Iron is an element of the side subgroup of the eighth group of the fourth period of the periodic system of chemical elements of D.I. Mendeleev with atomic number 26. It is designated by the symbol Fe (lat. Ferrum). One of the most common metals in the earth's crust (second place after aluminum). Medium activity metal, reducing agent.

Main oxidation states – +2, +3

A simple substance, iron is a malleable silver-white metal with high chemical reactivity: iron quickly corrodes at high temperatures or high humidity in the air. Iron burns in pure oxygen, and in a finely dispersed state it spontaneously ignites in air.

STRUCTURE

Two modifications of the iron crystal lattice

Several polymorphic modifications have been established for iron, of which the high-temperature modification - γ-Fe (above 906°) forms a lattice of a face-centered cube of the Cu type (a0 = 3.63), and the low-temperature modification - the α-Fe lattice of a centered cube of the α-Fe type (a0 = 2.86). Depending on the heating temperature, iron can be found in three modifications, characterized by different crystal lattice structures:

- In the temperature range from the lowest to 910°C - a-ferrite (alpha ferrite), which has a crystal lattice structure in the form of a centered cube;

- In the temperature range from 910 to 1390°C - austenite, the crystal lattice of which has the structure of a face-centered cube;

- In the temperature range from 1390 to 1535°C (melting point) - d-ferrite (delta ferrite). The crystal lattice of d-ferrite is the same as that of a-ferrite. The only difference between them is the different (larger for d-ferrite) distances between the atoms.

When liquid iron is cooled, primary crystals (crystallization centers) appear simultaneously at many points in the cooled volume. With subsequent cooling, new crystalline cells are built around each center until the entire supply of liquid metal is exhausted. The result is a granular structure of the metal. Each grain has a crystal lattice with a certain direction of its axes. With subsequent cooling of solid iron, during the transitions of d-ferrite to austenite and austenite to a-ferrite, new crystallization centers may appear with a corresponding change in grain size

Isotopes

Main article: Isotopes of iron

Natural iron consists of four stable isotopes: 54Fe (isotopic abundance 5.845%), 56Fe (91.754%), 57Fe (2.119%) and 58Fe (0.282%). More than 20 unstable isotopes of iron are also known with mass numbers from 45 to 72, the most stable of which are 60Fe (half-life according to data updated in 2009 is 2.6 million years), 55Fe (2.737 years), 59Fe (44.495 days) and 52Fe (8.275 hours); other isotopes have half-lives of less than 10 minutes.

The iron isotope 56Fe is one of the most stable nuclei: all of the following elements can reduce the binding energy per nucleon through decay, and all previous elements, in principle, could reduce the binding energy per nucleon through fusion. It is believed that iron ends the series of synthesis of elements in the cores of normal stars (see Iron Star), and all subsequent elements can only be formed as a result of supernova explosions.

Crystallographic characteristics

Cubic system

Class hexoctahedral

Crystal structure of native iron – Body-centered cubic lattice (for low-temperature modification)

Form of being in nature

The appearance of crystals. Only microscopically small ferrite crystals are known.

Twins in native iron at (111) with a fusion plane (211), often repeated.

Aggregates.

Grains, scales, wire-like sticks, curved ribbons, impregnations in rocks, sometimes large continuous deposits weighing up to several tons (ferrite), often intergrown with cohenite.

Composition and structure of iron

Iron is a typical metal, and it is chemically active. The substance reacts at normal temperature, and heating or increasing humidity significantly increases its reactivity. Iron corrodes in air, burns in an atmosphere of pure oxygen, and in the form of fine dust can ignite in air.

Pure iron is inherently malleable, but the metal is very rare in this form. In fact, iron means an alloy with small proportions of impurities - up to 0.8%, which is characterized by the softness and malleability of a pure substance. Alloys with carbon - steel, cast iron, stainless steel - are important for the national economy.

Iron is characterized by polymorphism: there are as many as 4 modifications, differing in structure and lattice parameters:

- α-Fe – exists from zero to +769 C. It has a body-centered cubic lattice and is ferromagnetic, that is, it retains magnetization in the absence of an external magnetic field. +769 C – Curie point for metal;

- from +769 to +917 C β-Fe appears. It differs from the α phase only in lattice parameters. Almost all physical properties are preserved with the exception of magnetic ones: iron becomes paramagnetic, that is, it loses the ability to magnetize and is drawn into a magnetic field. Metallurgy does not consider the β-phase as a separate modification. Since the transition does not affect significant physical characteristics;

- in the range from 917 to 1394 C there is a γ-modification, which is characterized by a face-centered cubic lattice;

- at temperatures above +1394 C, the δ phase appears, which is characterized by a body-centered cubic lattice.

At high pressure, as well as when the metal is doped with certain additives, an ε-phase with a hexagonal close-packed lattice is formed.

The temperature of phase transitions changes noticeably when doped with the same carbon. Actually, the very ability of iron to form so many modifications serves as the basis for processing steel in different temperature conditions. Without such transitions, the metal would not have become so widespread.

Now it’s time for the properties of the metal iron.

