One of the most annoying problems that can arise with your kitchen drain is a clog. If excess fat enters the system, the inner surface of the pipes gradually becomes coated with plaque. Over time, deposits narrow the lumen of the pipe, and the water stagnates. This limits the functionality of the entire system, and a heavy smell appears in the kitchen. Constantly fighting blockages is very tiring. You can prevent them by installing a grease trap under the sink. Let's look at what this device is and how to make it yourself.

Useful device for preventing blockages ↑

Of course, the house must have an effective drain cleaner, but if you have to use it constantly, it is easier to prevent blockages. To do this, install household grease traps under sinks.

Plastic grease trap

The design of the device is very simple. The device consists of a housing with a partition dividing it into compartments, a flow damper and a gas outlet with a ventilation tube. Depending on the purpose and volume of wastewater, devices can be of different sizes and differ in design.

Polish grease trap JPR AQUA

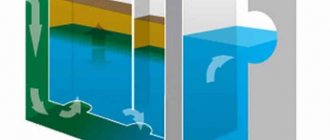

The operating principle is based on the difference in density between water and fat. If the liquid is cool, the fat cools and rises to the surface in the form of clumps. Water flows into the second compartment, and then into the sewer. Fat is retained in the first chamber due to the septum.

When the container is filled, it is cleaned, removing a lot of fat, and again connected to the system for further work. The cleaning method depends on the type and size of the device. Household grease traps are easy to clean with your own hands, and dirt is pumped out of large structures using pumps.

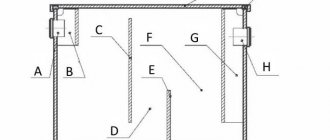

Diagram: grease trap design

Video: design and principle of operation of the device ↑

Household grease trap for the sink. Design and mode of operation

The structure of the device determines the basis of its operation. Contaminated wastewater passes into the receiver. They can enter from the side and from above. The chamber is divided by one or more partitions.

Both water and fat have different densities. Therefore, the fat solution rises to the top, where it accumulates.

If there is one partition in the chamber, then it covers two-thirds of the cross-section in diameter. And when there are two of them, they are located alternately: below and above. The first screens out solid waste, and the second screens out fatty deposits.

In essence, we can say that the device is divided into chambers (or compartments). In them, fat masses settle on the walls. Any compartment can be called a sump. When the chambers are filled enough to hold no more fat, they must be cleaned manually.

Accessories

- Rectangular body

- Partitions (one or more)

- Lid

- Input Tube

- Outlet Tube

- Ventilation outlet (additional option)

The device body is equipped with two openings: inlet and outlet. The holes are located at opposite ends of the device. Through one, the entrance, contaminated wastewater enters. After another, the output, clean water comes out.

The partitions located in the housing inhibit the water flow in the drainage system and prevent fatty deposits from entering the sewer system.

The lid must be equipped with a rubberized gasket and closes tightly. This is necessary to prevent air from entering the room from the interior of the grease trap.

The water inlet tube is shaped like a short elbow. And the graduation looks like an open tee. The release tube has a longer part, reaching almost to the bottom of the body, and a shorter part, ending at the top under the lid.

High-quality equipment undergoes the necessary testing and is supplied with appropriate documentation.

What benefits does a grease trap under the sink bring? ↑

Grease removal devices are used in many cafes, restaurants and bars, at industrial enterprises that produce meat and dairy products, bakeries, etc. They began to be used in private homes relatively recently, but very successfully.

Diagram: operating principle of the device

Owners note the following advantages of grease traps under sinks:

- Simple design. Thanks to the simple design of the grease trap, you can assemble it yourself. The main thing is to find a container of suitable volume.

- Easy installation. Anyone can install and connect the device to the sewer network. Ability to use simple tools is sufficient.

- Minimal maintenance. If you clean your household grease trap at least once every two weeks, there will be no problems with it. Additional maintenance may only be required for large industrial installations.

- Efficiency. The device really reliably protects the sewer from blockages. The collected fat remains in the container and does not pass further, because floats on the surface of the water. Only a small amount can enter the sewer, which is not enough to form deposits on the walls of the pipes.

