What is sealant for sewer cast iron pipes and how to choose the right material for sealing joints? One of the main tasks facing the master at the final stage of construction is to prevent leaks that appear in the sewer system.

Sealant for sewer pipes is a special composition that protects joints from leakage. In addition, it provides ease of installation and helps cope with emergency situations. In this article we will look at what types of sealing substances there are for PVC pipes and cast iron channels.

When is sealing of sewer pipes required?

Often the sewer riser or outlet parts of a cast iron pipe receive serious damage. An inspection shows that a piece of the cemented patch is falling off, and the pipe itself may fail. In this case, the master decides to use sealant for cast iron sewer pipes or PVC plastic pipes. During the work, the recommendations specified in SNiPs and technical regulations, pipe wear, hydraulic effects and the possibility of leaks are taken into account.

Sealant for sewer pipes must be selected taking into account the fact that this external sewer has a significant diameter and a large length.

Sealing PVC sewer pipes is necessary to prevent sewage from entering the apartment and eliminating unpleasant odors in residential areas.

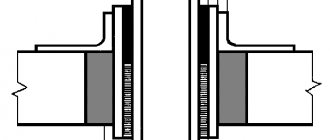

Scheme for sealing a pipe joint

Solving the problem of sealing joints must be taken quite seriously.

Having identified the cause of the malfunction that is interfering with the operation of the cast iron pipe, the owner can carry out the entire cycle of necessary work to eliminate it.

The causes of pipe leaks are varied:

- defect in the material used to install the sewer;

- improper laying of cast iron sections;

- the presence of cracks and holes in the riser.

Causes of leakage

First of all, it is necessary to accurately determine the location of the leak. This is not easy, as you must first ensure access to the pipes or connections. If you find that the toilet is leaking at the connection to the sewer, you need to carefully inspect the area where the outlet is connected to the sewer tee outlet. This procedure should not be postponed, as the problem will not go away on its own. It is necessary to remove all interfering objects and, if possible, remove the casing around the outlet area. You will have to flush the water several times to make sure that it is the toilet that is leaking at the junction with the sewer. In order not to create unnecessary worries for yourself, you need to place some suitable container under the connection area into which the water will flow. It will be useful to install additional lighting in the problem area to see the location of the leak. If the water does not flow much, but only drips occasionally, you can lay newspaper under the junction of the outlet and the pipe. It will clearly show where the drops fall.

When it is definitely established that the connection between the toilet and the sewer pipe is leaking, and not some other area, it is necessary to establish the cause of the leak. The most common sources of the problem are:

- the appearance of a crack in the socket of the connecting element of the tee;

- dried rubber with cracks on the adapter;

- the appearance of a crack on the toilet outlet element.

The appearance of cracks in the tee or on the exhaust pipe indicates the need to replace the defective element. However, in both cases difficulties may arise. Most often they appear due to the difficulty of dismantling pipes or earthenware bowls. In addition, replacing intermediate sewerage elements is not always possible. For example, if the socket of a cast iron fitting turns out to be a defective element, it will be very difficult to disassemble or replace it.

Rubber coupling

Often the reason why the toilet leaks at the junction with the sewer lies in the condition of the rubber adapter coupling. If it was made from low-quality rubber, or is simply too old, the material dries out, loses its elasticity, and cracks. Unfortunately, it is somehow impossible to foresee such an outcome, since high-quality couplings serve for more than 10 years without deformation or destruction. The only way to detect emerging problems in a timely manner is to periodically pay attention to the connection between the outlet and the tee.

Toilet outlet pipe cracked

The appearance of a crack in a faience bowl or outlet pipe is a clear signal to replace the problematic plumbing fixtures. This is evidence of excessive load on the outlet, misalignment during installation, and other unacceptable influences. Often, inexperienced craftsmen stand on the bowl during repairs or other work, hoping for its strength. This is an undesirable, extremely dangerous behavior, since the split earthenware has sharp cutting edges. They can seriously injure you, leading to hospitalization and long-term treatment. The behavior of a crack cannot be predicted - it may not change for years, or it may grow in a matter of days. Earthenware reacts to temperature changes, so the crack is unstable and can spread very quickly.

