the safety rules for welding work.

The work of a welder is associated with the risk of various injuries: mechanical damage, thermal and radiation burns, poisoning by metal vapors and gases. Burns are the most common injury among welders. Read on to learn how to prevent injury and how to provide first aid for burns.

Learning the basics of welding begins with becoming familiar with the electrical safety requirements for a welder. The acquired knowledge should not only be remembered, but also applied in everyday work. According to statistics, the majority of injuries occur to beginners, as well as to fairly experienced welders who neglect safety requirements.

stalevarim.ru

Important prohibitions

Safety regulations for manual arc welding prohibit continuing to work with a broken protective helmet and with small gaps in the mask or cracks in the glass.

Do not weld with the exhaust system turned off or faulty, or continue welding in the open during rain and snow.

When welding and cutting, you should not work with a loose part, especially one that is hanging and held by hand. For safety reasons, it is prohibited to cook in places where there are flammable liquids or gases. Do not weld pipelines under pressure or use thick steel parts for grounding.

It is prohibited to hold a closed electrode or holder on metal for a long time. At a minimum, this will lead to breakdown of the ballast that regulates the welding current.

What safety precautions are acceptable when gas welding?

- Date: 08/15/2015

- Rating: 16

Potentially hazardous welding work requires compliance with certain safety precautions. They include a list of special events, working conditions for the welder, preparation of equipment and the premises itself for work. Safety precautions in this case are mandatory. The rules cannot be neglected, as this can lead to accidents.

Welding work can only be carried out in special clothing impregnated with fire-resistant compounds.

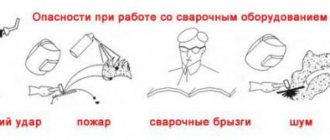

Risks during welding work

Various dangerous situations may arise in the welding area during work.

Proper transportation of gas cylinders.

- Increased fire hazard of work, since you have to deal with high temperatures, sparks and splashes of molten metal. Not only must all surfaces be protected, but special protective clothing, gloves and a tinted face mask must be used.

- Risk of explosion of cylinders with gas mixtures. Welding work is often carried out using gas mixtures that are easily flammable. Therefore, they must be stored and used carefully, in full accordance with the requirements for a particular type.

- There is a high risk of injury during welding. This is due to poorly reinforced workpieces and pipes.

- During welding, harmful fumes are released that have a negative effect on humans. It is necessary to use a special mask and use respirators.

- Welding work is harmful to the eyes, so when using equipment, you must use a special mask with glass that has a different darkening index. Under no circumstances should you start welding without such a mask. This applies not only to the sparks that occur during operation, but also to the fact that a high-temperature arc can literally blind. Therefore, a mask is one of the main and basic elements of protection for a welder.

- Burns may occur during operation. Most often this happens when workpieces or welding machines are handled incorrectly, or when sparks and splashes get on your hands. To prevent this, it is necessary to strengthen all workpieces firmly and reliably, and use special thick gloves for your hands.

Recommended filters for gas welding.

Safety precautions when welding are the most important part of the process; work cannot begin without it, since welding work is potentially dangerous not only for the operator, but also for others.

Safety precautions should include the following points:

Acetylene generator safety devices.

- Working with acetylene generators. It is quite dangerous for a number of reasons. Overheating of calcium carbide and acetylene is possible. If the water seal is faulty, backlash of flames may occur. Therefore, heat sources must not be installed near such generators, smoking or welding must not be carried out, as sparks can cause ignition.

- Safety precautions also regulate the procedure for carrying out work and preparing premises and sites. Work is carried out only on the first floors; for premises above or below this level it is necessary to obtain permission and arrange the site in accordance with safety requirements. It is necessary to ensure constant ventilation and not to carry out work near boiler rooms and hot shops during their operation.

- Gas welding places strict requirements on the use and storage of cylinders. It is worth considering which mixtures will be used and at what temperature the welding is carried out.

- Calcium carbide and other substances necessary during operation should be stored only in sealed and dry containers. Safety precautions require transportation only on special trolleys; shaking is not allowed. In warehouses, such substances must be stored at a distance of 10 m from the walls. The walls themselves should not be lined with flammable materials.

Special fire measures

To ensure safety during welding work, the following measures must be taken:

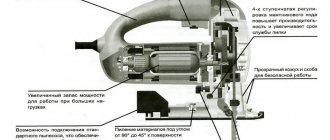

Burner ignition order.

