Miter saws Interskol

Along with foreign analogues, the construction tool Interskol occupies not the last place. This is a domestic manufacturer, which is already one of the world leaders in the production of electrical construction equipment. The equipment is very reliable, high quality and affordable.

How does this product differ from similar ones? Among the main features are the following:

- the circular saw makes precise cuts, regardless of the angle at which it was made;

- accuracy of setting angles and reliable fastening in a given parameter;

- powerful engine

with a reliable cooling system; - allowed for cutting plastic, aluminum and copper workpieces;

- The cross-cutting tool is made from high-quality materials;

- cutting depth adjustment;

- laser pointer.

I bought an Interskol circular saw in Leroy. Initially I took what was cheaper. At the dacha we had to cut boards for a fence at an angle. I was very pleased with the accuracy of the angle and the fact that the disc does not tear, but makes very beautiful cuts. I've had this machine for over a year now. I work for them constantly and for myself, I need to do some hacking.

We were working on site, and our Makita broke down. There was no one from the authorities, so we bought it ourselves at the nearest market. The seller was very complimentary. Since there was nothing else and there was nothing to choose from, we decided to take this one. We have completed the entire scope of work with this trim. Never let me down. Maybe I was just lucky. I would like to think that ours have learned to do it.

A homemade circular saw is not such a rare thing on the farm and is certainly necessary. To do it, of course, having only the initial ability to work with metal, a table adapted for a workbench and accuracy.

Circular saw with electric motor 1.1 kW 3000 rpm

A circular saw on your own makes sense if, of course, you already have some backlog of information: pieces of an iron angle, a profile rectangular pipe and, in particular, an engine. Another name for it is an angle drill (“grinder”). There is an option to look for a used motor on the “iron” market, they are not unique there.

Using a hand-held circular saw on your own is much easier if you already have a grinder on the farm, of course. It is enough to make only two common improvements: a sliding stop and an axial handle.

The sliding stop is two pieces of a small iron corner located on both sides of the working body: a disk with teeth installed instead of an abrasive wheel. The gap is 3-4 mm on each side. The horizontal edges of the corners must be rounded at the bottom so that they do not cling to the workpiece. The corners must be connected with cross braces in front and behind. Bolts and nuts are suitable for this purpose, and a pack of washers will provide the appropriate clearance.

We put a clamp made of iron tape on the body of the grinder; The helical tie of the clamp is located at the bottom. A double-folded strip of sheet metal or galvanized steel with a hole for the rear bolt of the sliding stop is aggressively attached to it. This way the stop is secured at the back. Of course, the clamp with the rear stop post should be made as a single piece, unfortunately, the thickness of the metal strip at the same time must be more than 1 - 1.5 mm. By shifting the washers that provide clearance, similar gaps are achieved between the working body and the sides of the stop.

In the gearbox housing of the angle grinder we make two to four threaded holes for small bolts (M3 - M5). The gearbox must first be disassembled and found in a place where you can drill. These holes are necessary to attach a homemade axial handle. Using the standard side handle of an angle grinder, making an even cut will be difficult even on a physical level for a strong man with strong working abilities.

READ Kazakov Yu in welding and cutting of metals

We make the axial handle from an iron tube, also called a rod, in the form of a horn directed upward forward or a transverse bracket the width of a palm with a certain supply. Do NOT spill the ends with which it will be attached to the gearbox and drill holes for the mounting bolts. If the fastening ends are spilled, the handle will bend from effort during operation.

If the handle is in the shape of a horn, we splash its far end in a horizontal plane and drill a hole in a personal computer for an axis of 4-6 mm with a margin, i.e. 6-10 mm. If the handle is a bracket, under it, in the same holes in the gearbox, we attach a piece of rod sticking forward, or tube, and we spill its end and drill a hole here, as indicated above. Obviously, between the rod and the bracket there will be a distance sufficient for ease of work - 100-150 mm.

Now we take a piece of iron rod 4-6 mm. This will be the adjustment rod. We bend one end of it like a loop, spread it out a little and drill a hole for the front bolt of the stop. By selecting washers at the front end of the stop, we achieve a uniform gap width along its entire length. With a 6 mm rod, most likely only two thin washers will be useful, one on each side.