This video tells about the structure of iron:

PROPERTIES

Iron ore

In its pure form under normal conditions it is a solid. It has a silver-gray color and a pronounced metallic luster. The mechanical properties of iron include its level of hardness on the Mohs scale. It is equal to four (average). Iron has good electrical and thermal conductivity. The last feature can be felt by touching an iron object in a cold room. Because this material conducts heat quickly, it removes most of it from your skin in a short period of time, which is why you feel cold. If you touch, for example, wood, you will notice that its thermal conductivity is much lower. The physical properties of iron include its melting and boiling points. The first is 1539 degrees Celsius, the second is 2860 degrees Celsius. We can conclude that the characteristic properties of iron are good ductility and fusibility. But that's not all. Also, the physical properties of iron include its ferromagnetism. What it is? Iron, whose magnetic properties we can observe in practical examples every day, is the only metal that has such a unique distinctive feature. This is explained by the fact that this material is capable of magnetization under the influence of a magnetic field. And after the end of the action of the latter, the iron, the magnetic properties of which have just been formed, remains a magnet for a long time. This phenomenon can be explained by the fact that in the structure of this metal there are many free electrons that are able to move.

Crystal lattices

The crystal lattice is the spatial arrangement of atoms or ions in a crystal. The points of the crystal lattice at which atoms or ions are located are called lattice nodes.

Crystal lattices are divided into molecular, atomic, ionic and metallic.

It is very important not to confuse the type of chemical bond and crystal lattice. Remember that crystal lattices reflect the spatial arrangement of atoms.

Molecular crystal lattice

Molecules are located at the nodes of a molecular lattice. Under normal conditions, most gases and liquids have a molecular lattice. Bonds are most often covalent polar or nonpolar.

The classic example of a substance with a molecular lattice is water, so associate the properties of these substances with water. Substances with a molecular lattice are fragile, have low hardness, are volatile, fusible, capable of sublimation, and are characterized by low boiling points.

Examples: NH3, H2O, Cl2, CO2, N2, Br2, H2, I2. I would especially like to mention red and white phosphorus, orthorhombic, plastic and monoclinic sulfur, and fullerene. We studied these allotropic modifications in detail in an article devoted to the classification of substances.

Ionic crystal lattice

At the sites of the ionic lattice there are atoms connected by ionic bonds. This type of lattice is characteristic of substances that have ionic bonds: metal salts, oxides and hydroxides.

Associate this series of substances with table salt - NaCl. Substances with an ionic lattice have high melting and boiling points, are easily soluble in water, brittle, solid, their solutions and melts conduct electric current.

Metal crystal lattice

The nodes of the metal lattice contain metal atoms. This type of lattice is characteristic of substances formed by a metallic bond.

Associate the properties of these substances with copper. They have a characteristic metallic luster, are malleable and ductile, conduct electricity and heat well, and have high melting and boiling points.

Examples: Cu, Fe, Zn, Al, Cr, Mn.

Atomic crystal lattice

At the sites of the atomic lattice there are atoms connected by covalent polar or nonpolar bonds.

Associate these substances with sand. They are very hard, very refractory (high melting point), non-volatile, durable, and insoluble in water.

Examples: SiO2, B, Ge, SiC, Al2O3. I would especially like to highlight: diamond and graphite (C), black phosphorus (P).

© Bellevich Yuri Sergeevich 2018-2020

This article was written by Yuri Sergeevich Bellevich and is his intellectual property. Copying, distribution (including by copying to other sites and resources on the Internet) or any other use of information and objects without the prior consent of the copyright holder is punishable by law. To obtain article materials and permission to use them, please contact Yuri Bellevich

.

Melting point table

It is important for anyone involved in the metallurgical industry, whether a welder, foundry worker, smelter or jeweler, to know the temperatures at which the materials they work with melt. The table below shows the melting points of the most common substances.

Table of melting temperatures of metals and alloys

| Name | T pl, °C |

| Aluminum | 660,4 |

| Copper | 1084,5 |

| Tin | 231,9 |

| Zinc | 419,5 |

| Tungsten | 3420 |

| Nickel | 1455 |

| Silver | 960 |

| Gold | 1064,4 |

| Platinum | 1768 |

| Titanium | 1668 |

| Duralumin | 650 |

| Carbon steel | 1100−1500 |

| Cast iron | 1110−1400 |

| Iron | 1539 |

| Mercury | -38,9 |

| Cupronickel | 1170 |

| Zirconium | 3530 |

| Silicon | 1414 |

| Nichrome | 1400 |

| Bismuth | 271,4 |

| Germanium | 938,2 |

| Tin | 1300−1500 |

| Bronze | 930−1140 |

| Cobalt | 1494 |

| Potassium | 63 |

| Sodium | 93,8 |

| Brass | 1000 |

| Magnesium | 650 |

| Manganese | 1246 |

| Chromium | 2130 |

| Molybdenum | 2890 |

| Lead | 327,4 |

| Beryllium | 1287 |

| Will win | 3150 |

| Fechral | 1460 |

| Antimony | 630,6 |

| titanium carbide | 3150 |

| zirconium carbide | 3530 |

| Gallium | 29,76 |

In addition to the melting table, there are many other supporting materials. For example, the answer to the question what is the boiling point of iron lies in the table of boiling substances. In addition to boiling, metals have a number of other physical properties, such as strength.