- Possibility of installing several grease traps under the sink. Sometimes it is not possible to make a device of the required volume or an additional “level of protection” is required. In this case, you can connect two devices in series, the second of which will be used for wastewater treatment.

Compact grease trap under the sink

Grease trap for restaurant

The mode of wastewater entering the grease trap is the main factor by which the selection of a grease trap is made. For public catering establishments, such as restaurants, banquet halls, etc., with an unregulated supply of wastewater, there is a high content of fats and large undissolved particles in the wastewater. It must be remembered that a grease trap for a restaurant in most cases serves several sinks and a dishwasher. Based on the above conditions and operating conditions, it makes sense to focus on models with average performance. When using more than 3-4 sanitary appliances, it is necessary to choose the following models of grease traps: • Grease trap EVO STOK 3.6-240 • Grease trap EVO STOK 7.0-500

Materials for the manufacture of grease traps ↑

The most popular materials from which fat separators are made: fiberglass, plastic, galvanized or stainless steel. Devices made from them vary in strength, durability, and price. When choosing a device for a specific kitchen, you should decide on priorities and focus on operating conditions.

Plastic grease trap container

Option #1: plastic ↑

Household grease traps for sinks are most often made of plastic. This is an inexpensive material that is not afraid of corrosion, chemicals and can last up to 30 years. The advantages of plastic also include ease of maintenance. The disadvantages are poor resistance to mechanical damage.

There are models of various shapes, sizes, and with different capacities. They are purchased for installation in apartments, private houses, small restaurants, cafes, and pubs. Plastic fat separators of the domestic brand “Fifth Element” have proven themselves well.

Plastic grease trap

Option #2: fiberglass ↑

A good choice is under-sink grease traps made of fiberglass. This is an option for autonomous sewage systems of public catering outlets, industrial enterprises or private homes where a fat separator with high throughput is needed.

The main advantage of fiberglass housings is their high resistance to external influences. The material is so durable that the devices can be installed outdoors. Fiberglass grease traps are lightweight. They are very easy to install, use and clean. As for manufacturers, special attention should be paid to models.

Fiberglass grease trap

Option #3: steel ↑

Typically, fat separators are made of stainless steel, less often - of galvanized steel. The advantages of the material are obvious: it is durable, resistant to mechanical damage and chemical influences. Stainless steel devices are more expensive, but they are also of better quality than galvanized steel devices.

Stainless steel model

Stainless steel looks nice, so grease traps can be installed not only under the sink, but also at a distance from it, without being disguised. These models are resistant to corrosion, so they can last for decades without repairs. The disadvantages include the relatively large mass. Steel grease traps are more difficult to install than plastic and fiberglass ones.

When choosing a brand, you should pay attention to ACO Group products. These are not cheap fat separators, but there are no complaints about their quality. The company's product range includes household and industrial models designed for both indoor and outdoor installation.

Steel model ASO

Types of grease traps

Grease traps for sewerage differ in types, of which there are quite a few. They all have different performance, types and completeness. But it is still possible to identify the main characteristics by which these devices are classified.

Signs of classification of grease traps:

- By design features (device types)

- According to the case material

Specialization by type

- appliances for washing

Small devices with small dimensions and simple design features. Necessary for equipping private farms. They are also suitable for catering establishments with low traffic. They can simply be cleaned once every few days.

- industrial

Devices designed for large food units intended to serve large numbers of people. There are such catering establishments in sanatoriums, holiday homes, and so on. The peculiarity of these models is that they are equipped with sensors that indicate when they are full.

- automatic

Equipped with mechanisms for collecting fat masses, which facilitates cleaning and prevents pipe blockages.

- Well

They look like a cylinder. To be installed in wells. Serviced through a hatch.

- For installation below sewer level

Mounted in the ground or in a basement. Equipped with an electric pump for pumping purified water to the sewer drain level.

Classification according to materials of manufacture.

- Made of plastic (polyethylene, polypropylene).

Plastic grease traps are used both in industry and in everyday life. These devices are inexpensive, lightweight, and do not require specialized maintenance. Most grease trap models are made from plastic.

