There are many hole machining operations. They are needed in mechanical engineering and machine tool building to bring the hole to a certain state. So, sometimes it is necessary to chamfer the beginning of the channel (centering hole) or make a conical recess in it to hide the head of a bolt or screw. For all these purposes, a tool such as a countersink for metal was invented. This is a special cutter with an original configuration, which is used with drilling or turning equipment.

The countersink tool is sometimes mistakenly called a countersink. This is fundamentally wrong: the countersink is designed to improve the quality of the hole in terms of geometric parameters; its shape does not allow making recesses in the form of a cone. The countersink and countersink have a common multi-blade structure of the working part, and in most cases their blades run in a spiral.

It is necessary to use a countersink, strictly observing the technical conditions for its use.

Kinds

According to physical parameters, countersinks are divided into the following types: - conical; - end tools; - having cylindrical external parameters. Cylindrical countersinks, in turn, are divided into types such as: - mounted; — with a cylindrical shank and a journal (permanent guide); — with a shank made for a pin lock and a trunnion (replaceable guide); - with a conical shank and a trunnion (replaceable guide). In addition, models are manufactured in compliance with certain standards and are divided according to the diameter of the holes processed: - with or without a safety cone (holes with a diameter of 0.5 to 6 mm); — with a cone-type shank (holes with a diameter of 8 to 12 mm); - simple countersinks (for holes with a diameter of 0.5 to 1.5 mm).

How to choose the countersink size?

In order for the screw to fit perfectly into the countersunk, it is important to select the correct conical countersink for the head of the hardware and countersink the hole to an exact depth equal to the height of the head. The angle of the tool must correspond to the angle of the head cone, and its diameter must correspond to the diameter of the head. If you take a countersink that is too large, the head will sink into the “crater” of the hole, and if it is smaller, then it will protrude above the plane, which also does not look aesthetically pleasing.

The GOST 12876-67 standard specifies the dimensions of the supporting surfaces for fasteners with countersunk and semi-countersunk heads. Based on this data, we have compiled a table that will help you quickly determine which countersink is suitable for a particular screw thread diameter.

Table 1. Countersink size for the screw head (including tolerances).

| Thread diameter d, mm | Standard head sizes | Countersink diameter, mm | Maximum deviations, mm | ||||

| Diameter, mm | Height, mm | D1 (to H13) | D2 (by H12) | D3 (to H14) | |||

| 2.0 | 3.8 | 1.2 | 4.3 | 4.6 | 4.3 | — | |

| 2.5 | 4.7 | 1.5 | 5.6 | 5.7 | 5 | — | |

| 3 | 5.6 | 1.65 | 6.3 | 6.6 | 6 | 7 | |

| 3.5 | 6.5 | 1.93 | 7.3 | 7.6 | 7 | — | |

| 4 | 7.4 | 2.2 | 8.3 | 8.6 | 8 | 9 | |

| 5 | 9.2 | 2.5 | 10.4 | 10.4 | 10 | 11.5 | |

| 6 | 11 | 3 | 12.4 | 12.4 | 11.5 | 14.5 | |

| 8 | 14.5 | 4 | 16.5 | 16.4 | 15 | 18.5 | |

| 10 | 18 | 5 | 20.5 | 20.4 | 19 | 22 | |

| 12 | 21.5 | 6 | 24.0 | 24.4 | 23 | 26 | |

| 14 | 25 | 7 | 28.0 | 28.4 | 26 | — | |

| 16 | 28.5 | 8 | 31.0 | 32.4 | 30 | — | |

| 18 | 32.5 | 9 | 35.0 | 36.4 | 34 | — | |

| 20 | 36 | 10 | 39.0 | 40.4 | 37 | — | |

Purpose

The main purpose of countersinks is to make holes of various sizes and shapes, including for placing fasteners. In addition, such a tool allows you to adjust holes that were prepared in advance, as well as process the supporting surfaces around the holes, thanks to the teeth on the ends and guide pins. Such elements can be replaceable or manufactured together with a countersink. In accordance with the current GOST 14953-80, which regulates industrial conditions for countersinking, typical dimensions of the tool, as well as taking into account the mechanical characteristics of the material being processed, the mode of work.

