A blade for a hacksaw for metal is one of the most short-lived elements from the entire range of consumables for tools. Of course, a lot depends on the technology of working with metal and the skills of using a hacksaw, but first of all you need to be able to make the right choice of blade. Today, we will talk about the choice and types, and also learn how to easily change the hacksaw blade.

Types of hacksaw blades

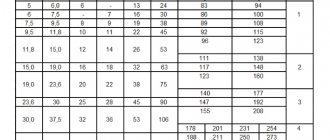

GOST R 53411-2009 “Hacksaw blades for metal” establishes two types of such tools - for machine and manual cutting. We won’t touch on the former, but the latter are available in three main sizes:

- Single, with a distance between fastening holes of 250±2 mm, with a total length of the blade of no more than 265 mm;

- Single, with a distance between fastening holes of 300±2 mm, with a total length of the blade no more than 315 mm;

- Double, with a distance between mounting holes of 300±2 mm, with a total length of the blade of no more than 315 mm.

At the same time, the thickness of the blade s for a single version is 0.63 mm, for a double version – 0.80 mm. The height with a single row of teeth is 12.5 mm, and with a double row it is 20 mm.

GOST also regulates the values of the tooth pitch P, mm and their number z, which for blades of the first type are 0.80/32, 1.00/24 and 1.25/20, respectively. Owners of longer hacksaws, in addition to those listed above, can also use hacksaw blades with parameters 1.40/18 and 1.60/16.

According to the grade of material used for the manufacture of blades for hacksaws for metal, they are made from tool steels:

- Brands X6VF.

- Brands V2F.

- High-speed, grades P6M5, P12 or P18.

The range of domestically produced hacksaw blades is limited to this, however, in specialized retail chains, so-called diamond blades, surface-sprayed with titanium nitrides or other refractory metals, are widespread. Such blades can be easily distinguished by color: regular steel blades are dark gray, while sprayed steel blades can have different colors - from bright orange to blue (depending on the manufacturer).

There are also blades with so-called tungsten carbide coating, however, with very high hardness, they are extremely sensitive to bending stresses. Therefore, when cutting metal, their durability is negligible.

The high strength of blades for hacksaws for metal is ensured by appropriate heat treatment. On the surface of the blade, two zones with different hardness values are distinguished: directly at the teeth it ranges from HRC 64...67 for alloy tool steels to HRC 73...78 for high-speed steels (for diamond blades this parameter reaches HRA 82...84), and in the rest zone - HRC 44...46. A significant difference in hardness confirms the high sensitivity of the product to bending stresses, therefore the standard also limits the maximum force applied to a hand saw. It should not exceed 60 kg when working with blades with a tooth pitch of less than 1.4 mm, and 10 kg for blades with a tooth pitch of more than 1.4 mm.

Description of the canvas

A steel narrow thin plate with two holes and teeth on one edge. It can be manual or machine depending on the purpose. The following steels are used to manufacture these elements:

- U10A;

- P9;

- X 6VF.

The hardness of the material should be HRC 61−64. They are inserted into the frame with the teeth facing forward. They are almost always used for hand saws with a length of 250-300 mm, a thickness of 0.65 and 0.8 mm, and a height of 13 and 16 mm. The operation of the blade varies depending on the operating conditions of the cutter, which explains the difference in angle values .

When cutting a large metal workpiece, long cuts can be made: each tooth removes chips, which should fill the chip space until the tip of the tooth leaves the cut. The amount of space depends on the tooth pitch S, front (Y) and back (A) angles. Depending on the hardness of the workpiece being processed, the rake angle of the blade can be zero, negative or positive. The cutting efficiency of a hacksaw with a blade with a zero angle is lower compared to one whose angle is greater than 0°. To cut harder materials, elements with a large tooth angle are used (they are more wear-resistant). To cut soft materials, this figure should be lower.