- Made from fiberglass composition

Fiberglass devices have bodies of increased strength and resistance to chemicals. These properties make it suitable for installation outdoors and in the ground.

- Made of stainless steel

When making metal grease traps, stainless steel is used. They have durable bodies. But these devices are expensive and susceptible to corrosion.

Where can I install a fat separator ↑

There are two options for installing grease traps - indoors or outdoors. Device manufacturers often choose a certain “specialization” and produce devices of one type - for installation inside or outside a building.

Plastic fat separator

Models for indoor installation ↑

Indoor models can be installed in the kitchen, a separate room, or even the basement. The location should be selected based on considerations of ease of operation and maintenance. The ideal option is to install a grease trap under the sink, but in some cases this is not possible.

The issue of fire safety also plays an important role in choosing a location. If it is impossible to mount the device at a sufficient distance from sources of open fire, it is better not to risk it.

Attention! Fat is flammable, burns for a long time and is difficult to extinguish. If the stove is located too close to the sink, then it is better to install the grease trap in another room.

Cleaning the grease trap

Features of operating street grease traps ↑

Outdoor grease traps are more efficient than those designed for installation under the sink. They are made of fiberglass or stainless steel and buried in the ground. The STK series models have proven themselves well.

The installation technology is quite simple, but involves labor-intensive work - digging a pit, concreting, etc. Therefore, it is better to entrust the installation of a grease trap outdoors to professional craftsmen. It is also worth taking care of additional devices that facilitate the operation of separators, for example, special sensors that monitor the level of deposits.

Note! Cleaning an outdoor grease trap is a complex procedure, and you often have to turn to sewage disposal services for help. These are additional costs. They pay for themselves by increasing the time between cleanings.

Grease trap design for outdoor installation

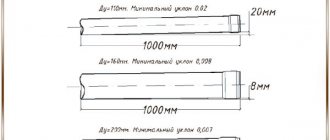

Formulas for calculating technical parameters ↑

When choosing a grease trap for a sink or making the device yourself, you need to decide on the desired technical parameters. The main one is considered to be peak discharge, i.e. the volume of water that the device can pass at one time. For an ordinary city apartment or private house, a model with this figure of 30-40 l/s is suitable.

Grease trap of the simplest design

If we are talking about installing an industrial model, then it is better to entrust the calculation of technical parameters to specialists. If you plan to purchase household equipment, you can use a simple formula:

Р=nхPs, where

P – required device performance in l/s;

n is the number of sinks from which wastewater will flow into the grease trap;

Ps is the speed at which water will be supplied to the container (it is equal to the speed of water flow in the water supply system and is usually about 0.1 l/s).

Let's look at an example of how to calculate the desired performance of a grease trap for a sink. If one sink is connected, then P=1x0.1=0.1 l/s, i.e. For the kitchen, a household model with minimal performance is sufficient.

Steel box for grease trap

Based on the data obtained, you can find out the required container volume. Calculation formula:

V=60xPxt, where

V – required volume in liters;

P – productivity;

t is the time required for fat to settle, in minutes (most often this period is 6 minutes).

An example of calculating the required volume if the productivity is 0.1 l/s: V=60x0.1x6=36 l.

Grease traps of various sizes

Having found out the volume, you can already choose a ready-made model or calculate the dimensions of the device if you plan to manufacture it yourself. The ideal option for a grease trap for washing with a capacity of 0.1 l/s and a volume of 36 l is a capacity of 0.3x0.3x0.4 m. When choosing a container, it does not matter whether the height will be 0.3 or 0.4 m.

Based on the data obtained, you can already prepare a sketch and drawing. An example of a finished drawing with explanations is provided below.

Drawing for making a grease trap

Grease trap for dining room

There are different grease traps for each type of catering establishment, this is due to the conditions of wastewater discharge. A grease trap for a dining room must first of all satisfy the following characteristics: • high performance; • resistance to peak discharges of wastewater with a high fat content; • have an increased volume of chambers for collecting solid particles and fat compared to the standard one.

