During operation, any water source gradually silts up. It is for this reason that systematic cleaning of the well using a pump with preliminary removal of large-sized debris is so important.

By regularly performing these operations, we can significantly improve the quality of well water, as well as extend the service life by at least twice.

Pumping out sludge using a pump

Causes and signs of well contamination

Signs that it is time to clean the mine well are cloudy or darkening of the water, the appearance of rust or a green tint, or an unpleasant taste or odor. Sometimes the source simply stops functioning.

The main causes of well water contamination:

One of the reasons, related to time and the effect of water on concrete, why it is necessary to clean the well

- the seams between the rings with which the shaft is lined are diverging;

- The bottom filter does not work well due to errors made during filling or prolonged use without flushing;

- the head does not have a lid or is often not used;

- insufficient analysis of well water or its complete absence for a long time;

- increasing the iron content in water - in this case, cleaning will not help, you need a special iron filter;

- changes in the composition of groundwater due to the discharge of industrial wastewater near the site - the problem can only be solved by drilling a well;

- an animal fell into the mine.

But even if there are no such problems, it is necessary to carry out regular preventive cleaning of silt, sand, clay, and other mechanical impurities. It is better to do this once a year, in the spring, after the snow melts.

If the properties of the rock at the bottom of the mine allow, then water can be pumped out once every 2-3 years.

Cleaning a well using a drainage pump

When using a mud pump to clean wells, you must follow the rules for using the device, as well as follow the instructions for carrying out such work.

Operating rules

Rules that must be followed when cleaning a well with a pump:

- Work can be performed at air temperatures not lower than +5°C.

- A submersible pump or surface suction pipe is installed at a depth of about 60 cm from the bottom. If you lower the equipment lower, it can be sucked into the sludge; if you raise it higher, the device will pump clean water without reaching the layer of dirt.

- Work inside the mine must be done by two people - there is a high risk of gas poisoning. One person must be on the surface. You can go down into a well, especially one that has not been used for a long time, only in a respirator and with a safety rope attached to your belt.

- If a person in the mine has lost consciousness, it is forbidden to go down after him. It is necessary to lift it using a safety rope.

Compliance with these rules will not only increase the service life of the device, but also reduce possible health risks.

Cleaning instructions

Procedure for cleaning a well with a mud pump:

- Check the integrity of the device cable and extension cord leading to the power outlet.

- Make sure the equipment is in good working order. Never operate the pump without water.

- Turn on the device.

- Slowly pump out all the water. Periodically remove the submersible pump from the shaft and clean it. The surface apparatus also needs to be cleaned. The device is washed for the first time after 1-2 hours of operation, then as it becomes dirty - when productivity decreases or energy consumption increases.

- Go down into the mine. Clean the walls mechanically - with a brush. The use of chemical cleaning agents in drinking water sources is prohibited.

- If necessary, seal the seams and cracks with a hydraulic seal.

- Disinfect the walls of the shaft with a solution of potassium permanganate (1 tsp per 10 liters of water) or copper sulfate (100 g per 10 liters of water).

- Clean the bottom with a special bucket or grab. You can hire a suction pump, but it is expensive for a summer house.

- Remove the bottom filter (if any), wash it or replace it completely. If it is not there, then decide whether it is needed (depending on the type of rocks at the bottom), choose a construction method and materials, and fill it up.

- Start pumping out the water again.

- Turn off the device after a stable stream of clean water appears. If there is permanent water-lifting equipment and a pipeline leading into the house, then a special filtration system can be installed.

The cleaning process can last up to a week. If you cannot achieve results for a long time, then it is better to invite specialists with professional equipment.

Approximate list of work for cleaning a well

To clean the green walls of the above-water section of the mine shaft and seal mechanical damage to the rings, a pump is not needed. This will require a ladder, a steel bristle brush, and appropriate supplies. Processing the underwater part of the walls and cleaning the bottom requires a technical solution to several problems. Among them:

- pumping out clean, continuously flowing water;

- pumping bottom pulp with silt, gravel, sand, mule;

- discharging purified water into a well;

- creating a pressure jet: with its help you can clean the walls (knock off new growths from them) and stir up bottom sediments and silt.

