A grease trap in the kitchen is one of the optional, but very useful devices. The unit effectively purifies water, which is washed into the drain hole from animal and vegetable fats. Timely installation of a grease trap under the sink will help avoid clogging of pipes and fouling of the sewer system with plaque, and as a result, an unpleasant odor from the drain. The best part is that Plumber Portal knows how to make a grease trap for your sink with your own hands! But first things first.

What is a grease trap, its structure and principle of operation

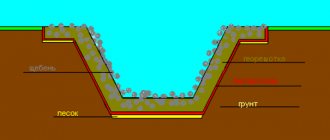

These are special tanks used to remove fats contained in wastewater. A simplified drawing of such a device is shown below.

Grease trap design

Designations:

- A – pipe installed at the inlet;

- B – partition, plays the role of a flow damper;

- C – first separation partition;

- D – separation chamber;

- E – second separation partition;

- F – settling compartment;

- G – output distribution compartment;

- H – pipe for discharging treated waste;

- I – seal that ensures the tightness of the structure;

- J – tank cover.

The most common method of fat separation is mechanical. Separator partitions are installed in the tank, which help slow down the movement of wastewater and cool it. As a result of this, the fatty formations contained in them, due to the transition to a non-emulsified state, accumulate on the surface of the water. When a certain amount of fat accumulates, cleaning is carried out. A visual diagram of the device’s operation is shown below.

Grease trap operation diagram

Designations:

- A – supply of wastewater to the tank;

- B – sediment from heavy pollution;

- C – fat accumulated on the surface of the water;

- D – separation partitions;

- E – water level line;

- F – discharge to the sewer.

The main technical characteristics of separators are determined by their size, productivity, peak discharge volume and installation method.

Process of creation

Now you can proceed directly to making the filter. In the selected container you need to make two holes on opposite sides where the pipes will be inserted. Be careful to use as little sealant as possible. After this, a partition pipe is attached to the bottom of the household grease trap in a vertical position using sealant. You should wait a bit for the glue to dry.

A small five-centimeter section of the pipe is installed inside the partition pipe, and its narrow end should be located at a distance of 3-4 cm from the bottom of the container. Next, this pipe must be connected to a tee, which, in turn, is attached to the outlet. The upper outlet of the tee must face the tank lid - ventilation is ready.

Then all that remains is to install the inlet elbow and perform a good sealing of the inlet/outlet of the container. The edges of the lid should be sealed with a sealant. And after the homemade equipment has dried, it can be connected to the ventilation system.

Main types

Devices of this type are classified according to the principle of cleaning; it can be performed in three ways:

- Mechanical. This most common option was described above, its main disadvantages are:

- during operation, it is necessary to regularly clean the device from the accumulation of fats;

- low efficiency and level of purification; some impurities still remain in the wastewater.

- Gravitational. The design of such separators and the operating principle are similar to the previous type (see Fig. 3), the only difference is in the cleaning process. The effluent is given time to settle (about a day), which allows almost all impurities to collect near the surface. Often, these devices use special chemical reagents that bind fatty impurities, forming heavy conglomerates from them that precipitate.

The principle of operation of the Evo Stok gravity grease trap.

Such devices have a much higher cleaning percentage, approximately 98%, but they also have characteristic disadvantages:

- manual cleaning and subsequent disposal of fat is required;

- In the precipitated organic matter, the process of decay may begin, which manifests itself in the form of an unpleasant odor.

- Biological. Such separators are called biological destructors. The difference from previous types also lies in the cleaning technology. It is produced by adding biological products (special cultures of microorganisms), which, feeding on fat, convert it into a neutral sediment.

Tablets for the Custom GT grease trap

The advantages of this method are obvious: after the grease decomposes, there is no unpleasant odor and the cleaning process is less difficult.

Concluding the topic about the types of grease traps, we should mention devices for ventilation systems, for example, a kitchen hood, which also has special devices for separating fats.

Grease traps in kitchen hoods: a – grille filters; b – labyrinth type

Passing through the filters, fat vapors settle on them, which reduces contamination of duct ventilation systems.

Kitchen hood diagram

In order to better understand what you are going to do, you must first know the circuit diagram of the device and the principle of its operation, otherwise you will not be able to do anything normally. This is also necessary so that you can disassemble and then reassemble the hood yourself in case of breakdown or cleaning, which it is advisable to do at least every six months to avoid a possible fire.

The motor or motors play a big role in the hood, since in some more powerful models two of them are installed. This is a kind of “heart” of the entire device; the power of the operating device depends on it. Most often, such engines have a power from 50 to 200 watts, their speed is from 1500 to 2000 per minute. The performance of the device depends on this, but do not forget that the higher the power, the more electricity the hood will consume, be sure to take this into account

In addition, more powerful hoods will have a high noise level, you also need to pay attention to this

A large role in the energy consumption of the hood and its structure is played by the lamps installed in it and aimed at illuminating the stove or hob. Most often, LED or halogen lamps are installed. If you want to save on energy consumption in the future, then you should give preference to LED lamps, since halogen lamps consume virtually the same amount of energy as conventional incandescent lamps.

To connect the device to the network, a regular cord is used, most often its length is one and a half to two meters; if this is not enough for you, you will have to use an extension cord. If you want to hide the cord and extension cord, think about it in advance.