- All areas where work is carried out and workshops should be located only on the first floors and specially equipped areas. All premises must be equipped in such a way that they fully comply with group G for fire safety and have a II degree in fire resistance of finishing and building materials. Floors are made fireproof, they should not conduct heat, and be easy to clean.

- All wooden partitions, walls and other surfaces that will be located 5 cm from the welding station must be sheathed with asbestos sheets or plastered. Sheet iron is well suited for this, under which felt is stuffed, previously generously soaked in a clay solution.

- It is prohibited to store flammable materials on sites and in rooms where welding work will be carried out. Safety precautions state that tow, kerosene, gasoline, gas and oxygen cylinders, wood scraps, oily rags, etc. should be stored in specially designated places.

- According to welding safety precautions, it is forbidden to lay live cables and wires from equipment together with pipelines and hoses that supply gas.

- A fire fighting station must be equipped at work sites. The operator of welding equipment must be familiar with the rules for using fire-fighting tools, be able to extinguish the flame and prevent its spread.

- If welding work is carried out approximately 5 m from flammable or wooden walls and partitions, then safety precautions require their protection. For this, any shields made of non-flammable materials are used, which provide excellent protection against sparks and splashes of molten metal. The floor is protected from a layer of sand, which is abundantly wetted with water.

- If welding work is carried out above or below the level of the first floor, then all gas supply must be carried out in compliance with safety provisions. What matters is the length of all supplied pipelines, which cannot be more than 40 m. Only special rubber-fabric hoses, which are produced for welding machines, should be used for the connections.

- If work is carried out at a level of more than 10 m, then it is necessary to deliver the acetylene generator to the work site. This requires obtaining special permission from the fire inspectorate and the construction manager.

When performing gas welding, it is necessary to check that there are no influxes of flammable gases, materials, or substances near the site. The order of work must be entered in a special journal.

Safety precautions for welding work have a number of requirements:

Protective equipment used when performing welding work.

- Buildings where work is carried out should, if possible, be one-story, constructed of non-combustible and lightweight materials. This requirement is mandatory for equipment of permanent operating points.

- For external walls, cinder blocks, concrete, and brick are used.

- Floor coverings should be made of concrete or asphalt. For an intermediate warehouse, the floor level should be approximately 15 cm higher compared to the generator room.

- Inside the room where work is being carried out, it is forbidden to install open electrical wiring networks or install electrical equipment that could be potentially dangerous.

- When carrying out gas welding, it is necessary to provide only natural ventilation in the premises. No other measures can be taken.

- Heating must be central water or steam, which in the cold winter months can provide the room with a temperature of at least + 5°C.

- You cannot carry out work closer than 10 m from the building, work that involves fire. Smoking, matches and lighters are not allowed in the premises, as this can lead to accidents.

https://moyasvarka.ru/youtu.be/LVKx31I-cB8

Safety precautions during welding are an important part of work that is considered potentially dangerous. Before the operator is allowed to use the welding machine, he is familiarized with the safety rules. This is the only way to start welding, otherwise the welder should not be allowed to work.

moyasvarka.ru

Working with electrical equipment

Electrical safety during welding requires the use of only serviceable and grounded equipment. Under this condition, electric shock to a person is completely excluded.

Safety regulations require that lighting fixtures be powered from 12 V, but in practice this is rarely done. The workers are completely dependent on the production owners and follow their orders, not safety regulations.

Despite this, knowing the basic requirements to ensure personal safety is useful in any situation. All equipment must operate at no-load voltage of no more than 90 V.

The lethal voltage is slightly higher - 110 V. A current strength of more than 5 hundredths of an Ampere can cause electrical injury and death.

The following safety rules can help protect against electric shock:

- All electrical appliances must have reliable and high-quality grounding and grounding. They are made of copper conductor with a sufficient cross-section;

- safety precautions require connecting welding equipment through an electrical panel to a separate circuit breaker and RCD device;

- the length of the wires for connecting welding equipment should not exceed 10 m. If there is a need to splice the wire at the break point, the connection must be made using a special coupling. It is better to hang the wires at a height of more than 2.5 m, and consumers need to lower them through a grounded steel pipe. All wiring locations must be equipped with special rubber couplings.

- When welding on the street or in the field, safety precautions recommend installing the welding machine under canopies or in covered pavilions. Work stops in case of heavy rain or snowfall;

- All cables and wires must have proper insulation. In case of significant damage and twists, the instructions require replacing the welding cable.