Iron crystal lattice:

| 500 | Crystal cell | |

| 511 | Crystal grid #1 | α-iron (ferrite) |

| 512 | Lattice structure | Cubic body-centered |

| 513 | Lattice parameters | 2.866 Å |

| 514 | c/a ratio | |

| 515 | Debye temperature | 460 K |

| 516 | Name of space symmetry group | Im_ 3m |

| 517 | Symmetry space group number | 229 |

| 511 | Crystal grid #2 | γ-iron (austenite) |

| 512 | Lattice structure | Cubic face centered |

| 513 | Lattice parameters | 3.656 Å |

| 514 | c/a ratio | |

| 515 | Debye temperature | |

| 516 | Name of space symmetry group | Fm_3m |

| 517 | Symmetry space group number | 225 |

| 521 | Crystal grid #3 | δ-iron |

| 522 | Lattice structure | Cubic body-centered |

| 523 | Lattice parameters | 2.93 Å |

| 524 | c/a ratio | |

| 525 | Debye temperature | |

| 526 | Name of space symmetry group | Im_ 3m |

| 527 | Symmetry space group number | 229 |

RESERVES AND PRODUCTION

Iron is one of the most common elements in the solar system, especially on the terrestrial planets, in particular on Earth. A significant part of the iron of the terrestrial planets is located in the cores of the planets, where its content is estimated to be about 90%. The iron content in the earth's crust is 5%, and in the mantle about 12%.

Iron

Iron is quite widespread in the earth's crust - it accounts for about 4.1% of the mass of the earth's crust (4th place among all elements, 2nd among metals). In the mantle and crust, iron is concentrated mainly in silicates, while its content is significant in basic and ultrabasic rocks, and low in acidic and intermediate rocks. A large number of ores and minerals containing iron are known. Of greatest practical importance are red iron ore (hematite, Fe2O3; contains up to 70% Fe), magnetic iron ore (magnetite, FeFe2O4, Fe3O4; contains 72.4% Fe), brown iron ore or limonite (goethite and hydrogoethite, respectively FeOOH and FeOOH nH2O ). Goethite and hydrogoethite are most often found in weathering crusts, forming so-called “iron hats”, the thickness of which reaches several hundred meters. They can also be of sedimentary origin, falling out of colloidal solutions in lakes or coastal areas of the seas. In this case, oolitic, or legume, iron ores are formed. Vivianite Fe3(PO4)2·8H2O is often found in them, forming black elongated crystals and radial aggregates. The iron content in sea water is 1·10−5-1·10−8%. In industry, iron is obtained from iron ore, mainly from hematite (Fe2O3) and magnetite (FeO·Fe2O3). There are various ways to extract iron from ores. The most common is the domain process. The first stage of production is the reduction of iron with carbon in a blast furnace at a temperature of 2000 °C. In a blast furnace, carbon in the form of coke, iron ore in the form of agglomerate or pellets, and flux (such as limestone) are fed from above, and are met by a stream of forced hot air from below. In addition to the blast furnace process, the process of direct iron production is common. In this case, pre-crushed ore is mixed with special clay, forming pellets. The pellets are fired and treated in a shaft furnace with hot methane conversion products, which contain hydrogen. Hydrogen easily reduces iron without contaminating the iron with impurities such as sulfur and phosphorus, which are common impurities in coal. Iron is obtained in solid form and is subsequently melted in electric furnaces. Chemically pure iron is obtained by electrolysis of solutions of its salts.

Story

Main article: History of iron

Iron as a tool material has been known since ancient times. The oldest iron objects found during archaeological excavations date back to the 4th millennium BC. e. and belong to the ancient Sumerian and ancient Egyptian civilizations. These are made from meteorite iron, that is, an alloy of iron and nickel (the content of the latter ranges from 5 to 30%), jewelry from Egyptian tombs (about 3800 BC) and a dagger from the Sumerian city of Ur (about 3100 BC). e.). Apparently, one of the names of iron in Greek and Latin comes from the celestial origin of meteorite iron: “sider” (which means “stellar”).

The Hutts were the first to master the method of smelting iron. This is indicated by the oldest (2nd millennium BC) mention of iron in the texts of the Hittites, who founded their empire on the territory of the Hattians (modern Anatolia in Turkey). Thus, the text of the Hittite king Anitta (circa 1800 BC) says:

When I went on a campaign to the city of Puruskhanda, a man from the city of Puruskhanda came to bow to me (...?) and he presented me with 1 iron throne and 1 iron scepter (?) as a sign of submission (?) ...

— Giorgadze G. G.

“Text of Anitta” and some questions of the early history of the Hittites // Bulletin of Ancient History. 1965. No. 4.

In ancient times, the Khalibs were known as masters of iron products. The legend of the Argonauts (their campaign in Colchis took place about 50 years before the Trojan War) tells that the king of Colchis, Eet, gave Jason an iron plow so that he could plow the field of Ares, and his subjects, the Calibers, are described:

They do not plow the land, do not plant fruit trees, do not graze flocks in rich meadows; they extract ore and iron from uncultivated land and exchange food for it. The day does not begin for them without hard work; they spend the whole day in the darkness of the night and thick smoke...

Aristotle described their method of producing steel: “the Khalibs washed the river sand of their country several times, thereby releasing black concentrate (a heavy fraction consisting mainly of magnetite and hematite), and smelted it in furnaces; The metal thus obtained had a silvery color and was stainless.”

As a raw material for steel smelting, magnetite sands were used, which are often found along the entire Black Sea coast: these magnetite sands consist of a mixture of small grains of magnetite, titanium-magnetite or ilmenite, and fragments of other rocks, so the steel smelted by the Khalibs was alloyed and had excellent properties. This unique method of obtaining iron suggests that the Khalibs only spread iron as a technological material, but their method could not be a method for the widespread industrial production of iron products. However, their production served as an impetus for the further development of iron metallurgy.