Rules for using the tool

When using a countersink, work should be carried out using a lathe or drilling machine. It is very important that the chuck is in good condition, otherwise, when the cutter runs out, it will not be possible to obtain a clear cylindrical recess. The rules for using the tool are as follows:

- For each type of work, you need to choose the type of cutting element suitable for this purpose: to form a cone with a recess - a countersink with an oblong body and a guide pin, for small recesses - a regular conical countersink, for hard alloys - a tool with carbide tips.

- The diameter of the cutting element must correspond to the required diameter of the recess. If you machine with a tool with a much larger diameter, this can lead to poor centering of the recess relative to the hole, non-compliance with the cone angle and the exact depth.

- When choosing the rotation speed of the cutter, you must adhere to those speeds that are recommended for this particular tool. Excessive speed leads to overheating of the working part and rapid wear of the cutting edges.

- When working with cast iron or alloys made of solid material, it is necessary to remove heat from the working area; for this, special emulsions must be used.

- The countersink must be precisely centered relative to the middle of the hole.

Materials for production

Countersinks are made from carbide materials, various steel alloys, and high-speed steels. In order to process products made of plastic, wood, or soft metal, countersinks made primarily of steel alloys are used. Carbide types are required for machining holes made from harder metals.

countersinks

Definition

In accordance with GOST 25751-83 “Cutting tools, terms and definitions,” a countersink is defined as “an axial cutting tool for increasing the accuracy of the hole shape and increasing its diameter.” Let us immediately note that this type of tool is not intended directly for drilling holes. Also note that the definition of a countersink does not say anything about changing the shape of the hole. This is an important detail and will be useful later.

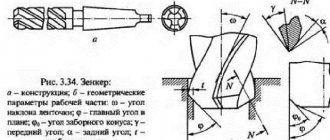

Countersink design

To describe the design of countersinks, it is convenient to divide them into two classes - countersinks with shanks and mounted countersinks. Countersinks with cylindrical and conical shanks The design of such countersinks is in many ways similar to the design of a twist drill (Fig. 1).

Fig.1 Solid countersink with a conical shank: a) for through holes, b) for blind holes, c) with carbide plates

The tool also consists of a working part, a connecting part (neck) and a tail part (shank). The difference from a drill lies in the shape and number of cutting edges on the working part. In particular, according to GOST 12489-77, countersinks have three blades on the end and cylindrical surface.

A countersink with a cylindrical or conical shank can be solid GOST 12489-77 (the entire working part is made of high-speed steel), or with carbide inserts (GOST 3231-71). In addition, each type is available in two versions: for blind and through holes (Fig. 1, c)). For countersinks for through holes, the angle of the main blade φ has values of 45 or 60 degrees, for countersinks with carbide plates φ=600, for all types of countersinks for blind holes φ=900.

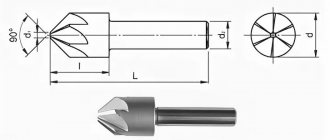

Mounted countersinks

Mounted countersinks do not have a tail section. Instead of a shank for mounting on equipment, they have an internal cone for a mandrel (Fig. 2). This type of design also features a large number of blades. In solid mounted countersinks according to GOST 12489-77, four teeth and, accordingly, four spiral grooves are provided. Further division of mounted countersinks into types is identical to the class with shanks.

Fig.2 Mounted countersink: a) solid, c) with carbide plates

Application of countersinks

Countersinking tools are used in technological countersinking operations aimed at improving the quality of holes - improving surface cleanliness, obtaining a more accurate cylindrical shape. Accordingly, the main part of a countersink is a cylindrical section of the working part. Using countersinking, holes are brought to 4–5 accuracy classes with H11 quality and surface finish corresponding to 5–6 classes. The required result is achieved due to the higher rigidity of the tool, as well as due to a larger number of blades compared to a drill.

We emphasize that all of the listed GOSTs describe countersinks with a working part of an exclusively cylindrical shape. In the descriptions of the designs of standard countersinks there is no wording “conical countersink” and there are no drawings of countersinks with a conical working part. Those. The result of using a standard countersink is a cylindrical hole of constant diameter.