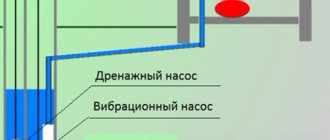

In the latter case, two pumps are needed. The first - bottom drainage - delivers an aqueous suspension containing sand and silt into the filter tank. A barrel with two valves filled with gravel is used as such a device. The filtered water enters the intermediate storage tank, and from there, using the “Rucheek” pump, it is supplied through a hose under pressure to the bottom of the well. The worker operates a powerful jet in accordance with the task.

The process of cleaning a mine made of concrete rings with your own hands

Let's take a closer look at how to do this correctly, without using a pump. All work consists of several successive stages, such as:

- Pumping out.

- Inspect and clean the bottom filter.

- Analysis and repair of joints between reinforced concrete rings.

- Mine cleaning.

The first step is to solve the pumping problem. The easiest way is to use a pump. If it is missing, then pumping is done with buckets. A very long and labor-intensive process. In the latter case, a winch and a drum are installed to lift the buckets.

Advice : this work should be done one at a time, because one person will be under a serious load. It is important to reach the conveyor so that the liquid is continuously pumped out.

You can pump out liquid with a pump within a couple of tens of minutes, but the same work using buckets will require several hours.

The next step is cleaning the walls of the shaft. Lower the ladder into it and secure it. You need to start working from top to bottom.

For cleaning, a metal brush or some kind of scraper is used; some use a hoe. Very convenient as they have a long handle.

Having cleaned the walls of the shaft, it is necessary to begin cleaning the bottom of the well. First, sand, silt, dirt, etc. are scooped out using buckets. Once you fill it, you give a signal to remove it. Gradually the bottom will be cleared of silt and other contaminants. The condition of the bottom filter must be checked. If necessary, it can be replaced or the existing one washed.

The condition of each seam between the reinforced concrete ring should be inspected. If there are cracks or the existing mortar is peeling off, then you should completely remove the old putty, prepare a new mortar and seal the joints with it. Also, everything is covered with a waterproofing material, which is allowed in direct contact with clean water.

At the end of the work, the entire mine is disinfected. You can use ten percent bleach and a bucket of water. Having mixed them, you simply coat the walls with this composition. In this way, disinfection occurs, and all existing microorganisms will simply die out.

Pump purpose

Over the years, the well becomes clogged. This leads to a number of adverse consequences. External signs that it is time to clean the well with a drainage pump include:

- lack of transparency;

- presence of odors;

- weak inflow;

- presence of impurities.

As a rule, it is enough to clean the source of sand, clay rocks and solid inclusions once every 36 months so that the liquid returns in sufficient quantity, and the quality of the water allows it to be used for domestic purposes. But if the well is dug in fine-grained sandy soil or dusty soil, then cleaning activities are carried out using a pump at least once a year.

In addition to sucking out dirt, pumping equipment is used for draining reservoirs, pumping liquid out of pools (reservoirs), basements, etc. Using this equipment, you can eliminate the consequences of flooding during seasonal floods and solve a lot of other problems.

What you need to know about well cleaning

Cleaning a well is a difficult and time-consuming procedure with health risks. This is why it is important to take precautions.

How to clean a well safely:

- candle - the fire will inform you about the presence of poisonous gases inside the mine (to do this, you need to lower the burning candle inside and make sure that it does not go out);

- cable - will protect you in case of a fall (it is important not to ignore this safety requirement, even if the well shaft is not too deep);

- helmet – prevents head injuries;

- ladder - it is recommended to use a metal retractable one (the soft base is not stable enough, even if it is secured).

The process of cleaning a well yourself requires the presence of at least two people - such safety net is necessary in case of any incident.

It is important to know! Not every person can perform this procedure. If you have diseases of the cardiovascular system, including problems with blood pressure, as well as various types of asthma, going down the mine is strictly prohibited.

A ladder and a cable are required for safe cleaning of the well Source lanaza.ru

The oxygen level inside the well will be less, which can lead to problems - dizziness, lack of air, etc.

Preventive measures

Between major cleanings, it is recommended to take preventative measures to allow the water and walls of the well shaft to remain clean longer.