Clement of Alexandria in his encyclopedic work "Stromata" mentions that according to Greek legends, iron (apparently smelted from ore) was discovered on Mount Ida - that was the name of the mountain range near Troy (in the Iliad it is mentioned as Mount Ida, from which Zeus watched battle between the Greeks and the Trojans). This happened 73 years after the Deucalion flood, and this flood, according to the Parian Chronicle, took place in 1528 BC. e., that is, the method of smelting iron from ore was discovered around 1455 BC. e. However, from Clement’s description it is not clear whether he is talking about this particular mountain in Western Asia (Ida of Phrygia in Virgil), or about Mount Ida on the island of Crete, which the Roman poet Virgil writes in the Aeneid as the ancestral home of the Trojans:

The island of Jupiter, Crete, lies in the middle of the wide sea, Our tribe has its cradle there, where Ida rises...

It is more likely that Clement of Alexandria is talking specifically about the Phrygian Ida near Troy, since ancient iron mines and centers of iron production were found there. The first written evidence of iron is found in clay tablets from the archives of the Egyptian pharaohs Amenhotep III and Akhenaten, and dates back to the same time (1450-1400 BC). It mentions the production of iron in the south of Transcaucasia, which the Greeks called Colchis (and it is possible that the word “kolhidos” may be a modification of the word “halibos”) - namely, what the king of the country of Mitanni and the ruler of Armenia and South Transcaucasia sent to the Egyptian pharaoh Amenhotep II " along with 318 concubines, daggers and rings made of good iron.” The Hittites also gave the same gifts to the pharaohs.

In very ancient times, iron was valued more than gold, and according to Strabo’s description, African tribes gave 10 pounds of gold for 1 pound of iron, and according to the research of historian G. Areshyan, the cost of copper, silver, gold and iron among the ancient Hittites was in the ratio 1: 160 : 1280 : 6400. In those days, iron was used as a jewelry metal; thrones and other regalia of royal power were made from it: for example, the biblical book of Deuteronomy 3.11 describes the “iron bed” of the Rephaim king Og.

Nineteen iron objects were found in Tutankhamun's tomb (circa 1350 BC), including a gold-mounted iron dagger, possibly a gift from the Hittites for diplomatic purposes. But the Hittites did not strive for the widespread dissemination of iron and its technologies, as can be seen from the correspondence that has come down to us between the Egyptian pharaoh Tutankhamun and his father-in-law Hattusil, the king of the Hittites. The pharaoh asks to send more iron, and the king of the Hittites evasively replies that iron reserves have dried up, and the blacksmiths are busy with agricultural work, so he cannot fulfill the request of the royal son-in-law, and sends only one dagger made of “good iron” (that is, steel). As you can see, the Hittites tried to use their knowledge to achieve military advantages, and did not give others the opportunity to catch up with them. Apparently, this is why iron products became widespread only after the Trojan War and the fall of the Hittite power, when, thanks to the trading activity of the Greeks, iron technology became known to many, and new iron deposits and mines were discovered. So the “Bronze” Age was replaced by the “Iron” Age.

According to Homer's descriptions, although during the Trojan War (circa 1250 BC) weapons were mainly made of copper and bronze, iron was already well known and in great demand, although more as a precious metal. For example, in the 23rd song of the Iliad, Homer says that Achilles awarded a discus made of iron to the winner in a discus throwing competition. The Achaeans mined this iron from the Trojans and neighboring peoples (Iliad 7.473), including the Khalibs, who fought on the side of the Trojans:

Other Achaean men bought wine in exchange, Those for ringing copper, for gray iron, Those for oxhide or steep-horned oxen, Those for their full ones. And a joyful feast has been prepared...

Perhaps iron was one of the reasons that prompted the Achaean Greeks to move to Asia Minor, where they learned the secrets of its production. And excavations in Athens showed that already around 1100 BC. e. and later iron swords, spears, axes, and even iron nails were already widespread. The biblical book of Joshua 17:16 (cf. Judges 14:4) describes that the Philistines (biblical "PILISTIM", and these were proto-Greek tribes related to the later Hellenes, mainly Pelasgians) had many iron chariots, that is, at this time iron has already become widely used in large quantities.

Homer in the Iliad and Odyssey calls iron a “hard metal,” and describes the hardening of tools:

The efficient forger, having made an ax or ax, immerses the metal in water, so that it has double strength...

Homer calls iron difficult because in ancient times the main method of its production was the cheese-blowing process: alternating layers of iron ore and charcoal were calcined in special furnaces (furnaces - from the ancient “Horn” - horn, pipe, originally it was just a pipe dug in the ground , usually horizontally in the slope of a ravine). In the forge, iron oxides are reduced to metal by hot coal, which takes up oxygen, oxidizing to carbon monoxide, and as a result of such calcination of ore with coal, dough-like krichine (sponge) iron was obtained. Kritsa was cleaned of slag by forging, squeezing out impurities with strong blows of a hammer. The first forges had a relatively low temperature - noticeably lower than the melting point of cast iron, so the iron turned out to be relatively low-carbon. To obtain strong steel, it was necessary to calcinate and forge the iron core with coal many times, while the surface layer of the metal was additionally saturated with carbon and strengthened. This is how “good iron” was obtained - and although it required a lot of work, the products obtained in this way were significantly stronger and harder than bronze ones.

Later they learned to make more efficient furnaces (in Russian - blast furnace, domnitsa) for the production of steel, and used bellows to supply air to the furnace. Already the Romans knew how to bring the temperature in the furnace to melting steel (about 1400 °C, and pure iron melts at 1535 °C). This produces cast iron with a melting point of 1100–1200 °C, which is very brittle in the solid state (not even forgeable) and does not have the elasticity of steel. Initially, it was considered a harmful by-product (English pig iron, in Russian, pig iron, ingots, where, in fact, the word cast iron comes from), but then it was discovered that when re-melted in a furnace with increased air blowing through it, cast iron turns into good quality steel, as excess carbon burns out. This two-stage process for producing steel from cast iron turned out to be simpler and more profitable than the critical one, and this principle has been used without much change for many centuries, remaining to this day the main method of producing iron materials.