Stationary machine

Those who plan to get serious about woodworking should think about making a full-fledged stationary circular saw. This should be a separate unit installed on a workbench, equipped with a powerful motor, with the ability to quickly replace the disk. Making such a circular with your own hands will take time, but it will definitely pay for itself.

Read also: How to crimp a twisted pair socket

Despite the apparent simplicity of this device, before starting work it is worth creating a drawing of the machine. This will allow you to clearly see the future unit and choose its optimal configuration.

bed

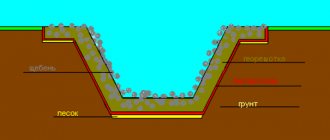

The basis of any machine is the bed, the frame on which all the main parts are mounted. The frame of the circular saw must be stable and reliable, which is why it is made of metal. It is preferable to use a profile pipe or a thick-walled angle. Welding is used to connect parts. If a collapsible structure is planned, a bolted connection is suitable.

Buying a suitable material will not be difficult; in any specialized metal store you can pick up both pipes and an angle. Those who want to save money can be advised to contact scrap metal buyers. You can buy the same thing from them, only cheaper.

Tabletop

The best material for making the tabletop of a professional circular table is metal. Steel and aluminum-based alloys are excellent. For a budget option, you can limit yourself to thick multi-layer plywood covered with sheet iron. In any case, the surface of the tabletop must be smooth, resistant to friction and not bend under a weight of up to 50 kg.

A groove is made in the tabletop for the disk. It can be done in two ways. You can make a cut in a single sheet, or you can assemble a tabletop from two halves. The second method is preferable for a metal tabletop, which is difficult to cut into at home.

A parallel stop is attached to the tabletop. The best material for this, regardless of the table material, is angle steel. To secure it, grooves are made or powerful clamps are used.

Motor

The engine of the future circular machine is selected depending on the existing disk. If you plan to work with small disks with a diameter of 150-170 mm, you can limit yourself to an electric motor with a power of about 0.5 kW. For disks with a diameter of 350 mm or more, you need to look for a unit of 1 kW or more.

If desired, you can make a sawing machine for work outside the workshop; for this it is enough to provide the possibility of installing a low-power gasoline engine; it can be removable.

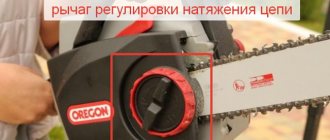

Rotation transmission

The optimal drive for a circular saw is a V-belt drive. Two pulleys are used, one on the engine and one on the drive shaft. It's convenient and safe. There is no direct connection between the motor rotor and the disk; if the tool jams, the belt will begin to slip, signaling the need to turn off the power. In addition, using pulleys with several grooves of different diameters, you can adjust the speed of the saw, choosing the optimal mode for different types of wood.

Rotation from the motor rotor is transmitted to the shaft. This is one of the most important parts of the circular. It is unlikely that you will be able to make a shaft yourself; it is better to buy a ready-made one or order it from a turner.

The shaft is mounted on bearings. They must be of a closed type: a circular saw is a sawing place and open ones will not last long.

What is a miter saw?

A crosscut saw is a mechanism with a cutting disc designed for sawing wood and composite materials at right or other required angles. Designed to work on a flat surface. Allowed to be moved and installed in a temporarily equipped workplace. Their appearance resembles machines for cutting pipes, fittings, and stone.

There are several types of miter saws:

Pendulum - a horizontal frame with a turning circle. A lever (pendulum) is attached to the reverse side of the circle, which is where it got its name. The saw blade is mounted on this lever. The workpieces are fed along the guide bar. To make a cut, a lever with a rotating disk is recessed into the board.

Combined - everything is the same. Thanks to the hinges, the ability to rotate the lever relative to the horizontal plane has been added.

With horizontal stroke. It resembles a pendulum saw, but allows you to cut wider parts by moving the mechanism with a rotating disk along the runners back and forth.

As an addition to all trims included:

- dust bag;

- laser illumination;

- pipe for connecting a vacuum cleaner.

Engine Installation

To make a homemade circular saw, you need to think in advance about what device will be used to transfer the force from the motor to the cutting disc. Small equipment can be placed directly on the engine axis. However, this will not have the best effect on the power of the circular machine

made with your own hands.