An important role in the structure of the hood is played by the anti-grease filter, which is located literally “at the entrance” of the device and is visible above the hob. This filter is needed to capture unpleasant odors, as well as protect the engine and other parts from dirt and large impurities. This is a kind of metal mesh or dense perforated foil, which has several layers; ideally, it should have an anti-corrosion coating.

Some inexpensive models have so-called disposable filters; they are made of synthetic fabric; they will have to be changed very soon. They are inexpensive, but it is not very convenient, so it is better to give preference to the first option. The filters need to be cleaned periodically, as they become covered with soot and grease, which can cause unpleasant odors and spoil the operation of the device.

Some more expensive models have carbon filters, which are usually installed behind the hood motor. Such filters help further purify the air; they contain microgranules made of carbon, which work on the same principle as filters for water purification. The disadvantage of such filters is that they need to be changed frequently; this is easy to do, but requires some skill. Dirty or old filters interfere with the normal operation of the kitchen hood.

Hoods also have several types of controls that differ from each other; you need to choose the type that seems convenient for you; by and large, they do not have any functional differences. Here are the main types of control:

- Push-button control. It represents the presence of ordinary recessed buttons that are familiar to every person. Usually the buttons are located on the front panel of the hood and are easily accessible. Such control is most often found in the cheapest models of the device, but at the same time it is also the most reliable

Slider control. Also an inexpensive type of control, which is found in many economical models. It works on the principle of a movable lever, it moves along the divisions, changing the power of the device and sometimes the lighting of the hob

Touch control. This control is the most popular; it is found in most modern devices. Firstly, it looks very stylish, does not require special care and does not lose its presentation even after long use. The touch panel is most often located on the front panel of the hood and works at the slightest touch. In more expensive models, you can even set a specific program for the operation of the device. For example, when a strong odor suddenly appears, the motor begins to work in an enhanced mode, aimed at quickly eliminating the unpleasant odor; when a person approaches, a light indicator is activated, which illuminates the surface.

Video - installation of a kitchen hood

Some of the smarter models also operate without human intervention, turning on and off automatically when an odor is detected or the stove is turned on/off.

Selection criteria and main manufacturers

To select the necessary device, you must first consider its purpose. The operating parameters of separators depend on this. For example, for domestic purposes, productivity will be sufficient within the range of 0.1-2 liters per second. But these characteristics are completely unsuitable for cleaning wastewater entering the sewer from a canteen, cafe or restaurant; this task will require industrial models with the appropriate technical characteristics.

It is worth noting that many industrial models (for example, for workshops where the production of dairy products is established) are equipped with additional equipment that increases the efficiency of service. These could be automatic pumps for pumping out wastewater, fill sensors, etc.

An important factor is the material from which the tank body is made; it can be plastic, fiberglass or stainless steel. In industrial devices, the well is often made of concrete.

Household cleaners, as a rule, are made of plastic, which is explained by the low cost of the material, as well as its following useful properties:

- light weight, which greatly simplifies installation and maintenance;

- long service life (at least 30 years);

- harmless to humans.

Grease traps made of Termit polypropylene

Such devices are designed for domestic use or installation in small catering establishments.

Fiberglass separators. A distinctive feature of such cases is high mechanical strength and resistance to aggressive chemicals. Such characteristics are excellent for industrial models, especially taking into account the fact that outdoor installation is allowed.

Fiberglass grease traps Flotenk

Fiberglass housings are resistant to any weather conditions, are lightweight and easy to clean.

Stainless steel housings are typically used for industrial separators. Characteristics:

- long service life;

- high hygienic properties;

- presentable appearance.

The listed characteristics perfectly meet the requirements of public catering establishments.

Stainless steel separator produced by ACO Group

The only drawback limiting the use of such a case is the high price.

When choosing a manufacturer, we recommend giving preference to well-known brands, for example: Ecoline, Alta, Fifth Element, Termite, etc. We also note that domestic products are not inferior in quality to foreign ones, but are significantly cheaper. As for unknown manufacturers from the Middle Kingdom, here, as always, the quality must be checked on site.

When choosing a separator model, it is necessary to take into account its installation location. There are models designed for installation indoors and/or outdoors. There are three installation options in the house:

- under the sink or sink;

- in the basement;

- in a room designated for this purpose.

Types of grease traps

Based on the material used, grease trapping devices can be divided into three groups:

- plastic;

- fiberglass;

- steel (galvanized and stainless steel).

Each variety has its own advantages and disadvantages. They are distinguished by strength, durability and cost.

Plastic. Grease traps for household use are usually made of plastic. This is a lightweight, durable and inexpensive material that is resistant to corrosion and chemicals. The advantages of plastic also include ease of maintenance, and the disadvantages are poor resistance to mechanical damage.

There are modifications of different configurations, volumes, with different throughputs. They are purchased for installation in small apartments, private houses, small restaurants, cafes, and pubs. Domestic plastic fat sumps “Fifth Element” have shown themselves to be excellent.

Fiberglass. This option is suitable for autonomous sewer systems of catering establishments, industrial enterprises or large private households, where a device with high throughput is needed. The main advantage of fiberglass containers is their high resistance to external mechanical and chemical influences.