Chemical composition

Telluric iron contains impurities of nickel (Ni) 0.6-2%, cobalt (Co) up to 0.3%, copper (Cu) up to 0.4%, platinum (Pt) up to 0.1%, carbon. Native iron usually contains Ni in solid solution. The composition of individual varieties has not been precisely established; the analyzes are mostly old, performed on material not verified by mineragraphic and x-ray studies. Minor admixtures of Co, Cu, S, C, Mn, P, Pt, As, Ge have been identified, partly associated, apparently, with a mechanical admixture of cohenite; the presence of gas inclusions (CO and CO2) was noted.

Varieties

Ferrite (Vernadsky, 1912) is the purest, almost Ni-free native iron. Awaruite - awaruite (Skei, 1885) 6 -(Ni, Fe). Native nickel-iron with a high Ni content (Ni: Fe from 4: 1 to 2: 1). Hardness. 5. Density 8.1. It resembles polyxene in luster and color. In reflected light, pure white or light cream, isotropic, highly reflective. Named for its location in Avarua Bay (New Zealand), where it is associated with gold, platinum, cassiterite, chromite, and magnetite. It is found as a secondary mineral in peridotites that have undergone serpentinization, serpentinites, trachytes, and quartz porphyries. Varieties of nickel-iron of terrestrial origin close to or identical to awaruite, found in placers and in serpentinized peridotites, are described under the names: josephinite (Melville, 1892), souesite-souesite (Hofman, 1905), octibbehite (Taylor, 1905). 1857), catarinite - satarinite (Damur, 1877). Under the name bobrovkite (Vysotsky, 1913), nickel-iron (iron-nickel) is described, found in the form of fine-scaled grains together with platinum (polyxene) in the placers of M. Bobrovka (Ural). Contains Ni 71.93, Fe 28.07, as well as Co, Mn.

Chemical properties

The main oxidation states of iron are +2 and +3.

When stored in air at temperatures up to 200 °C, iron is gradually covered with a dense film of oxide, which prevents further oxidation of the metal. In humid air, iron becomes covered with a loose layer of rust, which does not prevent the access of oxygen and moisture to the metal and its destruction. Rust does not have a constant chemical composition; approximately its chemical formula can be written as Fe2O3 xH2O.

Iron reacts with oxygen when heated. When iron burns in air, the oxide Fe3O4 is formed, when burned in pure oxygen, the oxide Fe2O3 is formed. If oxygen or air is passed through molten iron, the oxide FeO is formed. When sulfur and iron powder are heated, sulfide is formed, the approximate formula of which can be written as FeS.

Iron reacts with halogens when heated. Since FeF3 is non-volatile, iron is resistant to fluorine up to temperatures of 200-300 °C. When iron is chlorinated (at a temperature of about 200 °C), volatile FeCl3 is formed. If the interaction of iron and bromine occurs at room temperature or with heating and increased bromine vapor pressure, FeBr3 is formed. When heated, FeCl3 and, especially, FeBr3 split off the halogen and transform into iron(II) halides. When iron and iodine react, iodide Fe3I8 is formed.

When heated, iron reacts with nitrogen, forming iron nitride Fe3N, with phosphorus, forming phosphides FeP, Fe2P and Fe3P, with carbon, forming carbide Fe3C, with silicon, forming several silicides, for example, FeSi.

At elevated pressure, metallic iron reacts with carbon monoxide (II) CO, and liquid, under normal conditions, highly volatile iron pentacarbonyl Fe(CO)5 is formed. Iron carbonyls of the compositions Fe2(CO)9 and Fe3(CO)12 are also known. Iron carbonyls serve as starting materials in the synthesis of organoiron compounds, including ferrocene of the composition (η5-C5H5)2Fe.

Pure metallic iron is stable in water and dilute alkali solutions. Iron does not dissolve in concentrated sulfuric and nitric acids, since a strong oxide film passivates its surface.

Iron reacts with hydrochloric and dilute (approximately 20%) sulfuric acids to form iron(II) salts:

Fe + 2HCl → FeCl2 + H2↑;

Fe + H2SO4 → FeSO4 + H2↑.

When iron reacts with approximately 70% sulfuric acid, the reaction proceeds to form iron(III) sulfate:

2Fe + 6H2SO4 → Fe2(SO4)3 + 3SO2↑ + 6H2O.

Iron(II) oxide FeO has basic properties; the base Fe(OH)2 corresponds to it. Iron(III) oxide Fe2O3 is weakly amphoteric; it is matched by an even weaker base than Fe(OH)2, Fe(OH)3, which reacts with acids:

2Fe(OH)3 + 3H2SO4 → Fe2(SO4)3 + 6H2O.

Iron(III) hydroxide Fe(OH)3 exhibits weakly amphoteric properties; it is capable of reacting only with concentrated solutions of alkalis:

Fe(OH)3 + 3KOH → K3[Fe(OH)6].

The resulting hydroxo complexes of iron(III) are stable in strongly alkaline solutions. When solutions are diluted with water, they are destroyed, and Fe(OH)3 precipitates.

Iron(III) compounds in solutions are reduced by metallic iron:

Fe + 2FeCl3 → 3FeCl2.