These requirements are formed if you study the work of the dining room, in which food is prepared in cycles (breakfast-lunch-dinner), and, accordingly, the same cyclic washing of dishes, which leads to the operation of the Grease Trap for the dining room in a pulsating mode. At the same time, wastewater discharges contain large amounts of fat and food residues. If the installation of equipment occurs during the reconstruction of the existing sewer network, then it is reasonable to use models with increased technical performance characteristics, such as: • Grease trap EVO STOK 0.5-50 • Grease trap EVO STOK 1.0-80 • Grease trap EVO STOK 1.5- 175 • Grease trap EVO STOK 3.6-240

TOP 5 domestic and foreign brands ↑

The design of the grease trap is quite simple, so there is not much difference between models from different manufacturers. The quality of the devices can be judged by the materials used. The following brands have proven themselves best:

- EuroREK. This is a product of Wavin Labko. Grease traps are durable, strong, and resistant to external influences.

Model EuroRek SL

- The devices of this company are made of fiberglass. They are versatile, functional, durable.

Industrial grease traps Flotenk

- Nelyx. The company specializes in the manufacture of industrial grease traps and does not produce household models. This is a great option for a cafe, pub or restaurant.

Variety of Helyx models

- Evo Stock. High-quality domestic products made of reinforced plastic and polypropylene. There are household and industrial models.

Table: Evo Stok brand models

- "Fifth Element". The Russian company manufactures industrial and household grease traps, provides a 5-year warranty on its products and provides service. Another plus is the reasonable price. The model of this company is a good choice for a private home.

Table: household grease traps of the Fifth Element brand

What does a grease trap consist of?

The design of a grease trap is not complicated; any user can understand it.

- LiveJournal

- Blogger

The stainless steel grease catcher is cleaned mechanically.

The container is a box divided into several compartments. In one gravity flow, the incoming used water is cleaned of large debris, which settles to the bottom. Then, through the pipe, the liquid enters another chamber, where the fat rises to the top, and the water, freed from oil impurities, is drained into the sewer. The partition slows down the flow rate so that the fat has time to float to the surface.

The sealed lid does not allow unpleasant odors to escape and provides easy access inside.

A household grease trap can be cleaned mechanically, manually, using detergents. On an industrial scale, purification is carried out mechanically. Here the fat is pumped out by special pumps included with the device. The need to clean the fat storage tank is indicated by a fat level indicator built into the device system.

How to make a fat separator with your own hands ↑

To make a grease trap for a sink with your own hands, you will need the following materials:

- a plastic box, the dimensions of which may be slightly larger than the calculated ones, but not smaller;

- a low pipe with a diameter of about 100 mm to create an internal partition;

- elbow and PET tee with a cross section of 50 mm;

- a piece of pipe with a diameter of 100 mm, the length of which should be about 2/3 of the height of the box, and a pipe with a rubber cuff of the same length, but with a diameter of 50 mm.

You will also need a standard set of tools. You definitely need either an electric jigsaw or a file that can be used to cut through the body. Additional materials will have to be purchased: sandpaper, silicone sealant, and adhesive sealing tape.

Making a grease trap with your own hands

Main stages of work:

- Holes for the pipes are cut in the end walls of the plastic box and the cut is cleaned.

- Important! The diameter of the holes must match the cross-section of the pipes. They should fit very tightly. Slots and gaps are unacceptable.

- A piece of pipe with a diameter of 100 mm is glued to the bottom of the container, and when the composition is completely dry, a piece of pipe with a diameter of 50 mm is installed inside. The distance from the smaller pipe to the bottom should be about 3-4 cm.

- The branch pipe is connected to the drain outlet tee so that the end of the link falls into the outlet hole. The tee hole will point upward. This is necessary for ventilation.

- The inlet elbow is connected to the box and sealed with silicone compound.

- The final touch is to seal the edges of the lid with a sealant.

- Once the sealing compounds have dried, you can check the operation of the grease trap. It is installed under the sink, connected to the sewer and the water is turned on. If the joints do not leak, the device is ready for use.

Video: features of a homemade grease trap ↑

Is it possible to make a grease trap yourself?