Number of teeth

In most cases, for cutting metals, blades with a pitch of 1.3–1.6 mm are used; with a length of 25 mm, there will be 17–20 teeth. The thicker the material being processed, the larger the teeth should be, and vice versa. For different metals, blades with the following number of teeth are required:

- Soft metals - 16;

- Tempered steel of medium hardness - 19;

- Cast iron, tool steel - 22;

- Strip, angle and hard steel - 22.

Hacksaw 300 mm

Two or three teeth should be involved in the work process. To avoid jamming of the blade in the metal, the teeth are spread apart. The layout is carried out so that the width of the cut made with a hacksaw is slightly larger than the thickness of the blade. This prevents jamming in the blade cut and makes work easier.

For blades with a pitch of 0.8 mm (acceptable 1 mm), the tooth pattern should be wavy, that is, every two adjacent teeth are bent in opposite directions by approximately 0.25−0.6 mm. The working element with a pitch of more than 0.8 is set along the tooth (corrugated set), two or three teeth are set to the left and to the right. With an average step, one tooth is retracted to the left, the second is not retracted, and the third is retracted to the right. With a large step, one tooth moves to the right and the other to the left. It is appropriate to set the tooth at a pitch of 1.6 and 1.25 mm. The wiring should be completed at a distance from the end of no more than 30 mm.

Principles for choosing canvas

The selection criteria are:

- A type of hand hacksaw for metal, or more precisely, the distance between the mounting holes. It is better if it is changeable, then a hacksaw blade of any size will be suitable for the job.

- The tensile strength of the metal being cut. If the tool is supposed to be used to separate soft, ductile metals - copper, aluminum, etc., then it is advisable to have a hacksaw blade with the least hardness. The material can be steel Kh6VF; Imported canvases have the designation HCS on the side plane. For cutting stronger metals, blades made of high-speed steels (corresponding import marking - HSS) are suitable.

- The thickness of the metal being cut and the quality of the cutting surface. Foreign practice recommends using the PPI parameter as a selection criterion - the number of tooth vertices per inch of blade length. Thus, for thin metals, where it is required to obtain a very smooth cut surface, a PPI value of >24 is considered correct. If productivity is more important to the user than quality, then PPI should be

Hacksaw blade: classification, features of use.

To saw different materials, blades of different structures are required: with large and small teeth, made of carbon or hardened steel, with routing only along the teeth or along the entire length of the blade.

A hacksaw is used to cut metal and wood blanks, plastic and drywall, and different hacksaw blades are used to work with different materials.

Thus, the wood blade used for sawing boards, chipboards, and logs is very wide and has large teeth.

The metal blade is much narrower, with fine teeth; it is used in a suitable hacksaw.

In a hacksaw for metal, the degree of tension of the file is adjusted, which is adjusted to work with both soft and hard alloys, as well as non-metallic materials, for example, plastic, etc.

The cutting element of a hacksaw for stone, or more precisely, for concrete, is similar to a wood saw, but with much larger teeth.

Carbide metal is soldered onto individual teeth in order to saw, in addition to dense concrete, also foam concrete.

How to properly saw with a hacksaw for metal

The general theory of sawing with a hacksaw looks something like this:

Looking at this picture, you may suddenly feel sad, so further presentation of the material will be based on solving those problems that arose during the recent accidental practical application (in economic theory this is called learning-by-doing) of this ancient tool and the corresponding metal cutting technology.

horizontally with a hacksaw , grasping the tool with both hands. Why it would be good to use a hacksaw with a well-defined handle for gripping with the second hand.

In this video, the entire story about how to saw is, in fact, presented, but now a postscript will present a number of additions and amendments (plus a brief retelling of the contents of the video).

Sawing horizontally is inconvenient because it requires the workpiece to be secured at chest level, and sawing while standing. However, workbenches, as a rule, are tables at which you need to sit, and if you cut, then stand up and from top to bottom. Therefore, hacksaws are often made one-handed and sawed at an angle of 45° .

To regulate the pressure on the saw (the harder the metal, the more you need to load the blade, put pressure on it so that the teeth bite into the flesh; and vice versa - if the teeth cut too hard, for example, into aluminum, then you need to reduce the pressure) you can: a) change angle of inclination when sawing, b) put your hand on top to increase the weight, c) turn the blade with the teeth back.