In any case, if the connection between the toilet and the sewer pipe is leaking, it is necessary to urgently take measures to eliminate the defects. Having figured out the cause of the leak, you must immediately begin to eliminate it.

Types of sealants

Sealing of sewer pipes can be done with the following materials:

- reinforced aluminum adhesive tapes;

- silicone sealants;

- mastics from various manufacturers;

- polymer cement solutions;

- sanitary winding;

- epoxy resin;

- technical sulfur.

To choose the right sealant for sewer pipes, you need to know the material from which the drain is made. Silicone compounds and reinforced tapes are suitable for lightweight plastic pipes PVC, PEX, HDPE, etc. If you have to work with metal (steel or cast iron), you need to use something serious. It is also important to consider for what work the solution is purchased.

The joints of PVC plastic pipes are sealed with lightweight silicone, which is unlikely to cope with an emergency leaking sewer. It is also important to follow the instructions. It describes the optimal conditions under which sewer pipes should be sealed. For example, let's take the optimal conditions for curing silicone sealant (this is room temperature, at which it dries for about 4 minutes). When working in cold weather, the hardening time is significantly longer.

There is a need to purchase another type of sealant - frost-resistant silicone. We'll talk about the nuances of using different materials below.

Self-adhesive tapes and their properties

The structure of the sealing tape

This type of sealing can be used both to seal and protect joints, and to strengthen sealing plugs, fittings, taps, corners and elbows. The main advantage of the tape is its ease of use. It is wrapped in several layers around the pipe on the desired section of the sewer. This ensures reliable and long-term operation of the system, protection against corrosion and the effects of currents, and waterproofing of joints. Depending on the composition, adhesive tape can be used both on cast iron sewer pipes and on plastic, such as PVC or PE (HDPE) pipes.

The tape must be applied to a dry surface. Before winding, the pipe is cleaned of dirt and liquid and degreased. Next, we wrap the problem area with an overlap so that the previous round overlaps the new one by half the width. We keep the tape under tension and do not create folds.

As for the choice of insulating material, special anti-corrosion tape coatings should be used. They are used to seal joints between pipes, seal coupling units, tie-ins, and bends related to the sewer system.

What is a sealing tape that insulates a sewer pipe? The product is based on a bitumen-rubber mixture and a protective film.

The peculiarity of the material is that it has a high degree of strength, is used to work with various compositions, and does not collapse for a long time.

You can avoid the unpleasant consequences of a leaking sewer riser by sealing the joints with a silicone compound. For work, 2 types of materials are used:

- acid insulation;

- neutral sealant.

Repairing defects using a neutral compound will cost the owner much more than working with acidic insulation.

The use of silicone is economically beneficial, since the material has significant adhesion.

As for the use of other sealing compounds, here you can choose the following types:

- bitumen mastic;

- cement mortar;

- asbestos cement composition.

Cast iron for water supply and sewerage

First, let's look at what can be used to seal a leak if a cast-iron sewer or water pipe cracks.

There are two possible cases:

- leaks at the pipe joint;

- there is a crack or fistula in the riser.

Type 1 failure can be eliminated by using a new caulking of the socket.

To eliminate this type of leak, you need to perform the following set of actions:

- disconnect the sewage or water supply system;

- Dry the joint using a hairdryer or rag;

- remove remnants of old cement mortar and packing;

- using linen plumbing tape, caulk the gap between the pipes;

- Make 200-300 ml of an aqueous solution from polycement and PVA glue, and apply it to the embossing area several times, at intervals of 8-10 minutes;

- Do not use the sewer system for 24 hours.