The design of the device is quite simple; some people think that they can easily make a grease trap with their own hands and save on the purchase. This is possible if desired. Calculations of water consumption for a specific room are made, and the required performance of the future grease trap is selected. Materials and equipment are purchased. Ready-made plastic containers made from various materials or specially welded plastic or polypropylene sheets will do. The boxes are supplemented with internal partitions, holes are cut for hoses supplying wastewater and discharging purified liquid.

- LiveJournal

- Blogger

If you wish and have direct hands, you can make this device yourself

If you follow all the rules, you can make a durable and strong grease trap with your own hands, but it is not necessary that it will cost less than a factory one and will be protected for a long time from leaks and breakdowns.

Purchasing a grease trap from a store provides several advantages. Manufacturers provide long-term warranties for products, enterprises have a system of discounts, promotions are held, and free installation is offered.

Rules for installing a grease trap under a sink ↑

- Before you begin installing the device, you need to make sure that it will be placed correctly. It is necessary to ensure normal access to the device for its maintenance.

- There should be a distance of at least 2-3 cm between the body of the grease trap and the walls of the cabinet in which it will be hidden. This is necessary so as not to damage the furniture when the device is turned off for maintenance.

- The separator is installed only on a flat surface. Distortions will lead to fat pouring into the sewer.

- During installation, you must strictly adhere to the manufacturer's recommendations. The instructions should indicate the optimal distance from the appliance to the stove and other sources of open fire. This point cannot be violated.

- Industrially produced grease traps are equipped with special fasteners for installation and connection to the sewer system. If the owner decides to buy fasteners separately, you need to make sure that the required sizes are available.

- After installing the grease trap under the sink, it is connected to the sewer system. To do this, a corrugation from the main sewer pipe is inserted into the inlet pipe of the device, and another corrugation is connected to the outlet tee. The joints are sealed with silicone compound or sealing tape.

Note! Fat thickens and forms a film on water if its temperature is below 40 degrees. It is advisable to install the separator at a distance from the siphon so that the wastewater has time to cool before entering the device’s container.

Diagram: installation of a fat separator

Where is it used?

According to sanitary standards, grease traps are required in cafes and restaurants

The principle of operation of a grease trap is based on the difference in density of fat and water. Fat is lighter and always floats on the surface of the water. Liquid from the drain enters the plastic container, solid particles settle to the bottom, and fats float to the top and accumulate on top. The partition divides the container into two parts and has a gap at the bottom. Water flows from below into the second part of the container, and fat remains on top, floating in the first half or flowing into a special grease collection tray. At the outlet into the sewer pipe, purified water is obtained, which flows freely through the pipes and does not clog them.

Manufacturers produce special grease traps for installation at key points:

- into the hood;

- under the sink;

- dishwasher;

- sewerage

Devices are divided into two main methods of draining wastewater:

- volley discharge, in which a full wash of water is collected, the drain hole is closed with a plug, and after washing the dishes, all the liquid quickly drains;

- uniform discharge, when water flows from the tap in a stream, this is how dishes are usually washed at home.

The design of the grease trap is simple, the price is quite affordable, installation is possible with your own hands, and the factory kit includes all the necessary seals.

Manufacturers claim a device service life of at least 30 years with regular cleaning.

Under the sink

The productivity of a small plastic device is up to 2 liters per second

When installing a grease trap under the sink, it is often hidden in a cabinet or lower cabinet; you immediately need to leave 3–5 cm on each side of the container. Then, during cleaning and inspection, access to the device will be open. Even small plastic models require a solid base; the total weight including water reaches 30–40 kg; slight vibration and shift of the body are possible. We connect the drain hose tightly to the inlet pipe of the device, and connect the drain pipe to the sewer using gaskets and sealant. Then you need to check the system for leaks, if everything is in order, then install the cover. The grease trap is ready for use.

It's easy to care for:

- Remove the lid and remove the layer of accumulated fat on top using a shallow, wide container or spatula. A small plastic disposable container will do just fine.

- Remove solids and sediment from the bottom and pipes.

- Wash with hot water and detergent and replace the lid.