An ordinary bicycle spindle can act as such a transmission mechanism, without which the operation of any circular saw is impossible. This is often called the housing in which the shaft with bearings is located. To cut it off the bike, you can use a hacksaw. In this case, you will not need the sprocket, since in this case it is best to take it from the D6 or D8 engine. In order for this sprocket to fit securely on the new shaft, you will need to make an adapter sleeve. Before you install the circular saw on your bicycle spindle, you need to make sure that it has the size of the mounting hole you need. Now, taking this information into account, it is necessary to establish the outer diameter of the bushing intended for the transition mechanism. The bushing should be attached to the spindle in several places at once. Next, a plate with a thickness of at least 5 mm should be secured to the spindle assembly body.

Now take an asterisk, approximately 2-2.5 times larger in size than the one that was previously installed on the spindle, and install it on a homemade circular saw. And at the end of making a saw with your own hands, when all its parts are well secured, put on the chain and you can use it for its intended purpose.

READ Electric saw Makita Or Shtil What to choose

Mini circular saw: manufacturing instructions

Mini-circular base

To make such homemade products you will need:

- two metal plates;

- wooden beam;

- spindle from a bicycle;

- star;

- chain.

Circular saw device with a separate motor.

The mini-circular saw should be placed on a strong and stable table, since any rocking can pose a danger to human health and also interfere with normal operation of the saw. Before you start making a machine from a hand-held circular saw, you need to make a special table. In this case, you can use metal sawhorses and a regular old kitchen table as a bed. To begin, you will need to connect the trestles to each other with a wide wooden board at least 50 mm thick, and then secure the kitchen table to this base.

Read also: Rating of budget wood routers

You can make the tabletop itself from two metal (preferably steel) plates with a cross-section of about 4 mm. In addition, you can use thick wooden blocks for this purpose.

It is important not to forget to leave a small gap between the metal sheets, the size of which is usually 10-12 mm.

In this case, you need to make sure that the edges of the metal plates are perfectly parallel to each other. Now that the table is completely ready, you can begin attaching the circular saw itself to it. It is important to note that it should be secured from below, and in such a way that its cutting disk is directly in the gap between the two sheets of the tabletop.

Engine Installation

To make a homemade circular saw, you need to think in advance about what device will be used to transfer the force from the motor to the cutting disc. Small equipment can be placed directly on the engine axis. However, this will not have the best effect on the power of a handmade circular saw.

An ordinary bicycle spindle can act as such a transmission mechanism, without which the operation of any circular saw is impossible. This is often called the housing in which the shaft with bearings is located. To cut it off the bike, you can use a hacksaw. In this case, you will not need the sprocket, since in this case it is best to take it from the D6 or D8 engine. In order for this sprocket to fit securely on the new shaft, you will need to make an adapter sleeve. Before you install the circular saw on your bicycle spindle, you need to make sure that it has the size of the mounting hole you need. Now, taking this information into account, it is necessary to establish the outer diameter of the bushing intended for the transition mechanism. The bushing should be attached to the spindle in several places at once. Next, a plate with a thickness of at least 5 mm should be secured to the spindle assembly body.

Now take an asterisk, approximately 2-2.5 times larger in size than the one that was previously installed on the spindle, and install it on a homemade circular saw. And at the end of making a saw with your own hands, when all its parts are well secured, put on the chain and you can use it for its intended purpose.

How to choose a trimmer

An electric sawing tool is selected based on your needs. But the best, of course, would be one with a power of at least 1.5 kW.

Based on the power, you can select a cutting disc. The more powerful the machine, the larger the disk you can install on it. The most common disc is 250 mm in diameter.

An important factor is the number of revolutions of the disk rotation. Even in production, machines from 4000 rpm are used. Also, when choosing for yourself, pay attention to the fact that the passport indicates 4500 rpm.

The next point is the type of engine. Motors can be asynchronous and commutator. The first of them works silently and lasts longer. But the trouble is that it is not found on all models. The second type of motor will force you to change brushes often, but the price will be cheaper.

Next, look at the design as a whole and the turning system in particular. Each change in angle must be reliably recorded.

