Smoke generator for cold smoking - design features, types, useful tips

Smoking is an ancient and beloved way of preserving various foods.

The specific taste and aroma that they acquire as a result of this procedure are well known to all gourmets. However, cold smoking requires a fairly large smokehouse with a long corridor for the smoke, otherwise it will not have time to cool down and the technology will be disrupted. Construction of a stationary smokehouse requires space and is not available to all owners of private houses, not to mention residents of ordinary apartments.

However, there is a completely effective and compact replacement for bulky smokehouses. This is a smoke generator with which you can get exactly the same result. Let's take a closer look at this device.

What is cold smoking

Cold smoking is the process of processing food using smoke.

The smoking temperature does not exceed 30°, for which a long channel is made between the source (smoldering wood) and the smoking cabinet (the container into which the prepared products are loaded). Passing through it, the smoke loses its temperature and enters the smokehouse with the required parameters. Products processed in this way retain their beneficial properties, vitamins, and microelements. The absence of heating allows you to maintain the density and structure of the products. You can cook meat, fish, bacon, fruits and vegetables and a host of other foods this way.

Cold smoking is a very long process. Processing lasts many hours, sometimes days. In some cases, the duration of the procedure can reach a month. In addition, the quality of processing depends on the design features of the smokehouse, the length and design of the channel and other factors. Therefore, the quality of smoking varies slightly between different designs.

Hot smoked smoke generator options

The easiest way to carry out hot smoking is to place fuel on burning coals - leaves, sawdust, small branches, wood chips. Cover this structure with a box or other container in which to place the fish or meat. The smoke produced is sufficient for cooking.

An alternative is a smoke generator with an electric heater. An electric stove is used as the main element. It is installed inside the smokehouse; a baking sheet or other container with sawdust is placed on it. When turned on, the fuel will smolder and produce smoke.

A smokehouse with a heating element heater is constructed in the same way, but it will need to be firmly fixed inside the container.

Electric heater device

To assemble a smoke generator with your own hands, you will need the following elements:

- drill;

- drill;

- union;

- fitting;

- compressor;

- flexible hose.

You can add a thermometer to the smoke generator to monitor the temperature of the smoke produced. Assembly occurs according to the following algorithm:

- The smoke generator housing is selected. This could be a stainless steel pan or a can. In some cases, old fire extinguishers are used.

- A hole is drilled in the upper part of the container and a fitting is attached, firmly fixed with a washer.

- A fitting is attached to raise the smoke upward. You can order it from specialists; in this case, it is possible to improve the part. Those who ordered a fitting from a turner know that it is possible to make the part inside with an additional tube for more efficient functioning.

- A flexible tube leading to the compressor is attached to the fitting. You can use an aquarium or computer cooler as a supercharger.

- If a thermometer is provided in the design, it is attached next to the fitting.

- A tube is screwed into the free hole of the fitting. This is a chimney through which smoke moves into the chamber. An element of 10-15 cm is sufficient.

- Another hole is drilled in the lower part of the body to allow air circulation and ensure continuous smoldering.

.Following a simple algorithm, you can easily assemble the unit with your own hands.

What is a smoke generator

Specialists involved in smoking products have paid attention to the volume of stationary smokehouses. As a rule, they are designed for a large number of products, otherwise the lengthy procedure becomes unprofitable. When developing a design for processing small quantities of food, the idea arose of using compact devices that produce low temperature smoke. This is how smoke generators appeared.

These are compact devices that emit smoke from smoldering materials. A small amount and a soft smoldering mode allow you to produce smoke with a low temperature, which is further reduced when passing through the hose connecting the smoke generator and the smoking cabinet.

Using the same device you can produce smoke with different smells and properties. You just need to change the smoldering material. Typically, sawdust or hardwood chips are used. Experienced specialists know how to make mixtures from different materials, achieving certain qualities from the emitted smoke. This allows you to obtain delicious smoked products of gourmet quality.

Design Features

The smoke generator is a small chamber with two pipes.

One of them is input, it receives air flow from a fan or compressor. The second pipe is used to exhaust smoke. It is connected to the smoking chamber in which the products are hung. Its functions can be performed by any box, box or tank with a lid. The inside of the smoke generator body is a firebox in which small wood chips or sawdust smolder. The air flow supports smoldering and carries away the smoke, which enters the smoking cabinet.

Small compressors like those installed on large aquariums are used to supply air. There are installations that use natural draft, but they are ineffective and are too dependent on external conditions.