The saw often gets stuck in the cut when reaching the end of the blade . This is due to the fact that the blade has a wavy set of teeth (so that the cut is wider than the blade and it does not get stuck in the cut), but over time, the amplitude of this wave decreases in the center of the blade, and almost none at the ends.

This distortion arose due to sawing with this blade not of its entire length. It is no longer possible to correct this (increase the spread in the center or decrease it at the ends), due to the fact that the teeth are hardened. So the moral is: from the very beginning of using a new blade, you should always saw along its entire length.

Next problem: if you cut a thin sheet of metal, the thickness of which is less than the distance between the teeth, the saw gets stuck:

If the metal is hard (iron), you can barely move it, but if it is soft (aluminium), a huge piece of metal is torn out, torn edges are formed, and the edge bends.

Saw at an angle to form a cut of such length that at least two teeth lie on it at the same time (cut length ≥ two distances between teeth).

Next topic: sawing a thin-walled aluminum pipe:

We install the blade with the teeth backwards, twist the pipe in the direction of the teeth (otherwise the blade will get stuck on the near edge of the cut, and if force is used, it will tear).

Well, and even before the heap... the blade of a hacksaw for metal can be restored, the teeth can be sharpened , for example, like this:

Initially, this diamond disk was larger in diameter and this drill with this disk, being pressed in this way to the blade, was positioned strictly parallel to the line of the teeth of the blade, and the disk, accordingly, was perpendicular. And this was correct - the front edges of the teeth on the new hacksaw are orthogonal to the blade. Now a small negative angle is formed... - a little less better, but still normal.

Types of hacksaw blades

Blades for working with metal have their own purpose for different alloys, differing in their characteristics, the thickness of the material being cut and the volume of work to be done.

The expected scope of work divides the tool into 2 types.

• A hand tool – a hacksaw – cuts metal through the application of physical effort.

In this case, it is possible to saw a relatively small amount of material.

Accordingly, the blade is not designed for long-term loads and is made of carbon steel.

A blade for a manual jigsaw is always cheaper, but it is harder to work with.

Hand hacksaws can be both professional and household.

The blades, accordingly, can be either more durable - hardened, for example, blades for a sparta hacksaw for metal - or less reliable.

Choosing a hacksaw for metal

Any tool, even a hacksaw

on wood or metal, you need to know how to choose. Remember that, of course, rely not only on the advice of sellers, but also on your own strength. Be wary of buying budget-friendly versions of a tool and the most expensive models when you are questioning why a given tool is so expensive.

This tool must be convenient, so that when making a move in any direction and at different angles, you can, our client can do things simply, for example, cut metal not only with standard movements, but one hundred percent the opposite. Choose the size of the machine yourself: for standard blades, as it is also called, for universal functions, which will help you simply install blades of any size into the hacksaw.

When making a purchase, first of all look at the frame of the hacksaw. She is perhaps ordinary; made of composite heavy-duty materials, which is characterized by a long service life and the ability to cut even alloys of increased hardness; and with the ability to configure the angle of the tooth blade to perform work in inaccessible places.

Canvas dimensions, length, width

The dimensions of the file are determined by the fastening method.

— Most models provide double-sided fastening.

For such products, canvases are available in only 2 sizes: 300 and 150 mm.

The first option is considered standard; products of this size are made of all possible types and from all acceptable materials.

The 150 mm long file is made only of carbon steel.

The thickness depends on the purpose of the tool.

On professional models, the value varies from 0.63 to 1.25 mm.

Blades for electric saws are thick - up to 2.5 mm.

— Blades for hacksaws, where fastening is only on one side, are made in lengths of 220 and 260 mm.

The height of the file reaches 13 mm. They are made only from a bimetallic alloy, since all other options are too fragile.

— For products with a pistol grip, blades can be of different lengths and thicknesses.

