To install a drainage structure on a personal plot or in a vegetable garden, you can make a concrete tray with your own hands. The technology for draining excess liquid is used in areas where heavy rainfall occurs, as well as in areas with clayey soils. The topography and composition of the soil cannot absorb excess moisture, so the fertile layer of soil begins to wash out, which will have to be purchased and replenished.

Storm drainage system

A storm drain (also known as a storm sewer) is a special drainage structure made up of drains, pipelines, water receivers, filters (to hold debris), inspection wells and a volumetric storage well that collects rainwater. All these elements are collected into one system and make it possible to effectively remove excess water from territories and objects, which leaves by gravity.

The collection of rain and melt water is organized where it accumulates most. Concrete sewer trays are the first link of the system, along with pipes and funnels for drainage, water inlets located under drainpipes near sidewalks, roads, platforms, etc.

Main types of storm drainage:

- Open - the most primitive option, suitable for personal plots located outside the city. Water drainage in the system is carried out using open trays/ditches; the collected water goes into the ground or reservoir.

- Closed - involves high-quality collection/discharge of water. Closed water intakes and a system of underground pipelines are used, and inspection wells are created in the areas where fittings are installed to inspect the system. The collected water can then be used. Excavation work is expected.

- Mixed type - a combined system for removing water along sites and roads. The trays are open, but some of the elements run underground.

According to the type of water collection, the sewer system can be linear and cover everything (paths, platforms, roofing) or point-based with the installation of storm water inlets only under drainpipes.

What to consider when designing a system:

- The area from which water is removed.

- Average precipitation in the climate zone.

- Characteristics and properties of soil.

- Communications that pass underground.

The drainage system is most often created from polyvinyl chloride sewer pipes with a diameter of 11-12 centimeters, which have sufficient strength and durability. Pipes must be installed with a slope of 5 centimeters per linear meter towards the storage tank. Storm sewer pipelines are organized in the same way as in the case of installation of household sewerage.

Inspection wells are used to maintain the system and remove blockages in a timely manner. A well is needed in both mixed and closed storm drainage systems; it is installed at the lowest point. The well accumulates and distributes/discharges water; its volume must correspond to the volume of liquid.

The well can be made of metal (requires mandatory waterproofing), plastic (long life, resistant to various influences), concrete (or polymer concrete). A concrete sewer storage well is the best option for a suburban area, but you need to think about its delivery and installation (the heavy weight requires the use of special equipment).

For efficient operation, the bottom of the well is made from a finished product or by pouring concrete. A cover with a hatch is mounted on top of the well.

You can make a sewer storage tank with your own hands: dig a pit, fill it with sand and crushed stone, concrete the bottom, make formwork and lay a reinforced frame in it, install pipes, concrete it, waterproof it. Then a cast iron grate is installed.

When designing a stormwater system, it is advisable to take into account the subsequent use of the collected water - for irrigation, industrial and household needs (but only after purification). Water collection trays can be plastic or metal, made of composite or concrete. Most often, a concrete tray is chosen due to its obvious operational advantages.

To prevent injuries and the entry of various debris into the system, install a concrete tray with a grid that protects and makes the surface of the product safe. Typically, gratings are made of metal.

How it is made

A drain for a ditch can be made in two ways. Concrete products in accordance with GOST 23009-78 are produced by vibrocompression or vibrocasting. In the first case, the initial mixture is poured into a special mold and then pressed. In parallel with pressing, the mixture is exposed to a vibrating table, which ensures uniform distribution of the substance. Vibration allows you to obtain a uniform structure and density of the finished concrete structure.

When vibrating casting, the pressing operation is eliminated; the concrete mixture inside the pouring mold is distributed evenly solely due to the vibration effect. Regardless of the chosen method of forming the concrete mixture, a frame made of metal reinforcement is used in the manufacture of gutter elements.

The choice between vibratory casting or vibrocompression is usually based on where the gutter will be used. If the product is intended for private housing construction or quiet city parks, then it is better to choose cast structures. Since in this case, cast concrete gutters with gratings will cost less than vibration-pressed ones.