Countersink design

Structurally, the tool is a combination of 2 main elements - the shank and the working part. The main one, i.e. the working part is a cone with a regular series of angles located at the top at a certain degree. The countersink has from 6 to 12 cutting blades. In terms of its design features, the cylindrical model is similar to a drill, but it contains a larger number of cutting elements. For reliable fixation during work, a guide pin is located at the end.

Design features

The all-metal countersink tool in the drawing has several main structural parts:

- Working body. The main part of the element, which essentially performs the countersinking operation. It contains cutting edges - there can be a different number of them. There is also a base - a cylindrical part where the incisors converge from the top of the cone.

- The shank is an important part of the element. With its help, the cutter is fixed in the equipment chuck. The shanks are also different: in some the body is shaped like a cylinder, in others it looks like a truncated cone.

- There is a small isthmus between the shank and the working area - this is also a countersink element. The isthmus is the weakest part of the instrument. It has a smaller diameter than the shank and working head. Its purpose is to act as a fuse in case the cutter jams in the workpiece; in this case, it should simply burst and prevent larger-scale destruction.

In addition to all-metal countersinks, there are tools with insertable blades. In this case, the blade material is made of a stronger grade of steel than the base of the element. This design allows you to have a high-quality cutter, but at the same time, the cost will not exceed that of popular products.

Another cutter design has high-strength tipped cutting edges. These cutting elements are good for processing hard alloys or cast iron.

Areas of application

The areas of application of countersinks include use on machines such as: - lathes; — drilling; — milling; — boring; — turning-turret; — aggregate. In terms of the level of purity, the countersinking procedure, as a technological process, is classified as semi-finish processing. It is usually used before drilling holes in blank elements made of various materials. Carrying out such a technological operation must be performed at low machine speeds. Some types of countersinks are also used for processing and chamfering holes that are located in hard-to-reach places - these are reverse-type tools.

Differences between a countersink and a counterbore

The difference from counterbore counterbores is that the former are related to a countersink tool. Their main purpose is to work with ends. That is, the counterbore can drill a recess with a larger diameter than the hole itself, and at the same time align the end plane in this recess, making it perpendicular to the axis of the channel.

The counterbore also refers to elements where there are many blades. In addition to the blades, the counterbore necessarily has a guide element, which is called a trunnion. A counterbore is similar to a countersink in that it can perform almost the same operations: creating a hole for fasteners, chamfering, removing burrs after drilling.

Countering can also only be used on special equipment, which is a drilling or lathe.

Dear guests of the site, support this topic in the comments! When constructive communication occurs, it always benefits the cause!

The difference between countersinking and countersinking

Countersinking and countersinking are different concepts, although they sound very similar. Each technological operation has its own characteristics and specifics. Countersinking refers to cutting off a sufficiently large layer of material from a workpiece to create recesses that are intended for hidden installation of fasteners. Additionally, countersinking is used to select chamfers. Countersinking is the processing of the inner surface of the material of a future product to increase accuracy, improve shape and overall quality. The countersink does not deepen the hole, but only removes a very thin layer of material, improving the surface of the workpiece.

There are two main types of conical countersinks:

with cross hole

This is a cone-shaped cutting tool equipped with a hole passing through the side of the cone. The hole forms two cutting edges on the cone and is a channel for removing chips during the cutting process. This tool is best suited for working with wood, plastic and other soft materials. It is also advisable to use it to remove burrs left after a previous operation.

with multiple cutting edges

This is a multi-blade tool for working on metal, the working conical part of which consists of 3 to 12 cutting edges. Made from hardened high-speed steel. The larger the diameter of the cone, the more cutting edges it has. The tail part, with which it is attached to the cartridge, can be cylindrical, conical (Morse cone) or hexagonal (bit).

Note:

Countersinks should be distinguished from countersinks, since this metal-cutting tool is designed to solve other technological problems, namely, to improve the surface quality of drilled holes.

Useful tips Updated: 11/16/2020 15:38:35