By taking safety measures in a timely manner when performing electric welding work, you can completely protect yourself and others from electric shock.

Safety precautions for gas welding

Any work performed with an open flame is especially dangerous, and gas welding is no exception. In addition, this welding method has another danger factor, since the work uses acetylene and oxygen - gases that are classified as explosive.

Safety precautions for gas welding include a set of rules, the implementation of which can significantly protect the work of a gas welder. These rules concern both the behavior of the welder during work and the organization of the workspace, tools and equipment used.

Harmful production factors

The main sources of danger during gas welding and cutting can be:

- explosions of acetylene generators from the backlash of the flame if the water seal does not work (you need to ensure that the water seal is always filled with water to the proper level, and periodically check it by opening the control valve of the seal);

- explosions of oxygen cylinders at the moment of their opening, if there is oil on the cylinder fitting or on the reducer valve;

- careless handling of the burner flame; the flame can cause hair and clothing to catch fire, a welder’s burn, and a fire in the room;

- eye burns if welders do not use light filters (when cutting, welding and other gas-flame processing processes, welders must work in safety glasses with glasses G-1, G-2 and G-3, and auxiliary workers - with glasses V-1, V-2 and V-3, where glasses G-3 and V-3 are the darkest);

- poisoning by accumulated harmful gases in the absence of exchange ventilation in the room. When performing gas-flame work inside compartments, pits and tanks where accumulation of harmful gases is possible, supply and exhaust fans must operate.

Preparatory activities before starting work

Attention! Gas welding work can only be performed by adults who are proficient in gas welding technology, i.e. have undergone special theoretical and practical training

The welder must follow safety rules when performing work and wear personal protective equipment: overalls, gloves and a mask. Robes and mittens (gaiters) protect not only from splashes of molten metal, but also from thermal and ultraviolet radiation. The welding mask protects the eyes from retinal burns, which lead to loss of vision. It also protects the face and neck from ultraviolet radiation, infrared light and metal splashes.

Fire extinguishing means must be present during welding work. It is prohibited to use steel tools to service gas generators as they may cause a spark. For this, a safe non-sparking tool (copper-plated) is used.

We recommend! Safety requirements for welding work

Before starting welding in enclosed spaces, containers and reservoirs, it is necessary to ventilate to remove the accumulation of gases.

Before starting welding, you need to check the equipment:

- strength and tightness of connecting hoses to gearboxes and burner;

- the integrity of the hoses, the condition of the burner and the serviceability of the gearbox;

- connection density and water level in the seal;

- serviceability of pressure gauges.

The preparation and operation of the generator must be carried out by an authorized and qualified person. The following conditions must be met:

- maximum one-time loading of carbide is no more than 4 kg;

- a maximum of 2 burners can be used if there is a separate water seal for each;

- the total power of the burners should not be more than 2000 l/h;

- the room where the work is carried out must be ventilated and have a volume of at least 300 m3;

- the generator with acetylene must be located no closer than 10 m from open sources of fire and the welding site;

- It is strictly prohibited to install a portable generator in boiler rooms, forges and rooms with elevated temperatures.

The generator and cylinder are installed outdoors, and gas is supplied to the welding site through hoses. Do not install the generator near fans or air intakes. Warning signs must be posted near the installed generator: “Flammable”, etc. Cylinders and generators must be painted a certain color, the oxygen cylinder and reducer must be painted blue, the acetylene generator or cylinder must be painted white. Additionally, the acetylene cylinder must have a red inscription “Acetylene”.

Safety requirements for equipment

Hoses

The standard length of hoses should be no more than 20 m, but for installation work it is allowed to use hoses up to 40 m long. It is prohibited to connect tees, plugs and other devices to the hoses to power several burners. The hoses used must not have any defects. It is allowed to join hoses up to 3 m long. The hoses must be tightly secured to the nipples of the reducer and burner using tie wire or clamps.

Do not interchange oxygen hoses with acetylene hoses. Do not bend or flatten hoses when laying or storing them. Under no circumstances should there be any traces of oil on the hoses, as this will lead to oxygen detonation.

Generators

The acetylene generator must be installed in such a way as to avoid falls, shocks and shocks. The water seal must be in a vertical position and in good working order. Using generators without a water seal is strictly prohibited.

