I live in a house where grapes have been growing for over 40 years and I don’t know what to do with them (they have seeds, so I don’t eat them very much). I also have a great basement and project room and this year I decided to try making wine. Having tried to make grape jam last year, I realized that using a potato masher is inconvenient and ineffective.

I visited a local winery and asked about the brewing process and basic materials. The store manager said that 50 kg of grapes can make 35-40 liters of wine. From what I remember last year, we took about 7 kilograms of grapes (including stems) and got about 3 liters of juice after 45 minutes of rubbing and squeezing through a cloth. If we want to process all 50 kg, we need a more efficient processing method.

My basic crusher plan was to use a car jack to push a disc into a perforated pot to press the grapes. A little later you will see drawings of what I got and how to make a grape press with your own hands.

How to use the press

To use a homemade press, the basket is covered with filter cloth. As a filter, you can use gauze folded in several layers, special fabric, chintz or synthetic fiber. It is important that it does not contain dangerous dyes.

Squeezing grapes

The grapes are removed from the bunches. If juice is supposed to be made from it, the berries are washed under running water. For wine, washing the berries is not required, since it is the grape skins that contain wine yeast, which causes natural fermentation.

Next, grapes are loaded into the basket. It is covered with a wooden shield on top. Using a lever or handle, a metal “pancake” is lowered onto a wooden shield. Under metal pressure, the juice formed from the grapes gradually enters the pan and, entering the hose, is drained into a receiving container.

It is recommended to squeeze the pulp no more than 3 times. If the juice is intended for making wine, the grapes are pre-fermented. Only after this is it pressed.

After use, the grape press is disassembled, thoroughly washed and dried. These manipulations must be carried out after each use of the equipment. Otherwise, the wooden structural elements will rot.

Advice on how to make a grape juicer from scrap materials

Hello. Today I want to talk about how quickly and easily you can make a grape juicer from scrap materials. I'll start from the beginning, this is my dacha.

Growing grapes in the middle zone has recently become widespread among summer residents and gardeners. This is quite possible, you just need to choose the right variety.

This summer was warm and sunny, which contributed to an abundant harvest.

So it ripened for me, the clusters pressed the vine to the ground, the leaf turned yellow and began to fall off. The vine from the house spread to the early apple tree and entwined the top. There are no apples or foliage on the apple tree, just black clusters in a continuous carpet.

Having collected two buckets of “happiness” to begin with, I was puzzled as to how to process it all? The best option is juice. If you want, can it, if you want, make wine. Buying a juicer is a bit expensive. You can, of course, like Celentano, crush grapes with your heels while dancing to the music.

But no, health is not enough. All that remains is to manually look for a beater and... and then the idea came to make a juicer press from scrap materials.

At the dacha I managed to find:

1 saucepan for six liters 2 aluminum lid, then replaced with a metal one (it is more rigid) 3 baluster (left over from the stairs)

This will be the press piston

Let's call this a cylinder

But in general, like IA from the cartoon: - enters and exits. Made a little effort.

I used the armrest from an old chair to adjust the height of the press.

Drilled holes for different heights

Secured the key from being pulled out when applying a load

I screwed a screw into the lever instead of a dowel

A miracle of budget engineering is in front of you -). It's time to pump this device under load, fill it with grapes, a bucket, and press. As it subsides, we change the height of the lever mounting. Periodically draining the squeezed juice

At the end of the process, throw away the cake; it is tightly compressed and practically does not ooze.

Without particularly straining, in thirty-five minutes the juice was separated from two buckets of grapes. I will use this spin for conservation. Grapes from your own garden can only be harvested for wine in dry and sunny weather. In my case, there was light rain yesterday. Only after 2-3 days will the wild yeast recover.

Ideally, I think that if you throw away the wooden lever and put a hydraulic bottle jack in a metal frame, things will be more fun -)))

Stages of pulp pressing

I’ll say right away: the technologies for making red and white wine differ from each other. If you have the time, desire and inspiration to make real, proper red wine, you will have to work a little harder.

- First you need to make pulp and put it on fermentation along with berry peels and skins.

- After fermentation is complete, the pulp sinks to the bottom of the container with the wort.

- Part of the wine is drained by gravity, and the remaining pulp is unloaded from the container for pressing.

Pressed wines are richer in tannins, minerals and have a brighter color. To obtain pressed wine of good quality, the wort must be constantly stirred during fermentation for better aeration.

The simplest option is to crush the berries, squeeze out the juice and put it on fermentation. This is what they do when they want to get homemade wine with minimal labor.