The entire installation, together with the smoking chamber, can fit on a regular kitchen table, which allows you to make preparations even in a typical apartment.

Various accessories for smoke generator

To improve the quality of smoke, a smoke generator with additional accessories is suitable.

Smoke generator injector device

The most important and complex part of the device is the ejector. The quality and quantity of smoke and the operation of the entire installation depend on its manufacture and settings.

The operating principle of this device is as follows:

- the air flow moving through the chimney creates a reduced pressure inside it;

- Low pressure in the chimney pipe draws smoke from the smoke generator and creates additional draft through the lower holes.

Thus, the operation of the ejector increases the flow of smoke into the smoking chamber, the smoldering of wood chips and the intensity of smoke emission.

Design and self-assembly of the ejector

This device can be made from a water tee. The middle part is connected to the smoke source, one of the outer parts is connected to the smoking chamber, and a plug with a tube from the compressor is screwed into the opposite part. The temperature is relatively low, so the cork material can be anything: plastic, rubber or metal.

The tube for supplying air to the ejector is taken with a diameter of 6-10 mm and such a length that it extends 8-10 cm into the chimney. It is important to ensure the alignment of the nozzle and the chimney. To do this, it must fit tightly into the plug - it is inserted into the rubber one, and screwed into the metal one with a thread.

Cooler for smoke generator

Cold smoking uses smoke at room temperature, and it comes out of the generator up to 120°C, especially with a lower chimney connection. To reduce its temperature, a cooler or cooler is installed.

This is a cylindrical or square chamber similar in size to the smoke generator body. Once in this chamber, the smoke slows down and cools down. For greater efficiency, the entrance to the cooler is made from the top, and the exit from the bottom.

When cooling, condensate is released from the smoke, which accumulates at the bottom of the cooler, so in addition to it it is necessary to install a condensate collector.

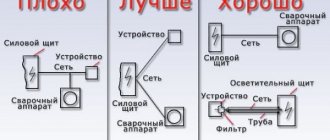

The principle of operation and operation diagram of the cooler are shown in the picture.

Filter for smoke generator

To improve the quality of smoke, it should be cleaned of resins, soot and other substances. To do this, a filter is installed in the chimney.

Structurally, this is an extension of the chimney filled with steel shavings or metal scourers for washing dishes. This extension can be made in the form of an additional chamber with a cover for replacing the filter or a pipe of a larger diameter than the chimney. In this case, to replace the chips, the chimney will have to be partially disassembled.

The operating principle is shown below.

Compressor for cold smoked smoke generator

One of the important components of a smoke generator is the compressor. It directs the air flow through the ejector. This flow carries smoke into the smokehouse, creating a vacuum in the combustion chamber and additional draft.

Making your own compressor

The simplest compressor can be made from a computer cooler and a plastic bottle:

- a hole is cut in the bottom of the bottle corresponding to the diameter of the cooler;

- a fan is inserted into it and secured with tape;

- a hole is made in the lid for the connecting tube;

- the tube is inserted into the lid, and the connection point is also wrapped with tape;

- The cooler can be connected to any 12V DC power source.

Making your own compressor

DIY liquid for a smoke generator

In addition to smoke generators designed for smoking products, there are devices that create smoke on theater and concert stages.

In these devices, smoke is produced when a special solution hits the heater and evaporates, that is, it is not smoke, but steam.

The composition may be different, for example:

- glycerin – 15%;

- alcohol – 10%;

- distilled water – 75%.

Naturally, the steam from such a solution is not suitable for smoking food.

How to choose the right option

The choice of a suitable smoke generator model is based on its performance characteristics.

First of all, you need to consider:

- size . A small device you can take with you to the dacha, fishing or hunting. Larger models have high productivity, but are much more difficult to transport;

- material and wall thickness . If the body is made of ordinary steel (there are models made from ordinary rectangular pipes), it is better to look in other stores. The best option is stainless steel with a wall thickness of at least 1.5-2 mm;

- equipment . Sometimes smoke generators are sold, for which you also need to select a compressor, connecting hoses and other elements. There are ready-made kits, fully equipped with everything you need, down to a certain amount of wood chips. This option is much preferable, as it allows you to immediately start smoking;

- performance . The size of smoke cabinet it can handle depends on how much smoke the generator can produce. It is recommended to buy devices with the ability to adjust the amount of smoke in order to be able to fine-tune the flow for a specific container;

- price . There are very expensive models, but for home use it is not at all necessary to spend a lot of money. You can choose a relatively inexpensive device that can perform its tasks quite efficiently and reliably;

- method of supplying smoke . There are devices with bottom and top feed. The former are considered cleaner, but the wood chips in them often fade. Generators with top smoke supply, where the air flow supports the smoldering of the wood chips, do not have this problem. At the same time, the parts and all internal elements are covered with a layer of carbon deposits, which requires periodic cleaning.

Manufacturers and models

The ease of use of smoke generators has contributed to the active production of models for home use. Many manufacturers are doing this, both in Europe and in Russia.

Let's look at a few of the most popular models:

| Name | Country of Origin | Compressor performance | Chamber volume | Heating element power |

| Devices with automatic ignition | ||||

| Haze | ||||

Mostly domestic models were considered, since they are in no way inferior to imported analogues, but their price is an order of magnitude lower.

Self-production

No matter how many models are on sale, home craftsmen will never stop making their own designs. Some of them are noticeably superior to factory models, demonstrating high quality and performance.

As a rule, a stainless steel pipe with a diameter of about 100 mm is used to assemble the device. Two holes are drilled in it for the inlet and outlet pipes, and a tightly closing lid is installed on top. A small hatch is made in the lower part to clean the bottom from ash. It also needs to be tightly closed to prevent smoke from escaping. If ignition is manual, this hatch is also used to ignite wood chips.

Air is supplied from the compressor from below, and smoke is exhausted through the upper pipe. For stability, legs or a solid solid support are welded on the outside. Chips are loaded through the top cover, and fuel residues are removed in the same way.

Some craftsmen install a spring with a diameter of about 10 mm and a length of almost the entire height of the installation inside the case in a vertical position. It is needed to create an air channel inside the wood chips, through which smoke rises more freely.

An aquarium compressor is used. You can replace it with a computer cooler, which is placed in a plastic bottle with the bottom cut off, and the upper part is connected to a hose from the smoke generator body.

The device is configured experimentally. Homemade smoke generators have their own operating characteristics, so each of them has its own smoking cabinet.

More experienced craftsmen make installations with long battery life, allowing them to process large quantities of products from one load of chips. As a rule, heating elements are not used in such installations, since connecting to the electrical network in camping conditions is excluded.

Do it yourself

It’s always easier to buy a finished product, but making a smoke generator for a smokehouse from what you have on the farm is a kind of skill. Having examined several schemes for assembling such a smoke generator, it will become obvious that the whole process will not take much time and effort. Subsequently, the smoke generator requires minimal intervention and operates automatically.

Pipe smoke generator

One of the best solutions is considered to be a smoke generator for cold smoking, which is assembled from a pipe. In this case, the pipe must be made of stainless steel. You will need a piece of pipe for the smoke generator with a length of up to 1 meter. Depending on the needs, it can be 50 cm. Everything will depend on the planned volume for smoking. One of the ends of the pipe is closed with a bottom. It's best to weld it. The easiest way would be to make it in the shape of a square. In this case, its sides must be 10 cm larger than the pipe. This is necessary so that hot sawdust, which produces smoke for smoking, falls onto the metal platform, and not onto the surface on which the smoke generator will be located.

Note! The bottom of the smoke generator can be made in the form of a glass on which the main pipe will be installed. To do this, you need to select a piece of pipe 15 cm high, whose outer diameter will be slightly smaller than the inner diameter of the main pipe of the smoke generator for cold smoking. A square bottom is welded to it. Sawdust for smoking is poured into a glass and the whole process starts.

Having retreated 5 cm from the bottom of the smoke generator, several holes are drilled around the perimeter. Their diameter should be up to 10 mm. They are required to allow air to enter the combustion chamber to ensure normal sawdust smoldering. The upper end of the smoke generator also needs to be welded. The lid does not require any holes and must be sealed so that no smoke escapes through the seams. If desired, it can also be made schematic so that the sawdust for smoking is poured from above, and not through the glass. When the main structure is ready, it is necessary to implement the ejector for smoking. Its main purpose will be to take smoke from the combustion chamber, mix it with air and deliver it to the smoking chamber.

It is necessary to retreat 5 or 10 cm from the top of the smoke generator for cold smoking. Everything will depend on the height of the smoking pipe. A hole with a diameter of 15 cm is drilled in the wall. Another hole of 15 mm is drilled directly opposite it. Each of them is threaded. A ½" pipe 15 cm long is screwed into one of them. A Christmas tree fitting is screwed into the other hole of the smoke generator for cold smoking. You will also need a copper tube with a diameter so that it can be inserted inside the tree fitting. The copper tube should extend 1 cm into the metal pipe that was screwed in earlier. A flexible hose is connected to the copper hose and will go to the air source. You can use a regular aquarium compressor for the smoke generator. It has several levels of adjustment, which will allow you to select the optimal smoking parameters.

Note! It is impossible to use the same smoke generator for cold or hot smoking, because the technology of these two processes itself does not allow the construction of such a structure.

The smoking chamber can be made from what is available. It could even be a cardboard box. It is necessary to make a chimney in it to allow gases to escape. The protruding pipe of the smoke generator is inserted into the chamber. The essence of the functioning of the smoking device is that when sawdust smolderes, it emits smoke; the compressor supplies a portion of air into the tube, creating a rarefied environment in it, due to which smoke is sucked from the combustion chamber. Next, it enters the smoking chamber and completes the entire procedure. An example of the operation of such a device can be seen in the video:

Smoke generator made from cans

This type of smoke generator will require minimal costs. The first step is to eat two cans of canned pineapples and champignons, as well as a can of peas. The bottom of one of the longer cans is removed to create a pipe. A hole with a diameter of 10 mm is cut or drilled in the second tin can. It will serve to supply air, which is necessary for smoldering wood chips in the smoke generator. These two banks are connected to each other. This can be done using a galvanized strip 5 cm wide. It is enough to wrap it around the joint and secure it with large clamps. In the same way, it is necessary to ensure that the third smaller can is fixed, but with the bottom up.

A hole is made in the top of the tin can and in the bottom. Its diameter should be such that a ½ inch thread can be screwed into it. The next step is to attach a tee to this hole. On one side, a 15 cm long pipe is screwed to the tee, and on the other, a herringbone fitting, as in the previous method. A copper tube is passed in the same way. The air source will be a compressor from the aquarium. You can clearly see the assembly process of such a smoking device in the video:

Note! The supply of smoke can be done without a forced compressor. To do this, it is necessary to ensure good draft in the smoke generator itself. To achieve this, the pipe from the chamber where smoking is carried out can be installed as high as possible or connected to an existing chimney.

Useful tips

When purchasing a unit, you need to check whether it has a condensate receiver. If it is missing, a tee with a thin tube must be installed on the hose leading to the smoking chamber. Condensate will flow through it into a pre-prepared container. The same applies to homemade devices. If there is no condensate drainage, moisture will begin to fall on the products, reducing the quality of smoking.

Do not coat the inside of the housing with any compounds, paint or oil. Sometimes you can find recommendations online about applying such materials. The authors of such advice claim that in this way the body can be protected from corrosion and burnout. However, the result will only be smoke spoiled by the combustion products of these compounds.

Sawdust or coniferous wood chips should not be used. The resin they contain makes the products bitter. It accumulates inside the case and takes a long time to clean out. Birch sawdust is also not recommended because it contains tar. It gives an effect similar to that of resin.

In conclusion, it should be noted the high efficiency and compactness of smoke generators. Any models, industrial or homemade, allow you to do without bulky and expensive stationary smokehouses. It becomes possible to smoke food even in an apartment, after first installing a chimney through a window. These abilities make smoke generators popular and popular devices.

Homemade smoke generators

Step-by-step instructions and detailed diagrams will help you assemble a cassette smoke generator with your own hands from scrap materials. Homemade installations can have no less functionality and safety if the assembly technology is strictly followed.

From a fire extinguisher

- Holes for ignition and blowing at the bottom.

- Cover (you can leave the original one from the fire extinguisher or make it wooden).

- Hole for the pipe under the cover.

- Inside there is an ash pan and an ash tray.

- Spring for dosed supply of chips and avoiding jamming.

- Outside the pipe is a chimney.

- Flexible hose for connection to the compressor.

The advantage of such a homemade device is that it has sufficient volume for autonomous smoking for 10-12 hours.

From the pipe

In this case, the device diagram looks like this:

- The lower part is an electric stove.

- A pipe is installed on top.

- Fuel is placed on the stove; it can be poured onto a baking sheet.

- In the middle of the pipe, fittings are inserted onto which a mesh or grate is placed to accommodate the products.

- A simple cover is made of plywood or sheet metal on top.

Such a smokehouse is quick and easy to construct, but it is not airtight, which leads to smoke leakage. In this regard, it should be placed exclusively outside, so that acrid smoke does not permeate things in the house.

How a smoke generator works and how to use it correctly

A smoke generator is a device that is designed to create smoke to smoke food. Smoke occurs due to the smoldering of sawdust poured into the device, temperature changes or with the help of a fan. The device is typical for smokehouses operating using the cold smoking method, since with the hot method, smoke is formed inside the device, and no additional unit is required to produce it.

Where can I buy a smoke generator and how much does it cost?

If you do not know how to work with tools or you are not interested in how to make a smoke generator for cold smoking yourself, this device can be purchased ready-made. Numerous companies produce smoke generators, so prices may vary. The cost level is mainly affected by the size of the smoke generator and wood chip container, as well as the time of smoke production.

The easiest way to purchase such a device is through online stores - their prices are usually lower than in regular retail outlets.

Why is it needed?

Cooking food using the cold smoking method takes a long time. To implement it, you need not only a special device, but also firewood and sawdust. The cooking process can take from two to seven days. During this period, the equipment must constantly maintain a fire. A smoke generating device makes this task easier.

Some models of units are capable of operating without human intervention for several days. With their help, smoke is produced in the room temperature range.

The smoke generator creates smoke and directs it into the smokehouse, where marinated products are located, for example, poultry, fish, meat, and seafood. Smoke affects food and activates certain chemical reactions, which result in tasty, aromatic and healthy dishes.

The unit facilitates the smoking process, has a simple mechanism, and you can even make it yourself. Thanks to it, food in the smokehouse is not baked, since the cooking temperature does not exceed 20-40°C degrees.

What is the difference between cold and hot smoking

Both cold and hot smoking are carried out by exposing the products to smoke. The difference is in its temperature. Cold - occurs at 25 ° C, and hot - at 45-120 ° C. Consequently, in the second case, heat treatment also occurs, which allows you to destroy harmful substances in meat or fish. But along with this, some useful vitamins, micro- and macroelements also disappear.

The difference in smoke temperature also affects the cooking time of smoked meats. Thus, hot smoking lasts from 2 to 4 hours, while cold smoking lasts about 3 days, depending on the raw material. This feature affects the shelf life. Cold-cooked foods last longer.

Principle of operation

A device for preparing food using the cold smoking method works on the principle of pyrolysis, that is, the process of decomposition of natural compounds that lack oxygen, that is, sawdust or firewood during smoking. The essence of the unit’s operation cannot be called complex; it lies in the production of smoke, which is created by two continuous, closely related processes:

- heating wood;

- smoldering without oxygen supply.

The device looks like a small closed box, where each part of the smoke generator plays its role:

- There are switches at the front of the device that allow you to control its operation.

- At the top of the device there is a bunker, which provides fuel supply, and a pipe necessary for removing smoke.

- In the inner part of the device there is a mechanism that provides a certain dose of sawdust to the heating apparatus, a place for collecting ash and an electronic controller responsible for the frequency of wood supply and temperature.

The controller in the device is always set to the mode that allows the temperature of the heating apparatus to ensure sawdust smoldering, but not allow it to ignite. The fuel supply process is also set in such a way that its dose is constant and ensures the presence of smoke in the smokehouse.

Despite the fact that the smoke generator is more often used in smokehouses that prepare food using the cold smoking method, some models of smokehouses that smoke food using the hot method are also equipped with it.

The principle of operation of devices of various types of smokehouses is the same, the only difference is in its placement. In smokehouses for hot smoking, it is located inside the chamber; in units intended for cold smoking, it is located outside the smoking chamber.

Making a smoke generator with your own hands for cold smoking: video and text instructions

To manufacture the main part of the structure, you can use the drawings that were presented earlier. The following tips will help you build without errors:

- Choose a wall thickness of the steel case of more than 2.5 mm to prevent deformation during strong heating.

- Since the temperature in the upper part will not be high, it is permissible to use a flexible hose to connect the compressor. The boss can be made of Teflon. It performs the functions of an insulator and a connecting element. Tubes of appropriate sizes are inserted into it.

Instead of this unit, you can use suitable standard hardware

- The bottom does not have to be removable. If desired, create a wide opening with a closing door. Ash is extracted through it. Moving the damper regulates the traction. This option is used for large case sizes.

- The top lid must close tightly.

- All welded joints are cleaned. To prevent rust, the outside of the body is coated with primer and paint. These compounds must be resistant to high temperatures.

- After assembling and connecting the compressor, the container is filled with sawdust and the functionality of the device is checked.