When storing aqueous solutions of iron(II) salts, oxidation of iron(II) to iron(III) is observed:

4FeCl2 + O2 + 2H2O → 4Fe(OH)Cl2.

Of the iron(II) salts, the most stable in aqueous solutions is Mohr's salt—double ammonium and iron(II) sulfate (NH4)2Fe(SO4)2 6H2O.

Iron(III) is capable of forming double sulfates with singly charged cations such as alum, for example, KFe(SO4)2 - iron-potassium alum, (NH4)Fe(SO4)2 - iron-ammonium alum, etc.

When chlorine gas or ozone acts on alkaline solutions of iron(III) compounds, iron(VI) compounds are formed - ferrates, for example, potassium ferrate(VI) K2FeO4. There are reports of the production of iron(VIII) compounds under the influence of strong oxidizing agents.

To detect iron(III) compounds in solution, a qualitative reaction of Fe3+ ions with SCN- thiocyanate ions is used. When Fe3+ ions interact with SCN- anions, bright red iron thiocyanate Fe(SCN)3 is formed. Another reagent for Fe3+ ions is potassium hexacyanoferrate(II) K4[Fe(CN)6] (yellow blood salt). When Fe3+ and [Fe(CN)6]4− ions interact, a bright blue precipitate of Prussian blue precipitates:

4K4[Fe(CN)6] + 4Fe3+ → 4KFeIII[FeII(CN)6]↓ + 12K+.

Potassium hexacyanoferrate(III) K3[Fe(CN)6] (red blood salt) can serve as a reagent for Fe2+ ions in solution. When Fe2+ and [Fe(CN)6]3− ions interact, a Turnboole blue precipitate forms:

3K3[Fe(CN)6] + 3Fe2+ → 3KFeII[FeIII(CN)6]↓ + 6K+.

It is interesting that Prussian blue and Turnboole blue are two forms of the same substance, since equilibrium is established in solution:

KFeIII[FeII(CN)6] ↔ KFeII[FeIII(CN)6].

ORIGIN

Native iron

Origin telluric (terrestrial) iron is rarely found in basalt lavas (Uifak, Disko Island, off the western coast of Greenland, near Kassel, Germany). At both locations, pyrrhotite (Fe1-xS) and cohenite (Fe3C) are associated with it, which is explained by both the reduction by carbon (including from the host rocks) and the decomposition of carbonyl complexes such as Fe(CO)n. In microscopic grains, it has more than once been established in altered (serpentinized) ultrabasic rocks, also in paragenesis with pyrrhotite, sometimes with magnetite, due to which it arises during reduction reactions. Very rarely found in the oxidation zone of ore deposits, during the formation of swamp ores. Findings have been recorded in sedimentary rocks associated with the reduction of iron compounds with hydrogen and hydrocarbons. Almost pure iron was found in lunar soil, which is associated with both meteorite falls and magmatic processes. Finally, two classes of meteorites - stony-iron and iron - contain natural iron alloys as a rock-forming component.

origin of name

Proto-Slavic *želězo

(Belarusian zheleza, Ukrainian zalizo, Old Slavic zhelezo, Bulgarian zhelyazo, Serbo-Croatian zhejezo, Polish żelazo, Czech železo, Slovenian železo) has clear parallels in the Baltic languages (lit. geležis, Latvian dzelzs ). The word is a cognate of the words “gland” and “nodule”; and has the meaning “rounded stone, pellet, blob.”

There are several versions of the further etymology of this Baltoslavic word.

One of them connects Praslav. *želězo with the Greek word χαλκός

, which meant iron and copper, according to another version

*želězo

is cognate with the words

*žely

“turtle” and

*glazъ

“rock”, with a common seme “stone”. The third version suggests an ancient borrowing from an unknown language.

Romance languages (Italian ferro, French fer, Spanish hierro

, port.

ferro, rum. fier) continue Lat. ferrum. Latin ferrum

(<

*ferzom

) may have been borrowed from some eastern language, most likely from Phoenician.

Wed. Hebrew barzel, Sumerian. barzal

, Assyrian

parzilla

.

This is probably where the Basque burdina

.

The Germanic languages borrowed the name of iron (Gothic eisarn, English iron, German Eisen, Dutch ijzer, Danish jern, Swedish järn) from the Celtic languages.

Pre-Celtic word *isarno-

(> Old Irish iarn, Old Brett hoiarn), probably goes back to the ancestral I.e.

*h1esh2r-no-

“bloody” with the semantic development “bloody” > “red” > “iron”.

According to another hypothesis, this word goes back to the ancestral i.e. *(H)ish2ro-

“strong, holy, possessing supernatural power.”

The ancient Greek word σίδηρος may have been borrowed from the same source as the Slavic, Germanic and Baltic words for silver.

The name of natural iron carbonate (siderite) comes from the Latin. sidereus - starry; Indeed, the first iron that fell into the hands of people was of meteorite origin. Perhaps this coincidence is not accidental. In particular, the ancient Greek word sideros (σίδηρος)

for iron and the Latin

sidus

, meaning "star", probably have a common origin.

B. Meteoric iron

Kamacite – Kamacite – nickel iron (6-9% Ni). The name kamacite comes from the Greek - beam, rod (Reichenbach, 1861),

A synonym for kamacite is beam iron, taenite is band iron (Reichenbach, 1861), edmonsonite (Flight, 1882). Plessite (Reichenbach, 1861) is a fine mixture of kamacite and taenite.

Taenite – Taenite – nickel-iron (up to 48% Ni), taenite – from Taivia - ribbon, strip (Reichenbach, 1861).