In the second case, there are several ways to repair the riser:

- Chemical method

To do this you need:

- using a wire brush or coarse sandpaper, thoroughly clean the area of future repair;

- Thoroughly degrease the problem area with acetone or another solvent;

- take copper oxide and phosphoric acid, prepare the mixture necessary for work in a ratio of 3:2;

- Using the resulting composition, carefully cover the joint. The procedure should be carried out with a freshly prepared mixture, since it hardens within a few tens of seconds. Therefore, you will be able to use the sewer in 2-3 hours.

- “Cold welding” To reliably seal the hole, you should buy “Cold welding” - this is the name of the special glue. So, before sealing the hole, you need to clean the desired area from dirt, water, rust, and mark the place for repair with chalk. After this, you should sand the desired area on the surface of the collector well with coarse sandpaper and degrease it. Then apply a small patch of glue to the hole and place a sealing rubber patch on top. A similar method is used to eliminate a hole in a plastic pipe.

- Reliable In order to give a complete answer to the question of how to repair a crack in a cast iron sewer or water pipe, you need to remember one more, most reliable, method. To bring it to life, it is necessary to take sulfur, iron filings, and powdered ammonia in approximately equal proportions.

Mix all ingredients thoroughly, adding the required amount of water to form a homogeneous mass, the consistency of which would resemble thick sour cream. Seal joints and other openings with this solution. As practitioners say, there is no best way to seal cracks and holes.

- Using a clamp Water supply and sewer systems have been repaired for decades using a special clamp. It is very effective at sealing holes. Before starting work, you need to purchase a clamp or, as a last resort, make it yourself, taking into account the diameter of the pipe. First, wrap the pipe very tightly in the place where the hole is located with a rubber winding. Then they put a clamp on this place and securely tighten the bolts on it. This way you can get rid of any leak, even a big one.

Silicone sealant

Sealing of joints is carried out using silicone adhesives made in accordance with TU 6-15-1822-95, GOST 6-02-4-53-96.

All plumbers have a weakness for this type of sealant. Meanwhile, silicone compounds have good sealing ability, allow you to seal seams and cracks in plastic and cast iron pipes, dry quickly and are easily removed from the surface.

There are two types of silicone compounds.

- The first type, neutral , allows you to work with any surface and does not come into contact with water and other substances. Features a higher price tag.

- The second sealant, acidic , is used only for PVC pipes and other plastics. Although it is a cheap substitute, it destroys metal and cement-containing materials. In the presence of water, it breaks off acetic acid, which can damage the inside of pipes. Therefore, for cast iron and steel pipes we choose only neutral sealant.

Silicone insulating material is a rubber-based composition consisting of a filler, a hardener and a catalyst. The vulcanization temperature of the material ranges from +60 to +200˚С.

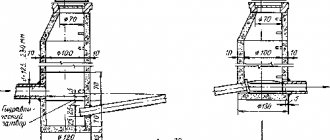

Stages of sealing cast iron pipes with sealant

Silicone sealant for repairing PVC pipes in the sewerage system has a density of 2.0 g/cm³, dries at a temperature of +20˚C in 150 minutes. The tensile strength characteristics are even more varied, ranging from 16 to 20 kgf/cm² and depending on the grade of material.

The peculiarity of the sealant is that the vulcanizer has high adhesion to steel, copper, aluminum, silicate glue, and concrete. Silicone sealant is resistant to adverse weather conditions, solvents, synthetic and mineral oils.

When repairing a pipe, there is no pollution of the environment with toxic substances, since silicone materials belong to class 4 of low-hazard products. The sealant is used for gluing and sealing joints and connectors when repairing sewer pipes.

Technical sulfur

Sealing an old cast iron drain can be very difficult. Technical sulfur was often used to repair cast iron pipes. But to apply it, it was necessary to heat the composition to a plastic state. A special vessel was used (bath for heating sulfur).

The material is pre-melted in an electric furnace at a temperature of 130-135˚C, and then poured into the socket. Unfortunately, the repair may be of poor quality if it was not possible to fill it at once.

Observing special precautions will help you avoid unpleasant consequences when working with sulfur, since the sealant easily spills, and careless handling leads to a chemical burn.

