Features and principle of operation

Anaerobic thread locker is a special gel for setting threaded connections. You've probably encountered a situation where one or another bolt or nut suddenly begins to loosen.

This can happen almost anywhere, from a small kitchen knife or a drawer in a furniture cabinet, to a car engine. Let's not forget about construction needs.

Various plumbing products, connections of working tools and equipment, all of them, one way or another, are fastened with threaded connections. And they are all in danger.

It's okay if a bolt comes loose on a small tool. You can just pull it up and forget about it. But what to do when the problem is more extensive? For example, when do the bolts on a car's engine box constantly become loose? Indeed, in this case, even one bad or weak thread can be fatal.

In addition, in large units that withstand enormous loads, threaded connections account for the lion's share of stress. These include, but are not limited to: vibrations, temperature changes, microscopic translational pressures, etc.

It is precisely for such situations that a thread locker was invented. It consists of several chemicals that can harden quickly. This is a kind of superglue for nuts and bolts.

The sealed fixative is sold in the form of tubes. The prefix anaerobic means that it is capable of hardening without contact with air. This, however, is the main requirement for such substances. After all, the retainer must set when applied to a twisted thread.

Anaerobic gel is applied to the connection using a small dispenser. It is advisable to do this in a short time. The faster the better. Then the thread is used for its intended purpose and left for several minutes. The thread locker will harden and be ready for further use.

Anaerobic gel is often compared to sealants. There is debate about whether it is really worth spending money on fasteners when you can get by with regular washers, nylon inserts, rubber seals, etc.

A bolt with a blue locking agent applied to its threads

What choice to make in this situation is up to you. However, clamps from well-known companies such as Permatex, Abro, TM and others still provide greater reliability. And they are quite cheap, their consumption is low.

A tube of good fixative from Permatex will cost you only 4-6 dollars. More advanced Permatex models with high levels of hold cost up to $7. There are also more expensive models, but the price level by all manufacturers is kept at approximately the same level due to strong competition.

Lifehacks

SIMPLE WAYS

Perhaps the simplest solution, used since time immemorial, is to connect the heads of bolts or nuts with a wire tie

:

Also a well-known method, often found in automotive suspension and chassis components, is fixing the castle nut with a cotter pin

:

If the nut is ordinary, it can be turned into a castle nut by putting a stamped cover on it. Fixation occurs as in the previous case - with a cotter pin:

The next nut is the hub nut. If you look closely, you can see that the upper ring of this nut is flattened and looks like an oval. Due to this, the thread is clamped on several upper turns, which is what is required for fixation:

The flatness on the upper ring is visible, fixing the thread

Another solution using compression. This time the outer ring will be compressed, the annular toothed notch of which, when compressed, will fit into the reciprocal grooves of the toothed crown on the nut. This will secure the nut. Naturally, the outer ring is also fixed to the shaft using an internal spike, similar to the spike on a claw washer.

When the outer ring is deformed, the teeth close and fix the nut.

Fastening with claw washer

- a very common method in which a claw washer is held by an internal tenon in a groove in the shaft and one or more claws are attached to a nut with grooves located on the side surface:

COMPLEX METHODS

Type 1. SAPER LOCK nut

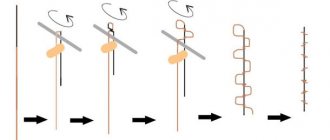

An interesting way of fixing a thread using some kind of spring that plays the role of a locking sleeve.

A spring is built into the nut, one of the ends of which protrudes in the form of a lever from a special groove on the side surface of the nut.

This protruding lever is needed when unscrewing. The fact is that when the nut is tightened, the spring, together with the nut, rotates freely along the thread without interfering with the tightening.

SAPER-LOCK nut device

And when trying to unscrew, i.e. By rotating the nut in the opposite direction, the spring compresses the threads and blocks the screw. You can unscrew the nut only by moving the spring lever to the extreme left position. To do this you will need to have a special set of heads.

The spring prevents the nut from unscrewing unless the lever is moved in the direction of unscrewing.