They are made only from bimetallic alloy.

Another important characteristic is the tooth.

Products with fine teeth are suitable for sawing hard metals.

The option with large ones is intended for processing soft ones.

They are not interchangeable.

Since when sawing soft metals with small teeth, the saw quickly becomes clogged with shavings, and the cut turns out to be sloppy and torn.

Wood blades design characteristics

One of the most popular saw blades for reciprocating saws is wood cutting attachments. The main difference between these nozzles is the presence of markings with the designation HCS. This marking indicates the type of steel from which the nozzle is made. HCS is a high-carbon alloy steel from which saw blades are made for cutting wood (both soft and hard wood), chipboard, plywood, fiberboard, rubber and even plastic. For the specific materials being cut, appropriate blades are used, differing in the design of the teeth.

Manufacturers produce canvases up to 400 mm long. If you plan to saw wood that may contain nails and other types of metal fasteners, then it is better to use wood saws with carbon fiber. The presence of carbon increases not only the reliability, but also the durability of the nozzle, however, their price is 1.5-2 times higher than conventional carbon materials. Nozzles according to the shape of the working part or the height of the profile are of three types:

- With variable profile height - when the part near the shank is wider than the end. Such attachments are used when the evenness of the cut is not important, but on the contrary, when it is necessary to make a curved cut in the material

- With the same profile - they are highly stable when sawing material. Stability lies in the fact that the file does not vibrate during the work, which means the cut is smooth

- For figured cutting, special blades with the same thin shape of the working part are used

The teeth on the nozzles come in different sizes, as well as with variable, constant, wide and narrow pitch.

- Wide pitch - the blade is used for sawing thick solid wood

- With large teeth - designed for sawing wood along the grain. The largest teeth have 3 teeth per inch (TPI). The larger the size of the teeth, the correspondingly higher the productivity of such an attachment.

- With small and large alternating teeth or variable pitch - when sawing is carried out across the grain, including for cutting damp (wet) fibrous wood

- With a constant pitch - for cutting homogeneous wood and materials

- With a narrow pitch - used for sawing plastic, as well as wood with metal fasteners, when it is necessary to ensure a neat and even cut

- With the inscription “Demolition” - intended for dismantling work. They are thicker and more durable in construction.

A reciprocating saw with wood blades is used not only when performing construction and carpentry work, but is also successful when pruning garden trees in a summer cottage or garden area. Cordless models of reciprocating hacksaws replace loppers. Popular manufacturers of canvases are DeWalt, Hitachi, Diablo, Marathon, Milwaukee and others.

This is interesting!

Wood blades are also made from bimetal (double metal).

This increases not only the service life of the equipment, but also efficiency, for example, when cutting wood with nails. If you are working on cutting wood with metal fasteners, then it is recommended to use attachments with at least 5-6 teeth per inch. One of the most popular types of reciprocating saw blades are bimetallic, which are designated BIM. They are made using two types of materials - high-carbon and high-speed steel. This combination of two types of steel in one nozzle made it possible to obtain files with such important advantages as high strength and flexibility.

https://youtube.com/watch?v=Jrkwp3CuBjc%3F

Recommendations

To select the appropriate tool, consider the following parameters:

• size – determined by the volume of work.

Compact products with a length of 150 mm are suitable for sawing small amounts of materials, since the hand gets tired quite quickly when working with such a jigsaw.

Standard saws with a length of 300 mm perform more work;

• tooth shape and sharpness;

• pitch – for sawing soft alloys, plastics, asbestos, large teeth with a pitch of 18 are suitable.

Hard materials are cut with fine-toothed hacksaws;

• material – the most durable and reliable today is a cloth made of different metals, the so-called bimetallic.

But if a blade is rarely needed, then the home craftsman can get by with a carbon steel model;

• cost – the nature of the fabric, the size and configuration of the teeth determines the price of the product.

Rating of hacksaw blades

According to consumer demand, the rating of the most successful models includes the following:

• Bahco is a Swedish company that offers a wide variety of tools. Sandflex bimetallic sheet is rightfully considered the best.