And the last, but no less important factor in the choice is safety. The casing must securely cover the disk. See how the sawdust ejection works. The machine must be equipped with a protection system against overheating and disk jamming.

circular machine with a 1.5 kw motor at 1500 rpm 220 volts

Large homemade circular saw

When making a frame for the top of the saw, it is best to use a metal corner 25 mm wide. In this case, a rectangle, which will represent the frame of the upper part of a homemade circular

, should have dimensions 600x400 mm. Next, four pipes are welded in the corners of this quadrangle, the diameter of which should be 17 mm and the height should be approximately 2.2 m.

After this, it is necessary to strengthen two corners on the frame, on which the bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix bearings, as a rule, clamps are used. It is best if the bearings installed on a homemade circular are closed. This way you won’t have to worry about wood chips getting into the space between the balls, rings and separator. Don't forget to also cut a thread at the very end of the shaft so that you can install a cutting blade on it later.

Circular saw device.

Electric motor for circular saw 220V 4kW 3000rpm.

The lower part of the circular saw should be made much more massive, which will provide it with the necessary stability and reliability. Therefore, when making the lower frame, you need to take a corner with a width of at least 40 mm. Next, across the frame it is necessary to secure two more additional corners, on which the engine

homemade

circular

.

The most suitable motor for a DIY circular saw is an asynchronous three-phase motor with a power of at least 1.5 kW and 1500 rpm. The pulley groove should be quite large, approximately 80 mm, and it should be mounted directly on the shaft itself. In addition, you will need to weld a fairly small metal platform to the frame on which the starting device will be placed. Large pipes 2.2 m long, which you previously welded in the corners of the frame, are necessary for high-quality tension of the belt so that the metal wings press the thin pipes.

Comments and reviews

Selecting a motor for a circular saw. :

A three-phase motor on one phase produces less than half the rated power. That is, a 3kW motor will produce 1-1.5kW. I think 3kW will not be enough. At 380 Volts it would be just right, but at 220 it would be better to take more.

Yes, for fifty you would need a more powerful engine. I have a circular machine with a 900W motor, but it’s very weak. Even sawing a forty tree will take you a long time, especially if the wood is damp.

I've been working for a long time: email. A 4 kW motor is normal for a 50 mm board, but smaller ones are already toiling. (380 V and 3000 rpm, saw with a diameter of no more than 250 mm).

3000 rpm, 3 kW is enough to loosen a 50mm board. provided 380 volts no problem. 220 volts through a starting capacitor can be an electrolytic or working capacitor at the rate of 70 microfarads per 1 kW. The main condition is a good circular disk and a good pulley. engine with the same diameter as the shaft or slightly larger. https://fazadom.com

-I would like to know about the power on the motor shaft. That is. the force required to rotate the engine without overheating is just not to guess, but to calculate. I have long been involved in the design of transmissions for machine parts and mechanisms. I would like to refresh it by trial and error. Reconnected E.D., 2.2 kW heats up after a short operating time. A universal shaft with replaceable knives for planing the surface of boards and cutting edges. How to determine the power on the engine shaft is a mystery.

Source

Which electric motor to choose for a circular saw

Electric motor for circular saw 220V 4kW 3000rpm.

Measuring with a mechanical tachometer requires direct contact with the surface of the object.

Now you need to insert both the lower and upper parts of the homemade saw into the finished supports made of pipes, and then tighten and tighten the belt with metal wings. You can start the motor in this model of circular machine yourself using starting capacitors. In order to additionally load the motor and increase its torque, you can use a 220/36,400 W transformer.

Circular with a 1.5 kw motor at 1500 rpm 220 volts

How to connect the motor?

Connecting the motor is the most important step of the work if you cannot connect the motor

from the washing machine, then you cannot make a circular movement with your hands. The whole difficulty is not even in the connection, but in order to achieve stable adjustment of the motor speed, without this circular movement it will not work properly - the drive will tear the lumber.

READ How to cut gypsum decorative tiles

On the washing machine engine, the automaker installs a so-called gearbox or speed sensor. But the problem is that the operation of this sensor is controlled by the electronic module of the washing machine, you cannot put such a module in a round one, so you need to think about a device that will control the speed of the motor. Detailed information on how to adjust the speed of the motor from a washing machine is described in the article of the same name.

How to make a homemade circular?