Separation of wort by gravity

From the very beginning of draining, the wort flows under gravity rather than under pressure. Gravity in Bordeaux is called “big wine”. It differs not only in the method of production, but also in its characteristics. It balances sugar and acidity. The taste is more subtle and soft due to less tannins. At the same time, the product has a weaker color and a reduced amount of anthocyanins, which are responsible for the anti-inflammatory properties of wine. Gravity separated wines are more susceptible to developing yeasty and sour odors. That's why they are mixed with pressed wine to add depth of flavor and color.

The main rule is to load crushed raw materials into the press

First pressure wort

After the wine has been drained or siphoned off, we need to press the remaining must. The wort is removed from the vat or bottle, moved to a press and pressed. The result is pressed first-press wine. It contains a reduced alcohol content and an increased sugar content, but there is no excess sugar content. First pressure wort has a brighter color and a more tart taste due to the increased content of anthocyanins and tannins. There is no malic acid in it, the taste qualities are bright.

The wort can be blended (mixed) with “big wine” immediately after the end of pressing. This is how young table wines are produced.

Second pressure wort

But the first pressing does not completely free the pulp from the wort. Therefore, a second and even a third spin is acceptable. Before each subsequent pressing, the residue is further crushed in order to achieve a greater degree of grinding of the material. Naturally, repeated crushing causes the destruction of the pulp material, releasing more bitter and astringent fractions. Second-press wort contains sugar, malic acid, and has a high tannin content. It is not blended immediately, but is allowed to mature separately, and only after that it is put into production. The second pressing must is used to produce dessert wine.

Third pressure wort

We grind the pulp again and put it under the press again. As a result of the third pressing, we obtain a wine with high acidity, high tannin content, but the level of sugars in it is minimal. The anthocyanin content decreases, as does color saturation. Third pressing must is not added to young wines. It is used to produce vintage wines, as well as strong red wines.

If you continue pressing the wort, the resulting raw material can be used to prepare grape alcohol.

DIY juice presses

It is quite possible to make a juice press with your own hands, the main thing is to find operating diagrams and drawings of such homemade products, which will not be difficult. Many of those home craftsmen who already have experience in making such equipment are happy to share photos of their devices and even videos showing the process of their manufacture and the principle of operation in detail.

Homemade juice presses

Most often they try to make screw-type presses with their own hands. Meanwhile, it should be borne in mind that it will not be possible to make a powerful screw for such a device without the involvement of a qualified turner. You can make a homemade press without third-party specialists if you replace the screw mechanism with a conventional jack (mechanical or hydraulic), which is in the arsenal of every car enthusiast.

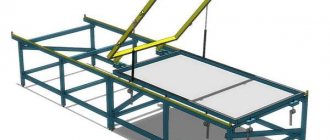

Drawing of a press based on a car jack

What to look for when choosing a wine press?

What criteria should be used as the basis for choosing a press?

Mounting location: floor or tabletop

For large rooms, it is logical to choose a floor press. As a rule, such devices have a large capacity.

If the size of the room is limited, you need to place the equipment compactly and conveniently, then opt for tabletop presses, especially since among them there are capacious models for 8–10 liters of the finished product.

Volume

The press has two volume characteristics - loading (basket volume) and output.

The basket volume shows how much raw material the press can accept at one time. The second is how much juice or wine the press produces in one cycle of operation with a full load.

Thus, a press with a 20 liter basket produces 8–12 liters of product. Equipment for 10 liters of raw material loading will produce 4–6 liters of juice.

The choice depends on what volumes you expect to work with. Take the press not “for growth”, but based on real needs.

Draw your attention! It is impossible to achieve the same juice yield for all types of raw materials. If it is said that a press allows you to get 4-6 liters of juice from 10 kg of product, then this is an average figure. Pressing, say, grapes will give you this volume, but from currants there will be much less juice. Therefore, I give average figures for the output volume.

Automatic or manual

I have already spoken about this above. The greater the volume of raw materials for processing, the more work. Therefore, to obtain wine from your own grapes or apples, you can use a hand press. If you have plans to process hundreds of kilograms of fruit and berry products, then it is worth investing in a productive automatic press.

Material of manufacture and price

Depends on your tastes and capabilities. Moreover, most modern models still have a stainless steel working part.

A press is a must-have attribute for craft fans.

Basic design of wine presses

The general structure of a wine press is well described by its colloquial name: a crusher.

There is a place for laying crushed raw materials, there is a tray for draining the liquid fraction. Pressure is applied to the plate or drainage grid, which is in direct contact with the pulp, using various mechanisms. For a screw press it is a screw, for a hydraulic press it is a hydraulic jack or a membrane. Liquid is squeezed out of the pulp under pressure. It flows into the pan, and from there into the prepared container.