Its purpose is to cut metal, plastic, and composite materials.

The latter are usually the most difficult to process, since different layers of such a product have different hardness and strength.

• Topex - the blade is made of hardened steel and is much more affordable than a bimetallic alloy.

Although it is inferior in durability to the previous option, it is quite suitable as a home tool.

It cuts metal alloys, plastic, and can work with ceramics, but not porcelain stoneware.

• Stanley – bimetallic files from this manufacturer are considered the best.

Exceptional flexibility of the fabric and strength guarantee a long service life.

It cuts the hardest metals, but only with the correct choice of tooth pitch.

• Anchor “osa” is another manufacturer of hardened steel blades.

The teeth remain sharp for a long time; cutting at right angles and at an angle of 45 degrees is allowed.

A hacksaw is considered a fairly common hand tool, which is designed to divide a workpiece into several separate parts of a certain size. Its design features are characterized by the fact that it is possible to periodically replace the worker. When processing metal, there is a very high probability of rapid wear of the cutting edge. Therefore, a function for replacing the tape was provided, which requires a small amount of time. There is simply a huge number of different canvases; let’s look at the features of choice and many other points in more detail.

Metal hacksaw design

The most common and more common device for working with metal is a special hacksaw

for metal, which differs from the outside from a hacksaw for wood. A hacksaw for metal is often used in construction and repair work, when it is necessary to accurately and accurately cut not too large pieces of wood and iron.

The design of hacksaws for metal is quite common: a narrow hacksaw blade is stretched between the two ends of an iron U-shaped bracket. The working part of a similar saw is a thin blade with teeth, and you only need to work with such equipment with two hands. The blade fastening system comes in two types: threaded clamp. under such circumstances, the canvas is tensioned and then fixed with a wing nut, lever mechanism. when the canvas is installed and removed using a special lever.

Hacksaws that use the second method of installing and tensioning the blade are more expensive than the first option due to their versatility, in addition to the speed of installation and removal of the blade. The main advantage of hacksaws for metal is that, in contrast to power tools, with a hacksaw for metal you can of course work at the site of a breakdown, for the reason that you do not need an electrical network. Among other advantages of hacksaws for metal. ease of operation, maintenance and low weight.

There are quite a lot of blades for hacksaws sold. And, this, the price of the paintings is also different. The cost of a hacksaw for metal depends on the type of blade and the number of teeth per inch (bimetallic, as it is also called, with hardened teeth). Bimetallic blades rarely break, are more flexible and cost more than hardened blades.

Types of hacksaw blades and their design

Do not forget that the production of working hacksaw blades is carried out in accordance with established standards in GOST 53411-2009. The specified information in this regulatory and technical documentation determines the identification of two main groups: for machine and manual cutting. It is worth considering that a machine hacksaw blade for metal is purchased extremely rarely, since such equipment is used extremely rarely. The following versions are produced for a manual hacksaw:

- Single hacksaw blade for metal with a distance between fasteners of 250 mm. In this case, the total length is 265 mm. This design option is suitable for a tool that is used when there is no need for high productivity.

- Single versions with a distance between two fasteners of 300 mm. The overall length is 315 mm.

- For greater productivity, a double hacksaw blade is installed. The length of this version is the same as the previous one.

When choosing, attention is paid to the width indicator, which for a single version is 0.63 mm, for a double version 0.8 mm. The height of the tooth in the first case is 12.5 mm, in the second 20 mm.

The value of the location step is also regulated, since such an indicator determines many operational characteristics.

In the manufacture of such a product, a variety of alloys can be used, on which the main performance characteristics largely depend. The most common alloys are:

- X6VF.

- V2F.

- High-speed alloys, for example, R5M5 and R12.

Hacksaw blades coated with tungsten carbide have recently become quite common, as they are characterized by increased wear resistance. It is worth considering that spraying can have a wide variety of colors; blue versions are available on sale; regular steel is dark gray.