Preventive cleaning is done in 3 stages:

- Stage 1 – preparing a solution of potassium permanganate and water;

- Stage 2 – infusion of the product into the well and a three-hour wait;

- Stage 3 – pumping out water.

Advice! If you don’t want to pointlessly pour water and solution into the ground when pumping, you can water the garden with it. The soil will be disinfected, which will prevent plant disease and eliminate pests.

To clean a well in a country house, a drainage pump is also used. This will help get rid of sludge, but will not do a thorough cleaning.

Attention! When purchasing a drainage pump, you should give preference to a device with more power. The higher the indicator, the better the bottom cleaning will be performed.

You should also indicate to the consultant the depth of the well shaft and its fullness, since each model is designed for certain operating conditions.

Operating principle of pumps

Drainage mud pumps are a single unit that combines a motor and a working mechanism. An oil chamber and seals are installed between them. They are distinguished from conventional submersible pumps (with a multi-channel working part) by a single-channel wheel, which allows pumping liquids with mechanical inclusions.

The power of the devices (in domestic versions) is 1.5–1.75 kW. Using drainage pumps, you can clean wells up to 60 m deep. The density of water should be 1.1–1.2 kgf/cm3, and the amount of impurities should be up to 10%. The size of suspended particles is limited by the filter mesh: in domestic products it is 5–10 mm, and in imported ones it is up to 50 mm. The main feature of drainage pumps is the need for water cooling. The environment is used for this.

Sand pumps - semi-submersible type are designed for pumping pulp with a density of 1.3–1.5 kgf/cm3. They operate at temperatures not exceeding 60°. The flow part of these devices can be made of cast iron, corundated steel, rubber or hard rubber.

Automatic Submersible Well Pump

Fecal pumps pump liquids whose density does not exceed 1050 kg/cm3. But the presence of fibrous formations, algae, rags and bottom flexible soft materials in the water is not a problem. Using a special impeller, the mechanism cuts inclusions into smaller fractions. These devices have wide inlet and outlet openings that allow sufficiently contaminated water to pass through.

Pump markings

The markings of different types of pumps from different manufacturers are not the same. You can find designations of this type:

- The digital index indicates the diameter of the inlet in mm divided by 25.

- Letter index – pump type. For example: K - cantilever - one in which the working mechanism is located on a shaft away from the engine. Next is the speed factor.

Drainage pumps produced by the Valdai plant are marked with:

GNOM is a single-stage monoblock mud pump. The digital pairs indicate the supply volume and pressure, respectively. For example, 6-10 means: 6 cubic meters per hour at a height of 10 meters.

The abbreviation for fecal pump includes groups of characters:

- SM – waste mass,

- XX – inlet size;

- XX – outlet size.

Some models (for example, “Drainer”) are marked as follows: XXX/X FN. It means:

- ХХХ — feed volume per minute, liters;

- X - water pressure, meters;

- F – fecal pump;

- N – stainless steel.

Other principles of product marking can be used, in which letter designations indicate the presence of automation, materials of the housing and impeller, and other nuances.

Labeling rules

When designating the model of pumping equipment, which is produced today by many domestic and foreign companies, manufacturers do not adhere to uniform rules and regulatory requirements, but a certain pattern in this matter can be traced. Thus, the markings of many models of such equipment contain both alphabetic and numeric symbols. The letter part of the mud pump marking usually contains the following information about the equipment:

- pump type;

- speed factor.

The digital part of the marking indicates the diameter of the inlet pipe in mm. The marking of slurry pumps classified as fecal pumps contains the following information:

- SM – mass waste device;

- XX – diameter of the suction pipe;

- XX – diameter of the discharge pipe.

An example of deciphering the markings of a drainage pump

On many models of high-pressure drainage pumps you can find markings of this type - XXX/X FN, which stands for as follows:

- ХХХ – volume of supply in liters that the pump can provide per unit of time (min);

- X – liquid pressure, measured in meters;

- F – pump type (fecal);

- N – case material (stainless steel).

The marking of pumping equipment may contain other information (in particular, about the presence of automation).

equipment requirements

First of all, the choice of equipment is influenced by the degree and nature of water contamination. If the well collects water free of suspended matter, you can get by with a budget model of a submersible or surface pump. However, when the water contains biological solids, sediment, sand, foreign objects - polymer bags, paper - it is better to use a specialized pump.