A home-made circular saw is an excellent way to save a lot of money, but in this case, acquire fairly high-quality, unreliable equipment. A properly assembled homemade circular saw is in no way inferior to a factory saw and is also capable of sawing logs of even very large diameters.

A circular saw is used for straight cutting of lumber.

There are currently 0 users on the page

There are no users viewing this page.

How to choose a circular saw (2019)

A circular saw is an indispensable assistant for a thrifty housekeeper. A wide range of operations performed also imposes great responsibility when choosing a tool. Today we’ll talk about how not to make mistakes.

In general, a circular saw (in everyday life a circular saw is more often used) is a power tool for sawing wood materials, in which the cut is carried out by a special cutting disc with teeth rotating at high speed. When using special discs, it is possible to cut not only wood materials, but also metal or ceramics. Features include the fact that sawing is carried out only in a straight line.

What types of circular saws are there?

The classic circular saw (with a transverse engine) is the most common and well-known option. Dimensions varying widely, different power ranges, disk rotation speeds, etc.

Mini circular saw – looks like an angle grinder. Due to their modest dimensions, they are distinguished by low power, low weight, but great convenience - you can work with one hand, in horizontal and vertical planes, at an angle, suspended or in limited space.

Plunge saws are used for high-precision sawing of materials, and there is absolutely no need to start sawing from the edge of the workpiece, as with other saws. Due to the special structure of the mechanism, the disk is located above the platform and, true to its name, is “immersed” in the material being cut in the right place.

In most cases, such saws are used with special tires for maximum cutting accuracy. Used for making grooves, holes and processing the ends of workpieces.

Hypoid saws are similar in size and purpose to classic saws, but in them the engine is located parallel to the plane of rotation of the disk, due to a hypoid transmission, which is more convenient. Another distinctive feature is that the saw blade is located on the left side.

Also, despite the fact that initially the saws operated from an alternating current network, many models have now appeared that use a rechargeable battery as a power source. Mains-powered models are more powerful, but also bulky, while battery-powered models are lighter, more convenient and portable.

In addition to the above options, there are models for stationary installation, used as small sawing machines.

Large homemade circular saw

At the frame production stage, it is much better to use a metal corner twenty-five mm wide for the top of the saw. Here is a rectangle that will represent the frame of the top of a homemade circular

, should have dimensions 600x400 mm. Next, four pipes are welded in the corners of this quadrangle, the diameter of which should be seventeen mm and the height should be approximately 5.4 m.

Later, it is necessary to strengthen two corners on the frame, on which the bearings will later be fixed. The distance between these corners directly depends on the length of the shaft. To fix the bearings, you use clamps. It is best if the bearings installed on a homemade circular are closed. This way you can easily not be afraid that wood shavings will get into the space between the balls, rings and the separator. Additionally, consider cutting a thread at the end of the shaft so that you can then install a cutting disc on it.

Circular saw device.

The lower part of the circular saw should be made much more massive, which will provide it with the necessary stability and reliability. Therefore, at the production stage of one of the frames, you need to take a corner with a width of two or more than forty mm. Next, two additional corners need to be secured across the frame, where the engine

homemade

circular

. The most suitable motor for a hand-made circular saw is an asynchronous three-phase motor with a power of 1.5 kW at one thousand five hundred revolutions per minute. The pulley groove should have an unusually large size, approximately eighty mm; it should not be mounted directly on the shaft itself. In addition, you will need to weld a fairly small metal platform to the frame, on which a DIY manual welding extruder

Which motors and saw blades to choose?

Proper selection of saw unit equipment will contribute to the efficient operation of the entire sawmill. To choose the most optimal option, several parameters should be taken into account:

There are two disks in the saw unit of the sawmill - horizontal and vertical. To drive them, you can install electric motors with a power of 15, 18.5 and 22 kW. Saw blades can be used with diameters of 450, 550 and 610 mm. The engines can operate at 1500 or 3000 rpm.

Let's lay out all the given numbers in a table to clearly see the difference or similarity:

Disc rotation speed, rpm

A disk for working at this frequency contains 24 or more teeth. The noise level is quite low during operation.

The surface of the product is rougher than the 3000 variant, and the overall performance is lower than that of more powerful engines.

It is technically possible to use disks with a diameter of 610 mm, but in practice it is extremely rare; the automatic control of the saw unit will reduce the cutting speed.