The material is so strong that the equipment can be placed outdoors. Fiberglass separators are characterized by their low weight, ease of installation, use and cleaning.

Steel. More often, grease traps are made of stainless steel; rarely, galvanized steel. The advantages of the material are undeniable: steel is durable, resistant to mechanical damage and chemical attack. Stainless steel devices are more expensive, but they are also of better quality than galvanized steel devices.

Stainless steel has a pleasant appearance, so such separators can be placed not only directly under the sink, but also at some distance from it. These products are impervious to corrosion, so they can last for several decades without repair. The disadvantages include the relatively large weight. In addition, steel grease sumps are more difficult to install than plastic and fiberglass ones.

When choosing an appliance for a specific kitchen, you need to clarify your priorities and focus on the conditions of use.

How to clean a grease trap?

Household appliances installed inside the house are cleaned manually. For this purpose, the separators are equipped with a special blade. This process is quite simple, does not take much time, but is somewhat unpleasant. The algorithm of actions is as follows:

- Open the top cover.

- We collect the accumulated fat with a spatula. It should be noted that waste fats when unloading grease traps are subject to mandatory disposal, but these standards do not yet apply to household devices.

- We check the pipes and, if necessary, remove large particles that have accumulated from them.

- Remove accumulated sediment from the bottom. Can be cleaned using any detergent.

- Flushing the system with hot water will remove particles of fat and oil from the pipes that can lead to clogging.

- Close the lid and continue further operation of the separator.

To pump out accumulated fat from a street separator, you will need to use special equipment.

Cleaning must be carried out regularly, otherwise there is a high probability of system clogging.

How does a grease trap work?

The operating principle of this device is quite simple. In fact, everything is done by gravity, which is not at all heartless, no matter what the hero of the popular series says.

Everyone knows that oils and fats are lighter than water, so they always float to the top. And all the most important things happen in the separation chamber, where water from the sink flows. The chamber has two pipes - through one, waste water flows into it, and through the second, fat-free water is discharged. The second pipe is lowered below the level of the fat layer, so only water flows into it. It should be remembered that these structures also require cleaning. Thus, the grease trap is designed quite simply. Although there are also more complex designs on sale, consisting of several adjacent chambers. And cleaning this type of grease trap requires a lot of effort. But the operating principle remains unchanged.

Do-it-yourself grease trap - is it possible?

Of course, such equipment is not difficult to buy, but many people want to know whether they can make it themselves. This question arises when a device is needed urgently and there is no way to buy it. So is it possible to make a grease trap with your own hands? Yes, of course, and it doesn't require too much.

How to make a grease trap for a sink with your own hands?

With a little time and patience, it’s easy to make a homemade simple separator for the kitchen sink from scrap materials. In this case, you can do without drawings. For production we will need:

- plastic box with a lid, volume about 40 liters;

- tee and elbow PET Ø 50 mm;

- pipe Ø 100 mm (its length should be approximately 2/3 of the height of the body);

- pipe Ø 50 mm (same length) it must have a mounting extension and a rubber cuff.

The following tools and supplies should be prepared:

- jigsaw (preferably electric);

- sealant;

- sandpaper;

- adhesive-based rubber sealing tape.

When everything is ready, we begin the manufacturing process, following the following algorithm:

- We make holes Ø50 mm at the opposite ends of the box. There should be approximately 50mm from the top edge of the drawer to the holes. Don't forget to clean the edges with sandpaper.

- We install a Ø 100 mm pipe under one of the holes with its end face and glue it so that its lower edge does not reach the bottom of the box by about 30-40 mm.

- As soon as the glue has dried, install a Ø 50 mm pipe inside the previously glued pipe. In this case, the lower edge of the pipe should be approximately 50 mm higher than the lower edge of the pipe.

- We connect a tee to the upper end of the pipe, insert one of its free ends into the hole, the second will be directed upwards and play the role of ventilation.

- We install the inlet elbow.

- We seal all cracks and joints with silicone sealant.

- We glue sealing tape at the junction of the lid and the box.

- We close the lid, wait until the silicone sealant hardens, after which we can connect the grease trap.

Guide to Building a Grease Trap for Sewers

A grease trap can be made without problems if you do the following:

- Determine where exactly the grease collection device will be added to the sewer system. This area can be right under the kitchen sink or outside, but not in an area where flammable items are placed.

- Seal the lid of the box suitable for creating a grease trap by pulling a silicone or rubber gasket over it.

- Make a hole in one of the walls of the prepared box through which the inlet pipe will be passed. Typically, this slot is created in close proximity to the lid or at a distance of 5 cm from the upper edge of the side wall of the box.

The holes are located opposite each other, but not necessarily exactly in the middle of the box

- Drill a second hole opposite the first hole, which is necessary for installing the outlet pipe. It is permissible to make this hole in such a place that the lower end of the pipe inserted into it is 10–15 cm below the slot for the inlet pipe. It is important that the edge of the pipe mounted in the box is several centimeters higher than the bottom of the container used.

- Secure the pipes in the created slots using sealants and epoxy resin.

- Insert two partitions into the box. One barrier must be fixed with hot glue in the upper part of the box so that it rises 10 cm above the bottom. And the second partition, the length of which is 2/3 of the height of the box, should be attached at the bottom of the grease trap, thereby creating 3 sections in the device.