We recommend! Sample of correct filling out of the welding work log

When using generators outdoors or indoors at temperatures below 0°C, it is necessary to prevent water from freezing. If the equipment is frozen: a generator, a water seal or a hose, it is necessary to warm them up in a warm room. It should not be heated by open fire sources and should not be located closer than 10 m to the fire source. It is recommended to warm up with hot water (steam).

It is strictly prohibited to use carbide of smaller granulation than specified in the generator data sheet, as excessive gas emissions may occur. Before loading, it is necessary to screen and remove fine fractions and carbide dust. Carbide may only be loaded into the basket and under no circumstances should it be loaded into the retort.

Cylinders

After removing the metal cap from the cylinders, you must immediately check the fitting and valve for serviceability or mechanical damage. If the cap cannot be removed, then it is strictly forbidden to unscrew it using an impact tool (hammer, chisel), this can lead to a spark and detonation.

Before connecting the gearbox, you should inspect the fitting and nut for damage, make sure that the threads are in good condition and that there is no oil or grease. Before connecting, the fitting must be purged by opening the valve a quarter turn for a short time. When opening the valve, you need to be careful so that the stream does not hit people. It is prohibited to use a gearbox with damaged threads or faulty pressure gauges (pressure gauges that have expired and have not been tested).

It is strictly forbidden to repair or disassemble cylinder valves yourself; for this there are special services and stations that carry out repairs and replacements.

The cylinders are installed either vertically or on special racks, to which they are firmly attached with clamps and chains, protecting them from falling. Cylinders should not be brought closer than one meter to heating devices and closer than 5 meters to a source of open fire, especially welding. Cylinders and hoses must not come into contact with live wires.

TB during work

During operation, the cylinder and the generator must be separated by a distance of at least 5 meters. Hoses must be suspended during operation to avoid damage. If gas welding is carried out in a room where other people are working, then protection should be placed around the perimeter. Before igniting the burner, the oxygen valve is opened slightly, then the acetylene valve, and after purging the hoses, the combustible mixture is ignited. Do not operate the burner with contaminated channels; this will lead to popping noises and backfires.

It is strictly forbidden to touch the torch or gearbox with oily hands and completely avoid contact of the welding equipment with oil, as it can provoke detonation. If a backfire occurs, you must immediately close the valves on the cutter, cylinders and water seal. The rate at which fire spreads through the hoses is low, and if this is done instantly, an explosion can be avoided.

We recommend! Treating eye burns from welding at home

To avoid kickback during welding, the following must not be allowed:

- a sharp decrease in oxygen pressure, which occurs when the oxygen in the cylinder runs out, the reducer freezes, the injector becomes clogged, etc.;

- bring the working mouthpiece closer to the object (reduces the rate of gas flow);

- excessive heating of the mouthpiece and cutter pipes;

- clogging of the mouthpiece (the flow area decreases and the gas flow rate drops sharply).

If the working torch overheats, then welding work should be stopped and cooled in a vessel with water. Do not empty the acetylene generator until it is completely empty, as this may lead to backfire.

While operating the generator, it is prohibited to:

- load carbide into wet containers;

- exceed the pressure more than indicated in the passport;

- turn off the regulator (in those models where it is);

- use boot devices that are faulty.

During operation, you need to ensure that there are no gas leaks from taps or plugs; this can be determined using a soap solution.

Welding of containers and pipelines under pressure is prohibited. Welding of containers, pipelines containing flammable materials, acids is carried out only after complete cleaning, washing and steaming with open hatches and covers.

During a technical break, the valves on the burner are tightly closed, and during a long break, the valves on the cylinders are also closed. In summer, cylinders should be protected from direct sunlight.

Completion of work

Extinguishing the burner is carried out in the following sequence: close the acetylene valve then the oxygen valve. After completing the welding work, be sure to close the valve on the oxygen cylinder and remove the reducer. The retort on the generator must be unloaded. If the carbide has not cooled down, the retort cannot be opened until it cools completely.

Then you need to clean the generator and rinse the housing with water. For cleaning, you can use a brass, aluminum scraper or hair brush. After completing all work, it is necessary to thoroughly ventilate the room in which the generator was located.

Fire safety requirements

The minimum distance of the generator from the place of welding work and the fire source is 10 m. If the hose catches fire, bend it on the side of the gearbox or generator and immediately close all the valves. The gas welding station must be equipped with individual fire extinguishing equipment. Acetylene can only be extinguished with a carbon dioxide fire extinguisher (dry sand); extinguishing with water is strictly prohibited.

svarkagid.ru