In addition to the high temperature and risk of fire, there was another risk factor during such work - toxic gas was released during combustion. Therefore, I had to work in a respirator. Nowadays, pipes can be sealed in safer ways, so technical sulfur is practically not used.

Epoxy resin (glue)

PVC sewerage equipment that is significantly worn out, with numerous damages, is repaired using epoxy resin. The material is necessary to eliminate leaks when repairing PVC pipes.

Through cracks discovered after inspection of the equipment are sealed using a two-component adhesive composition. The mixture is prepared immediately before use, following the manufacturer's recommendations.

Fragile types of sewerage (cast iron, ceramics) can also be sealed using epoxy resin. Such pipes require a stronger and more reliable connection, which epoxy glue does well.

Fixing a leak is quite easy if you use epoxy resin . The composition is used in combination with a hardener, and the ratio of components to form the working mixture is 1:2 or 1:1.

To seal seams and emergency areas, epoxy resin is mixed with a hardener and applied to the break site. The mass dries quickly, serves for a long time and reliably, and is resistant to aggressive acids and alkalis.

The polymerization reaction proceeds much faster when the temperature increases by 10˚ C. The sealing of the resulting cracks is quite strong, since the epoxy composition has minimal shrinkage, high resistance to adverse factors, and stable physical and mechanical characteristics.

Epoxy adhesive is obtained by mixing resin and hardener in a ratio of 1:10, and distilled water is used to form a composition with water-borne resin.

Epoxy resin is a common material for connecting PVC sewer pipes. The joint is sealed by pouring resin into the gap, and to obtain a lasting result it can be used in hot and cold conditions.

Heating systems

Steel pipes are most often used to connect heating radiators to each other. If you notice water on the floor, you need to immediately find out where the leak occurred. How to repair a crack or other hole in a heating pipe?

The most common ways to fix a leak:

- To temporarily solve the problem, just take soft rubber (for example, from an old bicycle tube), wrap it tightly around the damaged area, put a clamp on top or wrap it with wire.

- With the help of a bandage. To do this, you need to buy a factory-made bandage, which is equipped with a rubber seal, as well as a clamp, and mount it in the problem area.

- When water drips or flows at the connection of the heating pipe, this is a more complex option, since it is possible that there are different diameters of the risers. In this case, you can also use the factory bandage, you just need to replace the sealing rubber with a piece of soft rubber. The main thing is to wind it correctly on the pipe, as well as on the fittings, in order to smooth out the difference in diameters. After this, apply a clamp.

- Heating pipes can also be repaired using electric or gas welding. Although in most cases, at home, a crack in a pipe is repaired without welding. But these are temporary measures.

Video

Cement

Sealing the joint with cement

When sealing a cast iron socket, Portland cement can be used. This substance dries quickly and provides reliable protection against leaks and accidents. For sealing, a high-quality grade of Portland cement is used. When working with Portland cement, it is necessary to apply the mixture over the joint.

A plumber's wrap is applied to the end of the pipe, and resin strands can be used for thick channels. The end is inserted into the socket, compacted and filled with Portland cement. This design will last for many years.

True, when dismantling it, your followers will have a lot of difficulties. But that is another story.

How to Seal a Hole with Sealing Tape

Using this modern material, you can efficiently eliminate small leaks in pipes located in bathrooms. Externally, it is an adhesive fabric impregnated with special substances. Most often, joints and connecting elements are sealed with sealing tape. As for straight sections, they can also be repaired using this method.

READ ALSO: Welding HDPE pipes using the coupling method

When using sealing tape, it is important to follow the following sequence of work:

- The damaged area must be thoroughly cleaned and dried.

- After stretching a small piece of tape, it is wrapped around the pipe. It is important that this procedure is accompanied by constant tension in the tape, otherwise folds will appear.

- When winding, each new turn should be laid on half of the previous one. It is best to pack the pipe with two layers of sealing tape.

The main disadvantage of this method is the insufficient resistance of the repair material to sunlight. To achieve a good service life, the wound tape is coated with additional protection.