One grease trap pipe is connected to a pipe coming from the sink, and the other is combined with a sewer line through which water flows into a special well.

Useful tips

In order for the grease trap assembly to be successful, you need to listen to the following recommendations:

- suspecting that the partitions will not be able to withstand the pressure of water, instead of glue it is worth using a stronger fixative - epoxy resin in combination with corners;

- to protect the partitions from changing shape and breaking, they can be wrapped with rubber bands cut from automobile rubber;

- partitions can be installed not only vertically, but also diagonally, spreading them with long bolts;

- the holes for the inlet and outlet of the pipes do not have to be placed strictly in the central part of the box, because by making holes not in the middle of the box, you will be able to save space under the sink;

- holes for the pipes can be made with a children's wood burning device if there are concerns that it will not be possible to create holes with a jigsaw without avoiding the appearance of cracks;

- a vent is not necessary since the fermentation reaction in the grease trap is very slow.

Video: operation of a homemade grease trap

The manufacture and installation of the device described above will make it possible to safely use the sink without fear of contamination of the sewer pipes. You just need to disconnect the unit from the system at least once every 2 weeks and thoroughly clean it of its contents.

- Author: Ksenia Zubkova

I am a philologist by training and have been writing texts for more than 5 years. Rate this article:

- 5

- 4

- 3

- 2

- 1

(10 votes, average: 3.7 out of 5)

Share with your friends!

Grease trap under the sink: creating and installing it yourself

Cleanliness in the kitchen is very important since we deal with organic products every day. And we are talking not only about constant cleaning of the room, but also about keeping all appliances used in the kitchen clean, including pipes. The water that passes through them is purified from various contaminants. But what to do with the water used for washing dishes, etc. (by waste)? It is contaminated with fatty acids, which over time settle on the sewer pipes and this leads to various kinds of troubles, such as blockages, etc. To avoid this, use a grease trap. We will tell you how to make it and place it under the sink with your own hands, and also provide drawings and videos for clarity.

How to install a grease trap under the sink?

Before installing the unit, you should make sure that it will be placed correctly. It is necessary to ensure normal access to the device for its maintenance:

- There should be a distance of at least 2-3 cm between the body of the grease trap and the walls of the cabinet in which it will be hidden. This is necessary so as not to damage the furniture when the device is turned off for maintenance.

- Place the device only on a flat surface. Distortions will lead to fat pouring into the sewer.

- When installing, you must strictly adhere to the manufacturer's recommendations. The instructions indicate the optimal distance from the grease trap to the stove and other sources of open fire. This point cannot be violated.

- Separators of industrial production are equipped with special fasteners for installation and connection to the sewer.

- After installing the grease trap under the sink, it must be connected to the sewer. To do this, insert a corrugation from the main sewer pipe into the inlet pipe of the device, and connect another corrugation to the outlet tee. Seal the joints with silicone compound or sealing tape.

Attention! Fat thickens and forms a film on water if its temperature is below 40 degrees. It is advisable to install the separator at a distance from the siphon so that the wastewater has time to cool before entering the device’s reservoir.

There will be no problems with cleaning household grease traps. They are small in volume, so they can be easily removed and cleaned by hand. Devices with higher productivity are considered industrial, and to clean them you have to resort to either pumping equipment or special equipment.

Correct installation of a grease trap under the sink ensures clean sewer pipes and efficient operation of the sewer system. If you do not yet have a grease separator in your kitchen, then the editors of the Plumber Portal website strongly recommend that you purchase such a device or make it yourself.

Grease traps: design and principle of operation

The installation of grease traps at industrial and food facilities is subject to the availability of appropriate sanitary standards and regulations, but as for use in domestic conditions, is this device really necessary in the home? To do this, you need to understand what effect fatty substances have on the sewer system:

- When cooled, fatty acids turn into a flocculent mass, which settles on the walls of the pipes and over time leads to their clogging, reducing the flow of water. Over time, the system becomes completely impassable and must be cleaned (in the worst case, repaired).

- Fats lead to the gradual formation of caustic substances that have a persistent foul odor.

- Over time, fatty deposits oxidize and corrode the sewer system from the inside, rendering it completely unusable.

As you can see, using a grease trap is quite justified even at home. Let us briefly consider the device of a household installation. A grease trap is a completely sealed container with a removable lid, made of food-grade plastic and divided into several sections. The outermost ones are connected to pipes that cut into the waste pipeline. Installed under the sink.

Unit for prevention

A grease trap is an installation that, figuratively speaking, separates the wheat from the chaff. It is built into the sewerage system to prevent fatty deposits in pipes. And this technique is based on one simple principle - fat always rises to the surface of a certain volume of cool water. Most often, such devices are used in canteens and cookeries, where this is justified by sanitary standards. But you can also make a homemade grease trap at home. After all, its advantages are obvious:

- it prevents very unpleasant blockages in the sewer;

- the device of such a household installation is simple;

- Maintenance of such equipment is minimal.

Let’s first consider what the simplest “filling” of a household grease trap is. The main elements that a simple separator includes are given below.

- Inlet pipe.

- Partition.

- The outlet pipe to the sewer, usually in the form of a tee.

- All this is located in a box-shaped plastic case, the inlet and drain pipes look out.

Diagram of a household grease trap

If all these elements are present, the operating principle is as follows: water with fat enters through the inlet pipe from the kitchen sink. Inside our unit, liquid fills the primary chamber, where it settles a little, and meanwhile the fat rises to the top. This chamber is separated from the rest of the device by a partition.

However, this wall does not stretch all the way to the top. Its height is approximately two-thirds of the height of the box. So there remains a gap. It is through this upper “vent” that fat-free water flows into the adjacent chamber and at the very bottom enters the outlet pipe, most often made in the form of a tee. After which, in fact, the liquid flows into the sewer.

At the same time, all the collected fat remains on the surface of a constantly maintained volume of the working medium. Therefore, the described separator is serviceable. As the unpleasant suspension accumulates, the device must be completely disconnected from the line and then emptied of its contents. This operation must be performed at least once every two weeks. It all depends on the amount of dirt and the intensity of use of the sink. Next, we will consider the process of creating such a home appliance that needs to be cleaned periodically.

Making a grease trap with your own hands

Most often, materials such as steel, food grade plastic, fiberglass and polypropylene are used to manufacture this unit. We will consider the simplest option - making a plastic device.

Advice. If you have unnecessary products made from harmless plastic in your household, then you can safely use them to create a container for the unit.

Before proceeding directly to creating the design, it is important to make basic calculations that will help calculate the optimal installation volume for a particular water supply system. First, let's calculate the productivity of the unit being created. So, we use the following formula: P=nPs, where

- P - septic tank productivity, l/s;

- n is the number of sinks in the room;

- Рs — water supply speed (usually equal to 0.1 l/s).

After we know the productivity of the unit being constructed, we determine the required volume of the structure using the formula: V=60Pt, where

- t – average duration of fatty acid sedimentation (about 6 minutes);

- P is the unit’s performance, which we already know.

We make an installation drawing according to the received dimensions. Now you can start preparing tools and materials:

- material for the installation body (in our case - food grade plastic);

- sanitary silicone;

- construction adhesive;

- a piece of thermoplastic pipe with a diameter of 5 cm;

- thermoplastic elbow with a diameter of 5 cm;

- thermoplastic tee with a diameter of 5 cm.

The first step is to cut the parts for the body. For this we use a hacksaw / jigsaw. First we glue the sides (body) of our structure, only after that we fix the bottom. Then we install the internal partitions (their height should be 2/3 of the height of the side walls). We make the joints airtight using silicone.

We install an elbow into the assembled structure (it will act as an inlet pipe). We make an outlet pipe from a piece of pipe and a tee. There's only one small thing left to do - the top cover for the structure. We fix the rubber seal at the points of contact with the body. You can proceed to installing the unit in the work area.

Performance calculation

The efficiency of the simplest device is 25%, but you can make the device no worse. After all, according to reviews, the best household individual grease trap for each consumer will be the one that is made by hand.

But before you start producing a homemade grease catcher from the sink, you need to make a number of calculations. In order for the separator to effectively cope with its work, it is necessary to determine the degree of load or productivity.

For industrial equipment, complex formulas are used that take into account various factors. For domestic needs there is no need for these difficulties, and therefore you can use the formula P = n*Ps, where:

- P – productivity;

- n – number of serviced sinks;

- Ps – tap water pressure speed.

The Ps parameter is easy to determine. To do this, you should take a 1-liter jar, place it under the tap and open it with the pressure that is usually used (although, to be on the safe side, it is better to increase it a little), and note the time.

Let it be 1 minute, then the value needs to be converted to l/s. Typically it is 0.1 l/s.

Features of installation of the structure

Installing a grease trap is a fairly simple process, but it requires compliance with certain rules:

- First of all, we determine the location for installing the unit.

- We check and prepare the surface on which we will install the structure (it must be absolutely horizontal).

- We prepare all fastening elements for fixing the installation to the pipeline (clamps, fittings, etc.).

- We connect the inlet pipe to the sewer drain, and the outlet pipe to the drainage system.

- We test the installation after waiting for the first cleaning. If the unit has passed the test, the installation can be closed.

That's all, actually. In fact, as you can see, building and installing a grease trap for home use is quite simple. The main thing is to be careful, attentive and accurate. Good luck!

Household grease trap for sink: how to make it yourself

For every housewife, not only comfort and beauty in the kitchen is very important, but also the impeccable disposal of household fat waste in the kitchen . This is one of the main problems with the formation of blockages. A household grease trap will help solve this problem.

What is it? A grease trap is a special installation that will allow you to separate fat from wastewater. It is installed under the kitchen sink and connected in a special way to the sewage system.

The grease trap is in great demand in cafes, restaurants, canteens, etc. This is required by sanitary standards. However, it is also in great demand at home.

Types of filter elements

First, you need to understand why you need a grease filter for your hood in the first place, so that you don’t have the temptation to get rid of it, supposedly so that it “draws better.” This applies to disposable items that must be replaced frequently. And they are needed to protect the fan motor from sticky greasy deposits getting inside, which will cause the unit to fail very quickly.

The same sticky substance will cover the inside of the air ducts and walls of the shaft. Not only will they themselves begin to emit an unpleasant odor, but they can also become a hotbed for harmful microorganisms and food for cockroaches. This is prevented primarily by a grease filter for kitchen hoods, installed on all devices without exception. But the presence of the second type of elements - coal depends on the type of household appliance, which are:

- direct-flow;

- recirculating.

Direct-flow hoods are mainly hoods without a carbon filter, since they do not require one. The fan captures contaminated air and throws it into the exhaust shaft, from where it comes out under the influence of natural draft. Recirculation units do not require a shaft, since after purification they return all the air back into the room.

Important. When using a direct-flow type household appliance for exhaust hood in the kitchen, care should be taken to organize the flow of air from outside into the house

To do this, just open the window slightly or set the plastic window sash to ventilation mode. Otherwise, odor removal will be ineffective.

Recirculation hoods are equipped with a grease and carbon filter. The first traps fats, the second produces fine air purification. Carbon elements come in different configurations, but work the same way: the air mixture passes through a layer of activated carbon granules. This creates additional resistance in the flow path, which can be solved by using more powerful fans.

But filters that retain fat particles come in different types:

- disposable grease filter. Once contaminated, this element must be replaced; it cannot be restored by washing;

- perforated aluminum filters. They are in mid-price range hoods and can be cleaned by washing;

- mesh and perforated stainless steel elements. The most expensive cleaners, but they are durable and easy to regenerate (clean).

Main goals

One of the main tasks of a kitchen grease trap is to protect the inside of sewer pipes from household grease. Over time, the presence of grease in the inside of the pipes allows dirt to accumulate and cause blockages.

A grease trap for the kitchen also helps prevent the development of bacteria and unpleasant odors from the sewer. In private homes, a household grease trap will help solve the problem of clogged drainage wells and gutters; it is a simple and easy-to-maintain design.

If you take care of your household plumbing fixtures, they will serve as a reliable assistant for many years.

Requirements

The requirements for a grease trap for the kitchen are quite simple:

- Must separate grease from waste water;

- And reliably protect sewer pipes from sticking and accumulation of food and kitchen waste.

Operating principle

The operating principle of a kitchen grease trap is based on the difference in density between water and fat. Kitchen food waste tends to settle in the lower layers of wastewater. Fat has less density than water, so it always remains on the surface. That is, heavy liquids push lighter ones to the top - this is the basis of the principle of operation of a grease trap.

Necessity

As is already clear, the accumulation of grease in sewer drains creates serious problems. And now it’s worth thinking about how much of it can accumulate in the average cafe? In any case, special filters have been used in the kitchens of such establishments for a long time, so why don’t we, ordinary consumers, think about this problem? Better yet, ask yourself the question of how to make a household grease trap yourself.

Without such measures, sewer pipes would have to be cleaned almost every week, if not more often. What can we say about the entire sewage system of the region if all catering establishments do not equip their sinks with primary cleaning filters?!

For this reason, the sanitary service even has such a requirement - the mandatory installation of such equipment in all establishments whose activities are related to food. Also included here are those enterprises that specialize in processing oils, fats and other insoluble particles.

And for any conscientious housewife, the kitchen is its own mini-cafe. Therefore, if you do not want to often use cleaning products for sewer pipes (Mole, plunger, etc.), you should take care of installing good filters under the sink. If for public institutions they are large, then for the average consumer household grease traps will do.

Options for household grease traps

A household grease trap can be purchased at a store. For example, on the Internet there are a large number of online stores selling and installing grease traps for the kitchen. You can also do it yourself.

For its manufacture you can use materials such as:

- fiberglass;

- steel;

- polypropylene;

- food plastic.

The above material can be used to make the body of the product. You will also need plumbing silicone, construction adhesive, thermoplastic materials with a diameter of 5 cm:

Most often, plastic or fiberglass is used in manufacturing. These materials are easy to use, their service life is quite long and their cost is low.

Filter classification

As for the varieties, devices are divided into different types depending on a number of criteria. The general classification is as follows:

1. Based on the material of use:

- plastic;

- fiberglass;

- stainless steel;

- polypropylene;

- food plastic.

2. According to installation method:

- under the sink;

- for basements;

- for specially designated premises.

3. Taking into account the manufacturer:

- "Alta". Suitable for small cross-section sewer pipes, and the price on the Russian market is one of the best.

- Flotenk. This household grease trap can be installed not only indoors, but also outdoors. Due to their reliability, such devices are popular among owners of small cafes and restaurants.

- Labko. They are very popular among catering professionals.

- Evo Stock. Models in which the separator is made of reinforced plastic and polypropylene. Relevant for household use.

- Helyx. The filters are designed primarily for industrial applications.

- "5th element". In addition to ordinary consumers, these filters are ideal for industrial facilities.

The cost of the listed models is approximately the same. The same can be said about the principle of operation.

Service

Grease trap maintenance work begins with the process of cleaning the storage tank. It needs to be pulled out and the fat and oils thrown into the trash. To determine how often the grease trap needs to be cleaned, it is necessary to carry out this work for several days in a row. In the future, the frequency of cleaning the installation will become clear.

In addition , approximately once every six months it is necessary to open the grease trap and disinfect it. Such work is necessary to prevent harmful bacteria and microorganisms.

Is there a universal filter for charcoal hoods?

Today, universal carbon elements are quite popular, which can be used in almost all types of hoods in recirculation mode, that is, when there is no connection to ventilation.

VIDEO INSTRUCTION

Which is better, a charcoal or grease filter for a hood?

Often, air exhaust hoods make do with only one filter – a grease filter, but for complete air purification it is still recommended to install a carbon one. How are they different from each other?

The fatty one performs rough cleaning and is designed to trap large particles of fat and soot that can damage the motor blades. The fatty element also protects the inner walls from oil vapors. Absorbs up to 96% of fat particles and unpleasant odors.

Coal ones are intended for fine cleaning; it is no coincidence that they are called anti-odor or absorption. Absorbs gases, harmful impurities of steam, odors.

Fat disposables are made from synthetic fibers, for example, acrylic, padding polyester, non-woven fabric. Used in inexpensive hoods. They cannot be cleaned and therefore require replacement.

Reusable ones are made of metal and mesh foil - symmetrical or asymmetrical. For production, stainless steel or galvanized steel with a protective layer against oxidation is used. Reusable ones are more practical; they are easy to wash by hand or in the dishwasher. Used in more expensive hoods.

Let's look at several models of grease filters on the market.

Lissant-yug produces cassette versions suitable for use at temperatures up to +70C. They are non-separable, made of galvanized or stainless steel with a thickness of 0.5 mm. The filter element has five plates.

Manufacturer Roven offers customers a one-piece prefabricated structure made of stainless steel or galvanized steel that can withstand temperatures up to +80C. The filter element has three or five plates.

The manufacturer Titan produces options made of stainless steel with a thickness of 0.5 mm and a working environment temperature of up to +70C.

Carbon filters are all disposable. The degree of filling may vary. The denser the coal, the lower the throughput. The shape can be round, rectangular, concave, flat. The body is usually made of plastic.

Buyers can order a carbon element of the desired size or purchase a standard one.

The range of hoods with a carbon element is very large. Thus, carbon filters for hoods from Hansa, Gorenje, Krona, and Electrolux are popular.

It is impossible to unequivocally answer the question which one is better, since it is necessary to use them simultaneously. In this case, high-quality and complete air purification will be ensured.

Where to buy a carbon filter for an exhaust hood - review of manufacturers

Let's consider different options for hoods with carbon purification systems from popular manufacturers.

Hoods:

Filters:

Carbon filters for Krohn hoods are used in equipment in two modes: ventilation and recirculation. There is a large assortment of hoods in different price categories.

If your hood does not have a built-in filter, or you need to purchase a new one to replace it, you should pay attention to the carbon filter for the Jet air hood. The Portuguese manufacturer produces high-quality accessories and consumables that require replacement once every six months

Carbon filters for Folter hoods are produced at the Russian enterprise Folter. This is one of the leaders among domestic companies producing dust collectors and filters for both household and industrial use.

Chinese manufacturers do not lag behind Russian and European competitors, and if desired, you can purchase Shindo elements that can be easily used for equipment of different brands.

error: Content protected!!

Grease traps for washing: types and methods of cleaning

The problem of sewer blockages is acute in the private and commercial sectors.

Residues of food, debris and other components enter the drain system, forming blood clots, to clean which it is necessary to dismantle the pipes and dismantle the walls. To prevent this from happening, grease traps are installed under the sink - a kind of separator that separates liquid from solid particles. Where is such equipment used?

- Private and apartment buildings;

- Public catering points;

- In the food industry.

How does it work? The principle of operation of a grease trap is that water passes through several compartments. Once in the first, suspended waste particles settle on the walls. The second reservoir blocks the exit of the liquid until it overflows from the top, thus the product with a concentration of up to 25 mg per liter enters the next one. To understand in more detail, it is recommended to look at the drawing of grease traps:

Operating principle

The operation of the device is based on the principle of separation (separation) of fats from water. This is made possible due to the weight difference - fat is lighter than water. Thanks to this, it calmly floats to its surface. Thus he falls into the trap and remains there. All filters work according to this principle, without exception, regardless of their purpose: for a cafe or for ordinary everyday life.

How does a grease trap work? The water that flows out of the sink enters the first chamber through the inlet pipe. Here, dirty water is filled and partially purified. Fat accumulates on the surface. Due to the partition, the chamber makes up 2/3 of the entire size of the box. Through it, the water, which has gotten rid of the fat, enters another compartment. The purified liquid then flows along the bottom of the household grease trap under the sink to the outlet pipe, and then into the sewer.

The volume of the filter, of course, is not infinite, and therefore it is necessary to disconnect the device from the sewer every two weeks and clean it from accumulated grease. If a large amount of dirt gets into the drain pipes, then cleaning should be done more often.

Types of materials

Various materials are used in the manufacture of grease traps for sewerage. Take a closer look:

Made of plastic: such models are now becoming more and more common. This is due to their low cost and high durability. They can last up to 30 years. Look at other benefits:

- Environmental friendliness - no harm to nature and human health;

- Easy to maintain - no special tools required for cleaning;

- Large selection of formats - manufacturers produce equipment according to individual and standard sizes.

A household grease trap installed under a sink is almost always made of plastic. It is used not only in the private sector, but also in cafes, bars, etc.

Stainless steel: the most expensive type of product, used by elite restaurants and industrial facilities.

A grease trap for a cafe sink should be selected based on peak water discharges during busy operating hours.

Made of fiberglass: more often used in industry, installed outdoors or in basements. The material of such grease traps withstands the vagaries of the weather well and is not afraid of contact with reagents.

What does the market offer?

Today on the market of plumbing fixtures in the Russian Federation there are quite a lot of products from companies that produce grease separators for kitchen sinks. Among them are the leaders:

- Products

It can be found in four layout modifications: “standard”, “pro”, “auto-assembled”, “steel”. In each of these configurations, you can select a grease trap that matches the tasks assigned to it. The choice may be influenced by the following parameters: productivity - 0.5-1.5 m3/h, peak water discharge - 25-175 l, number of connected sinks - 1-3, material of the working container - polypropylene or steel. However, ease of maintenance is also important, which is provided by removable plates or canisters for fat, as well as garbage trays in certain modifications. The most compact device has dimensions of 420*320*370 mm (L*W*H). - Evostok OIL separators are also presented in models - from the smallest, designed for installation under sinks in standard apartments, to large-sized ones, capable of cleaning the drains of large cottages, canteens, restaurants, etc. They are distinguished by the simplicity of their internal structure, assembled in a polypropylene case using a two-chamber design. Dimensions of the smallest model – 420*320*370 mm.

- The Termit brand offers only four standard sizes of its separators, covering the most popular segment, installed under grease trap sinks. The containers of the devices are made of high-density polyethylene in a three-chamber design. An additional option in their configuration may be a tray for garbage and large waste. This is a removable plastic container that can be easily removed and washed when filled. The smallest installation is 450x350x395 mm.

- Triton-PM cleaners are reliable units of the Russian brand. Available in two-chamber cast polymer housings. Their models occupy the entire functional range in terms of operating capacity and peak discharge for use in everyday life, as well as in mini-industry (cafes, canteens, restaurants). Although the dimensions of the smallest standard product are 420*320*370 mm, the manufacturer is ready to manufacture a separation plumbing installation to suit the customer’s individual requests.

As a contrasting example, consider the Hydrig automatic grease removal equipment. These are quite complex and expensive stainless steel products intended for use primarily in catering facilities.

Grease trap "Hydrig"

In them, the technological separation process occurs due to electrical heating of wastewater, followed by separation and collection of fat mechanically. The equipment is energy-dependent, but provides the highest degree of purification compared to the above-described gravitational installations. The dimensions of the main unit of the smallest model are 590*500*335 mm.

Cleaning methods

Any grease trap installed under sinks must be periodically cleaned of waste accumulated in it. Otherwise, a blockage will occur - debris leaking into the pipeline is excluded, however, this does not mean that the situation should be neglected. With regular maintenance, the grease trap will last many times longer, and you will not have to deal with surprises in the form of having to drain stagnant water into a bucket.

How to clean a plastic product? Home units are the easiest to use, usually featuring an oval design with a screw-on lid. Reach under the sink and unscrew the grease trap with your own hands. Clean the walls with a knife or rag. Pay attention to holes and crevices and, if necessary, remove the gaskets and treat them.

Industrial: the design of this type of grease trap is identical to the previous ones. It stands out only due to its large size and the presence of bolted covers. To service it you will need the appropriate tools. Given the amount of substances collected, it will most likely be necessary to use chemicals. Today, a number of companies offer cleaning services for such systems.

A grease trap under the sink should be selected based on its performance. The device must freely pass the fluid flow used by a person.

Top 5 manufacturers

When choosing a grease trap for the kitchen , some people prefer cheap and popular models, while others buy more expensive, functional, durable ones - with a 30-year service life. When evaluating grease traps, you need to pay attention to their performance.

The Top 5 by popularity included several well-known manufacturers:

- Evo Stok - offers inexpensive devices made from durable reinforced plastic.

- FloTenk is engaged in the production of high-performance grease traps made of reinforced fiberglass, mainly round in shape. The products of this brand have a high price, but a longer service life.

- “Fifth Element” is a brand specializing in the production of steel and plastic devices with a removable water flow limiter; its products are customized to the individual parameters of kitchen sinks.

- Wavin Labko - offers automated fiberglass models that capture grease with high performance. There is a sensor that informs about the level of accumulated fat in the container.

- Vortex - produces devices that have a durable reinforced plastic body, including models for non-standard sewer systems. Special stiffening ribs on the body give the separator better resistance to mechanical deformation.

Stainless steel separators from ACO Group are in demand, as are sewer grease traps made from Termit polypropylene, which are used in small-scale catering establishments. Grease Guardian brand products operating in automatic mode are installed in all McDonald's.

Attention! Up to 10 washing baths can be connected to high-quality, energy-saving and efficient HYDRIG grease traps for wastewater from cafes and restaurants.

Installation procedure

Installing a grease trap is a simple procedure that does not require special skills. Essentially, you just connect it to the piping, just like any other plumbing item. It is important to pay attention to the following details:

- It is necessary to allocate a reserve space under the sink so that the grease separator can be serviced in the future;

Install a grinder on your sink to reduce the likelihood of blockages, eliminating the need to frequently open grease traps.