High-quality and rapid separation of fat from water occurs at temperatures from 5 to 40 ºС.

For sewerage

The unit is made of high-strength plastic

Another installation option involves collecting wastewater from several sinks into a common pipe and connecting it to a grease trap, and then to the sewerage system. In this case, devices of larger volume and productivity are used, approximately 15 liters per second. Such dimensions cannot be hidden under the sink; they are installed in a separate room or in the basement. During filtration, additional waste breakdown can be done using chemicals available in tablet form. This method provides a high degree of purification, up to 98%, but when organic matter decomposes, an unpleasant odor may appear that will remain outside the residential part of the house.

When installed externally in a basement or other separate room, it is important to maintain positive temperature conditions; freezing of the system can lead to an accident.

Methods for cleaning containers from deposits ↑

There will be no problems cleaning household grease traps under the sink. They are usually small in volume, so they are easy to disconnect from the sewer and clean out by hand. The productivity of such devices is 0.1-2 l/s. Models with higher productivity are considered industrial, and to service them you have to resort to either pumps or special equipment.

Industrial models are equipped with automation that monitors the level of contamination and signals the need for preventive maintenance. Household appliances most often do not have such devices; containers have to be checked regularly. Below we offer detailed video instructions for manual cleaning of the fat separator.

Cleaning an industrial grease trap

Step-by-step video instructions for maintenance ↑

When choosing and making a grease trap for your sink with your own hands, pay attention to the quality of the material from which the body is made. The service life of the device depends on this. Plastic and fiberglass models do not withstand strong impacts well, so care must be taken to ensure that the devices are installed correctly. If you are planning to buy an industrial device, give preference to manufacturers that provide a warranty. Otherwise, devices of different brands differ little from each other.

Grease trap for sewerage - different types:

Below are the different types and models of grease traps. After reading the brief description, you can proceed to a detailed study of the required series:

Grease separators for cafes and restaurants:

Relatively small grease traps for installation directly in the work area. The most popular type of grease trap today

Grease trap for sewer Standard - from 4990 rubles

Small appliances installed directly under or next to the sink. They are also used in shops and retail chains. Several washing baths can be simultaneously connected to one unit, depending on the overall dimensions of the trap. They are equally successfully used in everyday life, or at all kinds of public catering points. wherever reliable protection of the internal pipeline from fatty deposits is necessary. Due to the simplicity of the design, grease separators can be mounted at any accessible point. The specialist will not need special skills or tools to connect. They are the most common in supermarkets Pyaterochka, Magnit, Perekrestok... They are made of high-strength polypropylene, completely non-corrosive.

More details

Grease traps of the Pro series - from 6990 rubles

The grease trap for sewerage is equipped with a quick-removable perforated tray for collecting waste. The design of the product minimizes the time required for complete cleaning, and the presence of a quick-release tray with a flow damper and improved separation plates increases the overall system performance by 3-4% (according to our own tests). Developed according to the recommendations of service companies. Particularly relevant for forced drainage of wastewater through Sololifts. The use of grease traps in conjunction with pumps greatly extends the service life of the latter.

More details

Autonomous (aerated) grease traps that do not need to be cleaned

Innovative aerated grease traps that require virtually no maintenance. The key to efficiency is the combination of the principle of traditional settling tanks with aeration tanks, which are successfully used for cleaning household wastewater. Continuous saturation of settled wastewater with oxygen ensures the rapid growth of colonies of aerobic bacteria, which completely block anaerobic digestion (rotting) of incoming contaminants and their effective processing.

Aerated grease traps are the only existing modifications that provide cleaning from emulsified (dissolved in water) grease products and require virtually no maintenance. Cleaning such grease separators, with properly selected performance, is required no more than once every 6-12 months.

Read more

Automatic grease traps - with a system for collecting and discharging grease

Fully automatic grease traps of the “Avtosbor” series, equipped with a skimmer - a device for automatically collecting and discharging contaminants (grease products) into an external storage device. The system allows you to minimize the time and material costs of operating grease traps. aerated grease traps that require virtually no maintenance.