Applicability: sawmills UDP2-550 and UGP2-600.

At this frequency, for an engine of this power, the maximum permissible use of disks with a diameter of 550 mm. The number of teeth on the disc is 18 or less.

It will not be able to quickly cut down frozen wood. For fundamental stability of operation, it is imperative to install a soft start system.

Applicability: UDP2-550 and UGP2-600.

All disc diameters can be used. From 24 teeth on the disc.

Low operating noise, high performance. A soft start system is optional.

It is used on all sawmills and is the most popular option.

18 or fewer teeth on the disc. Surface quality close to planed.

High noise during operation, slightly lower performance compared to the 1500.

This option is not recommended, since in fact a very high load is applied to the disks and the automation will often reduce the speed of passage to avoid overheating.

High noise – and at the same time quite high productivity, as well as excellent surface quality of the product.

The engines are significant in weight and are the largest in size; in our case, they are used only on UPK-1 sawmills.

Thus, the following conclusions can be drawn:

Selection by engine power:

- 15 kW motors are suitable for those industries where the power grid is weak. This is an economical, purely compromise option.

- 18.5kW motors are the most popular choice, delivering high performance and quality across our entire range.

- We use 22 kW motors only as part of the most productive sawmill UPK-1. These are massive products that require reliable fastening and large space inside the carriage with the saw unit. Exactly what is implemented in the design of this sawmill complex.

Selection by saw speed:

- Frequency 1500 is generally characterized by low noise, fast operating speed, but a certain roughness of the cutting surface. However, this does not affect the accuracy of the dimensions themselves, and the surface itself in 90% of cases can be considered smooth without any reservations.

- The frequency of 3000 rpm is quite high noise and ideal surface quality of the product.

Selection by disc diameter:

- The smaller the diameter of the disk, the smaller the thickness of the cut, the less load on the engines - but also the smaller the maximum size of the product. For 450 discs, the maximum timber size is about 130 mm by 130 mm; for 610 discs, sawing 220 by 220 mm is quite possible.

- The design of the disc provides for a different number of teeth and different thicknesses of the disc metal, depending on the diameter and expected rotation speed. To avoid overheating and warping of the disc, discs with fewer teeth are used for high-speed work. For 1500 revolutions, discs with 24 teeth or more are used; for 3000, discs with 18 teeth or less are used. Understanding this principle allows you to quickly and easily select and purchase spare sets of sawmill blades.

- If you have chosen disks of one diameter, and your engines allow the use of a different diameter, then when compiling the configuration, we can equip the machine with adapter bushings for attaching disks of any diameter you need. Bushings can be purchased later, at any time.

What kind of engine is needed for a circular machine?

Moving parts

After the engine

connected, you can proceed to creating

a circular

. The next step is the assembly of the moving elements, since it is they that bear the load, namely:

- Motor shaft.

- Saw shaft.

- Drive belt.

- Motor pulley from the washing machine.

- Circular saw pulley.

The design itself is simple, but there are a lot of points that are important to consider, for example:

- It is recommended to sharpen the small pulley by making 4 transverse grooves, this is necessary so that the belt clings and does not slip.

- It is not necessary to use a drive belt from a washing machine; you can take any suitable one, as long as it has transverse serrations.

- The saw mounting shaft must be as reliable as possible, which also applies to the nut and washer. Otherwise, the saw may become deformed, or even jump out and injure the person working.

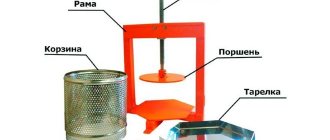

Homemade concrete mixer

If you have started a small renovation that requires, for example, plastering the walls, a concrete mixer will come in handy. Once again, washing machine parts will come in handy.

As a result, you will receive a compact device with low power, which you won’t mind throwing away after the repair work is completed.

As a container for concrete, you can use the same drum with pre-sealed holes for draining water. It is best to use parts from a front-loading machine; there will be almost nothing to redo. To strengthen the body, use a metal corner, and for convenient movement of the concrete mixer, equip it with wheels. The main difficulty in the design is the manufacture of a “swing” for the correct tilt and subsequent pouring of concrete. How to do it correctly in the video: