Designation

Soviet-made equipment is designated according to the ENIMS classification.

The first number indicates the equipment group, the second the type of drilling machine, the third and fourth - the maximum drilling diameter. The letter in the abbreviation indicates the modernization carried out. For example, 2M112 - the machine belongs to the drilling group, M - modernization was carried out, 1 - vertical drilling machine, 12 - maximum drilling diameter in steel is 12 mm.

Modern imported machines do not have a marking standard. Each manufacturer introduces its own labeling standard and adheres to it in its line of equipment. This point complicates the selection, because Its characteristics are not always clear from the name of the machine.

Rating of drilling machines

Manufacturers produce vertical, radial and drilling and milling machines, which differ in technical characteristics and accuracy when performing operations. Experts tested products from well-known brands, compared the data obtained with the declared characteristics, and assessed the quality of processing. When compiling the review, the opinions of users and professional locksmiths were taken into account.

Particular attention was paid to the following parameters during the analysis:

- Electric motor power - the higher the indicator, the faster you can drill in thick metal;

- Drill diameter - chuck dimensions are not unlimited. For domestic purposes, it is enough to drill holes of 14-20 mm; in an enterprise this parameter reaches 60 mm;

- Weight and working dimensions - weight affects stability, dimensions - the possibility of installation in conditions of limited space;

- Safety - Flying steel chips can cause serious injury;

- Functionality - automation, reverse and several speeds make the equipment universal and highly productive.

Not all models were able to pass expert control. Backlash leading to deformation of holes, unstable base, strong chuck runout - mechanisms with such defects were excluded from the rating.

Manufacturers

Today you can find machines from foreign manufacturers: Proma, Optimum, Jet, Triod, Knuth, Enkor. The line of these manufacturers includes machines ranging from household ones to large industrial drilling machines.

Proma brand machines

The production of machines is carried out in China, but the brand has Czech roots. The company has existed on the Russian market for about 20 years. 23 models of vertical drilling machines and 1 model of radial drilling machines are supplied to the territory of the Russian Federation.

According to the characteristics, this segment of equipment covers almost any task in household workshops, repair shops, and production facilities. The range includes machines with a vertical spindle with a maximum drilling diameter from 6 to 50 mm, with a belt drive and gearboxes, supply voltage 220 and 380 V.

Optimum brand machines

Optimum is a German brand. Some of the machines are manufactured in Germany, the other part in China. The range includes 36 drilling machines of various types: tabletop - with a maximum processing diameter of 13 - 26 mm, column - from 20 to 50 mm. Some models have automatic feeding and threading functions.

An important competitive advantage of the company is that the machines are equipped with a continuously variable spindle drive - the spindle speed is changed due to electronic frequency control (Vario models) or a mechanical V-belt variator (DH Vario models).

A mechanical V-belt variator provides high torque at low rotational speeds of the drilling unit, and also allows you to select the optimal operating mode - balancing cutting speed and tool life, thereby increasing processing productivity.

Optimum RB6T Optimum B30BS Vario

Optimum B23Pro Vario

The machines are divided into several series:

- B – for home and small workshops;

- Pro – professional – for production and repair shops;

- High – professional machines for industrial use, with a high rotation speed (4000 – 4800 min-1) and are designed for critical work.

The remaining models of machines that are not included in the series are specialized, i.e. designed for processing certain types of materials and certain jobs. For example, the B30BS Vario and B30VGM Vario models, thanks to their variators, are designed for drilling and threading in non-ferrous materials, composites and plastics.

Jet brand machines

The Jet company originated in the USA in 1958, and in 1988 it merged with the Swiss company Walter Meier AG.

The range includes 16 vertical drilling machines (with belt and gear drive) and 6 radial drilling machines.

The technical capabilities of the equipment allow processing holes with a diameter of 3 to 50 mm. The line also includes a drilling and tapping machine MASCHTEC KST-340, which allows you to cut threads in steel up to M12, in cast iron up to M14.

The best drilling and milling machines

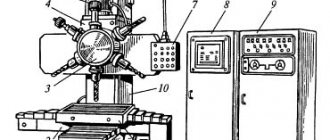

When choosing a tabletop drilling machine, many people prefer to opt for the most universal solution. Drilling and milling models that work with drills and cutters became such equipment. The design of the machine allows processing complex parts with curved surfaces. The equipment spindle is fixed to a movable support, and the work table helps to fix the workpiece. There are dozens of brands on the market, but we, VyborExperta.ru, recommend paying attention to 2 models that have fine-tuning systems and reliable electric motors.

Metal Master MF-20

A rigid design with a movable milling head that can rotate around a vertical axis allows you to solve complex problems. Processing mutually perpendicular surfaces increases the pace of work. A 550 W electric motor spins the spindle at a speed of 2200 rpm. Six speeds, which are switched using the rearrangement of the V-belt, allow you to process any material. To select the optimal mode, you can use the speed table.

Ergonomic handles are equipped with small pitch dials and a clearly visible scale. The micrometric feed mechanism is located on the milling head for comfortable work. The operator can select the spindle rotation direction by switching the lever on the control panel. The vertical feed lever is equipped with a handle for quickly lowering the quill.

Advantages:

- T-shaped slots for installing clamping equipment;

- Fixing the desktop with locking handles;

- Cast base design;

- The engine is designed for intensive work;

- Drilling depth stop.

Flaws:

- Overcharge.

Jet JMD-2S 230V 50000060M

Professional equipment with a body made of high-strength cast iron and an electric motor with a power of 1 kW. The control panel is located in a convenient location, and the digital display simplifies control over the parameters of the quill extension and spindle rotation. The speed is smoothly adjustable in the range from 40 to 2000 rpm, helping to select the optimal mode for workpieces made of any material.

Automatic feed along the X-axis increases the pace of work; three T-shaped grooves are provided to fix the clamping tool. The table is equipped with a ruler, which helps improve processing accuracy. The model has good functionality: users note the effective reverse and convenient spindle microfeed for solving high-precision tasks.

Advantages:

- Convenient protective screen;

- Stand made of high quality cast iron;

- Good equipment;

- Low noise level;

- Ergonomic control.

Flaws:

- There is no coolant supply to the working area.

Types

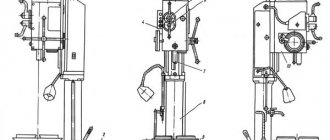

Vertical drilling machines are divided into several types according to their layout:

- manual tabletop - installed on tables, workbenches, feeding is carried out by moving the handle manually;

- with a spindle assembly on a column - installed on a foundation pad, have a gearbox, long changeover time;

- with permanent spindles;

- with adjustable spindles.

Tabletop manual machines Column machines With fixed spindles With adjustable spindles

Main technical characteristics

Model for machining large workpieces

When choosing a machine model of this type, you should analyze the maximum operational and technical requirements for its characteristics. These include not only quality performance indicators, but also design features.

All vertical drilling machines are divided by type of execution - tabletop and floor-mounted. The purpose of the former is to process small and medium-sized workpieces made of metal, plastic or wood. Floor-standing models are used to complete production lines and specialized workshops.

The main technical characteristics of the equipment include the following:

- Rated power of the electric motor and parameters of the electrical network. Typically the first characteristic is from 300 W to 1.5 kW. Household models are designed to connect to a 220 V network, factory models - 380 V;

- Speed. Manufacturers indicate this parameter for idle speed. It varies from 400 to 3500 rpm;

- Number of switchable speeds;

- Diameter range of drills installed in the chuck. For household models it is from 1.5 to 13 mm;

- Vertical extension of the spindle head;

- Desktop tilt angle. Typically ±45°.

You also need to consider the size of your desktop. They affect the maximum possible dimensions of the workpiece. Alas, manufacturers almost never indicate the permissible weight of the workpiece. For models with a height-adjustable desktop, it is smaller than with a stationary one.

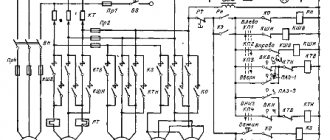

To increase operational safety, the protective casing for switching speeds must have a protective relay. When the lid is opened, the electric motor will automatically turn off.

Drilling tool

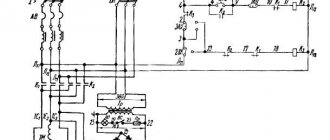

To secure cutting tools (drills, reamers, countersinks, taps), special chucks and intermediate devices are used, and if the dimensions of the tool allow, they are installed directly into the spindle.

The mounting holes of machine spindles are standardized. As a rule, they have a conical shape (Morse taper).

If the cone of the cutting tool shank has a different cone from the cone of the spindle of a vertical drilling machine, then adapter bushings are used. For example, a drill is attached to a sleeve, and the sleeve is mounted in a spindle seat. If it is necessary to secure a cylindrical drill, then split bushings are used: they have a cylindrical hole on the inside and a conical hole on the outside.

Drill chucks are more universal because... It is easier and faster to secure a cutting tool in them, and if they are quick-clamping, this also reduces time.

Which drilling machine is better

Our experts have selected the best machines in their categories. The review will help you purchase a reliable, productive tool for your home workshop, and cost-effective production equipment. Preference was given to models that have a good balance between performance parameters and price. The exception is electrical engineering for professional use: here machines with a quick payback have an advantage. In each category, we recommend paying attention to the following models:

- Bosch PBD 40 – semi-professional machine for the home workshop;

- RedVerg RD-4113 is an inexpensive tool for working in the garage;

- Optimum OPTIdrill RD3 – for working with large workpieces;

- Metal Master MF-20 is a universal solution with a quick payback;

- Lenz Steyr-35 – the choice of installers and builders;

- Bds MAB-825 – for working with thick workpieces.

All proposed models are worthy of the attention of professionals and those home craftsmen who take their hobby responsibly. Only a tool capable of accurately and accurately drilling, a milling cutter

Radial drilling machines

Radial drilling machine Z3050

Radial drilling machines are used for processing single holes or holes located in groups on workpieces with significant dimensions and weight.

Operations performed on radial drilling machines:

- Drilling through and blind holes.

- Drilling and boring (using a boring head) holes.

- Tapping threads.

- Countersinking of holes to obtain higher classes of cleanliness and precision of hole surface treatment.

- Countersinking, necessary for the formation of conical and cylindrical technological recesses for the heads of bolts, screws, etc.

- Reaming of conical and cylindrical holes necessary to obtain the required accuracy and surface roughness.

- Rolling and honing of the hole surface (using rolling and honing heads).

- Trimming the ends of the bosses to provide a surface perpendicular to the axis of the hole.

The use of special tools, mandrels and devices increases the productivity of drilling machines, expands the range of possible operations, allowing them to perform typical, for example, boring machines: turning internal grooves, cutting out circle-shaped parts from sheet material.

According to the classification of metal-cutting equipment according to GOST 8-82, radial drilling machines belong to class K1 (normal accuracy N), which meets the requirements for general-purpose machines in modern world metalworking practice.

How to buy a good mid-class drilling machine: ranking of the best ones

These are models that can already be used at service stations, and at repair bases of small-scale companies, and in the workshops of enterprises that produce their products in small volumes.

Ryobi RDP102L

This universal Japanese machine, with a 2-year warranty, can even handle complex plastic, wood, metal and composite parts.

With standard 5 speeds, it stands out for the accuracy of its results. Options:

- engine power – 390 W;

- rotation speed – 510-2430 rpm;

- spindle quill stroke – 50 mm;

- weight – 21.2 kg;

- dimensions – 610x390x305 mm.

Pros:

- equipped with a tool immersion depth limiter;

- there is laser marking that facilitates precision processing;

- The manufacturer provides a loyalty program with preferential service.

Minuses:

- relatively weak motor.

Einhell BT-BD-701

Of course, we have a subjective rating of drilling machines for the garage, and it’s up to you to decide which one is better to take for tasks at a higher level, but this model will definitely cope with work of average complexity.

It has a Chinese price, German build quality and no longer has the play inherent in its “younger brother” - this manufacturer is quickly correcting its mistakes. Characteristics:

- engine power – 630 W;

- rotation speed – 220-2450 rpm;

- maximum drill diameter – 16 mm;

- spindle stroke with chuck – 60 mm;

- weight – 35 kg;

- dimensions – 850x633x193 mm.

Advantages:

- 12 speeds at once;

- stable base 350x230 mm;

- measuring scale printed on the front panel;

- motor overload protection ensures continuous operation;

- The cutting depth is adjustable.

Flaws:

- comparatively bulky and heavy.

BISON ZSS-550

This Russian-Chinese monster is definitely one of the top 10 drilling machines for the garage, because it does an excellent job of processing large parts.

The speed changes stepwise and smoothly, the operator is completely safe, he can set the table position to almost anything, easily achieving high accuracy of countersinking or boring. Options:

- engine power – 550 W;

- rotation speed – 470-3030 rpm;

- spindle quill stroke – 100 mm;

- weight – 48 kg;

- dimensions – 320x925x410 mm.

Pros:

- precision result;

- the ability to adjust the angle of inclination, and not just the height;

- there is an emergency (instant) shutdown button;

- The transparent shield provides protection from chips.

Minuses:

- quite heavy, and the walls of the racks are thin;

- The vice is sometimes too weak for large workpieces.

Elitech CTC 5525VPL

If we choose a top-end drilling machine for a home workshop based on ratings and reviews, we will see that many people recommend this particular Chinese model.

Why? Because it is very modern and convenient: you can adjust the speed, surface inclination and even spindle play. And see all the settings on the electronic display. In terms of its functionality, this is practically professional equipment, which is why it is used in maintenance centers. Characteristics:

- engine power – 550 W;

- rotation speed – 440-2580 rpm;

- maximum drill diameter – 13 mm;

- spindle quill stroke – 50 mm;

- weight – 24 kg;

- dimensions – 720x460x300 mm.

Advantages:

- all entered information is displayed on the screen;

- equipped with an immersion depth limiter;

- there is an LED backlight and a laser sight;

- the rotation of the working surface can be set up to 45 0 to the right and left;

- there is an elevator rail.

Flaws:

- Sometimes there is a beating in the cartridge.

Bosch PBD 40

This is, perhaps, the best drilling machine for a garage or service station with small amounts of work.

Again we see German quality with Chinese availability, but now complemented by stabilization, support for cutters with a diameter of up to 40 mm, and digital speed control. And this with impressive stability, light weight and responsive handling that helps ensure maximum control of your workflow. Options:

- engine power – 710 W;

- rotation speed – 200-2500 rpm;

- weight – 11.2-13.7 kg;

- dimensions – 750x378x273 mm.

Pros:

- there is a high-precision cartridge with a locking ring;

- the handle of the built-in wheel has a soft pad;

- equipped with a digital display with electronic indication;

- a wide table and parallel stop are the key to precise positioning of the workpiece;

- There is a laser and LED backlight.

Minuses:

- only 2 speeds.