Type 2. SEAL LOCK nut

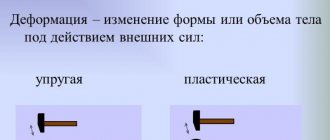

There is a plastic ring built into the lower inner part of the nut:

When tightened, this ring is deformed and takes the shape of the cavity formed by the body and the nut, thereby tightly pressing the thread and securely fixing it.

Type 3. SUPERBOLT nut

This type is used for large nut sizes. For example, there is a thread with a diameter of half a meter. How to tighten a nut onto such a thread with sufficient force? It is unrealistic to scale a regular hex nut to this size, because... To tighten it, you will need a corresponding monstrous wrench.

Instead, nuts are also used, but not hexagonal, but round. They are screwed onto the thread almost by hand, and force tightening is done with bolts located in this nut. The bolts rest against the washer installed under the nut and create the necessary tightening force.

The figure below shows how bolts 1, being in the body of nut 2, rest against washer 3 and pull nut 2 together with the central bolt 5, creating the necessary tightening force. Thus, we managed to move away from bulky nuts with enormous tightening forces to low forces on a larger number of bolts with a slight complication of the design.

Types of fasteners

There are a lot of fasteners for threaded connections on the market. This implies a variety of manufacturers. The companies Permatex, Abro, TM Loctite and others are considered to be the locomotives in the region.

Each manufacturer attracts customers with something of its own. This can be either a unique recipe for the composition or its unique properties. For example, increased wear resistance, instant adhesion, fluidity, response to temperature and vibration, etc. There are plenty of options here. Let's not forget about price motivation.

I would like to draw special attention to the products of the Permatex company. These guys produce high-quality clamps with average characteristics, but they impress with a relatively low price and a wide variety of models.

Permatex glue is mainly used in the automotive industry, although Permatex is also perfect for household needs. If we talk about the leaders, then the German manufacturer TM Loctite holds the brand.

Another important point is the division of fixatives by color. The most common fasteners are:

- Red;

- Blue.

Blue Medium Strength Thread Locker

These are the two main samples. Color markings were chosen by manufacturers for purely practical purposes. This makes it much easier to confuse them.

The red fixative is a higher order substance. It can withstand enormous loads, and even more. It is not always possible to unscrew a bolt treated with red gel by hand. You're more likely to rip his head off.

Only heating with a gas burner or something similar will help solve the situation. When the heat is too high, the lock will loosen for a short time. In those few tens of seconds or minutes (depending on the composition), the thread can be loosened. But it’s better not to hesitate, because when it cools, the gel will set again.

The blue fastener is intended for simple connections that are subject to medium loads, that is, the chance of them loosening is reduced.

There is no need to heat such a fixative. Just apply more force when unscrewing the bolt, and it will give in to you.

It is worth understanding that color marking also depends on the manufacturer. This is not a unified standard, but rather a generally accepted unspoken rule.

For example, the same retainers from Permatex are also sold in green and purple. The first is intended for fixing weak connections, and the second interacts well with non-standard environments.

According to power or gripping force, clamps are divided into:

- Weak (withstand loads up to 10 Nm);

- Medium (withstand loads up to 20-25 Nm);

- Strong (withstand loads up to 50 Nm, sometimes more).

Application of anaerobic fixatives (video)

How to unscrew a connection with a thread locker

It is possible to unscrew the thread lock, but the outcome will depend on what kind of glue was used initially. The universal method is temperature exposure in the range of 200˚C – 250˚C. This temperature is suitable for red clamps, the reliability of which is quite high. For blue fixatives, a heat of 100˚C is enough, while green fixatives lose their properties even at lower temperatures. You can heat the thread with an electric soldering iron or a hair dryer. The use of universal soaking agents is not suitable in this case. This is due to the fact that the latch is in working condition. To remove residual fixative, you need to purchase a special cleaner. A thread locker is useful and indispensable for many repair jobs. It guarantees the tightness and strength of the connections. It can be used not only for car maintenance, but also in any field that requires joining metals and others. Also, pay your attention and read the article about plastic polishing products and their varieties.