The equipment has no analogues in terms of compactness among similar systems, provided that the efficiency of the grease traps is fully maintained.

The improved design of the skimmer made it possible to produce a grease trap of a standard size, without increasing the dimensions. The materials from which automatic grease traps are made are 12 mm polypropylene and stainless steel, allowing us to provide a 10-year warranty on the equipment. The actual service life of such grease traps is practically unlimited.

Read more

Workshop grease traps.

For use in large catering establishments. Mainly used in large restaurants or canteens.

Rectangular workshop grease traps for sewerage

SPB workshop grease traps are equipment of impressive size. The maximum load reaches 10 l/s. The maximum salvo discharge is 2.5 m3. Working volume from 400 to 5000 l. On request they can be manufactured with a capacity of up to 100 l/sec.

The characteristics are very close to underground, but there is a noticeable difference. Unlike industrial grease traps, they are installed in technical rooms. This approach provides significant savings in kitchen space. The rectangular shape allows connection in any convenient place.

The housings are reinforced with steel square pipes around the perimeter. Extrusion welding and absolute inertness of the material ensure trouble-free operation for more than 50 years.

Shop grease separators can be equipped (optionally) with systems for automatic collection and removal of fat products, slurrying and sediment removal systems.

Read more

Underground grease traps

They are divided into two main types - “Vertical” or “Horizontal”. The principle of operation of grease traps is completely identical, the only difference is ease of installation. The connection to the sewerage is carried out underground.

Vertical

The optimal solution for wastewater treatment at low flow rates. Grease traps for sewerage of this series are especially in demand in confined spaces. Affordable price and compact dimensions make this modification the most popular among industrial grease traps for sewage. Our factory offers vertical grease traps in three versions:

- “A” - with an adjustable neck;

- “B” - in a single building with a staircase;

- “C” - equipped with an inspection platform;

They are usually installed underground.

A pit is prepared, a loading plate is installed, and a tie-in into the pipeline is carried out. For ease of installation, the extended necks are removable. This allows for precise height adjustment before final backfilling and reduces transport costs. Non-standard production is possible, according to the submitted technical specifications. Production of an individual order - within three days. Go to study

Horizontal grease trap for sewerage

Option "A"

Efficient grease separators, with a maximum throughput range of 1 - 200 liters per second.

Grease traps have a classic two-chamber design with one or two technical wells - the number depends on the dimensions.

The largest product range allows you to select a grease trap for sewerage for almost any conditions; if necessary, it can be manufactured according to the Customer’s drawings.

High structural rigidity allows insertion at a depth of up to 10 meters, without additional reinforcement (concreting). Connection is possible “under the lawn” or under the asphalt.

More details

Option "B"

A complete analogue of the previous type, additionally equipped with a riser for pumping out sludge in the first compartment.

There are no fundamental differences; the choice is determined solely by ease of maintenance and depends on the volume of the grease separator. Recommended for selection with case length less than 3000 mm. In all other cases, option A with two wells will be preferable.

The only advantage of the system is the presence of stairs by default. However, grease separators in version “A” can also be equipped with the same ladders.

To learn more

Sewage grease traps OTB

Industrial and (or) workshop grease traps for sewage systems, over a fifteen-year history, have gained recognition from designers as productive and reliable grease separators for trapping and removing fat products.

Grease traps OTB PP are more often found in catering establishments, OTB PC at small and medium-sized processing enterprises, grease traps for sewerage SV and SG are equipment for large plants (max. - up to 30 l/s)

Details

Grease traps STK

Grease traps for STC sewerage are presented in two categories:

- Vertical grease traps (up to 5 l/s)

- Horizontal grease separators for sewerage (up to 50 l/s)

STK fat traps are the most common choice of engineers for large meat or fish processing plants.

High-performance underground grease separators used in enterprises with a high content of fatty products in wastewater, for cleaning before feeding into the general network or to subsequent stages. They are equipped with PP, PE, Pragma or Korsis pipes.

More details

Above, we presented you with the main series of sewer grease traps. You can go to the required section to get acquainted with a detailed description or, if you are not tired yet, continue your acquaintance with grease separators below.