Structures made by vibration casting are cheaper than those made by pressing Source iv-proect.ru

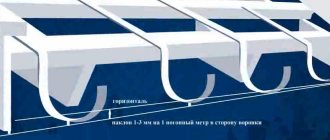

For more aggressive operating conditions, for example, for installing gutters along highways, it would be more correct to choose vibro-compressed elements. Vibrocompression technology makes it possible to obtain products with high precision tolerances and to form a slope of the working surface of 1 millimeter per linear meter of the tray.

See also: Catalog of companies that specialize in water supply and sewerage.

Classification of concrete trays

The production of concrete trays is carried out in accordance with GOST 21509-76, as well as 26633-2015 and 13015-2012. Trays P, U, trapezoidal in shape are used to drain water. Water flows through the trays by gravity; often products are made with a structural slope (or without).

Main types of storm drains by load and area of use:

- A15 - can withstand loads of up to 1.5 tons, the most popular for installation on roadsides, in pedestrian areas, in parking lots, children's and sports grounds, in private households.

- B125 - maximum load of 12.5 tons, relevant for the implementation of water drainage in garage cooperatives, along asphalt roads.

- C250 – load up to 25 tons, trays are suitable for use in systems in parking lots, gas stations, car washes.

- D400 – design load within 400 tons, these products are used in the installation of systems at railway stations, piers, and highways.

- E600 - reinforced concrete trays can withstand loads of up to 600 tons; they are installed at militarized facilities, industrial enterprises, warehouses, and logistics centers.

- F900 is the maximum load that high-power products can withstand; they are used for installation in spaceports, airports, and military bases.

Types of trays according to installation location and application:

- Edge covers – for arranging roads, protecting against water accumulation. The most popular option is the B1-18-50 tray, which is mounted at the junction of the curb and the roadway (but not below/above the roadbed). Also often used are more capacious B1-20-75, B1-22-75. The trays are mounted on a cement base, the nodes between the road and the product are coated with bitumen-rubber mastic.

- Telescopic - they are made from heavy concrete M200/M300, reinforced, and used for installation on a slope in road construction (for transverse drainage), and landscaping of household territories. Water is diverted to lowlands.

According to the production method, trays are vibro-cast and vibro-pressed. The first technology assumes lower strength and durability of the final product, while the second significantly improves quality.

Concrete drainage trays (gutters, channels)

Selection by parameters

- Sort:

- New and popular

- Name

- Price

- Bestsellers

- Customer ratings

- Date added

- In stock

Concrete drainage tray BetoMax Basic LV-10.14.06

Article: 4010 Material: fiber-reinforced concrete Size: 500x140x60 mm Load: 250 kN Maximum…

Product type Tray Load class C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 5.4 kg Length 0.5 m Height 60 mm Concrete drainage tray Standartpark BetoMax Basic LV-10.14.13-B 4000

Parameters: Article: 4000 Material: fiber-reinforced concrete Size: 1000x140x125 Weight: 22.0…

Product type Tray Load class C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 23 kg Length 1m Height 130 mm Drainage tray -10.14.12.5-concrete (with vertical drainage)

Parameters Material: fiber-reinforced concrete Size: 1000x140x130 Weight: 22.0 Hydraulic section: DN 100 Classes…

Product type Tray Load class C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 22 kg Length 1m Shallow-drawn concrete channel BGF DN100, h 80, without slope, class C250

Size 1000x160x80 Manufacturer Gidrolica (Gidrolica) Product weight 19 kg Throughput…

Product type Tray Load class A (up to 1.5 tons), B (up to 12.5 tons), C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 19 kg Length 1m Color grey Shallow-drawn concrete channel BGF DN100, h 100, without slope, class C250

Size 1000x160x100 Manufacturer Gidrolica (Gidrolica) Product weight 22 kg Throughput…

Product type Tray Load class A (up to 1.5 tons), B (up to 12.5 tons), C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 22 kg Length 1m Concrete tray BGU Universal DN100, no. 0, no slope, class C250

Size 1000x160x132 Manufacturer Gidrolica Product weight 32 kg Throughput…

Product type Tray Load class A (up to 1.5 tons), B (up to 12.5 tons), C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 32 kg Length 1m Concrete tray BGU Universal DN100, no. 5-0, no slope, class C250

Size 1000x160x157 Manufacturer Gidrolica (Gidrolica) Product weight 32.5 kg Flow area…

Product type Tray Load class A (up to 1.5 tons), B (up to 12.5 tons), C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 32.5 kg Length 1m Concrete tray BGU Universal DN100, no. 10-0, no slope, class C250

Size 1000x160x182 Manufacturer Gidrolica (Gidrolica) Product weight 36 kg Throughput…

Product type Tray Load class A (up to 1.5 tons), B (up to 12.5 tons), C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 36 kg Length 1m Sand trap -10.14.38.5-concrete

Parameters: Article: 4080 Material: fiber-reinforced concrete Size: 500x140x390 Weight: 22 Hydraulic section: DN…

Product type Sand trap Load class C (up to 25 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 22 kg Length 0.5 m Set: BetoMax Drive LV-10.16.16-B concrete tray with slotted cast iron grating HF class C, D, E

Article: 04057633, 040571334 and 04057155 Material: fiber concrete Size: 1000x160x160 Weight: 43.1 and…

Product type Set of trays Grill material cast iron Load class C (up to 25 tons), D (up to 40 tons), E (up to 60 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 43.1 kg Length 1m Set: BetoMax Drive LV-10.16.21-B concrete tray with slotted cast iron grating HF class C, D, E

Parameters Material: fiber-reinforced concrete Size: 1000x160x210 mm. Weight: 50.3 and 51.9 kg. Hydraulic…

Product type Set of trays Grill material cast iron Load class C (up to 25 tons), D (up to 40 tons), E (up to 60 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 0 kg Set: BetoMax Drive LV-10.16.23-B concrete tray with slotted cast iron grating HF class C, D, E

Article: 040676333, 040671334 and 04067155 Material: fiber concrete Size: 1000x160x230 Weight: 53.19 and…

Product type Set of trays Grill material cast iron Load class C (up to 25 tons), D (up to 40 tons), E (up to 60 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 53.19 kg Length 1m Set: BetoMax Drive PV-10.16.50-B concrete sand trap with slotted cast iron grate of HF class D and E

Article: 040871334 and 04087155 Material: fiber-reinforced concrete Size: 500x160x500 Weight: 54.8 kg….

Product type Sand trap kit Grill material cast iron Load class C (up to 25 tons), D (up to 40 tons), E (up to 60 tons) Material concrete (fiber concrete) Hydraulic section DN 100 Weight 54.8 kg Length 0.5 m Set: BetoMax LV-11.19.13-B concrete drainage tray with HF cast iron grating

Parameters: Article: 04142, 04144, 04140, 041444 Material: fiber concrete Size: 1000x187x130 mm…

Product type Set of trays Grill material cast iron Load class C (up to 25 tons), D (up to 40 tons), E (up to 60 tons) Material concrete (fiber concrete) Hydraulic section DN 110 Weight 46.84 kg Length 1m Set: Maxi LV-11.19.18-B concrete drainage tray with HF cast iron grate

Dimensions (LxWxH), mm: 1000x187x180 Section: DN110 Articles: 04150, 04152, 04154 Supplied in…

Product type Set of trays Grill material cast iron Load class D (up to 40 tons) Material concrete (fiber concrete) Hydraulic section DN 110 Weight 55 kg Length 1m Set: Maxi LV-11.19.23-B concrete drainage tray with HF cast iron grate

Dimensions (LxWxH), mm: 1000x187x230 Section: DN110 Articles: 04100, 04102, 04104 Supplied in…

Product type Set of trays Grill material cast iron Load class D (up to 40 tons), E (up to 60 tons), F (up to 90 tons) Material concrete (fiber concrete) Hydraulic section DN 110 Weight 64 kg Length 1m Set: Maxi-11.19.50-B concrete sand trap with high-frequency cast iron water intake grate

Parameters Article: 04182 Material: fiber-reinforced concrete Size: 500x190x496 mm. Hydraulic section:DN110…

Product type Sand trap kit Grill material cast iron Load class D (up to 40 tons), E (up to 60 tons) Material concrete (fiber concrete) Hydraulic section DN 110 Weight 57.39 kg Length 0.5 m

Concrete drainage trays are manufactured by vibration pressing using modern equipment, which allows us to obtain a product of the highest quality.

Concrete channels made by vibration pressing last much longer than similar cast channels. Combining two mechanical methods of compacting a concrete mixture - pressing and vibrating, vibrocompression is the most progressive method of manufacturing products for drainage and drainage. The technological process for producing concrete drainage gutters using the vibrocompression method consists of vibrating a semi-dry concrete mixture in a mold under high pressure.

The finished product has the following properties:

1) almost zero moisture absorption;

2) smoother channel surface;

3) precise geometric parameters.

Characteristics of drainage trays

The technical characteristics and properties of concrete drainage trays are determined by their purpose and production method. The higher the load that the tray can withstand, the higher the grade of cement used for its production. Reinforcement from steel rods is used for strengthening.

Main characteristics of trays according to GOST requirements:

- Compressive strength corresponds to minimum concrete grade M300.

- The filler fraction is a maximum of 15 millimeters.

- Cement for production is at least M400 grade.

- The thickness of the concrete above the reinforcement is a layer of at least 15 millimeters.

- Appearance – absence of any irregularities and sagging, cracks and chips.

The dimensions of the products can be different - the standard ones assume a length of 1000 millimeters, width and height, wall thickness can be different.

How are the dimensions of drainage trays indicated:

- DN – internal width in millimeters (100, 150, 200 and 300, 500 in Europe, in Russia 110, 150, 160, 200, 300 and 500 are used). If the marking indicates DN 500/150, then the second number indicates the internal depth.

- L – section length, can be in the range of 50-300 centimeters, less often you can find 6 meters or 70 centimeters.

- B – the outer width of the tray, varies from 40 to 190 centimeters.

- H – tray height, varies in the range of 38-150 centimeters.

Advantages and disadvantages

The main advantages and disadvantages that any storm drain has are determined by the characteristics of production. The most popular are products created by vibration pressing, which provides excellent technical characteristics and features.

The main advantages of storm drains:

- High level of resistance to moisture and sudden temperature changes.

- Resistance to dynamic loads and corrosion.

- Safety in operation and environmental friendliness.

- Long service life - up to 70 years.

- Good mechanical strength.

- The versatility of using the element to create various systems.

- Stability due to high weight, which is important especially when large volumes of wastewater accumulate.

- Easy to install and maintain.

- Relatively low cost.

Among the disadvantages of concrete products of this type, it is worth mentioning such as heavy weight and the need to bring special equipment to the site, and fairly high transportation costs.

Production of concrete trays

Drainage trays can be produced in several ways - in a factory using vibration casting or vibrocompression methods, as well as at home by pouring them yourself.

Factory production

Most often, enterprises use the vibrocompression method, which involves higher costs of time and money to create products, but also guarantees appropriate quality, which is especially important when pouring products that have high demands.

Production of concrete trays using vibrocompression:

- Mixing concrete mortar from M400 cement, sand, fine/medium crushed stone (1:2:4), mixing with water.

- Pouring the solution into a prepared mold placed under a press. The products are reinforced with steel rods with a diameter of 5-6 millimeters, pre-treated against corrosion.

- Pressing elements to remove air and excess moisture.

Making your own trays

To make drainage trays with your own hands, you need to make a U-shaped formwork from boards/plywood and line it inside with polyethylene film. Then the solution is mixed, reinforcement is placed inside the mold, the mixture is poured into the formwork, and half of the sewer pipe is pressed in (it will create a recess with a smooth surface of the desired shape). The structure is dismantled every other day, and the tray is allowed to gain strength within 28 days.

To remove excess air from the mold, it is advisable to periodically tap the mold, bayonet it with a reinforcing rod, or use a deep vibrator.

Laying concrete trays

Before installing the trays, you need to correctly perform the calculations and select the optimal elements for the entire system. In Moscow and the regions you can easily find all the necessary products.

Installation process for storm concrete gutters:

- Digging a trench to install a tray with a certain slope of 5-10 centimeters per 1 meter. The depth of the trench should be such that the water intake grid is 3-5 millimeters below the ground level.

- Compacting the bottom of the trench.

- Filling the bottom of the trench with a layer of sand to create additional drainage and compaction.

- Installation of a storm drain with grate.

- The trays are connected using grooves (arrows in the direction of water movement must be indicated on the product itself).

- When the installation is completely completed, all joints are sealed.

Periodically, storm drains need to be serviced - remove debris by opening the grates.

Storm concrete gutters are high-quality products, thanks to which you can create reliable and durable water drainage systems, protecting territories and buildings.

Stages of work

Mold making

For formwork, a material is selected that will withstand the pressure of the poured building mixture.

A tray for concrete with a “P” configuration is assembled from wooden material (leveled board, laminated plywood 1.0–1.5 cm thick). The formwork material is selected carefully - it must withstand the pressure of the poured solution. Individual elements of the form are reinforced with metal corners. This creates additional rigidity of the structure.

After making the main part of the tray for filling, we begin to prepare the molding part of the structure. For these purposes, a metal or plastic pipe of the required size is sawed lengthwise. An important element of the form is its smooth, non-porous surface, which ensures the formation of a semicircular gutter along which waste water will move by gravity. To ensure continuity of the concrete pouring process, it is advisable to produce 10 products, otherwise the construction of a drainage structure on the site will take a long time.

Reinforcement

A reinforcement cage embedded in concrete increases the strength properties of the cast product. Also, when removing the tray from the formwork, the “skeleton” of the structure will not allow it to collapse. The strengthening property of metal rods or mesh makes it possible to produce elongated trays. When placing reinforcing elements in molds, they are placed at a distance of 50-100 mm, in a vertical and horizontal plane - this creates a mesh frame configuration, which is fixed with wire or connected by welding. To prevent corrosion of metal elements of concrete, the edges of the rods should not be located at a distance of less than 50 mm from the plane of the wooden tray and the molding part.

Pouring into molds

After pouring the solution, it is recommended to compact it, for which a vibrator is used.

After laying the reinforcement cage, they begin pouring the prepared concrete into the molding trays. During this stage of work, it is advisable to use a special vibrator. The unit will compact the poured solution and remove air and excess water from it. If it is not possible to use such a device, take a sharp metal object and, with its up-and-down movement, bayonet the mixture into the molds.

To prevent the solution from leaking out of the wooden formwork, it is tightly covered with plastic film.

When the solution is in the molds, using a blank and a cut pipe, begin to form a semicircular shape of the drainage gutter. To do this, press the part into the solution, scrolling in different directions several times, without pressing hard on it. This will give the tray a smoother surface. To improve the properties of concrete and “harden” its surfaces, sprinkle the top of the formwork with cement. Such manipulations will give the monolith greater strength.

The maturation period for concrete poured into molds is 4 weeks. But after 1 day, the constructed formwork is dismantled, and the monolith has reached a level of preliminary readiness. It did not achieve the design strength, but it also did not collapse when removed from the wooden tray. The poured product will have a rectangular shape, its inner part will be semicircular in shape, smooth, without cracks or other flaws.

Installation of concrete drainage systems

When making a drainage system, it is necessary to take into account some points, including the direction of liquid flow.

Drainage systems installed on the territory of a personal plot can be of several varieties, but there are several mandatory rules for constructing a structure:

- Slope of trays in the ground. Should be 1 cm per 1 linear meter.

- Angles and turns of the structure. Their number should be minimal.

- The direction of water movement across the estate. The liquid should go outside the area and not flow into it.

When trees and shrubs are planted in the drainage area, then a branching system is performed. For areas with flat terrain, the standard placement is used - linear. To do this, lay channels parallel to each other in the soil. Then the connection is made in a place that has a minimum angle of inclination.

Before the process of laying concrete trays, rectangular channels are dug according to the selected laying system. A sand cushion is placed at the bottom of the structure, which helps adjust the slope angle. When performing work, this indicator is controlled in 2 ways - using a level or a level with a strip or beam attached to it. After regulatory measures along the entire length of the system, the installation of drainage systems begins. When the work is completed, the structure is tested. To do this, pour water into the gutters and then mix it with sand. If after simulating heavy rain there is no solution in the trays, then the structure is functioning correctly. When constructing channels near garden paths and through monolithic areas, they are covered with gratings, which prevent debris from accumulating and ensure the safe operation of the structure.