For taenite of the Fe2Ni composition, the following names have been proposed: nikdiferrite (Chirvinsky, 1928), orthotenite (Badhu, 1936) and chirvinite (Astapovich, 1950); a compound of this composition is established in the Fe-Ni system. Metakamacite is a metastable a-modification of pickled iron, and, in addition, a granular variety of plessite (Owen, 1940). Metatenite is taenite with an admixture of kamacite (Badhyo, 1936).

Native iron of cosmic origin makes up the mass of iron meteorites. Found in most stony meteorites. Forms:

a) a solid mass of a meteorite;

b) a spongy mass in which grains of olivine or other silicates are immersed;

c) grains and scales scattered throughout the meteorite;

d) separate crystalline individuals with numerous twin plates. Kamacite and taenite are always closely intergrown. Iron meteorites from the octahedrite group are characterized by systems of intersecting stripes, which are called Widmanstätten figures: individual stripes consist of kamacite with taenite rims, with plessite between the intersecting stripes. Widmanstätten figures arise as a result of the decomposition of a solid solution of γ-iron and nickel. In intergrowths of kamacite and taenite, the plane of the rhombic dodecahedron (110) of kamacite is parallel to the plane of the octahedron (111) of taenite, which is explained by their structural similarity.

At what temperature does it melt?

Metal elements, whatever they are, melt almost one to one. This process occurs when heated. It can be both external and internal. The first takes place in a furnace, and for the second, resistive heating is used, passing electricity or induction heating. The impact is almost the same. When heated, the amplitude of molecular vibrations increases. Structural lattice defects are formed, which are accompanied by the breaking of interatomic bonds. The process of lattice destruction and the accumulation of such defects means melting.

Different substances have different melting points. Theoretically, metals are divided into:

- Low-melting - temperatures up to 600 degrees Celsius are sufficient to obtain a liquid substance.

- Medium melting - requires a temperature of 600 to 1600 ⁰C.

- Refractory are metals that require temperatures above 1600 ⁰C to melt.

Melting iron

The melting point of iron is quite high. A technically pure element requires a temperature of +1539 °C. This substance contains an impurity - sulfur, and it can only be extracted in liquid form.

Without impurities, pure material can be obtained by electrolysis of metal salts.

Melting cast iron

Cast iron is the best metal for smelting. The high fluidity rate and low shrinkage rate make it possible to use it more effectively during casting. Next, consider the boiling point of cast iron in degrees Celsius:

- Gray - the temperature can reach 1260 degrees. When pouring into molds, the temperature can rise to 1400.

- White - the temperature reaches 1350 degrees. It is poured into molds at 1450.

Important! The melting rates of a metal such as cast iron are 400 degrees lower compared to steel. This significantly reduces energy costs during processing.

Melting steel

Melting steel at a temperature of 1400 °C

Steel is an alloy of iron mixed with carbon. Its main benefit is strength, since this substance is capable of maintaining its volume and shape for a long time. This is due to the fact that the particles are in an equilibrium position. Thus, the forces of attraction and repulsion between particles are equal.

Reference! Steel melts at 1400 degrees Celsius.

Melting aluminum and copper

The melting point of aluminum is 660 degrees, which means that it can be melted at home.

Pure copper is 1083 degrees, and for copper alloys it ranges from 930 to 1140 degrees.

APPLICATION

Iron ring

Iron is one of the most used metals, accounting for up to 95% of global metallurgical production. Iron is the main component of steels and cast irons - the most important structural materials. Iron can be part of alloys based on other metals - for example, nickel. Magnetic iron oxide (magnetite) is an important material in the production of long-term computer memory devices: hard drives, floppy disks, etc. Ultrafine magnetite powder is used in many black and white laser printers mixed with polymer granules as a toner. This uses both the black color of the magnetite and its ability to stick to the magnetized transfer roller. The unique ferromagnetic properties of a number of iron-based alloys contribute to their widespread use in electrical engineering for magnetic cores of transformers and electric motors. Iron(III) chloride (ferric chloride) is used in amateur radio practice for etching printed circuit boards. Ferrous sulfate heptate (ferrous sulfate) mixed with copper sulfate is used to combat harmful fungi in gardening and construction. Iron is used as an anode in iron-nickel batteries and iron-air batteries. Aqueous solutions of ferrous and ferric chlorides, as well as its sulfates, are used as coagulants in the purification processes of natural and waste water in the water treatment of industrial enterprises.

Iron – Fe

| Molecular weight | 55.85 g/mol |

| origin of name | Possibly Anglo-Saxon origin |

| IMA status | valid, first described before 1959 (before IMA) |

Alloy smelting technology + what is the boiling point of iron?

According to experts, iron reserves around the world amount to almost 200 billion tons. Any country with a more or less developed economy establishes its own industrial production of iron ore with its further processing into ferum.

But even here there are niche leaders - Brazil, the USA and Australia, which have the largest reserves of iron near the surface of the earth. By the way, the core of our planet consists of 86% pure iron, but the problem is that with the current level of industrial technology, it is physically impossible to extract it from there.

1) What is the melting/boiling point of iron: exact value for element and alloys

Iron is rarely used in its pure form, because the metal does not have high-quality properties in terms of any physical characteristics.

More than 95% of the metal is used to produce alloys. Thermodynamic characteristics of pure ferum:

- 1539 Celsius or 1812 Kelvin – melting point;

- 2,861 Celsius or 3,134 Kelvin – boiling point;

- 14 kilojoules/mol – specific heat of fusion;

- 240 kilojoules/mol – specific heat of evaporation;

- 25 Joules/(Kelvins*mol) – molar heat capacity.

In 2021, there are about 15 industrially significant varieties of iron-based alloys. Each of them has its own set of characteristics regarding physics and chemistry. More details on the most popular ones in the table below.

Technology and steel hardening temperature 45

| Alloy | Melting point (in C) | Peculiarities |

| Steel | 1 450-1 520 | It is based on iron + carbon, and the proportion of the second does not exceed 2.2% of the total mass. The marking of steels according to GOSTs is diverse, and it will take more than one article to analyze its types. You can study the issue in more detail on our website in other sections. |

| Cast iron | 1 150 – 1 200 | An extremely popular alloy, with a carbon content of 3.5% of the total mass. In addition to iron, there is manganese, sulfur and phosphorus. |

| Perlite | 1 100- 1 200 | The share of carbon is less than 0.8%. The alloy itself is natural - it is a rock of volcanic origin. |

| Ferrite | 1 100 | Ferromagnetic compounds of iron oxide with basic oxides of other metals. Carbon impurity occupies only 0.04% of the total mass of the substance. |

| Cementite | 1250 | Chemical combination of carbon and iron. The alloy has a hardness of 800 HB and has extremely low ductility. |

| Austenite | 730-1 550 | The fractional carbon content is 2.14%. The peculiarity of the material is that it can exist only at high temperatures. |

All specified alloys are classified as ferrous metals. The greatest use is in cast iron and steel, followed by perlite and ferrite. In terms of mining/production volumes, the same countries that are engaged in the development of iron deposits are distinguished.

Properties and Applications of Ductile Iron

Description of the process of mining and smelting iron using a graphite crucible:

History of discovery

Everyone remembers the “Iron Age” from school. This is the period in history when man first learned to extract this metal from ore. The Iron Age spans the period from the 9th to the 7th century BC. This metal had a huge influence on the development of people of that time. According to its characteristics, it has replaced mixtures of non-ferrous metals. Tools, weapons, armor, materials for construction and much more were made from it. Gradually, blacksmiths began to mix it with other metals to create new materials. This is how new alloys appeared.

PHYSICAL PROPERTIES

| Mineral color | iron black |

| Stroke color | grey |

| Transparency | opaque |

| Shine | metal |

| Cleavage | imperfect by {001} |

| Hardness (Mohs scale) | 4,5 |

| Kink | hackly |

| Strength | malleable |

| Density (measured) | 7.3 – 7.87 g/cm3 |

| Radioactivity (GRapi) | |

| Magnetism | ferromagnet |

Advantages and disadvantages

There are many advantages, but no less disadvantages.

| Advantages | Flaws |

| Easy machining | High density; products turn out heavy |

| Hardness, elasticity, strength - the best properties of alloys | Metal corrosion in the presence of moisture |

| The ability to obtain specified properties of alloys by adding a small amount of impurities | Tendency to electrochemical corrosion |

We recommend: COBALT - a generous gift from mountain spirits

Malleability makes it possible to produce decorative products.

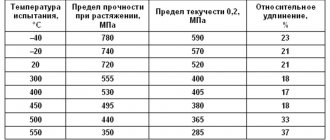

Strength of metals

In addition to the ability to transition from a solid to a liquid state, one of the important properties of a material is its strength - the ability of a solid body to resist destruction and irreversible changes in shape. The main indicator of strength is the resistance that occurs when a pre-annealed workpiece breaks. The concept of strength does not apply to mercury because it is in a liquid state. The designation of strength is adopted in MPa - Mega Pascals.

There are the following strength groups of metals:

- Fragile. Their resistance does not exceed 50MPa. These include tin, lead, soft-alkaline metals

- Durable, 50−500 MPa. Copper, aluminum, iron, titanium. Materials of this group are the basis of many structural alloys.

- High strength, over 500 MPa. For example, molybdenum and tungsten.

Metal strength table

| Metal | Resistance, MPa |

| Copper | 200−250 |

| Silver | 150 |

| Tin | 27 |

| Gold | 120 |

| Lead | 18 |

| Zinc | 120−140 |

| Magnesium | 120−200 |

| Iron | 200−300 |

| Aluminum | 120 |

| Titanium | 580 |

Atomic crystal structure of metals

What is this structure, what is it characterized by? The name itself suggests that all metals are crystals in the solid state, that is, under normal conditions (except for mercury, which is a liquid). What is a crystal?

This is a conventional graphic image constructed by intersecting imaginary lines through the atoms that line up the body. In other words, every metal is made up of atoms. They are located in it not chaotically, but very correctly and consistently. So, if you mentally combine all these particles into one structure, you will get a beautiful image in the form of a regular geometric body of some shape.

This is what is commonly called the crystal lattice of a metal. It is very complex and spatially voluminous, therefore, for simplicity, not all of it is shown, but only a part, an elementary cell. A set of such cells, collected together and reflected in three-dimensional space, forms crystal lattices. Chemistry, physics and metallurgy are sciences that study the structural features of such structures.

The unit cell itself is a set of atoms that are located at a certain distance from each other and coordinate a strictly fixed number of other particles around themselves. It is characterized by packing density, distance between constituent structures, and coordination number. In general, all these parameters are characteristics of the entire crystal, and therefore reflect the properties exhibited by the metal.

There are several types of crystal lattices. They all have one feature in common: the nodes contain atoms, and inside there is a cloud of electron gas, which is formed by the free movement of electrons inside the crystal.