The tungsten hacksaw blade under consideration is characterized by the fact that, with a high hardness of the working surface, the structure is characterized by high sensitivity to bending load. That is why, if metal is cut carelessly, such a product will not last long.

Manufacturers can achieve high strength through heat treatment. It is worth considering the following:

- The main part of the product is characterized by a surface layer hardness of about HRC 44-46.

- Depending on the type of material used in manufacturing, tooth hardness varies within the HRC limit from 64 to 67. This indicator is characteristic of alloyed alloys. High speed steel is characterized by having an HRC hardness in the range of 73-78 units.

Do not forget that significant changes in hardness cause the product to be sensitive to bending. The tool is designed for varying loads, it should not exceed 60 kg with a tooth pitch of 1.4 mm, and 10 kg with a tooth pitch of less than 1.4 mm.

A fairly large number of varieties of such a product determines that there are no serious problems with the selection of a suitable version.

Universal saw – hacksaws for all occasions

Even a seemingly ordinary hacksaw can cause confusion in the average consumer; he will find many different tools on the shelves! To simplify the choice, we list three main types of tools into which, depending on their purpose, they are divided:

- Hacksaws are a narrow saw with thin teeth. It has a characteristic, recognizable appearance, mainly a C-shaped or U-shaped frame, between the ends of which the canvas is tensioned. Older models of hacksaws often have a handle that runs parallel to the blade; modern products are equipped with a much more ergonomic “pistol” handle.

- A hacksaw is a classic carpentry tool used for sawing wooden building materials, as well as sheets of plywood. As a rule, carpentry hacksaws have a wide, beveled working part, on the edge of which there are cutting teeth. The teeth are set alternately left and right to make cutting easier. At the same time, straight teeth in some models help remove chips from the cutting line.

- A hacksaw for concrete is similar in appearance to a joiner's saw, with the difference that the first tool has larger teeth. Quite often they are tipped with carbide metals, which makes it possible to saw foam blocks and sand-concrete structures with this tool.

The quality of the tool is determined by the following indicators:

- Blade length - depending on the size of the workpiece, the appropriate tool is selected. On average, the length of the working part ranges from 300-700 mm.

- Tooth pitch - this indicator determines the thickness and hardness of materials that the tool can handle. For example, a pitch of 3.5 mm is suitable for sawing soft wood materials, while five-millimeter hacksaws work with hard wood.

Principles for choosing canvas

It is important to correctly select the most suitable version of the product for specific operating conditions. If the surface does not have the required properties, it will not last for a long period. The selection criteria include the following points:

- The most important selection criterion is the distance between the two mounting holes. For some instruments, this indicator may change due to a special device.

- The next selection criterion is the strength of the metal being cut. If the work involves cutting common soft alloys, for example, copper or aluminum, then a product with the lowest hardness of the surface layer is selected. Kh6VF steel is very common; for paintings of imported origin, the HCS marking is used. It is also possible to process durable metals, for which a high-speed steel hacksaw blade is suitable, imported HSS marking,

- The thickness of the metal being cut and the quality that needs to be achieved after processing are also taken into account. Abroad, the determining criterion is the PPI indicator - the number of tooth tips per inch of length. To ensure high quality, a PPI of more than 24 is required; if performance is a priority, then a design option with an indicator of less than 24 is selected.

- When choosing, attention is paid to the quality of the cutting edge spread. This parameter must comply with the standards established in the previously cited GOST. There are three main options: dilution for each, through one tooth or two adjacent ones.

How to install a blade on a hacksaw for metal

The design of the tool in question allows for quick replacement of the hacksaw blade. It is worth considering that if a mistake is made, the product in question will not last for a long period. How to install a blade in a hacksaw for metal is a very common question, since this tool is found in almost all home workshops. The main recommendations are the following:

- The instructions largely depend on the fastening system used in a particular case.

- The threaded clamp, in which the hacksaw blade is installed and tensioned, has become widespread. A sudden change in the applied load becomes the reason why you have to periodically check the degree of tension.

