Classification according to technological schemes

Today, 3 technologies for the production of rounded logs are used:

1) Classic

The log is clamped in the center of the ends and rotates. The movable cutter removes chips by moving along the workpiece. Positional lathes operate according to this scheme.

2) Positional

The log is also fixed in the center, but is processed by a stationary rounding spindle equipped with a special rotary head. This technology was developed for rotary type positioning machines.

3) Passage

Log clamps are not used - the workpiece is moved through the rotary head by a roller mechanism. Machines operating on this principle are classified as rotary-type equipment.

Rounding parameters

Rounded logs are usually produced in standard sizes, allowing for the implementation of a wide variety of projects:

- The standard length of the finished whip is 6 meters. Most companies provide the opportunity to manufacture longer elements upon special order, but they will cost more.

- For bathhouses and outbuildings, as well as for summer houses, the diameter of the log is 12-20 cm. Such walls are not intended for long-term protection against freezing.

- For permanent structures, logs from 22 to 28 cm are used; you can also find products with a larger diameter, but they are very expensive.

Modern technologies make it possible to achieve very high quality surface treatment; even and smooth walls are built from rounded logs, reliably protected from blowing and freezing. Such houses look very neat and beautiful.

Leonid Bushuev

Author of publications on 1Drevo.ru with topics: Window in the attic | Cottages made of timber | Finishing of the façade from cylinders | Roundtech Machines | Rounded timber | Houses and baths made of cylinders | Floor standing gas boiler | Monolithic foundation | Log processing | Wood for a bath | Timber insulation | Repair of a frame house | House cladding, etc.

Collections of publications on topics:

Rounded timber

Was this publication useful to you?

Bookmark it on social networks!

Total score: 10Votes: 2

Who produces timber and builds houses from rounded logs in Omsk

Construction of houses from rounded logs in Vladivostok

We recommend! — Encyclopedia Wooden Houses — NEW

You can find out detailed and expanded information on the topic of the article from the book “Wooden Houses,” which reflects all stages of building a house, from laying the foundation to installing the roof. Book price = 77 rubles.

You may also be interested in other BOOKS on building houses from wood with your own hands.

We recommend other posts on this topic:

Features of shrinkage of a log house made of different materials

Installation of a log house from rounded logs: assembly sequence

Construction of houses from round or rounded timber

How much will it cost to build a house from 6 × 9 rounds?

What is included in the price of rounded timber per cubic meter?

Joining rounded logs: methods and varieties

Pros and cons of different technologies

Advantages of pass-through technology:

- continuous supply of logs is possible, which ensures processing speed;

- a high proportion of finished product yield (up to 90%) is achieved by uniform distribution of the allowance in the cross section. The allowance is necessary to form a log cylinder and a circle at its ends. With this technology, this indicator is no more than 1-2 1-2 msm in diameter;

- the length of the log is practically unlimited, but the minimum size must be such that during processing the workpiece does not end up in the gap between the rollers;

- good productivity - in an 8-hour shift, about 35-40 m3 of products (100-130 logs) are produced on such a machine;

- aspiration is used to remove chips;

- versatility - these machines can produce not only rounded logs, but also edged lumber, block houses, and decorative slab boards.

The main disadvantage: the curvature of the finished part is almost identical to the curvature of the original log; It is quite difficult to compensate for this shortcoming - either ensure the loading of relatively smooth raw materials, or saw the semi-finished product into blanks 1-2 m long.

The main advantage of positioning machines is the minimal curvature of the log at the exit, which allows you to work with any workpiece.

Flaws:

- the volume fraction of the output depends on the initial curvature and run of the log. For example, when processing 1st grade logs (according to GOST 9463-88), the waste rate can exceed 50%;

- the length of the workpiece is limited by the dimensions of the machine;

- lower productivity than pass-through equipment. But the problem of time-consuming readjustment in equipment with rotation of the workpiece has been partially solved - it is enough to move the support of the milling unit in the transverse direction. But when working on machines with log fixation, the complexity of setting up the tool is significant, since it is necessary to align the cutters of the cutting module as accurately as possible when changing the standard size of the raw material;

- the need for qualified personnel - incorrect reconfiguration of cutters can reduce the processing accuracy to zero.

The main drawback - average productivity - can be eliminated by installing a second milling unit on the machine, which will allow finishing and roughing to be carried out in one pass.

Selecting a machine for the production of rounded logs

To select a machine, you should not rely on advertised settings. It is necessary to evaluate the proposed samples well. Of course, it is useful to visit factories where such machines are used. Communication with direct equipment operators will bring good results when choosing an installation.

The following models are widely represented on the Russian market: Rus, Sherwood and Termite. Sherwood and Rus equipment can be separate components, or be part of a woodworking system. The volume of logs that passes through these installations is 24 cm. There are models that pass larger diameters. Such installations are used when processing various materials: birch, oak, ash, pine and others.

Of course, you can buy popular machines, but sometimes you have to modify them to suit your own needs. Therefore, a more practical way is sometimes to make a rounding machine with your own hands.

Profile forming equipment

The production of edges and grooves of rounded logs is carried out using saws or specialized cutters.

Depending on the type of machine and its configuration, these operations are performed either simultaneously, together with the formation of a cylindrical log, or in an additional pass. Of course, the first option is preferable in terms of processing speed and overall performance.

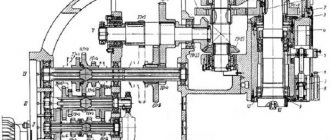

Depending on the type of cutting tool, the cylindering process is performed:

1) Turning

The main movement is the rotation of the workpiece or tool, during which chips are formed continuously.

The cutting module can be:

- rotor (female head with a set of round cutters for roughing and finishing gouging) - optimal equipment for machine tools that does not cause difficulties in reconfiguration;

- Passing cutters (angled, oblique knives) are an effective, but outdated technology, the use of which requires the participation of a qualified specialist.

2) Milling

The main movement is rotation of the tool:

- two longitudinal cutters;

- end mills with longitudinal feed;

- conical end mills with longitudinal feed.

The most common option today is end-conical cutters. But for pass-through machines, profile ones are considered the most promising.

On a positioning machine with a movable milling unit, the profile is made after the cylinder has been formed. The rotation mechanism is blocked, cutters/saws are attached to the support. In this case, the speed of reinstallation and correct adjustment of the equipment is crucial, otherwise significant downtime will result.

On most pass-through machines, milling and sawing units are included as standard. They are located in the direction of movement of the log, behind the cutting module. The straightness of the edges of the grooves, as well as the formation of the cylinder itself, directly depends on the degree of curvature of the feedstock.

Despite the fact that turning is recognized as a more accurate technology for obtaining an ideal cylinder, the quality of the cut does not particularly depend on the type of machine - only on sharpening the tool, its correct setting and operation. It is important that the workpiece setting bases are maintained between operations - any reconfiguration leads to a loss of manufacturing accuracy of various structural elements. In this regard, positional type equipment with a fixed position of the log is recognized as the best. On such machines, deviations in dimensions can only occur if the cutting tools are severely worn or the frame structure is insufficiently rigid.

Device

The installation has several main components. The bed is made in the form of a metal frame. It can have a rigid welded connection in the form of a rectangular pipe or a mobile connection of individual metal elements using bolts and nuts. It is the basis for fastening all structural elements.

The rounding machine contains guides along which the sawing tool moves. They usually form a single structure with a metal frame. In certain types of installations, the log moves along guides.

There may be one or two (front and back) headstocks. Their purpose is to secure and twist the log. On the headstock in some models of machines there is a dividing head, which serves to set a certain angle of rotation for different stages of processing.

The unit for fastening tools and moving mechanisms is a caliper.

The main purpose of the cutter is to fasten the cutting tool. It also provides reduced vibration, increased accuracy of operations and ease of entry into the workpiece. There are shaped and universal cutters.

The knives of the rounding machine are made of high grade steel. The cutting tool is attached to the cutter so that it can be easily replaced or removed for sharpening.

In addition, additional elements are installed. These are levers that make it easy to install the workpiece on the frame, and stop rollers that prevent it from sagging. There are also brakes and a carriage lock. They are used in machines with the function of removing the crown bowl and are installed at the end of the carriage. To excavate a longitudinal groove, a log rotation regulator is used.

Modern manufacturers of woodworking equipment equip such rounding machines with automated computer-controlled modules.

Formation of “cups” - connecting mounting grooves

The “cup” element is made using a milling unit and straight guides that feed the tool. After forming the groove, the cutter returns to its original position.

Such a structural unit can be part of the process flow - the edges of the laying groove, to which the axis of the “cup” is oriented, become the supporting base. In the most common arrangement, the cutter cuts into the workpiece below the center axis.

But, as practice shows, the best accuracy indicators are demonstrated by positional type machines, on which the cup cutter is installed on a support with a vertical cutter. In this case, the axis of the cup can be formed at different angles to the plane of the mounting groove. For such operation of the cup-cutting unit, it is necessary that the log is rotated along its axis and fixed in a new position.

If the rounding machine is not equipped with a cup-cutting module, equipment for cutting grooves can be purchased separately. The asking price is from 100,000 rubles.

Functions

The main function that any rounding machine has is the processing of logs as a body of revolution by milling. But to assemble a log house, simply cylindrical blanks are not enough. And in this case, additional equipment capabilities will come to the rescue:

- excavation of grooves to form various locking connections;

- production of parquet dies, timber;

- sawing of linear products;

- sawing timber into carriages and then into edged boards;

- all stages of log rounding, from roughing to final;

- removal of mounting bowls and compensation grooves.

In this case, the log itself is not reinstalled, but cutters and individual components are changed during the work. The result is parts with a wide range of diameters. The limitation concerns the length of the processed logs: the sleds are designed for seven-meter workpieces. A skillful combination of cutters and working techniques allows you to produce complex wooden structures.

About mechanization and automation

According to this criterion, rounding machines can be divided into 3 classes:

- automated - the entire complex of operations (including loading and feeding of workpieces) is performed by a machine;

- semi-automated - the process is automated within one working cycle. Next, only the loading/unloading of the machine is performed manually, and all other operations are performed by the machine;

- mechanized - loading/unloading, setting, and regulating the operation of the machine is performed by a person.

Today in our country, mainly mechanized machines are used, which are equipped with modules for loading/unloading, cutting and feeding. But basing, setting, monitoring and regulating the production process is done by man. Additional equipment is also used - forklifts and transporters.

Purpose and specifics of equipment

The technology for constructing house buildings from solid logs involves performing a number of operations necessary to prepare the wood for high-quality assembly of the log house.

The universal functions of the rounding machine make it possible to carry out preliminary and finishing processing of round timber during the construction of wooden houses. The wide capabilities of the machine for rounding logs allow you to perform almost a full range of work with a single installation of a wooden workpiece. The resulting element does not require additional processing and is fully ready for the assembly of the log house. The universal unit is capable of consistently performing work from debarking cut timber to selecting mounting grooves:

- removing a layer of tree bark;

- cylindering;

- creating grooves, cutouts of simple and curly shapes;

- production of longitudinal recesses and profile edges.

The machine can be used for finishing timber, processing sawlogs; it can easily cope with wood that has a curvature in shape and a high degree of knottiness. The unit operates on the turning-milling principle and performs work automatically, in accordance with the parameters specified by the operator.