An important factor in the choice should be the type of equipment. To clean shallow wells, surface pumps are used. Their advantages include:

- ease of maintenance;

- relatively low cost;

- ease of installation and connection;

- high electrical safety.

The surface pump is located above the water; only the hose is immersed in the liquid. With its help, you can drain any container, however, such equipment has low power, the pump provides low pressure and is designed for shallow immersion depths - up to a maximum of 8-10 meters.

Submersible drainage pump for hot water pumping

A conventional surface-type drainage pump is capable of lifting water from a depth of 4.5–6 m. The degree of water contamination should not exceed 10%, and the size of the fractions cannot be more than 1 mm.

Submersible pumps have greater capabilities. They are made for household use - universal, but there are also specialized models. Pumps are distinguished:

- for pumping sandy waters,

- chemically active liquids,

- fecal mixtures containing large inclusions, fibers, algae,

- drainage – for drainage of fresh or sea water with mechanical impurities 5–50 mm,

- oil and others.

Depending on the purpose, different brands have design features that increase their functionality and durability. If there is sand in the water, the pump impeller is made of cast iron. To pump out chemically active liquids, products with special materials for housings, seals, and electrical seals are used. All deep-well pumps provide powerful flow (from 12 to 300 m3) and high pressure (from 10 to 40 m).

Submersible pumps can be rotary or vibrating. Rotary mechanisms use impellers with blades to supply water. Vibrating ones have steel membranes. Under the action of an electromagnet, a thin plate vibrates at a speed exceeding 2 times the frequency of alternating current. Part of the liquid entering the working chamber under the action of elastic forces is pushed into the channel, where it is held by a rubber valve.

Vibration pumps are low-power, but reliable and durable: they have no friction. For this reason, vibration pumps are used to pump out dirty water - their blades will not break due to their absence.

Rotary pumps can be equipped with float switches - devices that protect the engine from running dry and prevent it from overheating. They have their own area of application: pumping water from flooded sewer mines, basements, and trenches. When cleaning a well, additional automation is usually not needed: the source is not cleaned dry, and the raised water is returned to the well.

Equipment selection

The characteristics of a pump suitable for cleaning a well from sand and clay should indicate “for dirty water.” Most of these models are submersible, but there are also surface-type devices. Mostly centrifugal mud pumps are sold; vibrating pumps are rarely found. The device of the second type does not have any significant advantages, and vibration during prolonged use can damage the walls of the shaft, which will lead to repeated siltation.

Types of mud pump: submersible and surface

Features to look for when choosing a sump pump for dirty water:

- Power. For different models it ranges from 180 to 2200 W. The higher the value of this parameter, the higher the performance of the device. But when choosing a powerful pump, you need to take into account that it consumes much more electricity.

- Productivity (supply volume, water consumption). For a pump, it is expressed by the volume of liquid that the device can pump per unit of time. When choosing equipment, you should pay attention to this parameter if the speed of work is important. The minimum value is 430 l/hour, the maximum is 42000 l/hour. For periodic cleaning of a small private well, it does not make sense to buy the most productive device.

- Maximum height of liquid lifting and immersion depth. You need to select a device based on these parameters, taking into account the depth of the well and the distance over which the water will be discharged. The submersible pump must be at a height of at least 60 cm from the bottom. This distance is subtracted from the depth of the mine and a 20-30% reserve is added. For example, a mine has a depth of 10 m, then 10 - 0.6 + 20% = 11.28. That is, the maximum immersion depth of the pump must be at least 11.5 m.

- The permissible diameter of solid particles contained in water varies from 5 to 46 mm for different devices. The greater the value indicated in the characteristics, the wider the scope of application of the unit. The most common mud pumps are pumping liquid with particles up to 35 mm.

- The material from which the body is made. Options: plastic, stainless steel, cast iron. A pump with a plastic housing is only suitable for small jobs. If you need a device for frequent use over a long period of time, then buy a device made of stainless steel or cast iron.

Regardless of the type and model of the selected pump, you will need to additionally buy a reinforced hose for pumping water, designed for high pressure.

Types of pumping equipment

Typically, wells are divided into types according to the type of lifting mechanism:

- Crane;

- With collar;

- With Archimedean Vitus and others.

However, their water intake can also be different; according to the type of water intake, they are divided into two types:

- An incomplete water intake is a structure in which the bottom of the well does not touch the water-resistant layer; water enters it through the lower part.

- A full water intake is when the bottom of the source is located on a water-resistant layer, and it is filled through the walls.

What is a mud pump for wells? There are two types of devices:

- Submersible;

- Superficial.

Submersible pumps are lowered directly into the well a short distance from the bottom. Based on the principle of operation, they are divided into centrifugal and vibration.

Surface pumps, as the name suggests, are located on the surface, with a suction hose immersed in the well; they are often stationary and used in industrial production.

Due to their simplicity and reliability, submersible pumps are most widely used in private households. Such a unit consists of a housing, an electric motor, and a suction unit with a filter. The main difference between such devices and conventional ones is the presence of a filter, which allows them to work in polluted environments.

These models also have disadvantages. Firstly, they cannot cope with deep wells, and secondly, they are not capable of purifying water, which makes them unsuitable for autonomous water intake systems. Unfortunately, there are no universal pumps that can operate in any conditions and be used for any purpose.

Submersible pumps with centrifugal mechanism

Models that use a wheel with blades as a suction device are called centrifugal. This design feature increases the pump’s performance and also prevents abrasive particles found in the pumped well water from entering it.

Depending on the model, water chambers and centrifugal wheels can be manufactured:

- of steel;

- made from high quality polymer.

Also, a distinctive feature of submersible drainers is the presence in their design of a float or electronic switch. Devices with a float switch are more widespread because they are simpler, cheaper, and most importantly, more reliable. The switch is needed to automate the process of pumping water.

Some models of drainage pumps use a centrifugal mechanism. Before purchasing them, you should find out whether the pump can pump abrasive particles

A float is a small sealed container with a contact block inside. As the water level decreases, the float mechanism gradually lowers until it reaches acceptable limits. At the maximum depth, it turns off the engine, preventing it from running dry. Dry operation leads to failure of the pumping device.

The drainage pump housing should always be immersed in liquid, as water helps cool the operating mechanism. Water also acts as a lubricant for rotating parts.

Vibrating Submersible Pumps

Vibration-type pumping equipment operates by changing the internal pressure, causing oscillations of the diaphragm. The difference in pressure appears as a result of the magnetic field generated when an electric current passes through the coil.

Parts set in alternating motion under the influence of a magnetic field raise the water flow upward. Vibration pumps are powered by a 220V power supply and consume approximately 270 W per hour (the figure depends on the power of the model).

Vibration pumps with upper and lower water intake are installed at different heights from the well bottom

Submersible vibration pumps can be produced with upper or lower water intake from the well:

- Devices with upper water intake operate without overloads, since they do not heat up during operation due to the cooling of the entire system. Also, such pumps do not suck in silt that has settled at the bottom of the well and do not contribute to cloudiness of the water during intake. Therefore, it is not advisable to use them to clean a well.

- Devices with bottom water suction, not equipped with automation and a thermal protection system, since the devices can overheat even during short-term dry operation. To protect mechanisms from sand and silt suction, a mechanical filter is used. Craftsmen replace the filter with an ordinary iron bucket in which the pump is placed. Lower the bucket with the apparatus into a low-flow well and pump water.

Vibration pumps are durable in operation, since their design does not contain rotating elements or bearings, and therefore the parts do not fail without being subject to friction.

When cleaning wells, vibration-type pumping equipment can only be used to pump out turbid water, and sand and silt deposits can be scooped out manually using buckets, homemade scoops, buckets, grabs and other devices.

Vibrating pumps are inexpensive, but have good performance and are suitable for pumping muddy water. When cleaning the well, the vibrating device should be regularly disassembled for cleaning and lubricant should be applied to the contacting parts of the system. To speed up the cleaning process and improve quality, two vibration pumps are used: one stirs, the second pumps. To pump muddy water from a well, vibration equipment can be placed in a bucket in which the pump is immersed in the shaft.

Types of drainage electric pumps

The main purpose of this equipment is pumping out liquid. A pump for pumping water from a well is used in cases where the level of pollution is low. The scope of operation of drainage electric pumps is very extensive. They can be used in the following cases:

- When eliminating the consequences of disasters associated with an increase in water level in the room.

- When pumping groundwater during flood periods.

- When cleaning reservoirs and other reservoirs.

- When eliminating flooding of basements and other premises as a result of significant amounts of precipitation.

- When watering green spaces and arranging fountains.

The currently existing types of drainage devices are divided into two categories:

- superficial;

- submersible

A drainage electric pump of any type for a well shaft or borehole is distinguished by its simple operation, affordable price, the prospect of independent installation and its easy replacement with a new one.

A common and widely used by summer residents and owners of country houses is a type 2 well pump, the types of which are divided into vibration and centrifugal. Each of them, of course, has its own positive and negative sides. However, all of them can be used to restore the normal functioning of the water source.

Selecting a pump based on performance and pressure

These characteristics matter most when it comes to purchasing. Productivity is taken to be the volume of pumped mass over a certain time period, which is measured in liters or cubic meters per hour.

Pressure is an indicator indicating from what depth the equipment can lift dirt to the surface.

Also, by pressure we mean the horizontal transfer of aqueous solutions. The description of this equipment always indicates the correspondence of these characteristics in the form of a ratio, for example, 1 to 10. Calculating the required pressure is simple. When a well is dug 8 meters deep, and the hose needs to be pulled 10 meters from it, the pressure must be at least 9.

Cleaning with a grab

There is another method that allows you to clean the well yourself without going into the mine. This method takes into account the use of a special device - a grab. The design of this load-handling device is quite simple. It consists of two bowls that are connected to each other using levers. The outer surfaces of the buckets have special fastenings to which the chains are fixed. Chains are used to regulate the position of the buckets (opening and closing).

Grab

This cleaning method has several serious advantages over manual cleaning. The main advantage is that all the work can be done by one person. There is no need to descend into the mine, so the safety of this method is also obvious. Let's look at how to make such a device yourself.

The first thing to do is prepare the metal sheets. Experienced craftsmen recommend using steel, as it is more resistant to corrosion and has good strength. The optimal sheet thickness is 2 mm. You also need to find 2 segments of metal pipes. They will act as jumpers located between the buckets. One pipe must have a larger diameter than the second so that they can be inserted into each other.

The metal chain on which the buckets will be fixed must be of sufficient length so that it can be folded 3 times and freely reach the bottom. It is also recommended to choose it with a margin of 1.5-2 m.

Using a grab, you can clean the well from silt, sand and other contaminants that condense at the bottom of the well. What tools are needed to assemble the grab? You will definitely need to prepare welding equipment and a cutter.

The work on making such a device begins with cutting out the plates for the half-bottoms. It is worth remembering that one side of the plate should have a smooth edge, and the other a stepped or zigzag edge. The teeth help capture silt and sand, so their presence is mandatory. Their size is usually 1.5 cm.

The next step is cutting parts for the side elements of the buckets. A total of 4 elements need to be cut. Next, the side parts are joined to the half-bottoms. Welding equipment is used for this work. To join the buckets, a steel roller is used, as well as a “finger”, which is placed inside the first element.

Interesting: Installation of sliding gates

Then the levers are performed. The material used to manufacture these elements is steel plates. The thickness of the plates should be 5 mm. You will also need to make a traverse, which is necessary to fix the grab in the open position. At the end, the cable is attached to the rod and the trigger ring is fixed. All that remains is to attach the chain to the device, and it is ready for use.

How to connect a drain pump

Before starting work to install the pump, determine or arrange a level area so that it operates in a strictly vertical position, then:

- A hose is connected to the pressure pipe using connecting elements for fastening.

- If the model has a float switch, install a check valve on the pressure line.

- A device equipped with a three-phase electric motor must be checked for correct rotation of the centrifugal wheel.

- Turn on the equipment and immediately turn it off, paying attention to the direction of rotation of the pump shaft: clockwise - everything is connected correctly, if not, swap the phases.

- The pump is connected using a carabiner to the electric winch cable or to a rope, making sure that the pressure pipe remains directed upward.

- The unit is slowly lowered to the bottom of the silted well.

- When operating pumping equipment, comply with safety requirements.

If there are signs of equipment malfunction, you must immediately turn off the power supply and stop pumping.

When is cleaning necessary?

The well can be cleaned by inviting a specialist. You have to pay money for their services. You can clean the structure yourself if the following signs appear:

1.if the water flows cloudy after passing through the filter.

2. if pungent odors are coming from the well.

3. if a film of oily consistency has formed on the surface of the water.

4. if the statistical and dynamic levels in the well decrease.

If a clear sign listed above appears, you should immediately begin cleaning the well. Such water can become a great threat to humans. If it is not possible to call specialists, then you can do the cleaning work yourself.

How to choose a hose

Hoses or tubes for pumps must be selected depending on the pressure force, as well as the cross-sectional diameter of the outlet pipe. The main requirement is that the diameter of the hose must match the diameter of the outlet pipe.

Compliance with this requirement will greatly extend the service life of the purchased pump and will have a beneficial effect on its performance.

A fire hose can be used as a flexible hose, which is attached to the outlet pipe using a clamp. At the edge of the well ring, the sleeve is pinched and the pump cannot push through the pumped out water. This problem can be eliminated using a plastic corner, to which fire hoses are connected on both sides.

Causes of pollution

There are many reasons why water in a well loses its original purity and freshness. Let's highlight those that owners encounter most often:

- Irregular use - stagnation and siltation of water can occur with infrequent use. Most often this happens when no one lives permanently at a country dacha and the hydraulic structure is used only from time to time.

- Lack of a cover - it is necessary to ensure that the well is tightly covered. It should only be opened at the time of use. Otherwise, dust, small debris, branches and leaves from trees will fall into the mine, significantly reducing the quality of the water. The presence of a lid will also protect from direct sunlight, which will significantly reduce the rate of growth and development of algae.

- Incorrect installation of the melt water shutter - the shutter is a permanent waterproof layer at least 50 cm thick covering the upper casing ring. If the technology was not followed during construction, perched water containing eroded pieces of soil and other debris will penetrate into the reservoir.

- Damage to seam joints - over time, cracks can form in the seams of concrete rings, through which groundwater enters the mine. The situation can be corrected by draining the tank and sealing the cracks with a mixture of mortar and liquid glass.

- Displacement of the rings most often occurs due to the impact of quicksand or soil freezing. In the first case, the lower part of the trunk moves, in the second, the upper rings are pushed out. To eliminate damage, the rupture sites are sealed with cement mortar or the displaced rings are tightened with pins with thick wire.

The tight lid reliably protects against external debris and sunlight from entering the tank.

Having found the reason why the well is dirty, you can determine the required amount of work and choose the most suitable cleaning method.

Cleaning a heavily silted well

The problem is that if there is a lot of sludge and its consistency is too thick, the intake and working chamber become clogged, which prevents the use of pumps for cleaning wells in normal mode. Enterprising summer residents and residents of private houses have become accustomed to loosening dirt with water pressure. This will require another pump that will supply purified water to the well under pressure.

The essence of the method comes down to the following:

- A container with a capacity of 0.2-0.3 cubic meters is required.

- The hose from the drainage pump is laid so that the raised dirty water falls into the barrel.

- Settling occurs in the tank, as a result of which the raised substance stratifies. On top there is clean water, below there is sand, clay, mud, silt.

- Impurities are removed from the bottom, and water is pumped back into the well using another pump.

Under the influence of the jet, the compacted sludge is washed away, and in the form of suspended particles is supplied to the surface by a drainage pump. The method is simple, but some people do not consider it advisable due to the high costs of purchasing two sets of pumping equipment. They believe that it is cheaper to hire a crew to clean the source manually.

What is swing used for?

The first water that appears after drilling or digging is cloudy, unsuitable for consumption and requires purification. Inaction and the desire to leave everything as it is, so that the turbidity settles and the water is clean, will lead to the fact that the structure will completely silt up and cease its functional activity. The pumping of the well and the well are combined by the cleaning process after all the work:

- The natural process of siltation does not stop its activity for a second.

- The aquifer consists not only of large fragments of stones and sand, but also of billions of tiny particles, completely invisible and elusive to filters.

- They easily overcome gravel and mesh filters, gradually settling at the bottom of the structure, “eating” the useful depth and slowing down the productivity of the well.

- The instructions for pumping up and further operation of the aquifer structure prescribe the provision of on and off intervals at high flow rates after 30 minutes; at low flow rates, the break is at least an hour. The minimum number of pump starts per day should be at least 4 times.

- Experts say that proper pumping of a new well will remove all small particles of turbidity, gradually washing out, the water becomes lighter and over time the required purity is achieved.

What you need to know about a new well

So:

- How to pump a new well without damaging the newly built structure and without spoiling the water?

- The first and basic rule is not to immediately start intensive pumping.

- Change the water in small portions, pumping out no more than ¾ of the column.

Attention: The structure on the quicksand is not pumped to compact the bottom and clarify the water.

- Most wells are filled with water to a certain level, and pumping water in one burst (immediately to the bottom) leads to an intense influx of liquid and filling it to the same level.

- Water is drawn under pressure, and the bottom of the well is eroded, as is the soil adjacent to the outer surface of the rings.

- What happens to water and how to properly pump a well is not idle curiosity. Water becomes cloudy during intensive pumping.

- The owner, eager to get clean water here and now, makes even more effort and pumps the well harder, trying to achieve clean water, but the result does not change.

- At the same time, negative processes are taking place, highlighted in the video in this article and in the recommendations of specialists.

- They know that the soil is necessarily washed away, the sealing of joints is deformed due to water pressure, and the external gap between the soil and the rings increases in size, opening up access to surface water.

- There is an opinion that pumping a new well will open up abundant paths for underground water, and that pumping will flush out the pores of the earth. I want to believe, but I don’t need to, you can argue with this opinion and disagree, but everyone has their own truth.

- Over time, water yield may indeed increase, but sometimes these processes drag on for many years and events should not be forced. This is exactly the case of “the slower you go, the further you will go.”

- New or very young wells must be pumped and need water pumped out, but the work must be done competently and competently.

Pump operating rules

When choosing the necessary model for cleaning a well, carefully read the instructions. After all, some drainage pumps are initially designed to lift and pump only clean water that does not contain impurities. The manufacturer warns about this in the description of the technical characteristics of the equipment.

If such devices begin to pump out contaminated water, they will quickly fail. Remember that cleaning a silted well must be done with a drainage pump that can handle the intake of contaminated liquid that contains impurities and even small fibers.

If persistent deposits appear on the walls and bottom of the well shaft, before using the pump, you need to clean the well manually in order to quickly get rid of contaminants and prevent clogging of the working parts of the pump.

Cleaning a well using a drainage pump

One way to simplify the procedure for cleaning the bottom is to use a drainage pump, which is capable of sucking silt particles from the very bottom, while having good power. During this cleaning process, you must not forget to clean and check the filter of the pump itself until the water coming from the pump is clear of silt and dirt.

It must be remembered that drainage pumps are effectively used when the depth of the well does not exceed 10 meters, otherwise their operating power will not be enough.

The best and popular models

Models from Russian and foreign manufacturers are represented on the pumping equipment market. Every brand has its fans.

Budget pumps from Russian companies Vikhr and Malysh attract with their affordable prices and good performance. German pumps of the brands Wilo Drain, Grundfos, Karcher, like Japanese Makita, do not need advertising.

These devices have high performance and reliability throughout their entire service life. When purchasing pumping equipment, be sure to check the availability of all components specified in the attached instructions.

Pay attention to the restrictions on use specified by the manufacturer. Remember that the technical characteristics of different pump models may differ significantly, which also affects the way they are used.

How to protect a pump in a well from sand

Most often, pumps fail for the following reasons:

- emergency operation – “dry running”;

- motor overload, poor-quality power wiring;

- too contaminated mixture with large fraction sizes.

High-quality models have automatic protection against most overloads, which will stop the pump from working. Separately, it is necessary to protect the equipment from sand and mud impurities. Sand getting into the working chamber will lead to rapid wear of the rubbing parts and failure of the device. You can avoid negative consequences:

- choosing modern equipment, parts of which are made of wear-resistant polymer materials;

- installation of an additional high-quality mechanical filter in the well.

For long-term operation of the pump against sand and sludge, it is better to use a set of measures - even the highest quality equipment needs additional protection measures.