There are other designs, for example, barrels with a membrane, popular in hydraulic and pneumatic presses. Expanding, it crushes the pulp, and the liquid is squeezed out of the barrel, flowing down the outer walls into the pan. The cake remains on the walls.

Even the simplest screw hand press turns out to be an order of magnitude more effective in squeezing than manual labor. If we talk about automatic or mechanical presses, then spinning takes place literally “with one left hand.”

The main rule for the safety and security of the press is to add only crushed raw materials, since the pressure must be uniform. Adding unchopped fruits or berries is fraught with failure of the pressing mechanism.

Homemade stainless steel crusher

In order to make a stainless steel grape press, in addition to a set of metalworking tools, you will need a welding machine, and some parts of such a device will need to be ordered from a turner. To make a press, it is not necessary to purchase new sheets of stainless steel; you can completely get by with the metal from which the tanks of failed washing machines are made.

Homemade press from washing machine tanks

A do-it-yourself steel press for grapes is made in the following sequence.

- Tanks from unnecessary washing machines are cut and from the resulting metal, using a welding machine, two cylindrical containers without a bottom are made. The height of both containers should be 24 cm, and the diameters should be 23 and 29 cm.

- A container with a smaller diameter will serve as a basket into which the berries will be loaded before pressing. In the walls of such a container along its entire perimeter it is necessary to drill holes with a diameter of 8 mm, placing them in a checkerboard pattern. An external container is necessary to ensure the collection of juice, which will come out through the holes in the walls of the basket when pressure is applied to the berries loaded into it. To ensure that the finished juice is drained from the outer container, a cutout must be made in its lower part.

- To install an outer cylinder with a basket, it is necessary to make a tray with sides, one of the sides of which should be beveled to ensure more convenient drainage of the squeezed juice. There should be no edge on the narrowed side of the pan, where the juice will drain.

- A flange with a diameter of 21 cm can be used as a punch that will exert pressure on the raw materials loaded into the basket. Such a flange is connected by welding to a screw rod, which can be used as a screw from a water valve. A head with a hole for a handle is welded to the top of the screw, with the help of which it will be driven into rotation.

- Paired with a screw, at the lower end of which a punch is fixed, there is a nut welded into the upper horizontal jumper of the U-shaped frame. To ensure high stability of the frame of a homemade grape press, it is concreted into the floor or securely fixed to the surface of the work table using screws.

Dimensions can be changed according to the dimensions of your washing machine tank

The screw is used purchased or ordered from a turner

We recommend perforating the working surface of the flange-punch of the design described above with a drill with a diameter of 4 mm, which will reduce the pressure on the side walls of the press basket. When making such a grape press, it is also advisable to weld bandage rings in the upper and lower parts of the basket, which will ensure its location exactly in the center of the outer container.

A homemade press made from steel elements can be used to squeeze not only grapes, but also currants, chokeberries, apples and herbaceous raw materials. In order to extract the maximum amount of juice from certain types of plant materials, the latter must first be crushed using a regular meat grinder or a special crusher for this purpose. A do-it-yourself grape crusher, as well as similar devices for other types of plant raw materials, can be made with minimal financial costs.

What materials are needed to make a press?

The grape press can be purchased ready-made. Manufacturers offer consumers various types of equipment, including hydraulic juicers. But it’s not at all difficult to make it yourself.

The grapes are loaded into a barrel or basket, touching its walls. Therefore, it is very important that it is made of high-quality material. Two options are most often used.

How to make a grape press with your own hands

Tree . Only hardwood, such as beech or oak, is suitable for these purposes. By making a basket from wooden planks, you will be able to obtain a durable and environmentally friendly structure. But when using wood, difficulties arise with caring for the equipment. After each juice extraction, the basket will have to be thoroughly rinsed and dried.

Metal . The ideal option would be cast iron or stainless steel. These materials do not oxidize upon contact with fruit. Metal barrels are easy to maintain, easy to clean and are highly hygienic.

The press itself is a circle, which is often made of wood. In addition, you will need to prepare bolts and nuts for fastening structural parts, a metal rod and bearings, as well as tools for working with wood and metal.

Squeeze it dry?

The very name of the equipment makes it clear that it is used to extract moisture from crushed raw materials. You can squeeze both juice and wort in a press, depending on the technology you use to prepare the wine.

How long should the pressing pressure be? The pulp is squeezed out until the juice stops flowing from it. In some cases, it is possible to carry out a secondary extraction, but for this the mass is crushed a second time. Sometimes a small amount of water is added to it to “revive” the pulp. The resulting juice or second-press wine will be inferior in quality to the first.