- There are tools with lever fastening. In this case, installation is greatly simplified, since it is enough to pull back the lever and install the hacksaw blade for cutting metal, and then tighten it in the opposite direction.

When considering how to properly insert a blade into a hacksaw for metal, it should be taken into account that after proper installation it creates a slight ringing sound during operation and may vibrate a little. However, at the time of sawing, the product should not change its position, as this may cause damage to the mounting holes.

Blade for hacksaw for metal. How to choose and install?

A blade for a hacksaw for metal is one of the most short-lived elements from the entire range of consumables for tools. Of course, a lot depends on the technology of working with metal and the skills of using a hacksaw, but first of all you need to be able to make the right choice of blade. Today, we will talk about the choice and types, and also learn how to easily change the hacksaw blade.

Selection rules

Subject to certain rules, it is possible to choose a suitable canvas that can last for a long period. The main recommendations are the following:

- The surface should be free of cracks or other defects, as well as traces of corrosion. This is due to the fact that even minor damage will cause increased wear.

- At the time of selection, you should make sure that the saw is elastic. To do this, bend it a little and then release it. A high-quality product almost immediately restores its shape, which indicates high flexibility.

- As previously noted, the permissible cutting speed largely depends on the number of teeth per inch.

- The determining factor in many cases is the type of material used. Often they give preference to hardened steel or bimmetallic products. The version with tungsten carbide coating lasts for a short period.

It is not recommended to use price as the main selection criterion. However, a design that is too cheap fails within a short period.

As practice shows, a low-quality version has to be changed several times, while a more expensive proposal will last for a longer period.

Hacksaw blade for metal – a choice based on knowledge!

When purchasing a canvas, pay attention, first of all, to its appearance - even the smallest flaws can affect its performance. Avoid canvases with traces of corrosion, cracks, or roughness. An ideal blade should be smooth, clean, with even teeth, and when bent it should instantly restore its original shape. The more teeth per inch, the faster you can saw the part. So, there are blades with 18 and 24 teeth per inch, most often these are bought for home use, but 32 teeth per inch are for professionals.

Avoid buying black products - these are enough for several passes, then the teeth fall off and make the job impossible. Although hardened products are not flexible, they are much more convenient to work with. In appearance, they look like a nickel-plated strip of stainless steel metal with dark teeth - it is by the color of the teeth that it is easiest to guess about their hardening. Bimetallic sheets are usually painted in some color, and although they are more expensive, they will last much longer. Having chosen the appropriate material, make sure that the length of the product matches the length of the hacksaw.

Recommendations for use

Only with proper use can you eliminate the possibility of damage to the hacksaw blade for metal. The main recommendations are as follows:

- It is necessary to carry out processing at the same speed and applied force. Even minor changes can cause a defect.

- You need to take breaks from time to time. The reasons are that too high a temperature causes an increase in ductility.

- At this point, the entire hacksaw blade must pass over the surface. This ensures even wear.

You can often encounter a situation where, due to strong heat and applied force, a metal plate bursts. Low-quality versions wear out quickly and become practically unusable.

Number of teeth

The determining factor is how many teeth there are per inch. The following depends on it:

- Performance depends on the indicator. As the number of cutting edges increases, the task at hand becomes significantly more complicated and the chips become smaller.

- A large quantity allows you to get a high-quality cut. This is achieved by reducing the resulting chips.

In addition, an increase in quantity causes an increase in the cost of the product.

Teeth setting

Removal of chips from the cutting zone is carried out due to a certain layout of the cutting edge. As previously noted, according to this criterion, several options are distinguished:

- Wiring for each.

- Setting through one or two teeth.

At the same time, attention is paid to the direction of the teeth. Taking this parameter into account, the plate is installed.

Today, many tool manufacturers specialize in the production of hacksaw blades. At the same time, domestic products are much cheaper, foreign ones are more expensive, but at the same time have higher performance characteristics. For long-term operation, several products are required, as they can wear out at a high rate.

If you find an error, please select a piece of text and press Ctrl+Enter.